Best CNC Machines for Woodworking

- April 4, 2024

- 0 comment

For anyone familiar with the challenges of using a handheld router, the introduction of Computer Numerical Control (CNC) technology has been a significant breakthrough. CNC technology revolutionizes the woodworking process by automating the cutting of various materials, notably wood, thus offering a streamlined and efficient approach.

The adoption of CNC machines in woodworking not only shortens the production timelines for a wide array of wooden artifacts but also elevates the levels of precision, safety, and the capacity to craft intricately detailed items.

Although the majority of CNC machines assert their capability to deliver these advantages, it’s important to recognize that the performance and outcomes can substantially vary among different woodworking CNC machines.

This variance underlines the reality that some CNC machines outperform others in terms of efficiency, precision, and overall value. In light of this, our discussion centers on identifying the top-performing CNC machines designed for woodworking purposes.

Furthermore, we will delve into the critical factors that should guide your decision-making process when selecting a CNC machine for your woodworking projects, ensuring you make a well-informed investment that meets your specific needs and budget.

List of Best CNC Machines for Woodworking:

- SainSmart Genmitsu 3018-PROVer CNC Router Machine

- MAKERMADE M2 CNC Engraving CNC Machine Kit

- BobsCNC Quantum CNC Router Kit

- Axiom Precision Iconic 8 CNC Machine

- Phantom SCV44 CNC Machine Router

- Phantom S1 Series CNC Router

Comparison Table By Each Model

Here’s a more streamlined version of the comparison table for the CNC machines:

| Model | User Level | Assembly | Size | Price | Features |

|---|---|---|---|---|---|

| SainSmart Genmitsu 3018-PROVer | Hobbyist | Easy | Compact | $226.21 | Entry-level, laser-capable |

| MAKERMADE M2 Kit | Hobbyist | Difficult | Flexible | $729.00 | Upgradeable, large sheet support |

| BobsCNC Quantum | Hobbyist/Small Shop | Moderate | Compact | $1,280.00 | Wood frame, user-friendly |

| Axiom Precision Iconic 8 | Advanced Hobbyist | Variable | 24″x48″ | $6.178.97 | Professional features, scalable |

| Phantom SCV44 | Professional | Moderate | 4’x4′ | $10,950 | Multi-zone vacuum, high-pressure rollers |

| Phantom S1 Series | Industrial | Pre-assembled | Large | $20,500 | Industrial-grade, low maintenance |

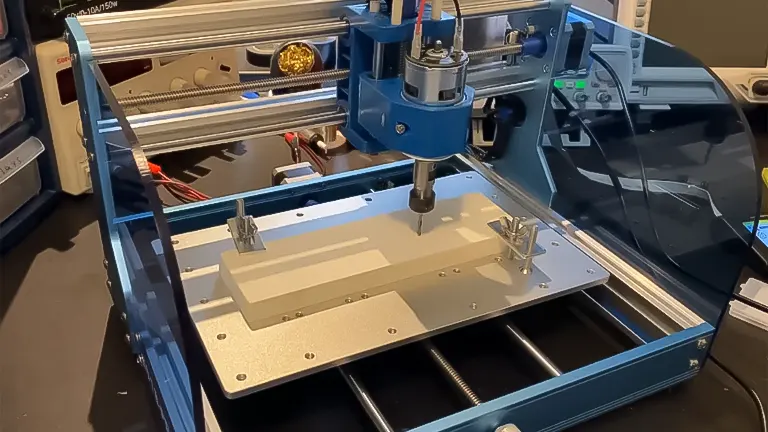

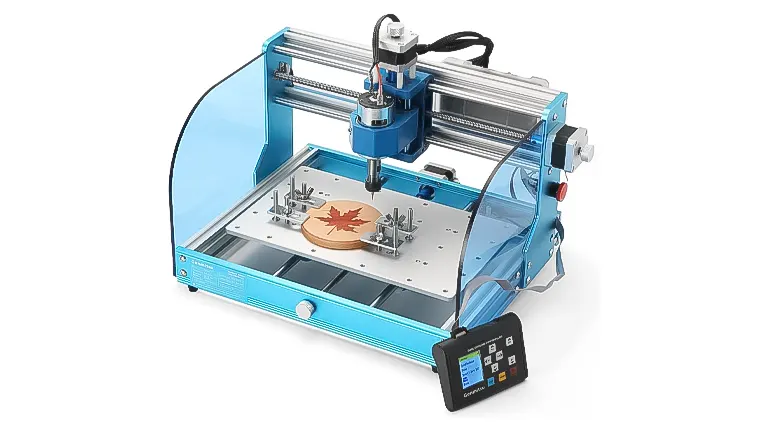

1. SainSmart Genmitsu 3018-PROVer CNC Router Machine

Features of SainSmart Genmitsu CNC Router Machine

The SainSmart Genmitsu 3018-PROVer represents an affordable entry-level option in the CNC router market, tailored for engraving and light cutting. This machine is versatile, supporting both a laser engraver and a router, with some users even successfully integrating a high-speed spindle for enhanced engraving performance and accuracy on tougher materials.

Assembly and operation of the 3018-PROVer are straightforward, benefiting from its user-friendly design. However, its bundled Candle software, compatible with Windows and Linux, receives mixed reviews. While Candle facilitates G-code editing, visualization, and transfer to the machine, some users have experienced software-induced freezes.

A workaround suggested by the community involves generating G-code on a separate computer and transferring it directly to the machine’s controller via a microSD card, bypassing these issues and ensuring smoother operation.

- Dimensions and Construction: The machine measures 260mm by 155mm, offering a Z-axis travel of 35mm.

- Software Compatibility: Utilizes Candle software, rooted in the open-source GRBL software, and operates on the main controller.

- Assembly Simplicity: The assembly process is straightforward, with comprehensive instructions and video guides available. Necessary tools for assembly are mostly included.

- Initial Cost: The starting price is $226.21 USD to $314.99 USD.

Pros of the SainSmart Genmitsu CNC Router Machine

- Cost-effective solution for woodworking CNC needs.

- Compact size, making it suitable for limited spaces.

- Allows for offline cutting, eliminating the need to expose a computer to dust.

- Supports upgrading to a more robust spindle for enhanced performance.

- Employs lead screws for x and y-axis movement, offering greater durability and accuracy compared to belt-driven systems.

Cons of the SainSmart Genmitsu CNC Router Machine

- The provided clamps are small, limiting the ability to secure thicker materials effectively.

- Users have reported performance issues with the recommended Candle software, including lags.

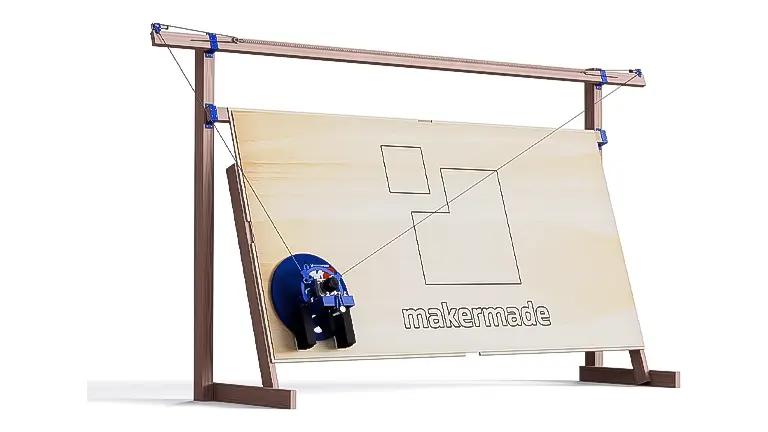

2. MAKERMADE M2 CNC Engraving CNC Machine Kit

Features of MAKERMADE-M2-CNC-Engraving-CNC-Machine-Kit

The M2 CNC Engraving Machine Kit stands out in the realm of CNC machining with its robust features designed for both hobbyists and professionals alike. This comprehensive kit is built to accommodate a wide range of engraving, carving, and cutting tasks on materials ranging from wood and acrylic to soft metals like aluminum.

Equipped with a powerful and precise spindle, the M2 ensures high accuracy and efficiency in operations. Its construction emphasizes durability and stability, utilizing high-quality materials and components to guarantee longevity. The machine’s compatibility with various software platforms, including open-source options, offers users flexibility in design and control.

With an intuitive setup and user-friendly interface, the M2 kit is engineered for ease of use, making it accessible to beginners while still meeting the demanding needs of more experienced users. This machine not only delivers on performance but also provides a scalable solution for creative projects, thanks to its modular design that supports upgrades and customization, ensuring it can evolve with the user’s skills and requirements.

- Build Size: Flexible.

- Software: Uses Ground Control.

- Assembly Difficulty: Challenging, requiring around six hours total for frame and electronics/software setup, assuming basic woodworking knowledge.

- Price: Starts at $729.00.

Pros of MAKERMADE M2 CNC Kit

- Handles large wood sheets up to 4×8 feet and smaller sizes.

- Cost-effective.

- Space-efficient design.

Cons of MAKERMADE M2 CNC Kit

- Complicated, time-consuming setup requiring DIY frame construction.

- Operates slowly.

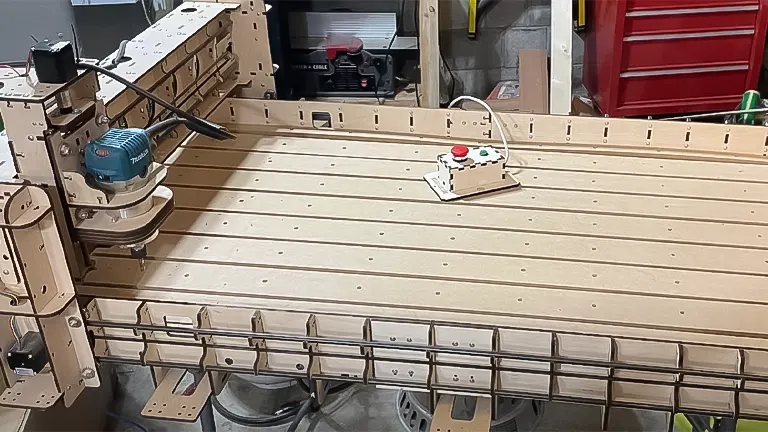

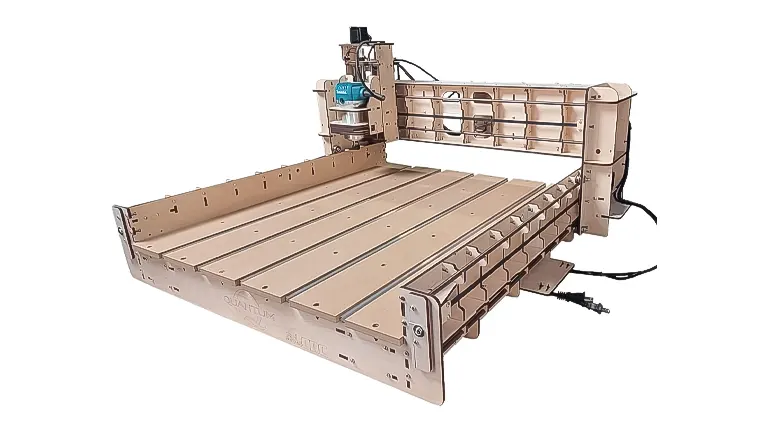

3. BobsCNC Quantum CNC Router Kit

Features of BobsCNC Quantum CNC Router Kit

The BobsCNC Quantum CNC Router Kit is designed as a desktop 3-axis machine, ideal for crafting 3D carvings and 2.5D projects like home decor and signage. This machine sets itself apart from others by being constructed from plywood, which adds to its unique build.

The assembly involves a significant number of pieces and flanges that screw together, enhancing its sturdiness but also adding to the assembly complexity and time. Despite this, the machine’s performance in cutting is reliable, thanks to the inclusion of a Makita router. It features belt-driven movement for the X and Y axes and a lead screw-driven Z axis for precise vertical motion.

Additional Attributes of this Plywood CNC Machine Included:

- Size and build: 24” by 24” with 3.8” Z-axis travel

- Software: GRBL firmware on the microcontroller paired with the BobsCNC’s Basic Sender software (installed on a laptop), which sends G-code files to the microcontroller

- Ease of Assembly: Difficult – this woodworking CNC machine contains many wooden parts, and assembly can take at least eight hours

- Starting Price: $1,280.00

- A sturdy, laser-cut frame.

- A self-squaring gantry system.

- A clamping table equipped with aluminum T-slots for versatile work holding.

Pros of BobsCNC Quantum CNC Router Kit

- Comes with detailed assembly instructions for ease of setup.

- The Makita router is pre-calibrated to the machine for user convenience.

Cons of BobsCNC Quantum CNC Router Kit

- The Makita router operates at high noise levels, reaching up to 103 dB.

- The machine’s precision can be adversely affected by various factors, including micro-stepping inaccuracies, bit deflection, errors in the lead screw, belt stretching, among others.

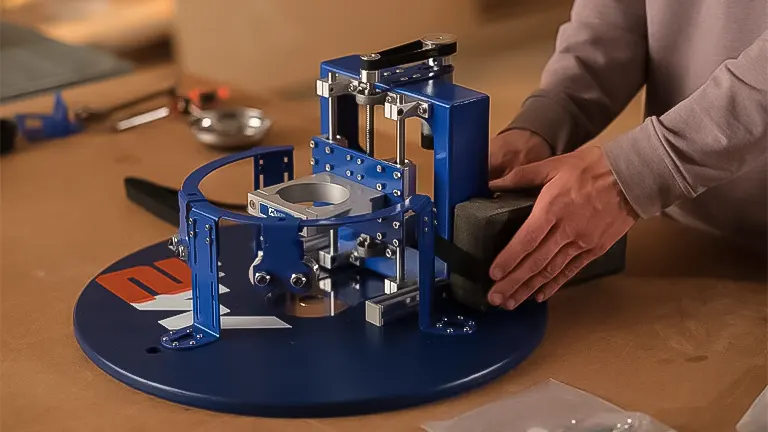

4. Axiom Precision Iconic 8 CNC Machine

Features of Axiom Precision Iconic 8 CNC Machine

The Axiom Precision Iconic 8 CNC Router stands out as a cost-effective alternative to the pricier ShopBot Desktop Max, offering a 3-axis configuration that delivers exceptional value. Noteworthy is its larger bed size, enhanced further by the availability of an optional stand equipped with built-in casters for mobility, leveling feet for stability, and an integrated toolbox for convenience.

The Iconic 8 is celebrated for its precision, a result of thorough testing by the manufacturer. Targeted at hobbyists, the Precision Iconic 8 doesn’t compromise on accuracy or the consistency of its performance over time.

It boasts a structure made from high-rigidity extruded aluminum, ensuring durability and stability. For those seeking a machine with professional capabilities within the Axiom Precision range, the Axiom Pro V5 Series presents an upgraded option. With dimensions of 24” by 48”, the Pro V5 Series is priced at $8,499.00, stand not included.

Some of the Precision Iconic 8’s Additional Attributes Included:

- 1.1 HP spindle

- RichAuto B11 Industrial 3-axis controller

- Available stand with built-in casters, leveling feet, and optional toolbox

- Optional customization with accessories such as tooling, dust collection, software, clamping, and much more

- Prismatic guides in all axes

- Size/Build: 24″x48″, 4″ Z-axis travel.

- Software: Recommends Vetric VCarve.

- Assembly: Easy without stand, instructions online.

- Price: Starts at $6,178.97.

Pros of Axiom Precision Iconic 8 CNC Machine

- Easy assembly with instructions.

- More powerful and accurate spindle.

- Stable at high RPM.

Cons of Axiom Precision Iconic 8 CNC Machine

- No direct PC or laptop operation.

- Restricted to Vetric software due to HUST controller compatibility issues.

- Expensive for hobbyists, with cheaper alternatives like the Carbide Shapeoko 4 available, albeit with a router instead of a spindle.

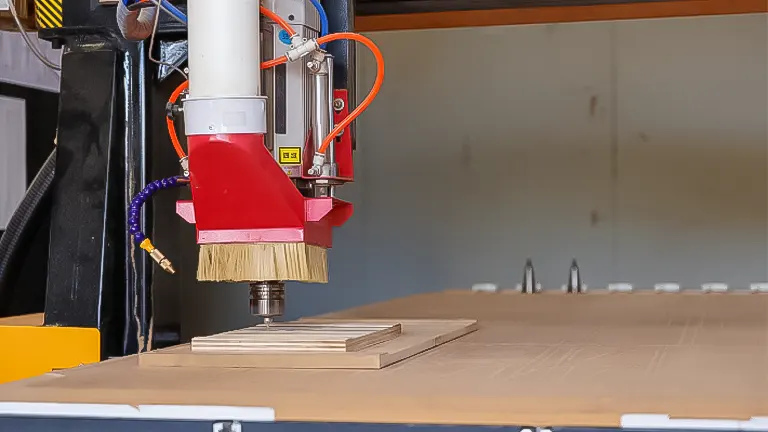

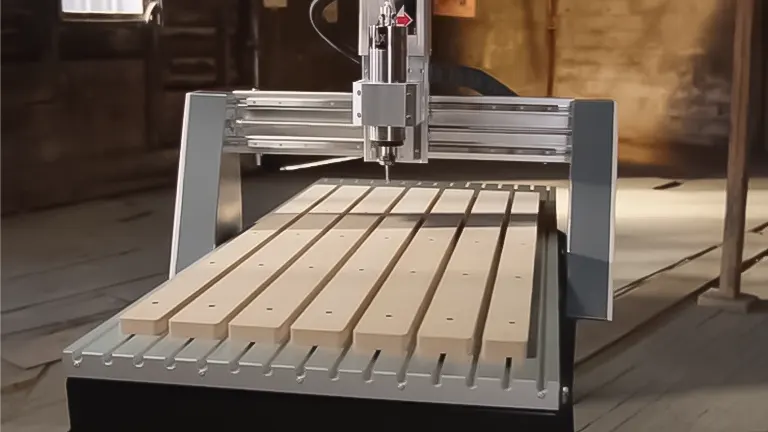

5. Phantom SCV44 CNC Machine Router

Features of Phantom SCV 44 Woodworking CNC Machine

The Phantom SCV 44 CNC machine, a 3-axis model, offers a compact solution while incorporating many of the advanced features found in Phantom CNC Systems’ larger S and T series. This makes it an ideal choice for production-grade woodworking, boasting attributes such as:

- A multi-zone 4′ by 4′ vacuum table.

- A 6.1 HP air-cooled spindle.

- An oil-mist cooling system.

- Automatic rollers exerting 600 pounds of pressure.

- Size and build: 4’ by 4’ work area with 9” of Z-axis travel

- Software: Phantom CNC’s custom software running on the HD-100 Pendant Controller

- Ease of Assembly: Easy – the machine is shipped pre-assembled

- Starting Price: $10,950 to $12,300 USD.

In comparison, the PRO4848 4′ by 4′ CNC router by Avid CNC, while similar in size, faces challenges with frame rigidity and y-axis stepping issues, leading to reduced accuracy. Despite these issues, the PRO4848 can cost up to $17,305, depending on its setup. These considerations have highlighted the Phantom SCV 44 as a superior option among woodworking CNC machines.

Pros of the Phantom SCV 44 CNC Machine for Woodworking

- Features automatic rollers that, together with the vacuum table, ensure sheets are firmly clamped.

- Control is simplified with a user-friendly handheld pendant system.

Cons of the Phantom SCV 44 CNC Machine for Woodworking

- The machine is quite bulky, tipping the scales at 1,350 lbs. (612 kg).

6. Phantom S1 Series CNC Router

Features of Phantom S Series Woodworking CNC Machine

The Phantom CNC Systems’ 3-axis S Series is a top-tier industrial-grade CNC machine designed for woodworking. This machine excels at executing intricate and precision-demanding tasks and is built to operate for extended periods without compromise. Its automatic oiler adds a layer of convenience by handling part of the maintenance automatically.

Notable Attributes of the Phantom S Series Include:

- A 6.1 HP spindle, adjustable between 6000 and 18000 RPM.

- A multi-zone vacuum table for secure material placement.

- Combined air and oil-mist cooling systems.

- An automatic oiler for maintenance ease.

- An automatic pneumatic roller capable of applying 600 pounds of pressure.

- The HD-100 pendant control system for easy operation.

- Optional accessories like vacuum pumps and dust collectors are available for purchase separately.

- Size and Build: 4’ by 8’ or 5’ by 10’ stock sizes (although you can request custom sizes) with 8” or 11.8” of Z-axis travel

- Software: Phantom CNC’s custom software running on the HD-100 Pendant Controller

- Ease of Assembly: Easy – it comes pre-assembled

- Starting Price: $20,500

Pros of the Phantom S Series CNC Machine

- Equipped with a multi-zone vacuum table for secure material holding.

- Features high rigidity with its fully welded steel frames, standing out against competitors like ShopSabre Pro, CAMaster Panther, and Laguna SmartShop M, while being more affordable.

- Includes automatic pneumatic rollers applying 600 pounds of pressure for working on warped sheets.

- Gear-driven gantry ensures precise movements.

- User-friendly handheld control system for easy operation.

Cons of the Phantom S Series CNC Machine

- Pre-assembled shipping can lead to higher freight costs due to its substantial weight.

- The machine itself is quite heavy, weighing between 2,300 and 2,600 lbs.

Factors to Consider When Choosing a CNC Machine for Woodworking

- Size: The size of CNC machines varies from compact models for hobbyists to larger units for production, which require more space due to additional features like vacuum pumps and dust collectors. It’s crucial to assess the space in your workshop before making a purchase.

- Setup or Assembly Time: CNC machines range from pre-assembled units to those requiring extensive assembly, impacting setup time and potentially adding to labor costs. For convenience, consider a pre-assembled machine if assembly time is a concern.

- Frame and Table Rigidity: The rigidity of a CNC machine’s frame and table is vital for minimizing vibrations and improving accuracy. While extruded aluminum frames offer ease of shipping and assembly, they may suffer from vibrations. Welded frames provide greater stability and precision.

- Upgradeability: Some CNC machines allow for future upgrades, such as extending the table size, which is ideal for those planning to expand their capabilities over time. However, machines with welded parts offer limited upgradability.

- Purpose: The intended use of the CNC machine, whether for business or hobby, influences the choice. Business use requires a focus on accuracy, precision, and speed, often leading to larger, more expensive machines. Hobbyists may prioritize compact, less expensive options.

- Budget: There’s a wide range of CNC machines available to fit various budgets, with the cost usually reflecting the size and features of the machine. However, the most expensive option isn’t always the best, and vice versa, making it important to weigh all factors, including intended use and required features, alongside price.

What Items You Will Make

When selecting a woodworking CNC machine, it’s crucial to consider the types of items you intend to create. The specific use of the machine significantly influences your choice, as different models excel in various applications. For instance, some machines are optimized for detailed engraving, while others might be more effective at robust carving tasks.

Additionally, the requirements for milling furniture pieces differ from those needed for sign carving or part engraving. Identifying the primary purpose of your CNC machine will guide you towards a model best suited to your specific woodworking projects.

All In All Final Thoughts

In conclusion, when evaluating this product, it’s clear that it stands out in its category for its blend of functionality, quality, and value. Whether you’re a seasoned professional or a newcomer to the field, its features cater to a wide array of needs, offering a versatile and reliable solution.

Its ease of use, coupled with robust support and durability, ensures that it not only meets but exceeds expectations, making it a wise investment for anyone looking to enhance their toolkit. Keep in mind the specific requirements and goals you have, as this product offers a compelling balance of performance and price, setting a benchmark in its market segment.

Frequently Asked Questions

- What Is a CNC Machine for Woodworking?

A CNC (Computer Numerical Control) machine for woodworking is a tool controlled by a computer, which carves, cuts, and engraves wood with high precision based on digital designs. - How Does a CNC Machine Work?

CNC machines operate by interpreting a computer-aided design (CAD) file and translating it into commands that move the machine’s drill and cutter across three axes (X, Y, and Z) to shape the wood. - What Are the Types of CNC Machines for Woodworking?

There are various types, including 3-axis, 4-axis, and 5-axis CNC routers, each offering different capabilities for carving, engraving, and cutting wood. - What Should I Look for When Choosing a CNC Machine for Woodworking?

Consider factors such as the machine’s size, power, precision, ease of use, software compatibility, and your specific project needs. - Can I Use a CNC Machine for Projects Other Than Woodworking?

Yes, many CNC machines are versatile and can also work on materials like plastics, foams, and soft metals, depending on their power and specifications. - What Is the Best CNC Machine for Beginners?

Look for a machine that is user-friendly, with comprehensive support and tutorials, and a strong community for guidance. Models specifically designed for entry-level users often prioritize ease of assembly and use. - How Much Does a Good Woodworking CNC Machine Cost?

Prices vary widely based on size, capabilities, and brand, ranging from a few hundred dollars for hobbyist models to tens of thousands for industrial-grade machines. - Do I Need Special Software to Operate a CNC Machine?

Yes, you will need CAD (for design) and CAM (Computer-Aided Manufacturing) software to create designs and translate them into commands for the machine. Many machines come with recommended or proprietary software. - How Do I Maintain My CNC Machine?

Regular maintenance includes cleaning debris from the machine, lubricating moving parts, checking for wear and tear, and ensuring that all components are tightly secured. - Where Can I Find Designs for CNC Woodworking Projects?

There are many online platforms and communities where you can download or purchase designs. Some popular options include Etsy, Thing verse, and specialized woodworking forums and websites.

We can’t wait to get your feedback! Let us know about your journey with the top CNC machines for woodworking by dropping a comment below. Your unique experiences and advice are crucial in guiding other woodworking aficionados towards making well-informed decisions. From helpful hints to your favorite picks or even warnings, your contribution is a priceless asset to our community!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment