KREG kphj320 Pocket-hole Jig 320 Review

- April 4, 2024

- 0 comment

The Kreg KPHJ320 Pocket-Hole Jig 320 is a popular jig used for creating pocket-hole joints. Pocket-hole joints are a strong and versatile way to join pieces of wood together. The Kreg KPHJ320 is a good option for beginners and experienced woodworkers alike. It is relatively inexpensive, easy to use, and can be used to create a variety of joints.

Product Specs

- Material Capacity: ½” to 1½” (13mm – 38mm) thick

- Drill Guide Spacings: Two pre-set options (19mm and 38mm), unlimited when drill guides are separated

- Construction: Glass-filled nylon, hardened steel, thermoplastic elastomer

- Number of Drill Guides: 2 with twist-apart design

- Clamping Method: Works with Kreg Clamps and most other clamps (not included)

- Warranty: Lifetime warranty on Drill Guides

Features of KREG kphj320 Pocket-hole Jig 320

Durability and Reliability

The KREG kphj320 Pocket-Hole Jig is a testament to the unwavering commitment to quality and durability KREG Tools is known for. Engineered with robust materials, this jig is built to last, standing up to the wear and tear of regular use in both amateur and professional woodworking environments. Its reliability is one of its hallmarks; users can count on consistent performance project after project, ensuring that joinery is precise and secure every time. This durability not only extends the life of the tool but also protects the investment of the user, providing excellent value over time.

Material Compatibility

One of the standout features of the KREG kphj320 is its exceptional compatibility with a wide range of materials. Whether you’re working with softwoods, hardwoods, or composite materials, this jig can handle it all with ease. This versatility makes it an indispensable tool for a variety of projects, from simple home repairs to more complex furniture making. The jig is designed to accommodate different material thicknesses, ensuring snug and strong pocket-hole joints in materials as thin as ½ inch to as thick as 1½ inches. This wide range allows woodworkers to tackle diverse projects without needing multiple jigs or tools, streamlining the woodworking process and making it more efficient.

Indexing Points and Drill Adjustment

The KREG kphj320 features intuitive indexing points and a straightforward drill adjustment mechanism that simplifies the setup process, making it accessible even to those new to pocket-hole joinery. These indexing points provide clear guidance for positioning the jig accurately, ensuring that each pocket hole is precisely placed for optimal joint strength. The drill bit depth can be easily adjusted to match the thickness of the material being worked on, which is crucial for creating strong and reliable joints. This level of adjustability not only enhances the tool’s versatility but also contributes to its ease of use, allowing woodworkers to quickly adapt to different project requirements without compromising on the quality of their work.

Unique Aspects of KREG kphj320

Design and Usability

The KREG kphj320 stands out in the woodworking tool industry not just for its functionality, but also for its thoughtfully designed usability. The ergonomic design ensures comfort during prolonged use, minimizing user fatigue and increasing productivity. Its compact size allows for easy storage and portability, making it a convenient tool for both workshop and on-site projects. The clear markings and intuitive layout of the jig make it user-friendly, ensuring that even beginners can achieve professional-grade results with minimal learning curve.

Clamp and Adjustability

A notable feature of the kphj320 is its innovative clamping mechanism, which is designed to securely hold the workpiece in place during drilling, thereby ensuring accuracy and consistency in the creation of pocket holes. The clamp is easily adjustable, accommodating a wide range of material thicknesses and sizes, which enhances the tool’s flexibility and usability across various projects. This adjustability is particularly beneficial when working with irregular or non-standard workpieces, as it allows the user to adapt the tool to the specific requirements of each project.

Expansion and Versatility

The KREG kphj320 is not just a standalone tool but part of a larger ecosystem of KREG products that enhance its functionality and versatility. The jig can be expanded with various accessories, such as additional drill guides, spacers, and specialized clamps, to accommodate more complex projects and wider materials. This expandability not only extends the range of projects the kphj320 can be used for but also increases its value as a long-term investment in your woodworking toolkit. The ability to customize and upgrade the jig as needed makes it a versatile tool that can grow with your skills and project needs, ensuring that it remains a go-to solution for pocket-hole joinery.

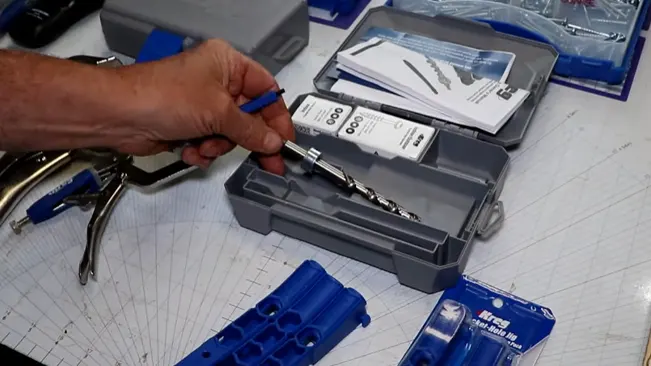

Setting Up and Using KREG kphj320

Step-by-Step Guide

- Select the Correct Drill Bit Setting: Begin by choosing the correct setting on your drill bit for the thickness of the material you are working with. This ensures that the pocket holes are drilled at the optimal depth for strength and aesthetics.

- Adjust the Jig for Material Thickness: Adjust the KREG kphj320 to match the thickness of your workpiece. This is crucial for accurate placement of the pocket holes. The jig features clear markings to guide you in setting it up for various material thicknesses.

- Clamp Your Workpiece: Secure the material you are working on in the clamp of the jig. Ensure it is tight and secure to prevent any movement during drilling, as this could affect the accuracy of your pocket holes.

- Position the Jig: Place the jig against the edge of your workpiece where you intend to create the pocket holes. Use the indexing points on the jig to ensure it is correctly positioned.

- Drill the Pocket Holes: Insert the drill bit into the guide holes of the jig and start drilling. Apply steady pressure and drill at a consistent speed to create clean and precise pocket holes.

- Detach and Inspect: Once you’ve drilled the necessary pocket holes, detach the jig and inspect your work. Ensure that the holes are cleanly cut and free of any debris.

Tips and Tricks

- Use a Clamp: Always use a sturdy clamp to secure the jig to the workpiece. This prevents any movement during the drilling process, ensuring that the pocket holes are accurately placed.

- Maintain Your Drill Bit: Keep the drill bit sharp and clean for the best results. A dull or dirty bit can lead to rough holes and can even damage the material you’re working with.

- Test on Scrap Wood: Before drilling into your final workpiece, practice on a piece of scrap wood. This allows you to adjust the jig and drill settings without risking your main project material.

- Use Dust Extraction: If available, use a dust extraction system or a shop vac to remove wood shavings as you drill. This keeps the work area clean and prevents any obstructions in the pocket holes.

Common Mistakes to Avoid

- Ignoring Material Thickness: One of the most common mistakes is not adjusting the jig and drill bit for the specific thickness of the material. This can lead to weak joints or damage to your workpiece.

- Over-Tightening the Clamp: While it’s important to secure the workpiece, over-tightening the clamp can cause distortion or damage to softer woods. Apply just enough pressure to hold the material firmly in place.

- Drilling Too Fast: Drilling at high speeds can cause the wood to burn or the bit to wear out prematurely. Use a moderate speed and apply steady pressure for the best results.

- Neglecting to Clear Debris: Always clear away any wood shavings or debris from the jig and work area. Accumulated debris can obstruct the drill bit and affect the accuracy of your pocket holes.

Table Comparison

| Feature | KREG kphj320 | Porter-Cable 560 QUIKJIG |

|---|---|---|

| Design & Portability | Compact and lightweight for easy portability and storage. | Robust and designed for heavy-duty use, less portable. |

| Material Compatibility | Adjustable for material thicknesses from ½ inch to 1½ inches. | Automated system adjusts to material thicknesses automatically. |

| Ease of Use | User-friendly with clear markings, ideal for beginners and hobbyists. | Features like a depth setting gauge and automatic clamp adjustment enhance ease of use for rapid changes. |

| Accessories | Various accessories available for expansion, may require separate purchase. | Comes with built-in features and gauges, reducing the need for additional accessories. |

| Durability | Durable design suitable for both hobbyists and professionals. | Heavy-duty construction geared towards frequent, professional use. |

| Price | Generally more affordable, making it a great entry-level option. | Higher price point due to advanced features and robust construction. |

Summary

The KREG kphj320 Pocket-Hole Jig 320 is a versatile, compact, and user-friendly tool ideal for hobbyists, DIY enthusiasts, and even professionals who need a portable solution for on-site work. It offers great value for its price, with the ability to handle a wide range of material thicknesses and an array of accessories for project customization.

The Porter-Cable 560 QUIKJIG Pocket-Hole Joinery System, on the other hand, is a more advanced, automated system designed for heavy-duty use. It’s particularly suited for professionals who require a robust tool for frequent use across various projects. Its automated features provide convenience and precision, albeit at a higher price point.

Maintenance and Care for Pocket-Hole Jigs

- Clean Regularly: After each use, wipe down the jig to remove sawdust, debris, and any residual wood chips. Use a soft brush or compressed air to clear out the hard-to-reach areas, especially around the drill guides.

- Check for Wear: Periodically inspect the drill guides for wear or damage, as these are the parts most susceptible to wear over time. Worn guides can result in inaccurate drilling and should be replaced if necessary.

- Lubricate Moving Parts: Apply a dry lubricant to any moving parts or adjustment mechanisms to ensure smooth operation. Avoid oil-based lubricants that can attract and accumulate dust.

- Inspect Clamps: Ensure that the clamping mechanism is functioning correctly and provides a firm hold. Loose clamps can lead to inaccuracies in your work.

Troubleshooting Common Issues

- Inaccurate Pocket Holes: If pocket holes are not accurate, ensure the jig is correctly adjusted for the material thickness and that the clamp is securely holding the workpiece. Double-check that the drill bit is set to the correct depth.

- Difficult Clamping: If the clamping mechanism becomes difficult to operate, check for sawdust build-up or debris that might be obstructing the mechanism. Cleaning and lightly lubricating the clamp can often resolve this issue.

- Drill Bit Binding: If the drill bit binds or struggles to penetrate the material, ensure it is sharp and free of damage. A dull or damaged bit requires more force and can lead to inaccurate drilling.

- Misaligned Joints: Ensure that the workpieces are properly aligned and clamped before drilling. Misalignment often results from inadequate clamping or incorrect jig positioning.

Conclusion

In summary, the KREG kphj320 Pocket-Hole Jig 320 is a highly versatile and user-friendly tool that suits both hobbyists and professionals, thanks to its adaptability to various material thicknesses and customizable options with accessories. Its longevity and performance can be significantly enhanced with routine maintenance, such as regular cleaning and proper storage. Addressing common issues quickly ensures it remains a reliable asset in your woodworking arsenal. Ideal for a wide range of projects, from simple repairs to intricate furniture, the kphj320 is a cost-effective investment that can improve the quality and efficiency of your work.

FAQs

1. Can the KREG kphj320 handle hardwoods as well as softwoods?

Yes, the KREG kphj320 is designed to work with a wide variety of materials, including both hardwoods and softwoods. Its adjustable settings allow for precise drilling in different material thicknesses and types.

2. What is the maximum and minimum material thickness the kphj320 can accommodate?

The KREG kphj320 can accommodate materials ranging from ½ inch to 1½ inches in thickness, offering flexibility for various projects.

3. Are additional accessories necessary to use the kphj320, or does it work well on its own?

The kphj320 works effectively on its own for most pocket-hole joinery tasks. However, additional accessories are available to expand its versatility for specific projects or needs.

4. How do I prevent the drill bit from dulling quickly when using the kphj320?

To prolong the life of your drill bit, ensure you’re using the correct speed and pressure, avoid overheating by taking breaks during prolonged use, and regularly clean the bit to prevent buildup.

5. Can the kphj320 be used for angled joints, or is it only for straight joinery?

While primarily designed for straight joinery, with the proper setup and technique, the kphj320 can be adapted for certain angled joinery tasks. It’s important to consult the manual for guidance on specific applications.

6. How often should I perform maintenance on the kphj320?

Routine cleaning should be done after each use, and a more thorough inspection and maintenance routine can be performed periodically, depending on the frequency and intensity of use.

7. What should I do if the clamp on my kphj320 isn’t holding the material securely?

First, ensure that the clamp is correctly adjusted for the material’s thickness. If the issue persists, check for any debris or damage to the clamp that might be affecting its performance, and clean or adjust as necessary.

8. Is the KREG kphj320 suitable for professional use, or is it mainly a DIY tool?

The kphj320 is versatile enough to be used by both DIY enthusiasts and professionals. Its durability, adjustability, and ease of use make it suitable for a wide range of projects and skill levels.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment