Fronius TransSteel 2200 MIG/TIG Welder Review

- January 4, 2024

- 0 comment

The Fronius TransSteel 2200 is not just a welding machine; it’s a powerhouse packed into a robust, lightweight frame, designed to cater to a diverse range of welding needs. From hobbyists to professional welders, this multi-process unit seamlessly transitions between MIG, TIG, and Stick welding, making it a versatile choice for any metalwork.

Design and Setup

Out of the box, the TransSteel 2200 impresses with its straightforward setup process, taking less time to assemble than unpacking. It includes a heavy-duty 15-foot MIG whip, noted for its durability and quality.

The robust design extends to the machine’s connections and ground clamp, both crafted from solid cast brass for optimal conductivity and strength. Additionally, the machine supports flexibility with multiple power cables and adapters to accommodate both 120V and 240V services, featuring a unique locking design for secure and tidy storage.

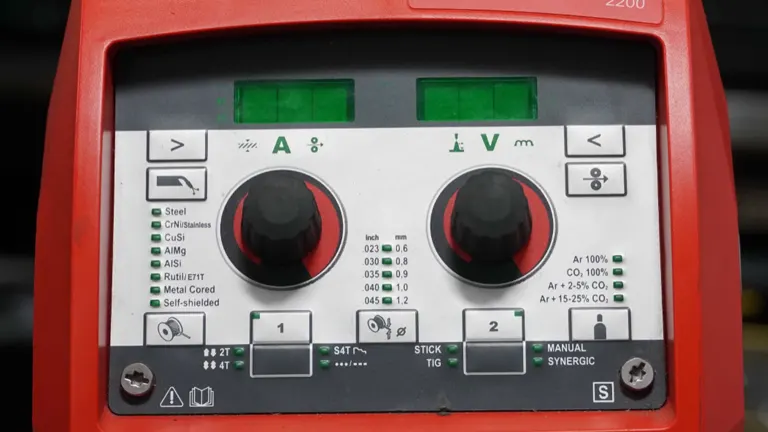

User Interface and Controls

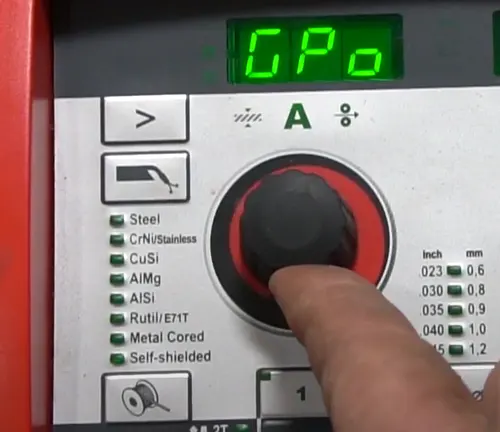

The front panel, initially intimidating due to its density, is logically organized into four easy steps that guide you from setup to welding in moments.

This user-friendly interface lets you select wire type, diameter, and gas type, then set the metal thickness to start welding. Advanced users can dive deeper into custom settings with toggles for arc length correction, current voltage display, and arc force dynamics, all adjustable in manual mode.

Performance and Features

The Fronius TransSteel 2200 excels in delivering exceptional performance across a variety of materials and welding techniques. Its synergic settings, which automatically adjust welding parameters based on user input, simplify the process for novices while providing ample customization for seasoned welders.

Here are some of the standout features:

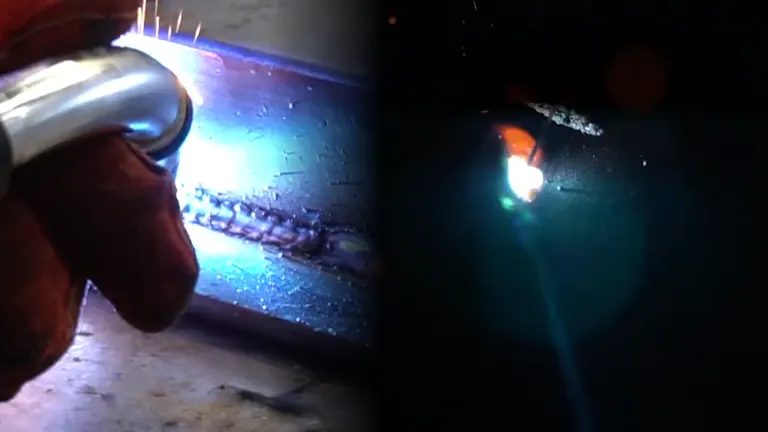

- Synergic MIG Welding: The TransSteel 2200 offers a user-friendly approach to MIG welding by automatically calibrating settings based on the metal type and thickness. This feature is particularly effective for welding aluminum, overcoming common challenges associated with it and ensuring smooth, high-quality welds.

- TIG Welding Enhancements: For those opting for the additional TIG package, the TransSteel 2200 includes a specially designed Fronius torch. This torch is noted for its robust build and ergonomic design, making it ideal for prolonged and intensive welding tasks. The controls on the torch are intuitively placed for ease of use, enhancing both comfort and productivity.

- Stick Welding Capabilities: The machine is well-equipped for stick welding with features such as hot start and anti-stick functionalities. These features facilitate easier starts and cleaner runs, making the TransSteel 2200 a reliable tool for diverse field applications involving various types of electrodes.

Each of these features is designed to make the TransSteel 2200 a versatile and powerful welding tool, suitable for a wide range of professional and DIY projects. Whether in a workshop or on-site, this welder provides top-tier performance that professionals can rely on.

Innovative Welding Modes

The Fronius TransSteel 2200 stands out not only for its versatility but also for its advanced welding modes that enhance functionality and user experience. These innovative features provide solutions to common welding challenges and allow for greater control and precision:

Spot Timer Mode

This mode is a game-changer for tasks requiring consistent stitch welding. It automates the start-stop sequence, ensuring uniform welds while continuously maintaining gas flow. This eliminates the common problem of gas interruption during stitch welding, which can lead to weld defects

Pulse Functionality

The TIG mode’s pulse functionality can achieve up to 990 pulses per second, offering unmatched control over heat input. This high level of precision is particularly beneficial for welding thin or sensitive materials, where managing heat input is crucial to avoid warping or burn-through.

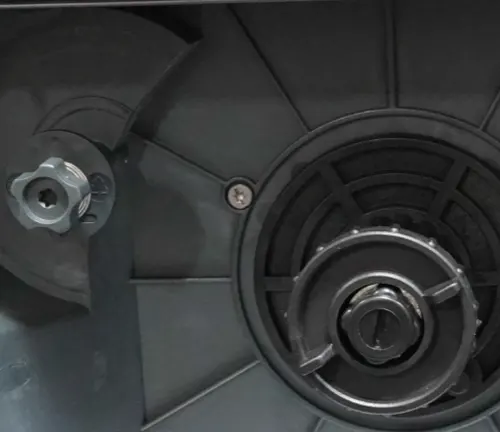

Dual Spool Capability and Storage

The TransSteel 2200 is designed to accommodate both large and small wire spools, enhancing its flexibility for different project sizes. Additionally, it features dedicated storage for consumables within the machine itself. This thoughtful design keeps essential items neatly organized and readily accessible, streamlining the welding process and maintaining a tidy workspace.

These innovative modes not only simplify the welding process but also open up new possibilities for crafting high-quality welds across a range of materials and applications. Whether you’re working in a professional shop or tackling projects at home, the TransSteel 2200 adapts to your needs with cutting-edge technology.

Durability and Portability

The Fronius TransSteel 2200 is a model of rugged durability and exceptional portability, weighing just over 34 lbs for easy transportation without sacrificing strength.

Designed with practical features like skid runners and an optional carrying strap, it excels in both workshop and field settings. This welder supports the use of extension cords over 300 feet long, allowing for flexible placement on large job sites or in various working environments, ensuring reliable performance wherever it’s needed.

Fronius TransSteel 2200 Product Details

| Specification | Value |

|---|---|

| Mains Voltage | 230V |

| Mains Voltage Tolerance | -20% / +15% |

| Mains Frequency | 50-60Hz |

| Welding Current Min. | 10 A |

| Welding Current Max. | 230 A |

| Welding Current / Duty Cycle | |

| 10 min/40°C 30% Duty Cycle | 210A MAG, 180A MMA, 230A TIG |

| 10 min/40°C 60% Duty Cycle | 170A MAG, 150A MMA, 200A TIG |

| 10 min/40°C 100% Duty Cycle | 150A MAG, 130A MMA, 170A TIG |

| Operating Voltage Min. | 14.5 V |

| Open-circuit Voltage | 90 V |

| Degree of Protection | IP23 |

| Dimensions (L x W x H) | 560 mm x 215 mm x 370 mm |

| Weight | 15 kg |

| Weight with Packaging | 16.2 kg (without packaging), 19.1 kg (with packaging) |

| Interference Emission Class | A |

| Power Factor (pf) | 0.99 |

Conclusion

The Fronius TransSteel 2200 offers an unparalleled combination of versatility, durability, and ease of use. Whether you’re welding thick industrial components or delicate custom pieces, this machine adapts to your needs without compromising on quality. Its extensive features, coupled with Fronius’s reputation for reliability, make the TransSteel 2200 an essential tool for any welder’s arsenal, promising performance that could redefine your welding projects.

FAQs

- What welding processes can the Fronius TransSteel 2200 handle?

The Fronius TransSteel 2200 is a versatile multi-process welder capable of MIG, TIG, and Stick welding. This allows for a wide range of applications across different materials and techniques. - Can the TransSteel 2200 weld aluminum?

Yes, the TransSteel 2200 can MIG weld aluminum right out of the box, with no need for a push-pull gun. Its advanced wire feed system is designed to handle aluminum wire smoothly, even when the wire is knotted or bent. - What are the power requirements for this welder?

The TransSteel 2200 is designed to operate on both 120V and 240V power supplies. It comes with multiple power cables and adapters to fit various outlet types and amperages, making it suitable for different environments and power sources. - Does the welder come with a TIG torch?

The TIG torch is available with the optional TIG package. This package includes a Fronius-made TIG torch with durable rubber coating and ergonomic controls, along with the necessary consumables to start welding. - What is the weight of the Fronius TransSteel 2200, and is it portable?

Weighing approximately 34 lbs, the TransSteel 2200 is one of the lightest in its class, enhancing its portability. It is equipped with skid runners and an optional carrying strap for easy transport, making it ideal for both shop and field use. - How user-friendly is the interface?

The TransSteel 2200 features a streamlined interface that breaks down the setup process into four simple steps. It also has an intuitive control panel with toggles for fine adjustments, making it accessible to welders of all skill levels. - Are there any special features for TIG welding?

Yes, the TransSteel 2200 includes a pulsar feature for TIG welding, which can be set up to 990 pulses per second. This feature provides precise control over heat input and metal deposition, ideal for handling delicate or thin materials. - How can I maintain the TransSteel 2200 to ensure longevity?

Regular maintenance such as cleaning the machine, checking cables and connections for wear, and replacing consumables like contact tips and nozzles is recommended. The machine should also be stored in a dry, clean environment and serviced professionally as per manufacturer guidelines. - What kind of technical support does Fronius provide?

Fronius offers robust customer service including access to manuals, replacement parts, and troubleshooting assistance. Technical support can be contacted via their website or phone for any queries or issues related to the TransSteel 2200. - Where can I purchase the Fronius TransSteel 2200 and what is the warranty?

The Fronius TransSteel 2200 can be purchased through authorized Fronius distributors or directly from their website. It comes with a standard manufacturer warranty, details of which are available on the product registration or through customer service.

We hope our review of the Fronius TransSteel 2200 has been informative! If you have any thoughts or questions, don’t hesitate to drop a comment below. Your insights could help others in making an informed decision. Feel free to share this review with other welding enthusiasts in your circle!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment