REXBETI Wood Biscuit Plate Joiner Review

- March 27, 2024

- 0 comment

The REXBETI Wood Biscuit Plate Joiner is a budget-friendly option for creating strong and versatile joints in your woodworking projects. It uses flat, oval-shaped wooden biscuits that are inserted into slots cut by the joiner. These slots are aligned on both pieces of wood to be joined, and then glue is applied before the biscuit is inserted. The compressed biscuit expands as the glue dries, creating a strong and invisible joint.

Technical Specs

- Motor: 10,000 RPM

- Blade: 4-inch carbide-tipped

- Fence Positions: 0, 45, and 90 degrees

- Dust Collection: Port and bag included

- Biscuit Capacity: May vary by seller, but common kits include 100pcs (size 10)

- Weight and Dimensions: Information not readily available

What is a Biscuit Joiner?

A biscuit joiner, or a plate joiner, is a specialized tool in woodworking designed to seamlessly connect two pieces of wood. It achieves this by carving crescent-shaped slots on the edges of the wood pieces, into which a wooden biscuit is glued and inserted. The biscuit expands as the glue dries, creating a strong, durable bond, making this method favored for its ability to produce clean, aesthetically pleasing joints without visible hardware.

This tool is indispensable in projects like cabinetry and furniture making, where joint aesthetics and strength are paramount. Equipped with a circular saw blade and adjustable settings for slot depth, the biscuit joiner accommodates various biscuit sizes, enhancing its versatility and utility in a woodworker’s arsenal.

Key Features of REXBETI

Design and Build

The design and build of a biscuit joiner focus on durability and precision. Typically constructed from high-quality metals and durable plastics, these tools are designed to withstand the rigors of regular use in a woodworking environment. The ergonomic design is another critical aspect, with comfortable grips and easy-to-access controls enhancing user comfort and reducing fatigue during extended use. The alignment and stability features are meticulously engineered to ensure accurate and repeatable cuts.

Performance

In terms of performance, a biscuit joiner’s effectiveness is measured by its ability to make quick, accurate, and clean cuts for biscuit insertion. High-performance models boast powerful motors that can handle various wood types and densities without bogging down, ensuring smooth operation and consistent results. The quality of the cut and the precision of the joint alignment directly impact the overall strength and appearance of the finished product.

Ease of Use

Ease of use is paramount in the design of biscuit joiners, making them accessible to woodworkers of all skill levels. Features like straightforward depth adjustments, clear markings for biscuit sizes, and intuitive controls contribute to a user-friendly experience. Quick blade changes and simple maintenance routines further enhance the convenience of using these tools. For many woodworkers, the ability to quickly set up and execute precise cuts without complex adjustments makes the biscuit joiner an indispensable tool in their workshop.

Using the REXBETI Joiner

Setting Up

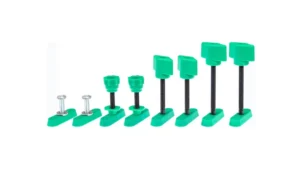

To start using the REXBETI joiner, ensure the tool is unplugged before making any adjustments. Begin by selecting the appropriate size biscuit for your project, which will determine the depth setting of your cuts. The REXBETI joiner typically offers adjustments for #0, #10, and #20 biscuits, among others. Adjust the cutting depth using the marked settings on the tool, ensuring it corresponds with your chosen biscuit size.

Next, check the angle adjustment if your join requires any angular cuts. The tool can be adjusted for standard butt joints or angled cuts, providing flexibility for various project needs. Attach the dust bag or connect a vacuum to the dust port to manage sawdust and keep your work area clean. Once all adjustments are made, ensure all locking mechanisms are tight, and the joiner is set securely for the task.

Making the First Cut

With the joiner set up, mark the position of your biscuit cuts on the pieces of wood you’re joining. Ensure the marks are precise, as they will guide your placement of the joiner. Plug in the tool, hold it firmly with both hands, and align the cutting guide with your marked line.

Press the joiner against the wood, ensuring it’s flat and stable. Activate the tool and gently push it forward to plunge the blade into the wood, creating the slot for the biscuit. The REXBETI’s ergonomic design and straightforward operation facilitate a smooth cutting process, but maintaining stability is key to precise slots.

Trouble Shooting Issue of REXBETI Woodworking Biscuit Joiner

- Blade not cutting properly: Ensure the blade is sharp and clean. A dull or dirty blade can lead to poor cuts. If the blade is worn out, it may need to be replaced.

- Misaligned joints: Check the fence and base plate alignment. Misalignment can lead to inaccurate cuts. Refer to the manufacturer’s manual for guidance on making adjustments.

- Dust extraction not working: Ensure the dust bag is correctly attached and not full. A clogged or improperly attached dust bag can impede dust extraction.

- Machine not starting: Check the power supply and ensure the biscuit joiner is properly plugged in. If using an extension cord, make sure it’s suitable for the power requirements of the tool.

- Inconsistent biscuit fit: Verify you’re using the correct size biscuits for the slots you’re cutting. Also, check the depth setting on the joiner to ensure it matches the biscuit size.

Comparison Table

| Feature | REXBETI Wood Biscuit Plate Joiner | AOBEN Biscuit Cutter Plate Joiner | VonHaus Biscuit Joiner |

|---|---|---|---|

| Weight | 7 pounds | 7.6 pounds | Not specified |

| Motor Power | 8.5 amps | 8.5 amps | 8.5 amps |

| RPM | 10,000 | 11,000 | 10,000 |

| Adjustable Tilt Fence | 0° to 90° | Yes (0° to 90°) | Yes (0° to 90°) |

| Preset Depth Settings | Yes (#0, #10, #20) | Not specified | Yes (3 levels) |

| Dust Collection | Yes (detachable dust bag) | Yes (dust bag) | Yes (cleaning port and dust bag) |

| Unique Features | Lightweight, safety-lock screw | Compact, includes carrying case | Large handle, comfortable grip |

| Cons | Noisy operation | Dust bag fills quickly, case quality | Lacks durability |

Summary

The REXBETI Wood Biscuit Plate Joiner is highlighted for its lightweight design, making it suitable for prolonged use without hand fatigue. It has a strong motor and includes 100 biscuits, providing good out-of-the-box convenience. However, its noisy operation is a downside.

The AOBEN Biscuit Cutter Plate Joiner also boasts a lightweight design and a powerful motor, suitable for various wood types and even synthetic materials. It includes a carrying case, although the quality of the case could be better. The dust bag’s quick fill-up is a minor inconvenience.

The VonHaus Biscuit Joiner offers a cost-effective solution for DIY enthusiasts and amateurs, with a comfortable grip and an easy-to-adjust fence for optimal angle positioning. However, its long-term durability is in question, making it a potentially less reliable option over time.

When choosing between these models, considerations such as weight, power, usability, and specific features like adjustable fences and dust collection should guide the decision. The REXBETI stands out for its balance between lightweight design and power, making it a strong candidate for hobbyists and intermittent users. The AOBEN model offers compactness and a carrying case for added portability, while the VonHaus is noted for its comfortable grip and ease of use, though its durability may be a concern.

Pros and Cons of REXBETI Wood Biscuit Plate Joiner

Pros

- Lightweight Design: Weighing just 7 pounds, the REXBETI joiner is easy to handle, reducing fatigue during extended use.

- Powerful Motor: Equipped with an 8.5-amp motor and capable of 10,000 RPMs, it offers ample power for cutting through harder wood types.

- Adjustable Tilt Fence: The fence can be set at any angle between 0° and 90°, allowing for flexibility in making precise cuts.

- Ease of Use: Features such as a bright orange-colored adjustment and locking dials simplify angle and height adjustments.

- Out-of-the-Box Convenience: Comes with 100 biscuits in various sizes (#0, #10, #20), providing immediate utility without the need for additional purchases.

- Safety Features: Includes a safety-lock screw to ensure the tool’s safety during operation

Maintenance Tips

- Regular Cleaning: After each use, clean the joiner to remove wood dust and debris. Use a brush or compressed air to clear the slots and moving parts. Ensure the dust bag is emptied regularly to maintain suction efficiency.

- Blade Inspection and Replacement: Check the blade regularly for wear or damage. A dull blade can affect the quality of your cuts. Replace the blade as per the manufacturer’s guidelines or when you notice a decline in performance.

- Lubrication: Some parts of the joiner may require occasional lubrication to keep them moving smoothly. Consult your tool’s manual to understand which parts need lubrication and the recommended type of lubricant.

- Tighten Loose Parts: Periodically check for any loose screws or fittings and tighten them. Vibrations from regular use can loosen parts over time, which can affect the tool’s accuracy or safety.

- Storage: Store your joiner in a dry, dust-free environment. If it comes with a case, use it to protect the tool from dust and moisture when not in use.

- Inspect the Power Cord: Regularly inspect the power cord for any signs of wear, fraying, or damage. A damaged cord can be a serious safety hazard.

- Fence and Plate Check: Ensure that the fence and plate are always aligned correctly. Misalignment can lead to inaccurate cuts. Make adjustments as needed according to the manufacturer’s instructions.

- Avoid Overheating: Don’t overwork your joiner. If it starts to feel hot, let it rest before continuing. Overheating can damage the motor and other critical components.

Read More:

Conclusion

In conclusion, the REXBETI Woodworking Biscuit Joiner stands out for its precision, durability, and ease of use, making it an essential tool for any woodworking project. Its combination of high-quality construction and affordability ensures both beginners and experts can achieve professional-grade results. Choosing REXBETI means investing in the quality and success of your woodworking endeavors, enhancing the strength and beauty of your creations with every joint.

FAQs

- What sets the REXBETI Biscuit Joiner apart from others? The REXBETI stands out for its ergonomic design, exceptional cutting precision, and great value, making it accessible and efficient for all skill levels.

- Can beginners use the REXBETI Biscuit Joiner? Yes, its user-friendly design and straightforward operation make it ideal for beginners, while still meeting the precision requirements of experienced woodworkers.

- How should I maintain my REXBETI Biscuit Joiner? Regular maintenance includes cleaning after use, inspecting the blade for sharpness, and ensuring moving parts are well-lubricated. Always refer to the manual for specific care instructions.

- Where can I buy the REXBETI Biscuit Joiner? It’s available at most hardware stores, online retailers, and directly through the REXBETI website.

- Is there a warranty for the REXBETI Biscuit Joiner? Yes, REXBETI provides a warranty, ensuring confidence in your purchase. Check the warranty details at the time of purchase for specific coverage.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment