True Position Tools Cabinet Hardware Jig Review

- April 8, 2024

- 0 comment

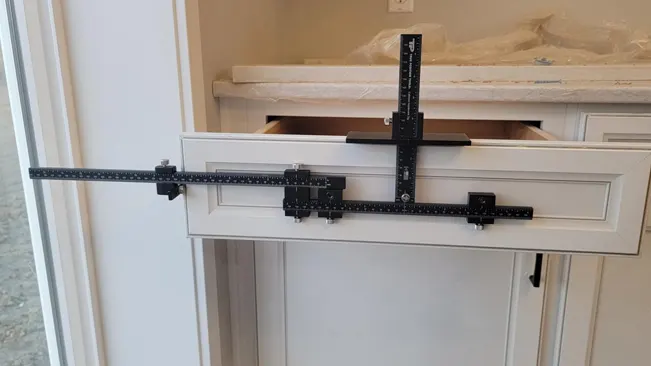

The True Position Tools Cabinet Hardware Jig is a jig that is used to accurately install cabinet hardware, such as knobs and pulls. It is a popular tool among both professional cabinetmakers and DIYers. The jig is made of anodized aluminum and features a T-square with a center bushing, two sliding drill guides, a sliding end stop, and a 5mm drill bit. The jig is also reversible, so it can be used for both left-handed and right-handed doors.

Product Specs

- Material: Aluminum

- Brand: True Position Tools

- Color: Black

- Product Dimensions: 17.32″L x 11.42″W

- Exterior Finish: Brushed

What is a True Position Tool?

A True Position Tool is an essential jig or device in woodworking and cabinetry, designed specifically to facilitate the accurate and precise installation of hardware such as handles, knobs, and hinges on furniture items like cabinets, drawers, and doors. Its main function is to remove the uncertainty and potential mistakes associated with manual measurements and alignments, thus enabling both professional craftsmen and DIY enthusiasts to accomplish neat, consistent, and professional-grade installations. By providing a tangible guide, the tool ensures that drill holes for the hardware are accurately positioned according to the specific requirements of each piece, thereby saving time and preventing costly errors that could lead to wood damage and necessitate repair or replacement.

The versatility and adjustability of True Position Tools make them suitable for a wide array of hardware types and sizes, catering to various project needs. Constructed from durable materials, these tools are built to endure regular use while maintaining their precision. The usage process involves setting the jig according to the hardware’s dimensions and desired placement, securing it onto the workpiece, and then using the guides to drill precise holes. This method can be replicated across multiple installations, guaranteeing uniformity and accuracy for all hardware fittings, and ensuring a professional appearance for the finished project.

Features of True Position Tools Cabinet Hardware Jig

Precision and Accuracy

The fundamental advantage of the Cabinet Hardware Jig lies in its ability to ensure unparalleled precision and accuracy in drilling holes for cabinet hardware. The jig is meticulously engineered to align each drill hole exactly according to the specifications of the hardware being installed. This level of precision eliminates the common pitfalls of manual measurements, such as slight deviations or misalignments, which can significantly impact the final appearance and functionality of the cabinetry. By ensuring that each hole is drilled at the precise location, the jig helps in achieving a polished, professional look that is free from errors.

Ease of Use

The Cabinet Hardware Jig is designed with user-friendliness in mind, making it accessible even to individuals who are new to cabinetry or do-it-yourself projects. The intuitive nature of the jig’s design simplifies the hardware installation process, guiding the user through each step with clarity. This ease of use is a significant advantage, as it empowers users to undertake their own installation projects with confidence, achieving professional-grade results without the need for specialized skills or extensive experience. The jig’s straightforward setup and operation make the task of installing cabinet hardware less daunting and more enjoyable for everyone involved.

Durability

Durability is a cornerstone feature of the Cabinet Hardware Jig, reflecting its quality and reliability. Constructed from robust materials, the jig is designed to endure the demands of frequent and sustained use. This durability ensures that the jig remains a dependable tool in your arsenal over time, consistently delivering accurate and precise results across numerous projects. The investment in high-quality materials pays off by extending the lifespan of the jig, making it a durable companion for both professional carpenters and hobbyists who value reliability and longevity in their tools.

How to Use a Cabinet Hardware Jig

Preparation

Start by gathering all necessary equipment, such as the Cabinet Hardware Jig, a power drill, appropriate drill bits, and the hardware you plan to install. Clear a workspace and lay out the cabinet doors or drawers you’ll be working on. This initial step is crucial for a smooth process, ensuring everything you need is within reach and organized.

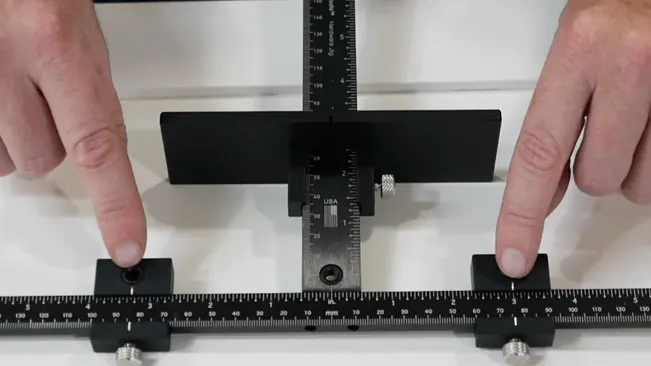

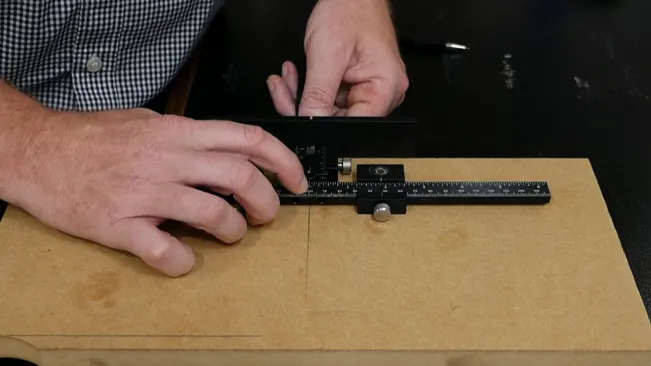

Adjust the Jig

Carefully adjust your Cabinet Hardware Jig to align with the size and spacing required by your hardware. This is a critical step as it directly influences the precision of your installations. Most jigs are equipped with rulers or measurement markings, enabling you to accurately set the distance between drill holes and the edge of the cabinet door or drawer. Take your time with this step to ensure the settings are exactly right for your hardware specifications.

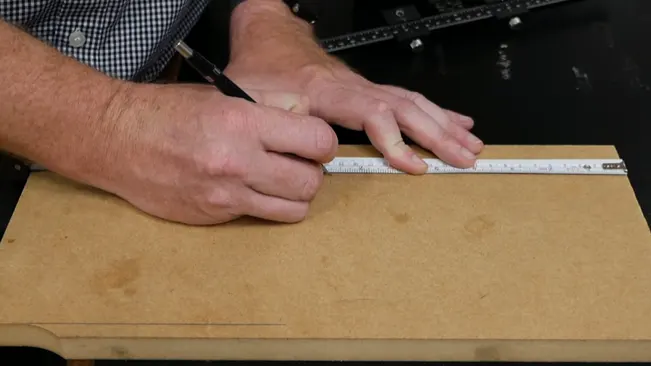

Mark the Spot

Decide on the exact location where you want to install the hardware. This could be based on aesthetic preference or functional need. Once decided, use a pencil to lightly mark the spot on the door or drawer. These marks serve as a visual guide to ensure the jig is positioned correctly and will help in achieving consistency across multiple installations.

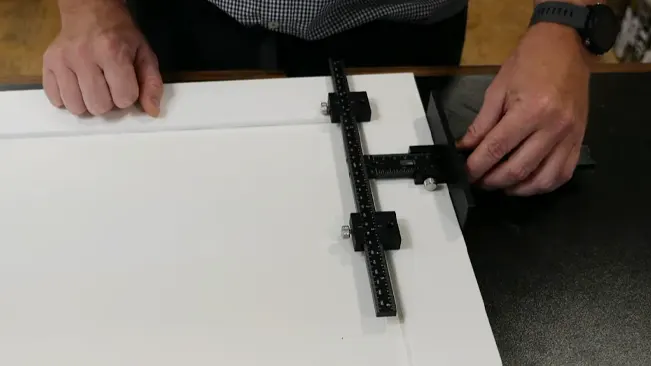

Position the Jig

Place the Cabinet Hardware Jig against the cabinet door or drawer, aligning it with the marks you’ve made or the intended hardware position. It’s important to make sure the jig is perfectly level to avoid any angled holes. Many jigs come equipped with features like clamps or magnets, which can be used to secure the jig in place, preventing movement during drilling and ensuring the holes are drilled at the correct spots.

Drill the Holes

With the jig securely in place, insert your drill bit into the guide holes of the jig and start drilling. It’s essential to keep the drill steady and perpendicular to the surface to avoid angled holes that could misalign the hardware. Apply consistent pressure to ensure clean and precise holes. The jig will guide the drill bit, allowing for accurate drilling according to the preset measurements.

Tips for Best Results

- Double-Check Measurements: Before drilling, double-check the jig’s settings and the position on the cabinet to ensure everything aligns with your hardware’s specifications and your desired placement.

- Use Sharp Drill Bits: Ensure your drill bits are sharp and the correct size for the hardware screws. This will make the drilling process smoother and help prevent wood from splintering.

- Maintain Stability: Keep the jig and the cabinet surface stable while drilling. Any movement could offset the hole positions.

- Test on a Scrap Piece: If possible, practice drilling holes using the jig on a scrap piece of wood. This can help you get a feel for the tool and make any necessary adjustments before working on your actual cabinets.

- Clean as You Go: Clear away any sawdust or debris after drilling each set of holes. Keeping the work area clean helps maintain visibility and accuracy for subsequent installations.

Table Comparison

| Feature | True Position Tools Cabinet Hardware Jig | Kreg Cabinet Hardware Jig |

|---|---|---|

| Precision & Accuracy | Exceptional precision, suited for high-detail projects | Good accuracy, ideal for DIY and less demanding professional tasks |

| Ease of Use | Clear instructions, adjustable, but with a slight learning curve for beginners | User-friendly and intuitive, great for DIYers |

| Durability | High-quality materials, built for frequent and long-term use | Durable with steel and plastic components, but may not withstand heavy professional use as well |

| Versatility | Highly adaptable for various projects and hardware sizes | Versatile for different hardware sizes, but slightly less adaptable for highly specialized tasks |

| Price Point | Higher, reflecting professional-grade design and durability | More affordable, offering great value for DIYers and less intensive tasks |

Summary

When comparing the True Position Tools Cabinet Hardware Jig and the Kreg Cabinet Hardware Jig, the choice largely depends on the user’s specific needs and the complexity of the projects they undertake. The True Position Tools jig stands out for its exceptional precision and durability, making it a preferred choice for professional carpenters and those undertaking intricate projects. Its versatility allows for use in a wide range of applications, though it comes at a higher price point, reflecting its professional-grade quality.

On the other hand, the Kreg Cabinet Hardware Jig is renowned for its ease of use and affordability, making it a popular option among DIY enthusiasts and for simpler professional projects. While it offers good accuracy and durability, it may not match the True Position Tools jig in terms of longevity under heavy use or in highly specialized installations.

Ultimately, the decision between the two should be guided by the projects’ complexity, the level of precision required, and budget considerations. The True Position Tools jig is an investment in quality and precision, ideal for those who regularly undertake complex installations. The Kreg jig, meanwhile, provides great value and ease for everyday tasks and DIY projects.

Pros and Cons of True Position Tools Cabinet Hardware Jig

Pros

- Accurate & Easy: Ensures perfect hardware placement every time, even for beginners.

- Saves Time: Avoids measuring and marking, streamlining installation.

- Versatile: Works with various hardware sizes and door/drawer styles.

- Durable: High-quality materials and a lifetime warranty on bushings.

Cons

- Cost: Can be pricier than measuring and marking manually.

- Limited Use: Primarily for cabinet hardware installation, not a general-purpose tool.

- Size: May not be suitable for very small cabinet doors or drawers.

Maintenance and Care Tips

- Clean After Use: Always clean your tools after each use. Remove dust, wood chips, and any other debris. For metal parts, a dry cloth can be effective. If necessary, use a soft brush to get into crevices. Avoid using water or liquid cleaners unless specified by the manufacturer, as moisture can lead to rust.

- Lubricate Moving Parts: If your tool has any moving parts or adjustments, keep them lubricated with a suitable lubricant. This reduces friction, prevents wear, and ensures smooth operation. Be sure to use the lubricant sparingly to avoid attracting dust and debris.

- Check for Wear and Damage: Regularly inspect your tools for signs of wear or damage. Look for issues like bent parts, loose components, or dull drill guides. Addressing these issues early can prevent further damage and ensure your tool continues to operate accurately.

- Store Properly: Store your tools in a dry, dust-free environment to prevent rust and corrosion. If the tool came with a case or protective cover, use it. Proper storage also protects the tool from accidental damage and keeps it clean and ready for the next use.

- Follow Manufacturer’s Instructions: Always refer to the manufacturer’s instructions for specific maintenance and care guidelines. These instructions can provide important details on cleaning, lubricating, and storing your particular tool.

- Avoid Drops and Impacts: Precision tools are often finely calibrated. Dropping them or subjecting them to impacts can knock them out of alignment. Handle your tools with care, and avoid placing heavy objects on top of them.

- Sharpen Drill Bits: If your tool involves drilling, ensure the drill bits are sharp. Dull bits can lead to inaccurate drilling and may even damage the tool or workpiece. Replace or sharpen bits as needed.

- Tighten Adjustments: Before each use, ensure all adjustable parts are tightened and secure. This prevents the tool from slipping or moving during use, which could lead to inaccuracies or injury.

Conclusion

In conclusion, the True Position Tools Cabinet Hardware Jig is an exemplary tool that combines precision, durability, and versatility, ideal for professionals and dedicated DIYers. Its design guarantees accuracy for professional-grade results, while its robust build ensures long-term reliability. This jig’s adaptability to various projects makes it a valuable investment for high-quality cabinetry work, enhancing both function and aesthetics in any space.

FAQs

- What makes the True Position Tools Cabinet Hardware Jig stand out from other jigs?

The True Position Jig is renowned for its exceptional precision, durability, and versatility, making it a favorite among professionals and serious DIY enthusiasts. Its robust design ensures accurate, consistent results across a variety of project types. - Can beginners use the True Position Tools Cabinet Hardware Jig effectively?

Yes, while the jig is a professional-grade tool, it comes with clear instructions and is designed for ease of use. Beginners can achieve professional-looking results with a bit of practice. - Is the True Position Tools Cabinet Hardware Jig suitable for all types of cabinets and drawers? Absolutely, the jig’s versatility allows it to be used on a wide range of cabinetry and drawers, making it a highly adaptable tool for different projects.

- How do I maintain my True Position Tools Cabinet Hardware Jig?

Regular cleaning after use, proper storage in a dry place, and occasional lubrication of moving parts will help maintain the jig’s performance and longevity. - Where can I purchase a True Position Tools Cabinet Hardware Jig?

The jig can be found at most professional hardware stores or online retailers that specialize in woodworking and cabinetry tools.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment