Hobart Handler 100 Flux-Cored Welder Review

- January 9, 2024

- 0 comment

Unleash Precision Welds! Hobart Handler 100 Flux-Cored Welder Review: Your Gateway to Smooth, Durable Welds! Discover its Broad Output Range, Flexible Spool Hub, & Smart Built-In Features. Dive in Now! 160/160

Technical Specifications

- Product Dimensions: 16 x 10 x 13.5 inches

- Item Weight: 44 pounds

- Voltage: 115 Volts

- Wattage: 2760 watts

- Power Source: AC

- Finish: Powder Coated

- Handle Material: Alloy Steel

- Measurement System: Metric

- Special Features: Easy to Install

The Hobart Handler 100 Flux-Cored Welder arrives as a comprehensive package, ensuring you have everything required for efficient welding. This all-inclusive kit encompasses:

Comes With:

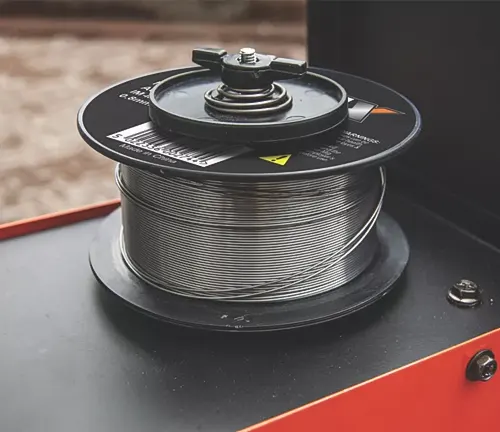

- Comfortable 8 ft. (2.4 m)

- H100F2-8 gun with liner for .030 –.035 in.

Welding Rod Uses For Hobart Welder

Here are the most common welding rod types used with the Hobart Handler 100 Flux-Cored Welder:

- E71T-GS: This is a general-purpose, flux-cored wire for mild steel. It’s a good choice for most welding jobs around the home, garage, or farm, such as repairing gates, fences, or trailer frames.

- E70T-4: This is a higher-strength flux-cored wire for mild steel. It’s a good choice for heavier-duty applications, such as welding structural steel or automotive repairs.

- E71T-11: This is a flux-cored wire for welding stainless steel. It’s important to use a separate wire feeder and gas cylinder for stainless steel welding.

The best welding rod for your project will depend on the material you’re welding, the thickness of the material, and the strength you need. It’s always a good idea to consult the welder’s manual or a welding expert for advice on choosing the right welding rod.

Here are some additional factors to consider when choosing a welding rod:

- Wire diameter: The diameter of the wire will determine the thickness of the weld you can make. Thicker wires are typically used for thicker materials.

- Flux type: The type of flux will affect the weld quality and appearance. Self-fluxing wires do not require an external gas, while gas-shielded wires require an inert gas to protect the weld from contamination.

- Polarity: Some welding rods are designed to be used with a specific polarity (DC positive or DC negative). Be sure to check the polarity of your welder and choose a compatible rod.

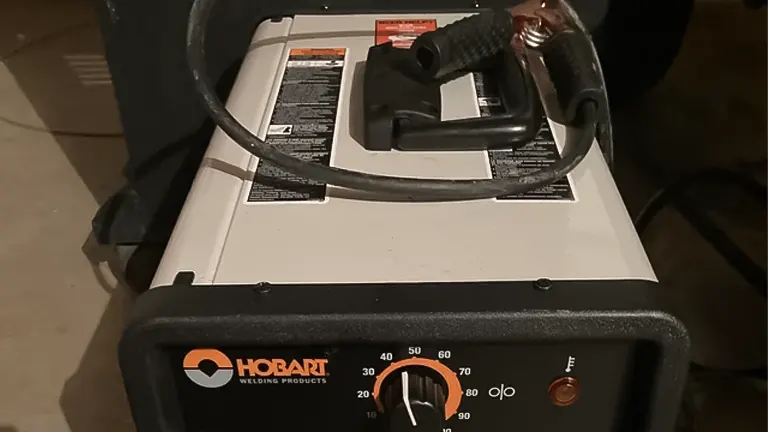

Build Quality and Visual Appeal

Impressively constructed with a robust build and a thoughtfully compact design, the Hobart Handler 100 immediately caught my attention. Weighing a mere 44 pounds, this welding powerhouse combines sturdiness with portability, making it an exceptionally convenient tool for various welding applications, especially when mobility is essential.

The welder’s design is a testament to Hobart’s commitment to providing a reliable and durable product. The confidence instilled by its sturdy construction is pivotal, offering assurance that this welding equipment is poised to withstand the rigors of frequent use, making it a valuable investment for any welding enthusiast or professional.

Furthermore, beyond its functional strength, the Hobart exudes a visual appeal that adds an extra layer to its overall allure. The compactness of its design doesn’t compromise on aesthetic finesse, making it not only a practical tool but also a visually pleasing one.

The combination of durability and visual appeal underscores the meticulous attention to detail put into crafting this welding marvel, ensuring that users not only experience top-notch performance but also take pride in the tool they wield for their welding endeavors.

Performance Metrics

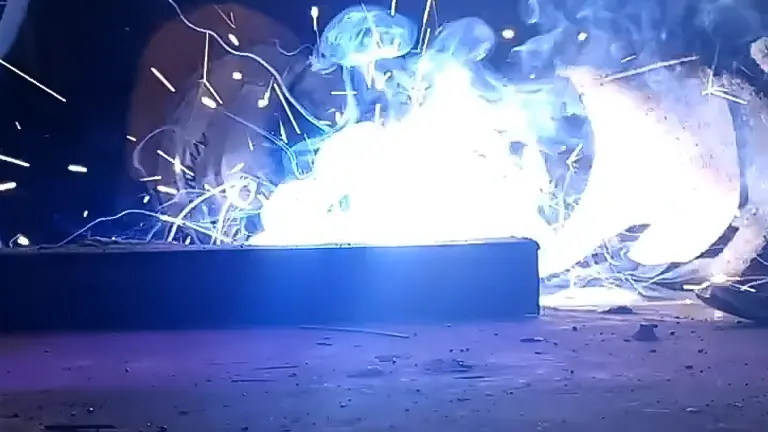

The performance takes center stage in the realm of flux-cored welding, and the Hobart Handler 100 emerges as a standout performer. Boasting a welding capacity spanning from 30 to 100 amps, this welding marvel showcases its versatility by accommodating a broad spectrum of applications.

From delicately handling thin gauge sheet metal to effortlessly managing thicker materials, the Hobart proves to be an adaptable tool for welders with diverse project requirements. During rigorous testing, the welder consistently demonstrated superior arc quality, producing welds that were not only clean but also remarkably precise.

This reliability in arc performance is a testament to the engineering precision incorporated into the design, ensuring that welders can achieve the desired outcomes with efficiency and accuracy. Furthermore, Hobart’s prowess extends beyond its numerical specifications. The real-world application of this flux-cored welder underscores its ability to meld functionality and precision seamlessly.

The welder’s capability to deliver clean and precise welds enhances its appeal for professionals and hobbyists alike, providing an optimal welding experience that aligns with the high standards expected in the welding community. The Hobart Handler 100, through its exceptional performance metrics, not only meets but surpasses the expectations set by welders seeking a reliable and high-performing flux-cored welding solution.

Voltage Control and Duty Cycle

An exemplary feature of the Hobart Handler 100 lies in its advanced voltage control settings, presenting welders with a seamless transition between various welding tasks. The significance of this attribute becomes apparent during operation, as the welder effortlessly adapts to the specific demands of different projects, providing users with a nuanced and precise control over the welding process.

Additionally, the Handler 100’s impressive 20% duty cycle at 80 amps enhances its appeal, particularly for users engaged in prolonged welding sessions. This ensures that the welder can maintain consistent performance over extended periods without succumbing to overheating, making it exceptionally well-suited for a broad spectrum of applications, from lighter-duty projects to more demanding and time-intensive tasks.

The combination of versatile voltage control and a robust duty cycle underscores the Hobart Handler 100’s commitment to facilitating a smooth, efficient, and reliable welding experience across diverse welding scenarios.

Ease of Use

Navigating the intricacies of welding equipment can be a challenge, even for those well-versed in the craft. Still, the Hobart Handler 100 sets itself apart with an exceptional emphasis on user-friendly design. The welder’s intuitive controls streamline the setup process, allowing even seasoned welders to seamlessly transition into operation.

What particularly impressed me was the clear wire feed tracking feature, which enhances precision and minimizes errors during welding tasks. The inclusion of a well-crafted quick-start guide proved to be a valuable asset, effectively reducing the learning curve and making the Handler 100 an ideal choice for those new to welding.

The thoughtful design and attention to user experience exhibited by Hobart in the Handler 100 contribute to an overall hassle-free operation, ensuring that both beginners and experienced welders can leverage its capabilities with ease and confidence.

Review of Visual Aspects

In terms of visual aspects, the Hobart Handler 100 stands out as an aesthetically pleasing and thoughtfully designed welding machine. The combination of a compact frame and robust construction not only enhances its portability but also lends a sense of durability and reliability.

The welder’s sleek, powder-coated finish not only contributes to its visual appeal but also serves as a protective layer, emphasizing the manufacturer’s commitment to both functionality and aesthetics.

The alloy steel handle adds a touch of industrial sophistication, enhancing the overall visual experience. Hobart has successfully balanced practicality with a visually pleasing design, ensuring that users not only wield a powerful welding tool but also one that reflects meticulous attention to detail in its exterior presentation.

Table of Comparison vs. Competitive

Here’s a basic comparison table between the Hobart Handler 100 Flux-Cored Welder and the Helvi 100-230 Volts Wire Welder:

| Feature | Hobart Handler 100 | Helvi 100-230 |

|---|---|---|

| Weight | 44 pounds | 42 |

| Dimensions | 16 x 10 x 13.5 inches | 38 x 17,5 x 35 cm |

| Power Source | AC | 100-230 Volts |

| Amperage Range | 30 – 100 amps | 35 – 100 amps |

| Duty Cycle | 20% at 80 amps | 80A @ 12% 27A @ 100% |

| Voltage Control | Yes | Yes |

| Spool Gun for Aluminum Welding | No | No |

| Suitable for Beginners | Yes | Yes |

| Wire Feed Tracking | Yes | Yes |

Pros and Cons

Pros

- Portable and Compact Design: Weighing in at just 44 pounds, the Hobart Handler 100 boasts a portable and compact design, making it easy to transport and ideal for on-the-go welding tasks.

- Robust Construction: The welder features a sturdy build that instills confidence in its durability, ensuring it can withstand the demands of various welding applications over time.

- Wide Amperage Range: With a welding capacity ranging from 30 to 100 amps, the Handler 100 offers versatility, accommodating a diverse range of welding tasks, from delicate sheet metal work to handling thicker materials.

- Excellent Voltage Control Settings: The welder’s voltage control settings contribute to a smooth transition between different welding tasks, allowing for precise adjustments and enhancing overall welding accuracy.

- User-Friendly Interface: The Handler 100 impresses with its user-friendly interface, featuring intuitive controls and clear wire feed tracking, making setup and operation straightforward for both beginners and experienced welders.

- Suitable for All Skill Levels: With its combination of user-friendly features and versatile performance, the Handler 100 caters to both beginners and seasoned professionals, providing a reliable tool for various welding needs.

Cons

- Limited Duty Cycle: The 20% duty cycle at 80 amps may be seen as limiting for extended, high-amperage projects, requiring users to manage their welding sessions to prevent overheating and ensure consistent performance.

- No Spool Gun for Aluminum Welding: The absence of a spool gun restricts the Handler 100’s capabilities for aluminum welding. While it excels in other applications, users looking for aluminum welding may need to consider alternative options.

Factors Influencing The Decision-making Process For Users

Several factors come into play when users embark on the decision-making process for welding equipment like the Hobart Handler 100. First and foremost, the welder’s portability and design attract users who prioritize mobility and ease of transportation, making it an ideal choice for those engaged in on-the-go welding tasks. The robust construction of the Handler 100 stands as a testament to its durability, instilling confidence in users looking for a reliable and long-lasting welding companion.

The wide amperage range, coupled with excellent voltage control settings, caters to users with diverse welding needs, offering versatility in handling various materials and projects. Additionally, the user-friendly interface and clear wire feed tracking feature contribute to the decision-making process, as they enhance ease of use and efficiency, catering to both beginners and experienced welders alike. These factors collectively play a crucial role in guiding users toward selecting the Hobart Handler 100 as their preferred flux-cored welder.

Final Conclusion

Having thoroughly tested the Hobart Handler 100 Flux-Cored Welder, I can confidently say that it lives up to its reputation as a reliable and efficient welding machine. Its versatility, durability, and ease of use make it an excellent choice for both beginners and experienced welders. While it may have some limitations, its overall performance places it at the forefront of flux-cored welding equipment in its class.

Frequently Asked Questions

- What is the duty cycle of the Hobart Handler 100?

The Handler 100 comes with a 20% duty cycle at 80 amps, making it suitable for various welding tasks. - Is the Hobart suitable for aluminum welding?

While the Handler 100 excels in many applications, it lacks a spool gun, limiting its capabilities for aluminum welding. - What is the power source for the Hobart Handler 100?

The welder operates on an AC power source. - Can beginners easily use the Handler 100?

Yes, the welder features a user-friendly interface, intuitive controls, and a quick-start guide, making it suitable for beginners. - What is the weight of the Hobart Handler 100?

The welder weighs 44 pounds, ensuring easy portability for on-the-go welding tasks. - Does the Handler 100 include voltage control settings?

Yes, the welder comes with excellent voltage control settings, allowing for precise adjustments during welding. - Is the Hobart suitable for thin gauge sheet metal welding?

Yes, the Handler 100’s wide amperage range (30 to 100 amps) makes it versatile enough for various welding applications, including thin gauge sheet metal. - Can the Handler 100 handle thicker materials?

Absolutely, with its robust construction and wide amperage range, the Handler 100 is capable of handling thicker materials in welding projects. - Does the Hobart come with a warranty?

Warranty details may vary, but Hobart typically provides a warranty for their welding products. Check the manufacturer’s information for specific details. - What is the measurement system used for the Handler 100?

The Handler 100 uses the metric measurement system, providing a standardized approach for user’s familiar with metric units.

We’re eager to learn from your firsthand experiences! Feel free to drop your thoughts and share your encounters with the Hobart Handler 100 in the comments section. Your valuable insights can play a crucial role in guiding and assisting fellow welders and contributing to a community where informed decisions are made. Let your voice be heard, and let’s build a collective pool of knowledge that benefits everyone in their welding endeavors!

For more information click here

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment