How to Make Biochar: Simple Cheap Methods

- February 29, 2024

- 0 comment

Biochar, a form of charcoal produced through the pyrolysis of biomass, has garnered attention for its myriad environmental benefits, including carbon sequestration, soil enhancement, and waste reduction. This carbon-rich material, when added to soil, not only enriches the soil fertility but also helps in the reduction of greenhouse gas emissions by trapping carbon that would otherwise be released into the atmosphere. Furthermore, biochar has been found to improve water retention in soils, reduce nutrient leaching, and stimulate microbial activity, leading to more sustainable and productive agricultural practices.

Materials Needed

Creating biochar in a 55-gallon drum is a straightforward process that requires minimal materials and preparation. The key component is the 55-gallon steel drum itself, which serves as the containment unit for the biomass during the pyrolysis process. Preparing the drum involves ensuring it is clean and free of any residual substances that could emit harmful fumes during burning. In cases where the drum comes with a bolt-on lid, the lid is removed to allow for open burning from the top. Some individuals may choose to modify the drum by cutting a larger opening in the top to facilitate easier loading of biomass and management of the burn.

List of Essential Materials

- 55-Gallon Steel Drum: A standard steel drum serves as the primary vessel for the biochar production. The drum should be clean and have any paint or external coatings removed to prevent toxic emissions during the burn.

- Wood: The biomass material, typically wood, should be of a size that fits easily within the drum. The ideal size for the wood pieces is no larger than two to three inches in diameter for optimal burning and carbonization. The wood should be arranged vertically within the drum to ensure a top-down burn, which is crucial for the creation of biochar.

- Isopropyl Alcohol (91% Solution): Used as an accelerant to initiate the burning process, isopropyl alcohol, particularly a 91% solution, is recommended due to its efficiency and cleaner burn compared to other accelerants. It helps in achieving a steady burn without the excessive smoke that can be produced by other materials like leaves, paper, or cardboard.

- Safety Equipment:

- Heat-resistant Gloves: To protect hands from high temperatures when managing the drum or adding biomass.

- Safety Goggles: To shield eyes from sparks, smoke, and debris.

- Fire Extinguisher: A precautionary measure in case the fire needs to be controlled or extinguished quickly.

- Long-handled Tools: Useful for adjusting the wood within the drum and managing the burn from a safe distance.

Method Overview

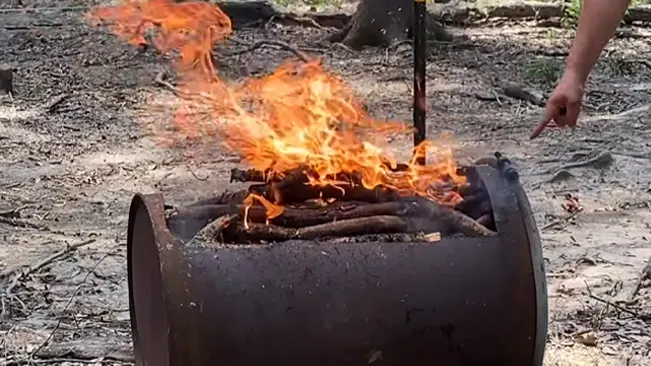

Upright Drum Method

In the upright drum method, the 55-gallon drum is used in its standard, vertical orientation. This method involves filling the drum with biomass, such as wood, arranged vertically to facilitate a top-down burn. The process is initiated from the top of the drum, allowing the fire to slowly consume the biomass, creating biochar through a process of slow pyrolysis. The vertical arrangement ensures limited oxygen flow, which is crucial for the formation of biochar rather than ash. This method is noted for its cleaner burn and the high quality of biochar produced, albeit with a longer processing time compared to the horizontal method.

Horizontal Drum Method

The horizontal drum method involves laying the drum on its side, with an opening cut out to allow for the addition of biomass and the management of the burn. This orientation allows for easier loading of longer pieces of wood and requires less cutting and preparation of the biomass. The fire is still initiated from the top (which is now the side facing up), and the drum’s horizontal position allows for easier management of the burn, although it may require more frequent monitoring to prevent the fire from consuming the biochar. This method can process material more quickly but may produce a slightly lower quality of biochar compared to the upright method.

Step-by-Step Guide: Upright Drum Method

Preparation of the Drum

Before beginning the process of making biochar using the upright drum method, it is essential to properly prepare the 55-gallon steel drum. This preparation involves thoroughly cleaning the drum to remove any residues or substances that could emit harmful fumes when heated. If the drum has a bolt-on lid, this should be removed to allow open access to the drum’s interior. The removal of the lid is crucial for facilitating the top-down burning process that is central to this method. Safety considerations are paramount; ensure the drum is placed on a stable, non-flammable surface, and keep a fire extinguisher and water source nearby. It’s also important to wear protective gear, including heat-resistant gloves and safety goggles, to safeguard against sparks and heat.

Stacking the Wood

The stacking of the wood inside the drum is a critical step that influences the efficiency and effectiveness of the biochar production process. The wood should be stacked vertically, as tightly as possible, to reduce the amount of air that can circulate underneath the stack. This vertical arrangement encourages a slow, controlled burn from the top down, which is essential for the creation of biochar. The goal is to limit the oxygen flow, which helps in the pyrolysis of the wood rather than complete combustion. Ensuring the wood is dry and of uniform size can also aid in a more consistent burn.

Lighting the Fire

To initiate the burning process, isopropyl alcohol, particularly a 91% solution, is recommended as an accelerant due to its clean burn and efficiency. Apply a small amount of alcohol to the top layer of wood; this will help start the fire without the need for leaves, paper, or cardboard, which can create excessive smoke. Light the fire from the top, ensuring that the flames spread evenly across the surface. Starting the fire from the top is crucial for establishing a top-down burn, which allows for the controlled gasification of the wood below the burning layer, contributing to the creation of biochar.

Monitoring the Burn

As the fire burns, it’s essential to monitor the process to ensure efficient gasification of the wood. A successful burn will exhibit a flame cap, where the flames cover the top layer of wood, preventing air from directly reaching the biochar forming below. This flame cap is a sign of proper operation, where the gases released from the wood are combusted at the top, contributing to the heat needed for pyrolysis without burning the already formed biochar. Adjustments may be needed to maintain this condition, such as adding more wood to the top or controlling the airflow to maintain the flame cap.

Step-by-Step Guide: Horizontal Drum Method

Drum Modification

To adapt a 55-gallon drum for the horizontal method of biochar production, significant modifications are necessary. The drum should be laid on its side, and a large opening must be cut out to facilitate the addition of biomass and the management of the burn. This can be achieved by cutting a rectangular or circular section on the side of the drum that now faces upwards. It’s important to smooth any sharp edges created during the cutting process to ensure safety during operation. The horizontal orientation of the drum offers a distinct advantage for processing longer pieces of wood, as it allows for the accommodation of biomass that would otherwise need to be cut down to fit into an upright drum. This can significantly reduce preparation time and make the process more efficient for materials that are naturally longer and straighter.

Filling the Drum

When filling the drum with wood, the strategy differs slightly from the upright method. In the horizontal drum, wood should be arranged in a manner that still allows for a top-down burn but also takes into account the horizontal airflow dynamics. The wood can be layered or stacked loosely to ensure that there is sufficient space for air to circulate, promoting an even burn. However, it’s crucial to manage airflow carefully to prevent the fire from burning too vigorously, which could lead to the complete combustion of the biomass instead of its conversion into biochar. The aim is to create a controlled environment within the drum where the biomass can pyrolyze effectively.

Lighting and Maintenance

Lighting the fire in a horizontal drum follows a similar principle to the upright method, with the use of a clean-burning accelerant like isopropyl alcohol to initiate the burn from the top. However, due to the drum’s horizontal orientation, attention must be paid to how the fire spreads and how well it is maintained throughout the burn process. The fire should be monitored and managed to ensure that it progresses slowly and evenly through the drum, creating a layer of biochar beneath the burning wood. This may involve occasionally adjusting the position of the wood within the drum to ensure even burning and to maintain the flame cap, which is crucial for the effective gasification of the wood.

Safety Precautions

- Personal Protective Equipment:

- Wear heat-resistant gloves for handling hot materials.

- Use safety goggles to protect against smoke, debris, and sparks.

- Wear long-sleeved, fire-resistant clothing for heat and spark protection.

- When smoke or particulate matter is present, wear a mask or respirator for respiratory protection.

- Work Area Preparation:

- Maintain a clear workspace free from any flammable materials.

- Have a fire extinguisher or water source readily available in case of emergencies.

- Conduct the burning process in an open or well-ventilated area to prevent gas and smoke buildup.

- Safe Practices:

- Continuously supervise the burning process to prevent uncontrolled fires.

- Establish a well-defined emergency plan that everyone involved is familiar with.

Conclusion

In conclusion, the use of 55-gallon drums for biochar production offers an efficient, accessible way to transform biomass into a beneficial soil enhancer, contributing positively to carbon sequestration efforts. The simplicity of both the upright and horizontal drum methods allows for easy adoption by individuals and communities, emphasizing minimal preparation and basic equipment. Success hinges on careful adherence to the provided guidelines, ensuring effective pyrolysis for high-quality biochar.

FAQs

1. What is biochar?

Biochar is a form of charcoal produced from the pyrolysis of organic biomass in a low-oxygen environment. It is used as a soil amendment to improve soil health, reduce pollution, and sequester carbon.

2. Why use 55-gallon drums for biochar production?

55-gallon drums are readily available, affordable, and offer a convenient size for small to medium-scale biochar production. They can be easily modified for both upright and horizontal biochar production methods.

3. What are the differences between the upright and horizontal drum methods?

The upright method involves burning biomass vertically in a standing drum, promoting a top-down burn for efficient pyrolysis. The horizontal method, on the other hand, involves laying the drum on its side, which can accommodate longer pieces of wood and may require more active management.

4. What materials can be converted into biochar?

Most organic materials, such as wood, agricultural residues, and yard waste, can be converted into biochar. However, it’s important to avoid treated or painted materials that can release harmful chemicals.

5. How do I prepare the drum for biochar production?

Preparation involves cleaning the drum to remove any residues and cutting openings for the horizontal method or removing the lid for the upright method. Safety measures, such as smoothing cut edges, should also be taken.

6. What safety precautions should be taken during biochar production?

Wear heat-resistant gloves, safety goggles, and long-sleeved, fire-resistant clothing. Ensure the production area is well-ventilated and free from flammable materials, and never leave the fire unattended. Always have a fire extinguisher or water source nearby.

7. How do I know when the biochar is ready?

Biochar is ready when the material has turned into a rich, black charcoal but has not turned to ash. The completion time varies based on the method and the materials used.

8. How should biochar be quenched and stored?

Biochar can be quenched with water or by cutting off the oxygen supply to the drum. Once cooled, it should be stored in a dry, covered container to prevent it from absorbing moisture or contaminants.

9. Can biochar production emit harmful smoke or gases?

If done correctly, biochar production should produce minimal smoke. Using dry biomass and ensuring proper airflow can reduce smoke production. Avoid burning plastics or treated wood to prevent harmful emissions.

10. How can biochar be used in soil?

Biochar can be mixed into garden soil, compost, or used in potting mixes. It improves soil fertility, water retention, and microbial activity, leading to healthier plant growth.

Joel Cunningham

Forestry AuthorI'm Joel Cunningham, an expert in pruning and weed management with over a decade of experience. My skills are rooted in formal training and extensive practice, focusing on advanced pruning techniques and efficient weed control. I'm known for my quality work, precision, and deep understanding of plant health and soil dynamics. My contributions extend to educational initiatives where I share sustainable practices and advice, establishing myself as a reliable and authoritative figure in the gardening community.

Leave your comment