Jackson WH 40 Insight Auto Darkening Welding Helmet Review

- March 20, 2024

- 0 comment

The Jackson Safety W40 Insight WH 40 is a highly regarded auto-darkening welding helmet that offers a blend of safety, functionality, and comfort for professional welders and hobbyists alike. This comprehensive review covers its key features, benefits, and some areas for improvement based on insights from various sources.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Jackson Insight WH 40 Specifications

- Brand: Jackson Safety

- Auto-Darkening: Yes, variable shades 9-13

- Viewing Area: 3.93″ x 2.36″

- ARC Sensors: 4

- Standards: ANSI Z87.1-2010, CSA

- Modes: Welding, grinding

- Battery: Replaceable

Comfort and Design

The Jackson Safety W40 Insight WH 40 welding helmet excels in comfort and design, blending safety with ergonomic features. The helmet’s construction emphasizes a comfortable fit, accommodating extended wear without discomfort, which is particularly important for professionals engaged in long welding sessions. Its design is not only focused on safety, protecting the wearer from heat, sparks, and harmful radiation, but also on ease of use, with controls that are intuitive and easily accessible.

The helmet offers a large viewing area, which is a crucial design element, ensuring welders have clear visibility of their work without needing to compromise their posture or safety. Additionally, its auto-darkening feature adjusts seamlessly to different lighting conditions, further enhancing the welding experience by reducing eye strain and fatigue. This combination of thoughtful design and comfort-focused features makes the Jackson Safety W40 Insight WH 40 a standout choice for welders prioritizing both protection and comfort in their gear.

Key Features and Benefits

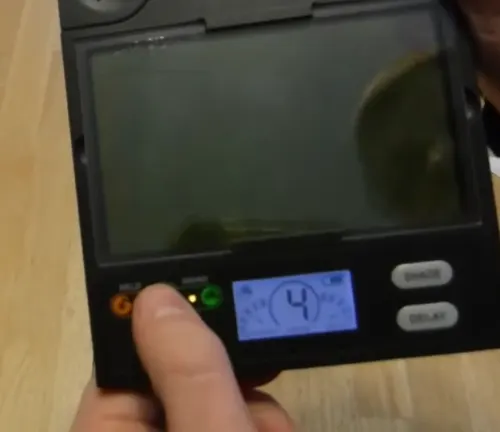

Auto-Darkening Filter

The helmet is equipped with a digital variable auto-darkening filter, providing clear visibility and protection against harmful light emissions. The filter adjusts automatically to varying light conditions, ensuring optimal protection and visibility.

Large Viewing Area

The helmet boasts a generous viewing area of 3.93″ x 2.36″, which ensures that welders have an unobstructed view of their work. This feature, coupled with its variable shades from 9 to 13, allows for precise work on various welding projects.

Areas for Improvement

While the helmet is highly rated for its features and functionality, some users have found it to be slightly heavier compared to other models. Additionally, the head straps may not fit all users perfectly, which could affect comfort during extended use.

Jackson Insight WH 40 Pros and Cons

Pros

- Variable shades for optimal eye protection.

- Enhances visibility and precision.

- Suitable for welding and grinding.

- Meets ANSI Z87.1 and CSA standards.

- Easy adjustments for comfort and visibility.

Comparison Table with Other Models

| Feature | Jackson Safety W40 Insight WH 40 | ESAB Sentinel A50 |

|---|---|---|

| Weight | Not specified | 1.4 lbs (640g) |

| Optical Clarity | Not specified | 1/1/1/2 |

| Viewing Area | 3.93″ x 2.36″ | 3.93″ x 2.36″ (100 x 60 mm) |

| Shade Range | 9-13 | 5-13 |

| Auto-Darkening Switch Speed | Not specified | 1/25,000 second |

| Number of Sensors | 4 | 4 |

| Solar Powered | Yes, with battery backup | Yes, with battery backup |

| Touch Screen Control | No | Yes |

| Grind Mode | Yes | External button |

| Comfort/Ergonomics | High, but some find it heavy | 5-point halo harness headgear |

| Accessories Included | Not specified | Carrying bag, hard hat adapter, magnifying lens |

| Price Range | Mid-range | Higher |

| Best For | Professional use, general versatility | Professional use, versatility |

ESAB Sentinel A50 Specifications

- Brand: ESAB

- Model: Sentinel A50

- Weight: 1.4 lbs (640g)

- Optical Clarity: 1/1/1/2

- Viewing Area: 3.93″ x 2.36″ (100 x 60 mm)

- Shade Range: 5-13

- Switch Speed: 1/25,000 second

- Sensors: 4

- Power: Solar with battery backup

- Controls: Touch screen

- Mode: Grind, external button

- Comfort: 5-point halo harness

- Includes: Bag, hard hat adapter, lens

- Price Range: Higher

- Best For: Professional use

Quantitative Measurements of Jackson Safety W40 Insight WH 40

- Viewing Area 3.93″ x 2.36″ (approximately 99.8 mm x 59.9 mm) – Offers a large field of view for better visibility during welding tasks.

- Shade Range:Variable shades from 9 to 13 – Suitable for various welding processes and light conditions.

- Number of Sensors 4 – Ensures responsive and accurate control of the auto-darkening feature.

- Switching Speed Auto-darkening filter switching speed is typically measured in fractions of a second, though specific speed for this model wasn’t provided, industry standards often range around 1/10,000 to 1/25,000 of a second for high-quality helmets.

- Weight Specific weight not detailed in provided information, but welding helmets of this type usually weigh between 1 to 2 lbs (approximately 453 to 907 grams) to balance protection and comfort.

- Battery Type Uses replaceable watch batteries – Ensures easy maintenance and continuous operation.

- Solar Panel Included for battery charging – Enhances battery life and reduces the need for frequent replacements.

- Optical Class Specific optical class not provided, but high-quality helmets typically feature a rating of 1/1/1/1 or 1/1/1/2, indicating clarity, angular dependence, uniformity, and light scattering.

- Certifications Meets ANSI Z87.1-2010 standards and is CSA compliant – Confirms the helmet’s safety and performance meet regulatory requirements.

- Grind Mode Feature Yes – Allows users to switch to a grind mode, providing versatility for welding and grinding tasks without changing helmets.

Maintenance for Jackson Safety W40 Insight WH 40

- Regular Cleaning Wipe the helmet with a soft cloth after each use to remove dust and spatter. Avoid harsh chemicals; mild soap and water are usually sufficient.

- Lens Care Inspect and clean the auto-darkening lens regularly with a lens cleaning solution and a microfiber cloth to avoid scratches and maintain clarity.

- Battery Replacement If the helmet uses replaceable batteries, check and replace them periodically to ensure the auto-darkening feature functions correctly.

- Inspection of Sensors Keep the arc sensors clean and unobstructed to maintain the helmet’s responsiveness to welding arcs.

- Headgear Adjustment Regularly adjust and check the tightness of the headgear to ensure a secure and comfortable fit.

- Storage Store the helmet in a cool, dry place away from direct sunlight and extreme temperatures to prevent damage to the auto-darkening lens and helmet shell.

- Checking for Wear and Tear Regularly inspect the helmet for any signs of wear, cracks, or damage, especially after significant impacts.

- Updating Settings Periodically review and adjust the helmet’s settings (shade, sensitivity, and delay) according to the welding tasks at hand for optimal protection and comfort.

- Replacement of Consumables Replace consumable parts like the cover lens and sweatband as needed to maintain visibility and hygiene.

- Professional Inspection If the helmet experiences a severe impact or malfunctions, have it inspected by a professional to ensure it’s safe to use.

Safety Tips for Jackson Safety W40 Insight WH 40

- Proper Fit and Adjustment Before starting any welding project, ensure the helmet is properly adjusted to fit snugly on your head. A secure fit protects against sparks and slag that could slip underneath.

- Regular Inspection Check your helmet before each use for any signs of damage, such as cracks or degradation, especially in the auto-darkening lens, to ensure it provides the necessary protection.

- Use Correct Shade Settings Adjust the auto-darkening filter to the appropriate shade level for the type of welding you’re doing to protect your eyes from harmful light emissions.

- Maintain Clear Visibility Keep the lens clean and replace the cover lens if it becomes scratched or too dirty, as impaired vision can lead to accidents.

- Wear Additional Protective Gear Besides the helmet, wear gloves, fire-resistant clothing, and safety shoes to protect against burns and other injuries. Also, consider respiratory protection if working in environments with hazardous fumes.

Conclusion

Overall, the Jackson Safety W40 Insight WH 40 welding helmet is a solid choice for those seeking a reliable, feature-rich helmet for welding projects. Its emphasis on safety, large viewing area, and versatility make it ideal for both professional and personal use. Despite minor criticisms regarding weight and fit, its benefits far outweigh these drawbacks, making it a recommended option for welders seeking quality protective gear.

Frequently Asked Questions(FAQs)

- What type of batteries does the Jackson Safety W40 use?

It uses replaceable watch batteries to power the auto-darkening feature. - Can I wear prescription glasses underneath the helmet?

Yes, there is enough room to comfortably wear prescription or safety glasses underneath the helmet. - Is the helmet suitable for all types of welding?

Yes, it’s versatile and can be used for TIG, MIG, and ARC welding tasks. - How do I clean the helmet and lens?

Use a soft cloth with mild soap and water for the helmet. For the lens, use a lens cleaning solution and a microfiber cloth to avoid scratches. - What is the viewing area size of the helmet?

The helmet features a large viewing area of 3.93″ x 2.36″. - Are the shade levels adjustable?

Yes, the helmet offers variable shades from 9 to 13, adjustable for different welding conditions. - Does the helmet meet any safety standards?

It meets ANSI Z87.1-2010 standards and is CSA compliant, ensuring high safety and quality. - Can the helmet be used for grinding as well?

Yes, it has a grind mode which can be activated for grinding tasks. - How do I replace the batteries?

The helmet’s battery compartment is accessible for easy battery replacement without needing specialized tools. - What should I do if the auto-darkening feature stops working?

Check the batteries first, as they may need replacing. If the issue persists, consult the manual or contact customer service for further assistance.

We’d love to hear from you! If you’ve used the Jackson Safety W40 Insight WH 40 welding helmet, share your personal experiences and thoughts in the comments section below. Your feedback is invaluable, helping fellow welders make informed decisions about their protective gear. Whether it’s about its comfort, functionality, or any tips you have for maintenance, your insights could greatly benefit the welding community!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment