Titanium MIG 170 Welder Review

- April 2, 2024

- 0 comment

The Titanium MIG 170 is a versatile welding machine designed for both home hobbyists and professional welders. It’s recognized for its ability to handle a wide range of welding tasks, thanks to its MIG (Metal Inert Gas), Flux-cored, and Stick welding capabilities. This makes it a multi-functional tool suitable for various projects involving steel, stainless steel, aluminum, and more.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Technical Specifications

- Welding Processes: MIG (Metal Inert Gas), Flux-Cored, Stick (Arc Welding)

- Input Voltage: 120/240V AC (Dual Voltage)

- Amperage Range: 30A to 170A

- Wire Feed Speed: Fully Adjustable

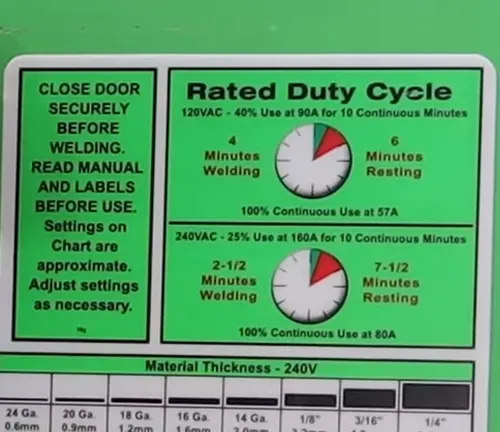

- Duty Cycle: Varies based on amperage and voltage settings, optimized for prolonged use

- Weldable Materials: Steel, Stainless Steel, Aluminum (with appropriate setup)

- Material Thickness: Capable of welding materials

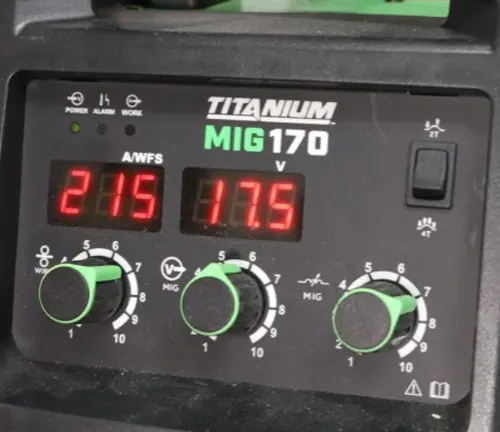

- Digital Display: Yes, for voltage and wire feed speed

- Portability: Compact design with a built-in carrying handle

- Dimensions: Specific dimensions indicating length, width, and height

- Weight: Indicating the machine’s weight for transport and setup considerations

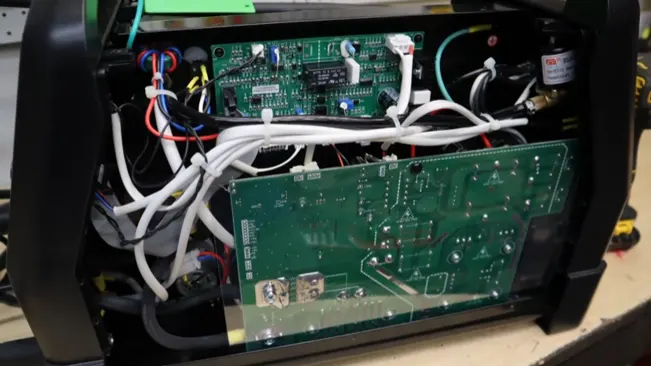

Durability

The Titanium MIG 170 welder is celebrated for its exceptional durability, a testament to the high-quality materials and robust construction it boasts. Designed to meet the demands of both the workshop and the outdoors, this machine proves its resilience time and again, standing up to the rigors of daily wear and tear with remarkable reliability.

Users consistently affirm its solid build quality, highlighting how it maintains performance and functionality over time, even under frequent or heavy use. This enduring durability not only underscores the welder’s capability to handle various welding tasks but also assures users of a dependable, long-lasting tool for their welding projects.

Digital Control Interface

The digital interface displays critical welding parameters, like voltage and wire feed speed, making it easier for users to monitor and adjust settings on the fly for consistent welding results.

Respectable Duty Cycle

The welder’s duty cycle is designed to support longer welding sessions at optimal amperage, reducing the need for frequent stops to let the machine cool down, thus improving workflow efficiency.

Adjustable Wire Feed Speed

The ability to fine-tune the wire feed speed enhances the welder’s capability to produce smooth, consistent welds across various materials and welding techniques.

Titanium MIG 170 Performance

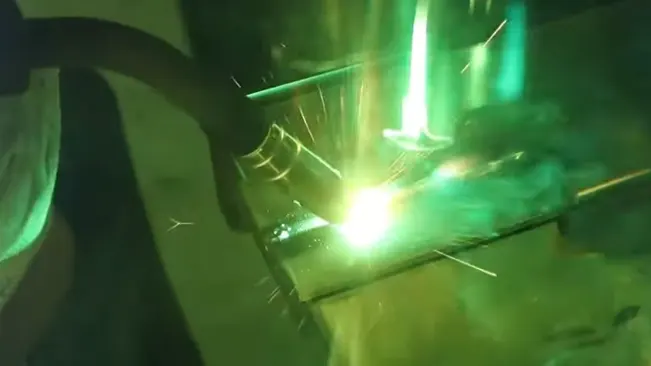

The performance of the Titanium MIG 170 welder stands out in the crowded field of welding equipment, earning accolades for its exceptional welding prowess. It distinguishes itself with a remarkably smooth arc start, ensuring precise control from the outset of the welding process.

This level of stability, coupled with its adaptability to a wide range of materials and thicknesses, underscores its capability to deliver high-quality welds under diverse conditions. Furthermore, its dual voltage capability enhances its versatility, enabling its use in a variety of settings without the need for additional equipment.

This feature, along with the seamless ability to switch between MIG, Flux-Cored, and Stick welding modes, minimizes downtime and maximizes efficiency. Such attributes not only make the Titanium MIG 170 a powerful tool in the hands of welders but also a highly adaptable machine that can tackle an array of welding tasks with ease, solidifying its reputation for superior performance in the welding community.

Ease of Use

One of the standout features of the Titanium MIG 170 is its user-friendly design. It’s suitable for both beginners and experienced welders, thanks to its straightforward controls and digital readouts. Setting up the machine is simple, and adjustments can be made quickly to adapt to different welding tasks.

Price Point

The Titanium MIG 170 offers excellent value for money. It’s competitively priced, especially considering its multi-process capabilities and the quality of its build. It’s an attractive option for those who need a versatile welding machine without breaking the bank.

Pros and Cons

Pros

- Supports MIG, Flux-Cored, and Stick welding, adaptable for various materials.

- Works on both 120V and 240V, suitable for home and professional use.

- Digital displays for easy control of welding parameters.

- Compact and easy to transport.

- Built to last, even in tough environments.

- Offers great value with multi-process capabilities at a reasonable price.

- Comes with a comprehensive set of accessories.

Cons

- Might be challenging for beginners to master all features.

- May need cooling breaks during extended high-amperage welding.

- Best suited for moderate thicknesses, might struggle with very thick materials.

- While versatile, it doesn’t have some of the high-end features found in more expensive models.

Quantitative Measurements

- Versatility (Multi-Process Capability): 9/10

The Titanium MIG 170 scores high for its ability to handle MIG, Flux-Cored, and Stick welding, making it exceptionally versatile for various welding tasks. - Portability: 8/10

Its compact design and built-in carrying handle allow for easy transportation and setup, though it might still be a bit heavy for some users, preventing a perfect score. - Ease of Use (Including User Interface): 7.5/10

With a user-friendly digital display and intuitive controls, it’s relatively easy to adjust settings. However, the learning curve for beginners slightly lowers this score. - Performance (Quality of Weld and Stability): 8.5/10

Offering smooth, stable arcs and good weld quality across a range of materials and thicknesses, its performance is commendable but might fall slightly short in more demanding industrial applications. - Value for Money: 9/10

Considering its multi-process capabilities, durability, and included accessories, the Titanium MIG 170 offers excellent value, making it a cost-effective choice for hobbyists and professionals alike.

Safety and Maintenance

Safety

- Wear Protective Gear Always wear appropriate welding safety gear, including a welding helmet with proper shading, flame-resistant clothing, gloves, and safety glasses.

- Ventilation Ensure your welding area is well-ventilated to avoid inhaling harmful fumes and gases produced during welding.

- Electrical Safety Check the welder’s power cord and plug regularly for any damage. Use a grounded electrical outlet and follow all manufacturer’s instructions regarding electrical safety.

- Avoid Wet Conditions Never weld in wet conditions to prevent electric shock. Ensure both the operator and the equipment are dry.

- Fire Safety Keep a fire extinguisher nearby and remove all flammable materials from the welding area to prevent fire hazards.

Maintenance

- Regular Cleaning Keep the welder clean from dust and debris, especially in and around the vents and fan to prevent overheating.

- Check Connections Regularly inspect all connections, including the ground clamp, MIG gun, and electrodes, for wear and ensure they are secure.

- Wire Feeder Maintenance Clean the wire feeder periodically to ensure smooth wire feeding. Check for and straighten any kinks in the wire spool.

- Replace Consumables Monitor the condition of consumables, including the nozzle, contact tip, and gas diffuser, and replace them as needed to maintain optimal welding performance.

- Software Updates If your welder has digital controls or software, ensure it’s updated to the latest version to maintain functionality and performance.

Comparison Table

| Feature/Specification | Titanium MIG 170 | Lincoln Electric PRO-MIG 180 |

|---|---|---|

| Welding Processes | MIG, Flux-Cored, Stick | MIG, Flux-Cored |

| Input Voltage | 120/240V (Dual Voltage) | 208/230V |

| Amperage Range | 30A – 170A | 30A – 180A |

| Wire Feed Speed | Fully Adjustable | Fully Adjustable |

| Duty Cycle | Varies, optimized for longer sessions | 30% at 130A (on 230V setting) |

| Portability | Compact, with carrying handle | Similar, with carrying handle |

| Digital Display | Yes | No |

| User Interface | Intuitive controls with digital displays | Knob controls, no digital display |

| Material Thickness | Suitable for various thicknesses | Suitable for various thicknesses |

| Versatility | High, due to multi-process capability | Moderate, lacks Stick welding |

| Construction/Durability | High-quality build, durable | Solid build, designed for durability |

| Value for Money | High, offers great versatility and quality | Good, known for quality and reliability |

| Included Accessories | Comprehensive set for immediate use | Comes with necessary accessories |

| Ease of Use | User-friendly, suitable for beginners to pros | Straightforward, but lacks digital precision |

| Overall Performance | Excellent across a range of materials | Very good, especially for MIG and Flux-Cored welding |

Lincoln Electric PRO-MIG 180 Technical Specifications

- Processes: MIG, Flux-Cored

- Voltage: 208/230V

- Amps: 30-180A

- Duty Cycle: 30% @ 130A

- Wire Speed: Adjustable

- Max Thickness: 1/2″ steel

- Portability: Carrying handle

- Controls: Knob, no digital display

- Accessories: MIG gun, clamp, gas gear, wire, tips

Conclusion

The Titanium MIG 170 welder stands out as a versatile, reliable, and cost-effective solution for a wide range of welding tasks. Its combination of performance, ease of use, and durability makes it a strong contender in its category, appealing to both amateur and professional welders alike. Whether for small home projects or more extensive professional applications, the Titanium MIG 170 offers a compelling package that should meet the needs of most users looking for a multi-process welding machine.

FAQs

- What welding processes can the Titanium MIG 170 handle?

It supports MIG (Metal Inert Gas), Flux-Cored, and Stick welding processes. - Is the Titanium MIG 170 suitable for beginners?

Yes, its user-friendly interface and adjustable settings make it suitable for beginners, while offering the versatility that experienced welders appreciate. - Can the Titanium MIG 170 weld aluminum?

Yes, it can weld aluminum using the MIG process with the appropriate wire and shielding gas, though a spool gun may be necessary for optimal results. - What is the input voltage of the Titanium MIG 170?

It features dual voltage capability, operating on both 120V and 240V. - What is the amperage range of the Titanium MIG 170?

The welder has an amperage range from 30A to 170A. - Does the Titanium MIG 170 come with a digital display?

Yes, it comes with a digital display for easy monitoring and adjustment of voltage and wire feed speed. - How portable is the Titanium MIG 170?

It’s designed for portability, featuring a compact design and a built-in carrying handle. - What materials can the Titanium MIG 170 weld?

It can weld a variety of materials including steel, stainless steel, and aluminum, among others. - What is included with the Titanium MIG 170?

It typically comes with a MIG gun, ground clamp, stick electrode holder, and other necessary accessories to start welding. - How does the Titanium MIG 170 compare in terms of value for money?

The Titanium MIG 170 is considered to offer excellent value for its price, given its versatility, ease of use, and comprehensive feature set.

We’re eager to hear from you! Share your personal experiences and thoughts about the Titanium MIG 170 in the comments section below. Whether you’ve used it for small home projects or larger professional tasks, your insights could greatly assist fellow welders in making informed decisions. Your feedback on its performance, ease of use, and overall durability can provide valuable information to those considering this versatile welder for their next purchase.

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment