How to Choose the Best Wood Stove Pipe

- November 8, 2023

- 0 comment

Understanding the importance of selecting the right wood stove pipe is crucial not only for the efficiency of your heating system but also for ensuring safety and extending the lifespan of your wood stove installation. The choice of the correct stove pipe has a profound impact on the overall functionality and safety of your wood stove within your home. It’s about creating a harmonious balance between efficient operation and stringent safety standards, which, when achieved, can significantly enhance your wood stove experience.

This article is designed to be a comprehensive guide, detailing the key factors to consider when choosing a stove pipe. We will explore various aspects such as the types of stove pipes, the importance of standard sizing, the significance of pipe diameter, and the necessity of adhering to clearance requirements. Additionally, we will delve into the relevance of pipe length, and the need for the right adapters, and provide essential installation and safety tips. Whether you’re undertaking a new installation or replacing an existing stove pipe, understanding these nuances is vital.

Our aim is to arm you with the knowledge needed for a well-informed decision, ensuring that your wood stove system operates efficiently and safely, adding warmth and comfort to your home while maintaining the highest safety standards.

What is a Wood Stove Pipe?

A wood stove pipe is a conduit used to safely vent smoke and combustion gases from a wood stove to the outside of a building. It is an essential component of a wood stove heating system, ensuring efficient operation and maintaining indoor air quality.

1. Understanding Stove Pipe Types

When selecting a wood stove pipe, understanding the differences between single-wall and double-wall pipes is crucial. These differences impact not only installation requirements but also safety and efficiency.

Single-Wall Pipes

Single-wall stove pipes are typically made from a thinner gauge of metal, making them more lightweight and affordable. However, their thinner construction also means they offer less insulation compared to their double-wall counterparts.

- These pipes are ideal for installations where there is ample clearance from combustible materials. Because they do not have the insulating properties of double-wall pipes, they require more space from walls and ceilings to safely dissipate heat. This is a key consideration in smaller spaces or in homes where the stove is closer to walls or other potential fire hazards.

- When choosing a single-wall pipe, one should look for features that indicate a higher quality, such as factory-welded seams. These seams are indicators of a robust construction, providing enhanced durability and safety. A well-constructed single-wall pipe with solid welding will be more rigid and less prone to warping or leaking over time.

Double-Wall Pipes

Double-wall stove pipes are designed with an air-insulated layer between two layers of metal. This design significantly enhances their safety and efficiency. The air gap provides insulation, reducing the surface temperature of the outer pipe layer, which is a critical safety feature in closer quarters.

Advantages

- One of the main advantages of double-wall pipes is their lower clearance requirement from combustible materials. This feature is particularly beneficial in tighter installations or when the stove needs to be placed closer to walls. The reduced clearance is due to the insulating effect of the air gap, which keeps the outer pipe cooler.

- The design of double-wall pipes helps to keep the heat within the pipe, improving the draft and efficiency of the stove. This can lead to more effective heating and can also reduce fuel consumption.

- The inner layer of these pipes is often made of stainless steel, which is resistant to corrosion. This is especially important for the longevity of the pipe, as corrosion can lead to leaks and decreased efficiency.

In summary, when choosing between single-wall and double-wall stove pipes, consider the specific needs of your installation, such as space constraints and safety requirements. Both types have their advantages, but the right choice will depend on your individual situation and local building codes.

2. Importance of Pipe Diameter

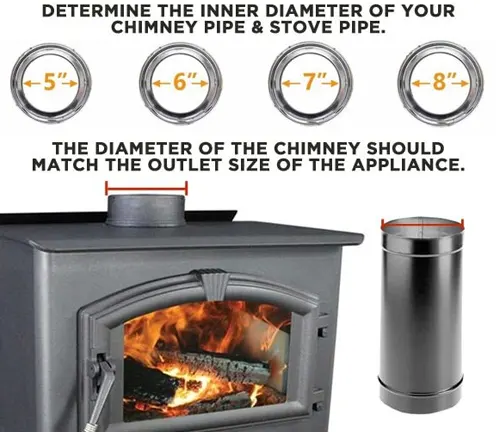

The diameter of your stove pipe is a critical factor in ensuring the efficient and safe operation of your wood stove. The correct diameter ensures a proper fit and optimal airflow, which is essential for the performance and longevity of your stove system.

Standard Sizes

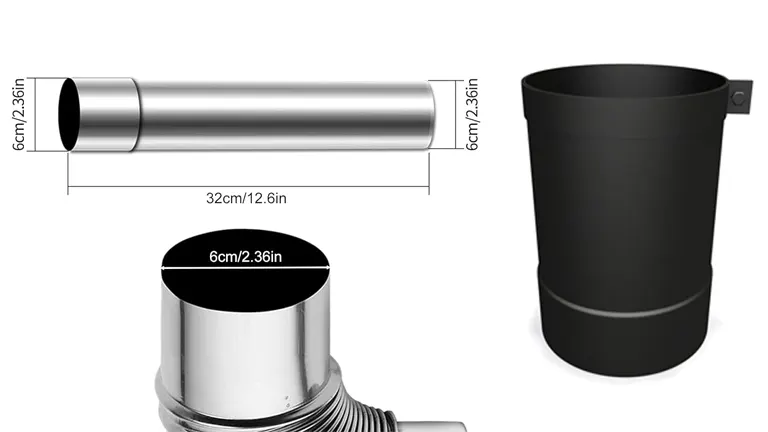

In the United States, the standard size for wood stove pipes predominantly accommodates a 6-inch diameter, catering to the majority of stove models. This size is not only widely available but also ensures compatibility across a diverse range of stove types, making it a common choice for numerous installations. However, it is essential to acknowledge that some models, particularly those designed to produce more heat, such as larger stoves, necessitate an 8-inch diameter pipe for effective exhaust management.

These larger pipes are crucial for handling the increased volume of smoke and gases emitted by high-output stoves. Therefore, understanding the specific requirements of your wood stove is vital in selecting the correct pipe diameter. This selection process often involves considering factors such as stove size, heat output, and the unique specifications provided by the manufacturer. Additionally, for stoves that do not conform to these standard sizes, especially older or specialty models, custom-sized pipes or the use of adapters might be required to ensure a safe and efficient installation. Ultimately, the choice of pipe diameter impacts not only the efficiency of your wood stove but also the safety of its operation, underscoring the importance of precise and informed decision-making in the installation process.

European Models

European wood stove models often present unique challenges due to their non-standard flue collar sizes. Unlike the common 6-inch or 8-inch diameters predominant in U.S. models, European stoves, as well as some older models, might feature flue collars in sizes like 5.25 inches or 7 inches. This difference in sizing can complicate the process of fitting stove pipes, which are typically manufactured to U.S. standard sizes.

To effectively address this issue, the use of adapters becomes crucial. These adapters are specifically crafted to facilitate a smooth transition from the stove’s non-standard flue collar to a stove pipe of standard U.S. size. This ensures not only a secure physical connection but also maintains the efficiency and safety of the exhaust system. When selecting adapters, it’s vital to prioritize high quality, as a well-made adapter can significantly impact the overall safety and functionality of the stove. By ensuring a proper fit and seal, these adapters play a key role in adapting European stoves or older models to work safely and efficiently with readily available U.S. standard stove pipes.

Measuring Tips

When determining the correct size for your wood stove pipe, it is imperative to measure the inside diameter of your stove’s flue collar accurately. This measurement is crucial because it directly correlates to the size of the stove pipe that will fit your stove properly. The inside diameter is the most relevant dimension in this context, as it ensures that the pipe will connect seamlessly to your stove, providing an efficient and safe pathway for smoke and exhaust gases.

Accuracy in these measurements is key, not just for the efficiency of your stove’s operation, but more importantly, for safety. A stove pipe that is incorrectly sized—whether too large or too small—can lead to a range of problems. An ill-fitting pipe can cause poor ventilation, leading to inefficient burning and potentially hazardous conditions. Moreover, improper sizing can significantly increase the risk of creosote buildup within the pipe, which is a major fire hazard. To ensure precision, it’s advisable to use a reliable measuring tool. In cases where there is uncertainty, or if the process seems daunting, don’t hesitate to consult a professional. An expert can provide the necessary guidance and assurance that your stove pipe is the correct size, thereby enhancing the overall safety and functionality of your wood stove system.

By understanding the importance of pipe diameter and how to measure it correctly, you can ensure that your wood stove operates efficiently and safely. Whether you have a standard U.S. stove or a European model, ensuring the right fit is paramount for optimal performance.

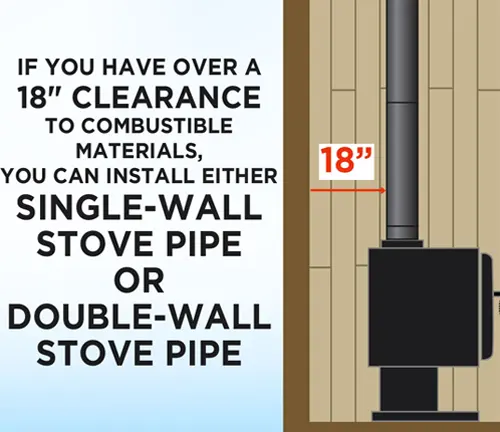

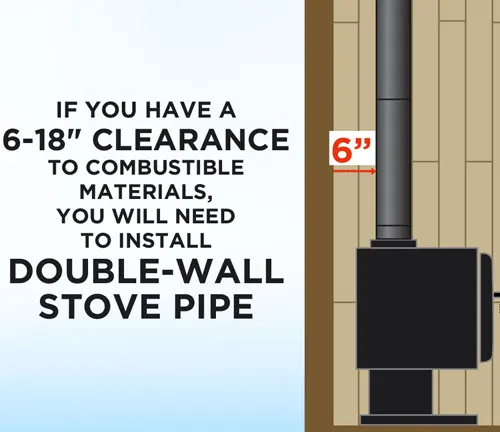

3. Clearance Requirements

Clearance requirements are a critical aspect of wood stove pipe installation, dictating how close the pipe can be to combustible materials like walls, ceilings, and furniture. Adhering to these requirements is essential for preventing fire hazards.

Single vs. Double Wall

Single-Wall Pipes

These pipes, due to their lack of insulation, require a greater distance from combustible materials. Generally, the clearance requirement for single-wall stove pipes is between 12 to 18 inches. This greater distance is necessary to safely dissipate the heat generated by the pipe.

Double-Wall Pipes

Thanks to their insulated design, double-wall pipes have significantly reduced clearance requirements. Most double-wall pipes require only 6 inches of clearance from combustibles. This reduced clearance is due to the air-insulated space between the two layers of the pipe, which greatly decreases the surface temperature of the outer pipe.

Local Codes

- Compliance with local building codes cannot be overstressed. These codes are established to ensure safety in home construction and renovations, including the installation of wood stoves and pipes.

- It’s crucial to recognize that clearance requirements can vary based on local regulations. Different regions or municipalities might have specific codes that pertain to the installation of wood stoves and stove pipes.

- In cases of uncertainty, consulting with a local professional or building inspector is advisable. They can provide guidance on the applicable codes and help ensure that your installation is compliant and safe.

- Always keep a record of the clearance requirements and how your installation adheres to them. This information can be valuable for insurance purposes and future reference.

In summary, understanding and adhering to the correct clearance requirements for your stove pipe is a non-negotiable aspect of installation. It ensures not only the efficiency of your wood stove but, more importantly, the safety of your home and its occupants. Whether you’re using a single-wall or a double-wall pipe, always prioritize safety by following local codes and seeking professional advice if needed.

4. Pipe Length and Adjustability

Choosing the correct length and adjustability of your stove pipe is essential for a proper and efficient installation. It’s not just about ensuring the pipe fits; it’s also about optimizing performance and maintaining the aesthetic integrity of your space.

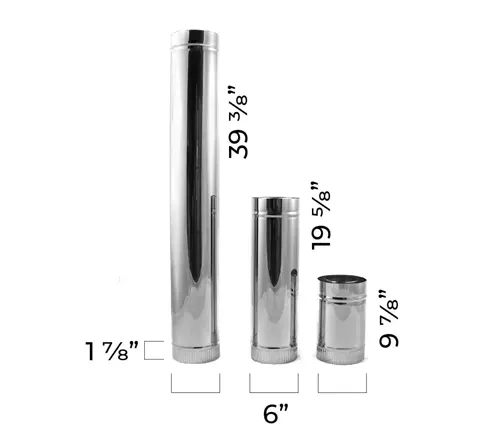

Available Lengths

- Stove pipes are available in a variety of lengths to suit different installation needs. They typically range from as short as 6 inches to as long as 48 inches. This range allows for flexibility in accommodating the distance between the stove and the chimney or venting system.

- It’s important to select a length that minimizes the number of joints and connections, as each joint can be a potential point of weakness or leakage. However, it’s also essential to have enough length to safely reach your venting system without stressing the pipe.

Adjustable Pipes

- Adjustable pipes provide an additional level of flexibility. They are particularly useful in situations where standard lengths are not an exact fit. For instance, an adjustable pipe that can extend up to 10 inches can bridge gaps or make up for minor miscalculations in measurements.

- Adjustable pipes are invaluable for custom or non-standard installations, where the distance between the stove and the venting system does not match up with standard pipe lengths. This feature can simplify the installation process by reducing the need for cutting or modifying standard pipes.

Installation Tip

- When installing stove pipes, it’s recommended to align the seams in a way that they are less visible, aiming them away from common viewing angles. This practice is not just about functionality but also about aesthetics, ensuring that the installation looks neat and professionally done.

- In living areas where the stove and its piping are visible, how they look is almost as important as how they function. A well-installed stove pipe with thoughtfully aligned seams can complement the overall look of the stove and the room.

In conclusion, selecting the right length and type of stove pipe, and considering its adjustability, are crucial steps in ensuring a successful installation. Not only does this impact the safety and efficiency of your wood stove, but it also affects the visual appeal of the installation in your living space. Remember, a well-installed stove pipe should be both functional and aesthetically pleasing.

5. Choosing the Right Adapter

Selecting the appropriate adapter is a pivotal step in the installation of your wood stove pipe system. Adapters serve as the crucial link between the stove pipe and the chimney or venting system, ensuring a secure and efficient connection.

Stove Pipe Adapters

- Stove pipe adapters are designed to transition seamlessly from the stove pipe to the chimney. This transition is essential for maintaining a continuous and effective exhaust pathway for the smoke and gases produced by the stove.

- There are various types of adapters available, each designed to accommodate different configurations and types of stove and chimney systems. The right adapter not only connects the different diameters but also different types (like transitioning from a single-wall stove pipe to a double-wall chimney pipe).

Considerations for Selecting Adapters

- The first consideration when choosing an adapter is the compatibility with your specific stove model. The adapter must fit the stove’s output flue collar both in size and shape. Misfitting adapters can lead to poor connections, smoke leaks, and decreased stove efficiency.

- Equally important is the compatibility with the type of chimney or venting system you have. The adapter must provide a secure and airtight connection to the chimney, ensuring that all exhaust is safely directed out of your home.

- Look for adapters made from durable materials that can withstand high temperatures and corrosive exhaust gases. Stainless steel is a common choice for its durability and resistance to corrosion.

- Consider adapters that offer ease of installation, such as twist-lock mechanisms or seamless slip-in designs. These features can simplify the installation process and ensure a secure fit.

- Ensure that the adapter you choose meets the relevant safety standards and certifications. This is crucial for not just the efficiency of your stove system but also for the safety of your home.

6. Installation and Safety Tips

Proper installation and regular maintenance of your wood stove pipe are key to ensuring the safety, efficiency, and longevity of your heating system. Here are essential tips to consider:

Professional Installation

Professional installation of your wood stove pipe is key to ensuring safety and efficiency. It’s crucial to regularly inspect and clean your stove pipes, as soot and creosote buildup over time can create significant fire hazards. Regular cleaning helps maintain a clear airway for safe and efficient stove operation. Additionally, it’s wise to schedule routine maintenance at least annually, ideally before the onset of the heating season. This proactive approach allows you to address potential issues before they become major problems. During these maintenance checks, be vigilant for signs of wear and tear, such as rust, corrosion, or physical damage. Catching these signs early on can help prevent larger, more complex issues in the future.

Regular Maintenance

Regular maintenance of your stove pipes is an essential aspect of ensuring the safety and efficiency of your wood stove. Inspection and cleaning should be done routinely, as soot and creosote can accumulate inside the pipe over time, creating a serious fire hazard. Regularly cleaning the pipes keeps the airway clear, facilitating safe and efficient operation.

It is recommended to schedule maintenance at least once a year, preferably before the start of the heating season. This timing is strategic, as it allows for any potential issues to be identified and resolved before the stove is used extensively for warmth. Additionally, during these maintenance checks, it’s important to look for signs of wear and tear, such as rust, corrosion, or physical damage. Catching and addressing these issues early can help prevent more significant problems from developing in the future.

Safety First

- Quality of Materials: Always use high-quality materials for your stove pipe and related components. Cheaper, lower-quality materials might save money in the short term but can be a safety hazard and may need more frequent replacements.

- Adherence to Manufacturer Guidelines: Follow the manufacturer’s guidelines for installation and maintenance. These guidelines are designed to optimize the performance of your stove and ensure safe operation.

- Awareness and Education: Educate yourself and your household about the proper use and maintenance of the wood stove. Knowing how to operate it safely and what to do in case of an emergency can prevent accidents.

- Installation of Detectors: Install and regularly test smoke and carbon monoxide detectors in your home. These devices are essential for early detection of dangerous conditions.

Conclusion

Choosing the appropriate wood stove pipe is a critical decision that significantly impacts the efficiency, safety, and functionality of your wood stove. It requires careful consideration of various factors to ensure that the system not only meets your heating requirements but also aligns with crucial safety standards. By understanding the differences between single-wall and double-wall pipes, selecting the correct diameter, adhering to clearance requirements, opting for suitable lengths and adjustability, and using the right adapters, you can create an optimal setup for your home.

Additionally, the importance of professional installation cannot be overstated. It ensures compliance with local codes and helps in achieving a safe and efficient installation. Regular maintenance, including inspections and cleaning, further enhances the safety and longevity of your stove pipe system. Always prioritize the use of high-quality materials and adherence to manufacturer guidelines to maintain the integrity and safety of the installation.

In essence, a well-chosen and properly installed wood stove pipe system is key to enjoying the benefits of your wood stove. It not only provides warmth and comfort but also ensures that you and your loved ones remain safe while enjoying the cozy ambiance that a wood stove offers. Remember, when it comes to wood stoves, cutting corners on installation and maintenance can compromise both efficiency and safety. Taking the time to make informed decisions about your wood stove pipe will pay off in reliable, safe, and efficient heating for years to come.

Related Articles:

- How Much Does Wood Stove Installation Cost?

- Wood Stove Installation Cost for Tiny Houses: A Complete Breakdown

- How to Install a Wood Stove in the Basement 2023

- 10 Best Wood Stove Fans 2023

- When To Replace Your Wood Stove Pipe 2023

FAQs

- Can I mix and match different brands of stove pipes and adapters?

It’s generally recommended to use stove pipes and adapters from the same manufacturer to ensure compatibility and safety. Different brands may have slight variations in size, fit, and design, which could affect the integrity of the installation. - FAQ: How does the altitude of my location affect my choice of wood stove pipe?

Altitude can impact the draft of your stove. In higher altitudes, you might need a different size or type of pipe to ensure proper ventilation due to thinner air. Consult with a local expert to determine the best option for your specific location. - Is there a difference in stove pipe requirements for different types of wood stoves, like pellet vs. wood-burning?

- Yes, different types of stoves, such as pellet stoves and traditional wood-burning stoves, have different venting requirements and may require specific types of stove pipes. Always refer to the manufacturer’s guidelines for your specific stove model.

- Can I paint my wood stove pipe to match my room’s decor?

While it’s possible to paint stove pipes, it’s crucial to use high-temperature resistant paint that can withstand the heat without emitting fumes or breaking down. However, the paint may affect the pipe’s ability to dissipate heat effectively and could void warranties. - How does the efficiency of my wood stove relate to the type of stove pipe I should choose?

The efficiency of your wood stove can be affected by the type of stove pipe used. High-efficiency stoves often require more precise venting solutions, such as double-wall pipes, to maintain the right temperature and draft. - Are there environmentally friendly options for wood stove pipes?

Some stove pipes are made with materials or manufacturing processes that are more environmentally friendly. Look for products with lower environmental impact in terms of material sourcing, production processes, and recyclability. - How does the length of the stove pipe affect my stove’s performance?

The length of the stove pipe can impact the draft and overall performance of your stove. Too long or too short pipes can lead to poor drafts, inefficiency, and increased creosote buildup. It’s important to calculate the optimal length based on your home’s layout and stove’s specifications. - What should I do if my home’s layout requires an unusually shaped stove pipe installation?

For unique or challenging layouts, custom-made stove pipe solutions may be necessary. Consult with a professional installer who can design a system that meets your specific needs while adhering to safety standards.

Thank you for joining us on this journey through the intricacies of choosing the best wood stove pipe! We hope you found our article “How to Choose the Best Wood Stove Pipe” enlightening and useful. Now, we’d love to hear from you!

Your thoughts, experiences, and even your own tips are what make this conversation so enriching. Have you picked out a stove pipe recently? How did it go? Maybe you’ve got some wisdom to share or a story that could bring a smile or a nod of understanding.

Feel free to drop a comment below – let’s keep this chat warm and lively. And if you know someone who’s tinkering with their wood stove setup, why not share this article with them? Together, let’s spread knowledge and help each other make our homes cozy and safe. Can’t wait to hear from you!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment