Festool 574432 Domino DF 500 Joiner Q-Set Review

- March 26, 2024

- 0 comment

Discover the Festool 574432 Domino DF 500 Joiner Q-Set, a professional-grade tool engineered for creating fast, easy, and strong mortise and tenon joints. Ideal for a wide range of woodworking applications such as cabinetmaking, furniture building, and millwork, this versatile machine elevates the precision and efficiency of joinery work.

Technical Specs

- Cutter Spindle Speed: 24,300 RPM

- Domino Slot Cutter Diameter: 5/6/8/10 mm (available in various sizes)

- Power Consumption: 420 watts

- Routing Depth Stop: 12/15/20/25/28 mm (selectable depths for precise mortising)

- Weight: 7 lbs (3.2 kg) for easy maneuverability

- Dust Extraction Connection Diameter: 27 mm for efficient dust collection

How Does It Work?

Festool 574432 Domino DF 500 Joiner Q-Set Cutter Movement

The Festool Domino Joiner DF 500’s functionality is its innovative oscillating cutter. This cutter is designed to move in a unique oscillating and rotating motion when the tool is engaged and pushed forward into the workpiece. This dual motion is critical for creating the Domino’s signature mortises – rectangular slots that are designed to accept the tenon. The oscillating motion of the cutter is particularly important as it allows the creation of mortises that are slightly wider than the cutter itself. This additional space is crucial for accommodating the tenon, ensuring a snug fit that is not overly tight, which could make assembly difficult. The precision of this movement allows for the creation of clean, consistent mortises that are essential for high-quality joinery.

Depth Adjustment

The Domino joiner’s depth adjustment feature is a testament to its versatility and user-friendly design. The adjustable cutting depth, with settings that range from 12 to 28 millimeters, is easily controlled via a lever on the tool. This flexibility allows woodworkers to tailor the depth of the mortises to the specific requirements of their projects. Whether working with thin panels or thicker blocks of wood, the ability to adjust the cutting depth ensures that the mortises are of the appropriate size, providing a solid foundation for the tenon and, consequently, a strong and durable joint. This feature is particularly useful for custom projects or when working with materials of varying thicknesses, making the Domino joiner a valuable tool for a wide range of woodworking tasks.

Fence Adjustment for Angles and Height

The Domino joiner’s adjustable fence system is a key feature that enhances the tool’s versatility and precision. The pivoting fence can be adjusted to various angles, allowing for the creation of angled mortises that are essential for joinery in mitered or beveled edges. This capability is crucial for creating strong, precise joints in complex projects, such as frame construction or angled furniture components. Additionally, the vertical adjustment of the fence enables precise positioning of mortises at varying heights from the base or edge of the workpiece. The combination of predefined stops and a clear, readable gauge facilitates easy and repeatable adjustments, ensuring that each mortise is positioned accurately, enhancing the overall quality and integrity of the joint.

Tenons and Tenon Placement

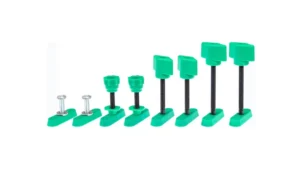

The use of pre-fabricated, solid beech Domino tenons is a hallmark of the Festool Domino system. These tenons, available in various sizes to match the cutter and the resulting mortises, are integral to the strength and durability of the joints created with the Domino joiner. The process of inserting the tenons into the mortises, typically with glue, is straightforward yet precise, resulting in a tight fit that ensures a strong bond. The precision of the fit is crucial for the structural integrity of the joint, as it maximizes the surface area in contact between the tenon and the walls of the mortise, providing a strong glue bond. This system not only simplifies the joinery process but also enhances the strength and durability of the finished piece, making it an excellent choice for both professional and hobbyist woodworkers.

Dust Extraction

The Domino joiner’s integrated dust extraction system is a critical feature for maintaining a clean and efficient workspace. By connecting a dust extractor to the tool, woodworkers can significantly reduce the amount of sawdust and debris generated during the cutting process. This not only keeps the work area clean but also ensures that the cutter’s path remains unobstructed, enhancing the precision and quality of the cuts. Moreover, effective dust extraction helps to prolong the life of the cutter by minimizing abrasive wear, a common issue in woodworking tools. The emphasis on dust management underscores Festool’s commitment to user safety and tool longevity, making the Domino joiner a more sustainable choice for woodworkers concerned with maintaining a clean and healthy work environment.

Performance of Festool Domino DF 500

Precision

- Mortise Accuracy: The Festool Domino DF 500 is renowned for its ability to create consistently precise and clean mortises. The oscillating cutter mechanism ensures that each mortise is cut to exact specifications, which is crucial for the fit and finish of the joint.

- Adjustability: The tool offers a range of settings for mortise size, depth, and angle, allowing for precise adjustments to suit different materials and joinery requirements. This level of control significantly contributes to the overall precision of the tool.

Versatility

- Range of Applications: With its ability to adjust mortise size and depth, along with the capability to make angled mortises, the Domino DF 500 can be used for a wide array of joinery tasks – from frame construction to furniture making.

- Material Compatibility: The Domino DF 500 performs well across various types of wood, from softwoods to hardwoods, maintaining its precision and effectiveness regardless of the material.

Efficiency

- Speed of Operation: The tool’s design allows for quick and easy setup, making it possible to execute multiple, consistent mortises in a short amount of time. This efficiency is a significant advantage in projects with numerous joinery elements.

- Learning Curve: While there is a learning curve to mastering the Domino DF 500, its intuitive design means that once the basic operation is understood, the tool can significantly speed up the joinery process compared to traditional methods.

Durability and Build Quality

- Construction: Festool is known for its high-quality construction, and the Domino DF 500 is no exception. Built to last, it withstands the rigors of both workshop and job site environments.

- Longevity: With proper maintenance, the Domino DF 500 can provide many years of reliable service, making it a worthwhile investment for serious woodworkers.

Dust Extraction

- Effectiveness: The integrated dust extraction system works exceptionally well, keeping the work area clean and ensuring clear visibility while cutting. This feature also contributes to the longevity of the tool by minimizing dust-related wear.

User Experience

- Ergonomics: Designed with the user in mind, the Domino DF 500 is comfortable to handle, even during extended use, reducing fatigue and enhancing control.

- Ease of Use: The tool’s design is intuitive, with clearly marked adjustments and straightforward operation, making it accessible even for those new to this type of joinery tool.

Table Comparison

| Feature | Festool Domino DF 500 | Biscuit Joiner |

|---|---|---|

| Precision | Extremely precise with adjustable mortise sizes | Precise, but limited to fixed slot sizes |

| Versatility | Highly versatile for various joinery tasks | Good for edge joining, less versatile overall |

| Efficiency | Time-saving with rapid setup and execution | Efficient for its intended tasks |

| Dust Extraction | Excellent dust extraction system | Generally effective with proper setup |

| Overall Value | Higher cost but offers unique capabilities | More affordable, great for specific tasks |

| Best Used For | Complex joinery, various woodworking projects | Edge joining, panel alignment |

| Ease of Use | Steeper learning curve but excellent once mastered | Relatively straightforward to use |

| Tool Weight | Heavier due to more features | Generally lighter |

| Price Range | Premium pricing | More budget-friendly |

Summary

The Festool Domino DF 500 stands out for its exceptional precision, versatility in handling a wide range of joinery tasks, and its efficient workflow that saves time on complex projects. It’s an investment suited for professionals or serious enthusiasts who need the best-in-class tool for joinery. The efficient dust extraction system is a bonus that keeps the workspace clean and extends the tool’s life.

In contrast, a high-quality biscuit joiner, while not as versatile as the Domino, excels in its domain of edge joining and panel alignment. It offers ease of use and efficiency within its scope of application, making it a valuable tool for both beginners and experienced woodworkers focusing on projects that align with its capabilities. The biscuit joiner’s more affordable price point makes it an attractive option for those who don’t require the extensive features of the Domino.

Choosing between the two depends on your specific woodworking needs, the complexity of the projects you undertake, and your budget. For intricate joinery and versatility, the Festool Domino DF 500 is unparalleled. For straightforward tasks like panel and edge joining, a biscuit joiner provides excellent value and efficiency.

Pros and Cons

Pros

- Revolutionary domino system offers superior joint strength and versatility.

- High precision and adjustability for a wide range of applications.

- Ergonomic design and efficient dust extraction enhance the user experience.

- Festool’s reputation for durability and high-quality engineering.

Cons

- Premium pricing makes it an investment primarily suited for professionals and serious enthusiasts.

- The unique domino tenons require the purchase of specific Festool accessories, adding to the overall cost.

Maintenance Tips

- Regular Cleaning: After each use, clean the tool to remove dust and debris. Pay special attention to the cutter and the dust extraction port, as build-up can affect performance.

- Check and Clean the Domino Slots: Make sure the slots where the dominos are inserted are clean and free from debris. Use a small brush or compressed air to clear out any dust.

- Lubricate Moving Parts: Occasionally, apply a small amount of lubricant to the moving parts of the tool, such as the plunge mechanism and the pivot points. This helps in keeping the action smooth and reduces wear.

- Inspect the Power Cord: Regularly check the power cord for any signs of wear or damage. If you notice any fraying or cuts, have the cord replaced immediately to prevent electrical hazards.

- Sharpen the Cutter: The cutter’s sharpness is vital for clean, precise cuts. Have it sharpened by a professional or replaced as needed to maintain the quality of your work.

- Store Properly: When not in use, store the Domino Joiner in a clean, dry place. If your model came with a Systainer case, use it for storage to protect the tool from dust and impact.

Conclusion

In conclusion, the Festool 574432 Domino Joiner DF 500 is a standout tool that has reshaped the landscape of woodworking. With its precise cuts, ergonomic design, and efficient operation, it caters to both professionals and DIY enthusiasts alike. Keeping it well-maintained will ensure it remains a reliable partner in crafting strong, beautiful joinery. Its unmatched quality and performance make it an invaluable addition to any woodworker’s collection.

FAQs

- Can the Festool Domino Joiner be used by beginners?

Absolutely! While it’s a favorite among professionals, its intuitive design makes it accessible for beginners too. Just be sure to read the manual and start with simpler projects to get the hang of it. - What makes the Domino Joiner different from a biscuit joiner?

The key difference is in the joinery. The Domino Joiner creates mortise-and-tenon joints, which are stronger and more versatile compared to the plate joints created by biscuit joiners. - How often do I need to sharpen the cutter?

It depends on how frequently you use the tool and the types of wood you’re working with. Generally, a visual inspection for dullness or damage after each project will guide you. If you notice a decline in performance, it might be time for a sharpening. - Can the Domino Joiner be used on all types of wood?

Yes, it’s quite versatile and can be used on a wide range of wood types. However, harder woods may require slower cutting speeds and more frequent cutter inspections. - Is it worth the investment for hobbyists?

While the Domino Joiner is on the pricier side, its efficiency, precision, and durability make it a worthwhile investment, even for hobbyists who are serious about their woodworking projects.

For more expert woodworking and advice, explore our guides, discover top recommendations in our best section, and delve into in-depth product reviews in our review section. Happy Cutting.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment