Kreg Cabinet Hardware Jig PRO Review

- April 8, 2024

- 0 comment

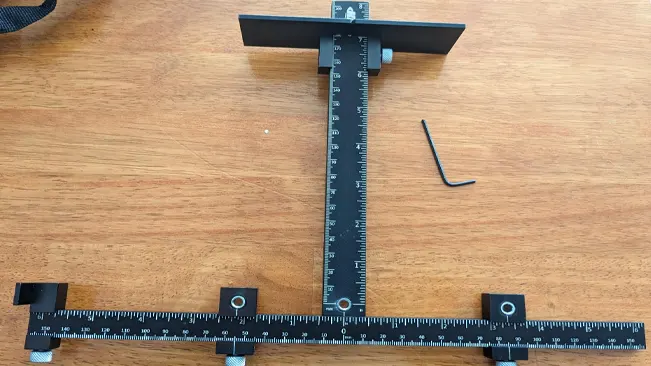

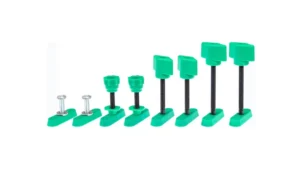

The Kreg Cabinet Hardware Jig Pro is a tool that helps you install cabinet knobs and pulls with accuracy and repeatability. It features a movable end stop and built-in measuring scales that make it easy to position knobs and pulls precisely. Plus, it has movable, hardened-steel drill guides that lock in place for repeatable results. The jig works with almost any style of knob or pull, making it exceptionally versatile.

Product Specs

- Material: Thick, durable, all-aluminum construction

- Drill Guide: Adjustable, hardened-steel drill guides

- Measurement Scales: Laser-etched measuring scales with imperial and metric markings

- Hole Spacing Capacity: Works with knobs and pulls with spacing from 1-3/4″ up to 12″ center to center

- Reversible: Yes, for left and right doors

- Drill Bit Requirement: 3/16″ drill bit (not included)

- Weight: Information not readily available, but likely lightweight due to aluminum construction

Key Features of the Kreg Cabinet Hardware Jig Pro

Movable End Stop

One of the most praised features of the Kreg Cabinet Hardware Jig Pro is its movable end stop. This ingenious component allows users to make quick, easy adjustments, ensuring that the positioning of knobs and pulls remains consistent across multiple installations. Whether you’re outfitting a single drawer or an entire kitchen, this feature streamlines the process, making it easier to maintain uniformity. The movable end stop is particularly beneficial when working on large-scale projects, where even minor deviations can become glaring inconsistencies. With this feature, users can lock in their desired measurements, move from one piece to the next, and trust that every installation will be precisely where it needs to be, eliminating the need for constant re-measurement and adjustment.

Built-in Measuring Scales

The Kreg Cabinet Hardware Jig Pro eliminates the guesswork commonly associated with cabinet hardware installation, thanks to its built-in measuring scales. These scales allow users to take precise measurements directly on the tool, facilitating accurate placement of hardware without the need for separate measuring tools or complex calculations. This not only speeds up the installation process but also significantly reduces the likelihood of errors. The convenience of having these measurements at your fingertips ensures that each piece of hardware is perfectly aligned, contributing to a professional-looking finish. Whether you’re a seasoned craftsman or a DIY enthusiast, the built-in measuring scales make the job simpler and more efficient.

Hardened-Steel Drill Guides

Durability and precision are at the core of the Kreg Cabinet Hardware Jig Pro, embodied by its hardened-steel drill guides. These guides are built to withstand the wear and tear of repeated use, ensuring the jig remains a long-lasting addition to your toolkit. More importantly, they guarantee that your drill bits are guided with unwavering precision, resulting in clean, accurate holes every single time. This precision is crucial in cabinet hardware installation, where even slight misalignments can compromise the look and functionality of your cabinetry. The hardened-steel drill guides offer peace of mind, knowing that each hole you drill will be perfectly positioned and executed, contributing to a flawless finish.

Versatility in Hardware Styles

The Kreg Cabinet Hardware Jig Pro shines in its ability to accommodate a wide range of hardware styles. Whether your project involves modern, sleek pulls or classic, ornate knobs, this jig is designed to handle them all with ease. This versatility is a significant advantage, as it allows users to apply the same level of precision and efficiency to a diverse array of projects. No longer do you need different tools for different styles; the Kreg Cabinet Hardware Jig Pro is your all-in-one solution for cabinet hardware installation. This adaptability not only saves time and space but also empowers you to take on various projects with confidence, knowing that you have the right tool for the job, regardless of the hardware style involved.

How to Use the Kreg Cabinet Hardware Jig Pro

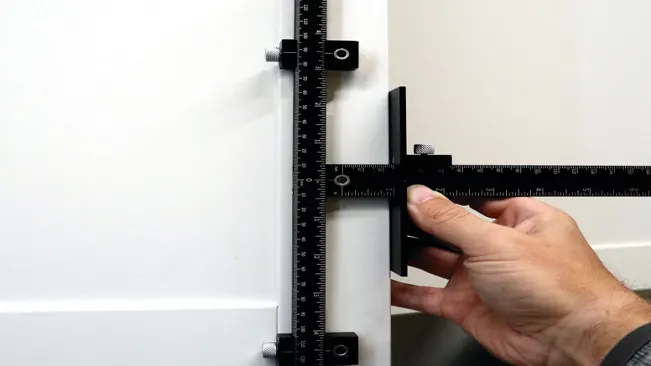

Setting Up the Jig

The initial step in utilizing the Kreg Cabinet Hardware Jig Pro is setting it up, which is designed to be user-friendly and straightforward. To start, you’ll need to adjust the end stop according to the specific measurements of your project. This is where the built-in measuring scales come into play, allowing you to dial in the exact placement for your cabinet hardware. Whether you’re aiming for a standard placement or something more custom, the jig’s adjustable features ensure you can set it up to match your specifications precisely. It’s important during this phase to take your time and ensure that your measurements are accurate, as this will form the foundation for the subsequent steps and ultimately determine the success of your installation.

Positioning for Knobs and Pulls

Once the jig is set up with the correct measurements, the next step is to position it on your cabinet door or drawer. This is where the Kreg Cabinet Hardware Jig Pro’s design really shines, offering clear markings and adjustable guides that make alignment intuitive and straightforward. You’ll align the jig with the marks or measurements on your cabinet, ensuring it’s in the exact position for the hardware you’re installing. The jig is designed to accommodate various hardware sizes and styles, so whether you’re installing small knobs or larger handles, you can adjust the guides to fit. This flexibility is key to achieving a professional-looking finish, as it allows for precise placement of hardware, no matter the design or dimensions.

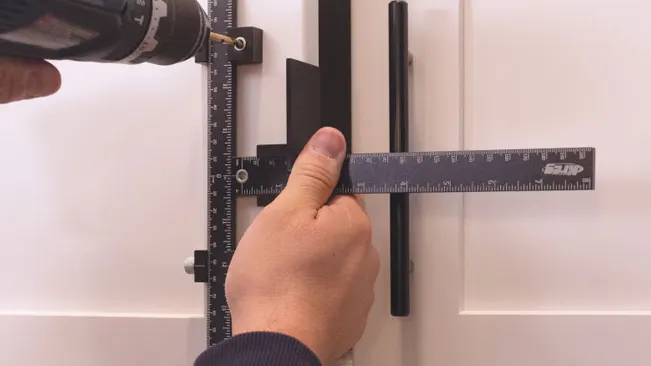

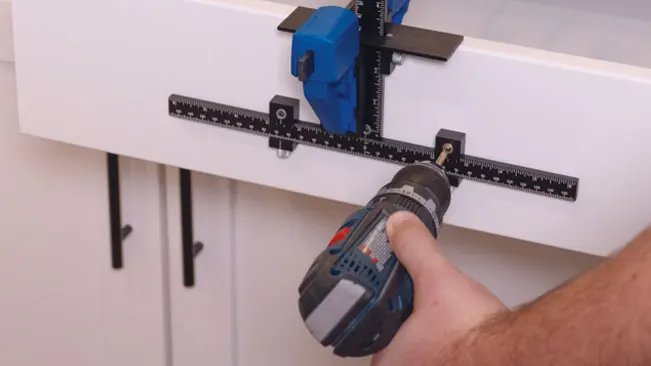

Securing and Drilling

With the jig properly positioned and aligned with your layout plans, the next step is to secure it in place. This is crucial, as any movement during drilling could result in misplaced or angled holes. The Kreg Cabinet Hardware Jig Pro is designed for stability, ensuring it stays firmly where you set it until the drilling is complete. Once secured, you’ll proceed to drill through the hardened-steel drill guides, which are engineered to direct your drill bit with unwavering accuracy. This ensures that every hole you drill is clean, straight, and precisely where it needs to be. The result is perfectly placed hardware, installation after installation. This repeatability is one of the jig’s greatest strengths, allowing even those new to cabinetry or DIY projects to achieve professional-level results with confidence.

Projects Suitable for the Kreg Cabinet Hardware Jig Pro

Kitchen Cabinets

The kitchen is often considered the heart of the home, and whether you’re undertaking a complete renovation or simply refreshing the look, the Kreg Cabinet Hardware Jig Pro is an indispensable tool. For full renovations, where cabinets might be replaced or extensively modified, the jig ensures that new hardware is aligned precisely, maintaining a cohesive and professional appearance across all elements. This precision is crucial in a kitchen environment, where functionality and aesthetics are paramount. Even for simpler updates, such as replacing old knobs and pulls to revitalize the space, the jig guarantees that each new piece of hardware is positioned accurately, enhancing the overall look and feel of the kitchen. The ease and accuracy of the Kreg Cabinet Hardware Jig Pro make it a favorite among both DIY enthusiasts and professional installers, ensuring that every kitchen project achieves a polished and refined finish.

Bedroom Furniture

Bedroom furniture, from dressers to bedside tables, often features hardware that can significantly impact the overall style and feel of the room. Using the Kreg Cabinet Hardware Jig Pro for updating or replacing this hardware ensures that every new knob or pull is perfectly aligned, breathing new life into your bedroom furnishings. This tool is especially valuable for projects involving multiple pieces of furniture, as it ensures consistency across all hardware installations. Such precision contributes to a harmonious and well-put-together look, elevating the room’s aesthetics. The jig’s adaptability to various hardware types and sizes also means that whether you’re aiming for a modern, minimalist look or a more traditional, ornate style, you can achieve the desired outcome with ease and confidence. The simplicity and effectiveness of the Kreg Cabinet Hardware Jig Pro turn the task of updating bedroom furniture into a satisfying DIY project with professional-quality results.

Office Cabinets

The functionality and appearance of office cabinets can significantly influence productivity and the overall ambiance of your workspace. Installing new hardware with the Kreg Cabinet Hardware Jig Pro can transform your office cabinets from mundane to magnificent, with precision that ensures every handle or knob is in its rightful place. This level of accuracy not only enhances the visual appeal of your office space but also contributes to the ergonomics and ease of use of your cabinets, which is essential in a work environment. Whether you’re updating a home office or a commercial workspace, the jig’s ability to deliver consistently perfect results can have a substantial impact on the project’s success. The Kreg Cabinet Hardware Jig Pro makes it simple to achieve a high-end, custom look, ensuring your office cabinets are both functional and stylish, thereby creating a more inviting and productive workspace.

Table Comparison

| Feature | Kreg Cabinet Hardware Jig Pro | True Position Tools Cabinet Hardware Jig |

|---|---|---|

| Precision | High precision with adjustable guides | Extremely precise with hardened steel bushings |

| Ease of Use | User-friendly with a slight learning curve | Slightly more complex due to extensive features |

| Durability | Hardened-steel drill guides for durability | Constructed with aircraft-quality aluminum for superior durability |

| Versatility | Versatile design for various hardware styles | Highly adaptable for a wide range of hardware types and installations |

| Adjustability | Movable end stop for quick adjustments | Adjustable guide for quick alignment changes, suitable for long handles |

| Built-in Features | Built-in measuring scales for direct measurements on the tool | – |

| Price | Generally higher priced, suitable for invested users | Premium pricing, reflecting professional-grade features |

| Ideal User | DIY enthusiasts and professionals looking for ease and efficiency | Professionals needing high precision and adaptability for complex projects |

Summary

Both the Kreg Cabinet Hardware Jig Pro and the True Position Tools Cabinet Hardware Jig stand out in the realm of cabinet hardware installation tools, offering precision, durability, and versatility. The Kreg Jig is particularly user-friendly, making it an excellent choice for DIY enthusiasts and professionals alike who value ease of use and efficient, repeatable results. It features unique built-in measuring scales and an adjustable end stop that enhance its convenience and efficiency.

On the other hand, the True Position Tools Jig, with its aircraft-quality aluminum construction and hardened steel bushings, offers superior durability and precision. It’s highly adaptable to various hardware types and complex installations, making it ideal for professional users who require the utmost precision and flexibility in their projects. The lifetime warranty further underscores its reliability and professional-grade quality.

Ultimately, the choice between these two jigs depends on the specific needs, preferences, and budget of the user. Both are excellent investments for those who prioritize quality and precision in their cabinet hardware installations.

Pros and Cons of Kreg Cabinet Hardware Jig Pro

Pros

- Accurate & Consistent: Easy positioning and drilling thanks to measuring scales and adjustable drill guides.

- Versatile: Works with various knob/pull styles and hole spacings (1-3/4″ to 12″).

- Durable: Built with strong, lightweight aluminum.

- Repeatable Results: Movable end stop ensures consistent placement for multiple installations.

Cons

- Cost: Can be pricier than some basic jigs.

- Extra Tool: Requires a separate 3/16″ drill bit (not included).

Maintenance and Care Tips

- After Each Use: Wipe down your jig with a clean, dry cloth after each use to remove sawdust, metal filings, and other debris. This prevents build-up that could affect the jig’s precision.

- Lubrication: Periodically apply a dry lubricant to moving parts to ensure smooth operation. Avoid oil-based lubricants as they can attract dust and debris.

- Rust Prevention: If your jig has metal components, consider using a silicone-based spray or rust inhibitor to protect against corrosion, especially if you work in a humid environment.

- Deep Cleaning: For a more thorough cleaning, use a soft brush or compressed air to remove stubborn debris from hard-to-reach areas, especially around drill guides and adjustable parts.

- Moisture-Free Environment: Store your jig in a cool, dry place to prevent moisture buildup that can lead to rust and corrosion. Consider using silica gel packets in your storage area to absorb excess moisture.

- Protective Case: If your jig came with a protective case or pouch, use it. This not only keeps the jig safe from physical damage but also from dust and debris when not in use.

- Organized Workspace: Designate a specific spot in your workshop for the jig to avoid misplacement and potential damage from other tools.

- Regular Checks: Periodically inspect your jig for signs of wear and tear, especially on critical components like drill guides and adjustment mechanisms. Replace any parts that show significant wear to maintain accuracy.

- Alignment Verification: Regularly check the alignment of adjustable parts to ensure they haven’t shifted over time, affecting the jig’s precision.

Conclusion

In conclusion, the Kreg Cabinet Hardware Jig Pro stands out as an indispensable tool for both DIY enthusiasts and professional woodworkers aiming to achieve precision and efficiency in cabinet hardware installations. Its key features, including the movable end stop, built-in measuring scales, hardened-steel drill guides, and versatility in hardware styles, cater to a wide range of projects and preferences, ensuring flawless results every time. By following the outlined usage instructions and maintenance tips, users can maximize the longevity and performance of their jig, making every installation project a success.

FAQs

- Can the Kreg Cabinet Hardware Jig Pro be used on all types of cabinet materials?

Yes, the Kreg Cabinet Hardware Jig Pro is versatile enough to be used on a wide range of cabinet materials, including wood, MDF, and plywood. However, it’s always best to test on a scrap piece if you’re working with an unusual or particularly delicate material. - Is the Kreg Cabinet Hardware Jig Pro suitable for beginners?

Absolutely! One of the jig’s strengths is its ease of use, making it suitable for beginners and seasoned professionals alike. The instruction manual and online tutorials can also provide additional guidance for first-time users. - How do I ensure the jig is accurately positioned for perfectly aligned hardware?

The Kreg Cabinet Hardware Jig Pro comes with built-in measuring scales and adjustable guides to aid in accurate positioning. Double-check your measurements and ensure the jig is firmly secured before drilling. Practicing on scrap material first can also help ensure accuracy. - Can the jig be used for both knobs and pull handles?

Yes, the Kreg Cabinet Hardware Jig Pro is designed to accommodate a variety of hardware types, including both knobs and pull handles. Its adjustability allows for precise placement of hardware, regardless of size or style. - How do I maintain my Kreg Cabinet Hardware Jig Pro to ensure it lasts?

Regular cleaning, proper storage, and occasional lubrication of moving parts are key to maintaining your jig. Avoid exposing it to extreme moisture or temperatures, and periodically check for and replace any worn components to keep the jig functioning optimally. - What should I do if I encounter difficulty with the jig?

Kreg offers excellent customer support and resources, including online tutorials and a detailed FAQ section on their website. For more specific issues, contacting Kreg’s customer service can provide direct assistance and troubleshooting advice. - Are there accessories or add-ons available for the Kreg Cabinet Hardware Jig Pro?

Kreg offers various accessories and add-ons that can expand the capabilities of the Cabinet Hardware Jig Pro, such as additional drill guides and extensions for handling larger projects. Check Kreg’s official website or authorized dealers for more information.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment