HITBOX MIG200II Mig Welder Review

- April 2, 2024

- 0 comment

The HITBOX MIG200II Mig Welder is a compact, versatile machine that aims to deliver a comprehensive welding solution for a variety of materials including steel, stainless steel, and aluminum. Its multifunctional capabilities make it a standout option for those who require a wide range of welding techniques without investing in multiple units.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

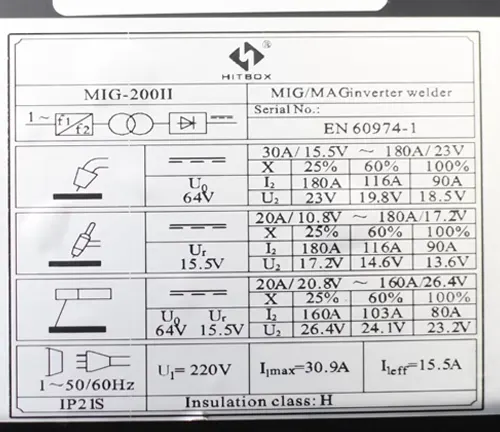

Technical Specifications

- Model: HITBOX MIG200II

- Processes: MIG (Gas and Gasless), TIG, Stick Welding

- Input Voltage: Dual Voltage 110/220V

- Maximum Output: 200A

- Wire Feed Speed: Adjustable

- Weldable Materials: Mild Steel, Stainless Steel, Aluminum (with appropriate setup)

- Welding Thickness Range: Up to 1/2 inch (material-dependent)

- Technology: IGBT Inverter

- Safety Features: Overheat Protection

- Dimensions: Compact design for easy handling and storage

- Weight: Designed for portability, relatively light

Usability

The usability of the HITBOX welder is one of its standout features, particularly appreciated by users for its straightforward setup and operation.

This welder is designed with the user in mind, featuring an intuitive control system that simplifies the adjustment of welding parameters, reducing the need for constant referral to the manual. Even those new to welding can quickly become comfortable with the machine, thanks to its clear, user-friendly interface. Additionally, the welder is accompanied by a comprehensive user guide that offers detailed instructions and tips for various welding tasks, ensuring users have the information they need at their fingertips.

The value of this resource is further amplified by the manufacturer’s responsive customer support team, ready to assist with any queries or issues that may arise. This combination of easy setup, intuitive controls, informative guides, and reliable support significantly enhances the overall user experience, making the HITBOX welder a favored choice for both beginners and experienced welders alike, emphasizing its commitment to user satisfaction and ease of use.

Multifunctional Welding Processes

This welder’s standout capability is its multifunctionality, supporting MIG, TIG, MMA, and more, making it adaptable for numerous welding tasks. This range of processes allows users to work on various materials and projects without needing multiple machines.

Digital Control Panel

The digital control panel enhances user interaction by offering precise control over welding parameters, which can be fine-tuned for different materials and thicknesses. This contributes to improved weld quality and user satisfaction.

Synergic Adjustment

Synergic adjustment simplifies the welding setup by automatically selecting the appropriate welding parameters based on the input material and wire thickness. This feature is especially useful for beginners, enabling them to achieve optimal welding results with minimal manual adjustments.

Duty Cycle

The HITBOX MIG200II features a commendable duty cycle that ensures sustained welding performance over time. A higher duty cycle rating allows for longer welding intervals before needing to cool down, making it efficient for longer projects and reducing downtime. This characteristic is particularly beneficial for professionals requiring consistent output during extensive welding sessions.

Performance

The HITBOX MIG200II MIG Welder is highly regarded for its consistent production of top-notch welds, demonstrating its proficiency in various welding tasks. Users have commended its smooth transition between different welding modes, including MIG (both Gas and Gasless), TIG, and Stick welding, offering unmatched flexibility to suit the specific requirements of different projects. This versatility is further enhanced by its user-friendly digital control panel, which plays a crucial role in its operation.

The control panel allows for precise adjustments of welding parameters, enabling users to easily customize the welder for a wide range of materials and thicknesses. This capability not only enhances the welder’s adaptability but also improves the quality of the welding results, establishing the HITBOX MIG200II as a dependable tool for professionals and hobbyists striving for excellence in their welding projects.

Durability and Reliability

Durability is essential for any welder, given the harsh environments they often operate in. THITBOX MIG200II Mig Welder is built to last, with a robust construction that can withstand regular use. However, long-term reliability can vary, and it’s crucial to maintain the machine properly to ensure its longevity.

Value

Considering its multifunctional capabilities, user-friendly design, and performance, the HITBOX MIG200II Mig Welder presents significant value for its price point. It’s an investment for both hobbyists who want to expand their welding skills and professionals seeking a versatile, reliable machine.

Pros and Cons

Pros

- Supports MIG, TIG, and Stick welding, suitable for various projects.

- Works with both 110V and 220V, enhancing flexibility.

- Digital panel allows for precise parameter adjustments.

- Compact and lightweight, easy to transport.

- Incorporates IGBT technology for reduced power consumption.

Cons

- Might be challenging for beginners to master all features.

- Requires a separate spool gun for aluminum welding.

- High-load use may necessitate cool-down periods.

- Some included accessories may lack durability.

Safety and Maintenance

Safety Practices

- Wear Appropriate PPE Always use personal protective equipment (PPE) including a welding helmet, fire-resistant clothing, gloves, and safety glasses to protect against sparks, spatter, and radiation.

- Ensure Proper Ventilation Work in a well-ventilated area to avoid inhaling harmful fumes and gases produced during welding. Use exhaust systems or respirators if necessary.

- Check for Combustibles Remove all flammable materials from the welding area to prevent fire hazards. Maintain a clean working space.

- Use Correct Settings Adjust the welder settings according to the material and welding process to prevent overheating and reduce the risk of accidents.

- Secure Workpieces Clamp down the pieces being welded to prevent movement and ensure a stable work environment.

Maintenance Tips

- Regular Inspection Periodically check the welder for any signs of wear or damage, especially the cables, connectors, and welding gun. Replace any defective parts immediately.

- Clean the Welder After each use, clean the welder to remove dust, dirt, and debris that could accumulate and potentially cause overheating or malfunction.

- Store Properly When not in use, store the welder in a dry, clean environment to prevent rusting and damage to its components.

- Check Gas and Coolant Levels For welders that use shielding gas or coolants, regularly check and refill these to ensure optimal performance and prevent overheating.

- Follow Manufacturer’s Guidelines Always adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure the welder operates safely and efficiently.

Quantitative Measurements

- Versatility and Functionality (out of 10): Considering its ability to perform MIG, TIG, and Stick welding, along with dual voltage capability, I’d rate it a 9/10. It loses a point because of the need for additional purchases for optimal performance with certain materials, like aluminum.

- Ease of Use and User Interface (out of 10): With its digital control panel allowing precise adjustments, it’s user-friendly for those familiar with welding. However, the learning curve for beginners brings it to an 8/10.

- Portability (out of 10): Given its lightweight and compact design, it’s highly portable. I’d rate it a 9/10, recognizing the balance it strikes between size and power.

- Energy Efficiency and Technology (out of 10): The inclusion of IGBT inverter technology enhances performance and energy efficiency. It earns an 8.5/10, as while it is efficient, there’s always room for improvements in technology to make it even more energy-saving.

- Durability and Build Quality (out of 10): Considering reports from users about the welder and its accessories, I’d give it a 7.5/10. The welder itself is robust, but the quality of some accessories and the variability in after-sales support suggest that there might be concerns regarding long-term durability and service.

Comparison Table

| Feature | HITBOX MIG200II | Titanium MIG 170 |

|---|---|---|

| Welding Processes | MIG (Gas/Gasless), TIG, Stick | MIG, Flux-Cored |

| Input Voltage | Dual Voltage (110/220V) | 120V/240V |

| Amperage Range | Up to 200A | 30A to 170A |

| Portability | Lightweight with carry handle, easy to transport | Compact and portable with a weight of 24.5 lbs |

| Digital Display | Yes, for precise control and adjustments | Yes, with easy-to-understand interface |

| Duty Cycle | Varies by process, generally high for sustained use | 30% at 170A (240V), higher at lower amperages |

| Wire Feed Speed | Adjustable | Adjustable |

| Versatility | High, with multiple processes and dual voltage | Moderate, focuses mainly on MIG and Flux-Cored welding |

| Energy Efficiency | Incorporates IGBT technology for efficiency | Efficient design, but specifics on technology not stated |

| Accessories Included | Generally comes with necessary accessories, but spool gun sold separately | Includes MIG gun, ground clamp, and more. Spool gun for aluminum sold separately |

Titanium MIG 170 Technical Specifications

- Welding Processes: MIG (Metal Inert Gas), Flux-Cored, Stick (Arc Welding)

- Input Voltage: 120/240V AC (Dual Voltage)

- Amperage Range: 30A to 170A

- Wire Feed Speed: Fully Adjustable

- Duty Cycle: Varies based on amperage and voltage settings, optimized for prolonged use

- Weldable Materials: Steel, Stainless Steel, Aluminum (with appropriate setup)

- Material Thickness: Capable of welding materials

- Digital Display: Yes, for voltage and wire feed speed

- Portability: Compact design with a built-in carrying handle

- Dimensions: Specific dimensions indicating length, width, and height

- Weight: Indicating the machine’s weight for transport and setup considerations

Conclusion

The HITBOX MIG200II Mig Welder stands out as a versatile, efficient, and user-friendly option for a wide range of welding tasks. Its ability to perform multiple welding processes with precision and ease makes it a valuable tool in any welder’s arsenal. While it offers excellent value, potential buyers should consider their specific needs and the welder’s performance across different materials to ensure it meets their requirements. With proper care and maintenance, this welder can be a long-term addition to workshops, offering flexibility and reliability for various projects.

FAQs

- What types of welding can the HITBOX MIG200II perform?

The HITBOX MIG200II is capable of MIG, TIG, and Stick welding, offering versatility for various welding tasks. - Can the HITBOX MIG200II weld aluminum?

Yes, it can weld aluminum, especially when using the MIG function with an appropriate spool gun. - What is the maximum welding thickness for the HITBOX MIG200II?

It can weld materials up to a thickness of around 1/2 inch, depending on the welding process used. - Does the HITBOX MIG200II support dual voltage?

Yes, it supports both 110V and 220V, making it adaptable to different power supplies. - Is a spool gun included for aluminum welding?

Typically, a spool gun is not included and must be purchased separately for optimal aluminum welding. - What is the maximum amperage output of the HITBOX MIG200II?

The welder has a maximum amperage output of 200A, providing ample power for most welding tasks. - Can I use the HITBOX MIG200II for professional projects?

Absolutely, its features and power output make it suitable for both hobbyist projects and professional work. - Is the HITBOX MIG200II portable?

Yes, it’s designed for portability, featuring a lightweight design and a carry handle. - Does it come with a warranty?

The HITBOX MIG200II typically comes with a 1-year warranty, covering manufacturing defects. - What additional accessories do I need to start welding?

You’ll need to acquire appropriate welding wire, gas cylinders for MIG/TIG welding, safety gear, and potentially a spool gun for aluminum.

We’re eager to learn about your journey with the HITBOX MIG200II MIG Welder! Please share your personal experiences and insights in the comments section below. Whether it’s about its performance, versatility, or any tips you have for fellow welders, your feedback can be invaluable in helping others make well-informed decisions. Let’s build a helpful community around our welding adventures!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment