How to Weld Pipe Root & Cap with 7018: Easy to Follow

- February 23, 2024

- 3 comment

Welding is both an art and a science, a skill honed over time with practice, patience, and a deep understanding of the techniques involved. Today, I’ll share my journey and insights into mastering the art of welding pipe root and cap using the 7018 welding rod.

This article is penned from my personal experience, aiming to provide a detailed, human-like review of the seven methods I’ve explored in my welding endeavors.

Table of Content List:

- Traditional Stringer Bead Method

- Weave Bead Technique

- Hot Pass Method

- Stepped Weave Technique

- Gravity Welding for Vertical Joints

- Backstepping Technique

- Pipe Oscillation Method

Understanding the Basics

Welding encompasses a diverse range of techniques each suited for specific applications. The effectiveness of a weld, especially in pipe welding, is significantly influenced by the chosen method. Techniques vary in terms of the type of electrode used, the angle of application, and whether the weld is applied in a single pass or multiple layers. A deep understanding of these techniques is crucial for ensuring structural integrity and longevity of the weld. Selecting the appropriate method based on the material, joint configuration, and intended use of the welded structure is foundational to achieving a successful weld.

Importance of Welding Techniques

Choosing the right welding technique is crucial for producing a high-quality weld. Techniques vary to tackle specific challenges like achieving deep penetration, reducing weld defects, and ensuring uniform heat distribution. Each method is tailored for different material thicknesses and types, affecting weld strength, appearance, and durability. Mastery of various techniques is vital for welders to adapt to different welding scenarios effectively.

Overview of 7018 Welding Rod

The 7018 welding rod is widely used for its superior weld quality and versatility. Its low hydrogen content minimizes the risk of cracking in thick materials, making it ideal for high-stress applications. This rod provides a stable arc and produces welds with excellent mechanical properties, including high tensile strength and toughness. It is suitable for both AC and DC welding, and its use spans structural welding, pressure vessels, and repairs. The coating of the 7018 rod ensures a smooth bead and easy slag removal, enhancing post-weld cleanup.

1. Traditional Stringer Bead Method

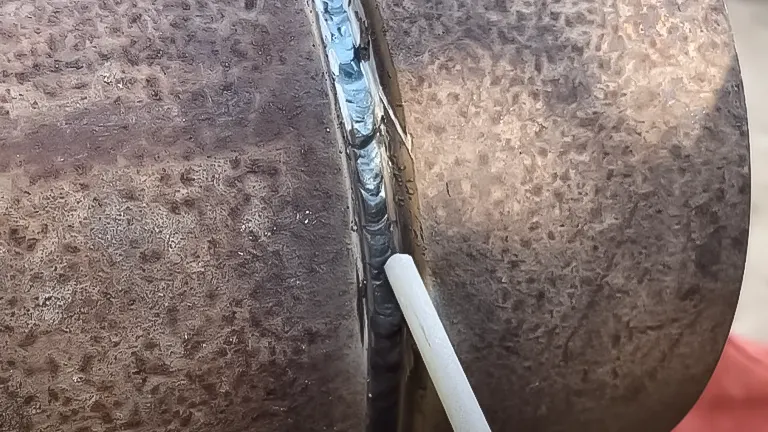

Starting with the basics, the stringer bead method using a 7018 electrode was my first foray into pipe welding. It’s a technique where the electrode is moved straight along the joint, focusing on maintaining a consistent arc length.

The key here was to ensure the bead was neither too wide nor too narrow, aiming for uniformity in weld penetration and bead appearance. Initially, I struggled with arc stability and travel speed, but with practice, I achieved a satisfactory root pass that provided a solid foundation for subsequent layers.

2. Weave Bead Technique

The weave bead technique introduced me to a side-to-side motion, significantly differing from the stringer bead approach. This method was particularly useful in covering larger areas and ensuring full penetration in the root.

The challenge was to maintain a consistent weave pattern without overheating the base metal or causing excessive spatter. It required a delicate balance between travel speed and electrode angle. After several attempts, I managed to produce a more robust root pass with better sidewall fusion.

3. Hot Pass Method

After laying down the root, I experimented with the hot pass method to add a layer of weld metal on top of the root pass, using the same 7018 electrode. This step was crucial for removing any potential slag inclusions and ensuring the weld’s integrity.

I found that slightly increasing the current for the hot pass helped in achieving deeper penetration and a cleaner weld area. It was a learning curve to adjust the heat input correctly, but the result was a significant improvement in the weld’s overall quality.

4. Stepped Weave Technique

As I progressed, I experimented with the stepped weave technique, which involved a more complex weaving pattern that included stepping back over the previously laid bead before advancing.

This method was particularly effective in controlling heat input and preventing warping or distortion of the pipe. Mastering this technique required patience and a steady hand, but it paid off by producing a visually appealing and structurally sound weld cap.

5. Gravity Welding for Vertical Joints

Facing the challenge of vertical welding, I learned the gravity welding technique, which utilizes the force of gravity to achieve deeper penetration and a cleaner root pass. Adjusting the electrode angle and travel speed was critical to accommodate the vertical position.

This method demanded a higher level of skill and concentration to control the molten pool effectively. The outcome was a revelation, showcasing an improvement in penetration depth and weld consistency.

6. Backstepping Technique

To address issues of heat management and distortion control, I adopted the backstepping technique. This involves welding in a direction opposite to the general progression, which helps in distributing heat more evenly across the weld.

Initially, it felt counterintuitive, but the technique proved invaluable for minimizing distortion and ensuring a uniform weld profile. It was particularly effective in the cap passes, resulting in a smoother and more consistent bead appearance.

7. Pipe Oscillation Method

Finally, the pipe oscillation method was a game-changer for me. It involves oscillating the pipe slightly while welding, which helps in achieving uniform heat distribution and penetration.

This technique was especially useful for the cap pass, ensuring a flat and even surface without undercutting or excessive reinforcement.

It took some practice to synchronize the pipe movement with the welding speed, but the results spoke for themselves, offering a perfect blend of aesthetics and structural integrity.

Pros

- Strong and Durable Welds: The 7018 electrode produces welds with high tensile strength, making them suitable for critical structures where durability is paramount.

- Low Hydrogen Content: This reduces the risk of hydrogen-induced cracking, a common issue in welding, especially in thicker materials or high-stress applications.

- Versatility: Suitable for both AC and DC welding, the 7018 electrode can be used across a variety of positions and metal thicknesses, offering flexibility in welding projects.

- Improved Weld Appearance: Welds made with a 7018 electrode are known for their smooth and clean finish, which can reduce the need for post-weld cleanup.

- Excellent Toughness: The welds exhibit good impact toughness, which is beneficial for applications that may experience high or fluctuating loads.

Cons

- Requires Skill and Practice: Achieving proficiency with a 7018 electrode, especially for pipe welding, requires significant practice and skill development.

- Moisture Sensitivity: The low hydrogen coating can absorb moisture if not properly stored, potentially leading to weld defects like porosity.

- Slower Welding Speed: Compared to some other electrodes, welding with a 7018 might be slower due to the need for careful technique and electrode manipulation.

- Need for Preheating: Certain applications may require preheating the base metal to prevent cracking, adding time and complexity to the welding process.

- Cleanup and Slag Removal: Despite producing a relatively clean weld, the 7018 electrode still generates slag that must be chipped away and cleaned, which could be a drawback for some.

Related Articles:

- First Welder Guide for DIYers: Practical Tips

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best Black Friday Welding Machine Deals 2023

- Troubleshooting Common Welding Machine Problems

- Best Cheap MIG Welder on Amazon

- Best Yeswelder Plasma Cutter

- Best MIG Welder by YesWelder

- Best STICK Welder by YesWelder

- Best 110v MIG Welders

- Best 120V MIG Welders

Final Conclusion

Diving into the process of learning pipe welding using a 7018 electrode presented both difficulties and rewards. Each technique introduced distinct challenges and chances for growth, requiring me to continuously improve and adjust my welding abilities. Starting with fundamental approaches such as the stringer bead method and advancing to more complex ones like pipe oscillation, my journey underscored the critical role of dedication, continuous practice, and resilience in welding. This experience is valuable for both beginners and those aiming to broaden their welding skills, providing a complete set of strategies for attaining high-quality pipe welds.

Frequently Asked Questions

- What is a 7018 electrode, and why is it used for welding pipe root and cap?

The 7018 electrode is a low-hydrogen, mild steel welding rod designed for high-quality welds with minimal risk of cracking. It’s preferred for welding pipe root and cap due to its ability to produce strong, ductile welds with good penetration and a smooth finish. - How do I prepare the pipe before welding with a 7018 electrode?

Proper preparation involves cleaning the pipe surface to remove any rust, oil, or contaminants. Bevel the edges to the recommended angle (usually about 30-37.5 degrees) to allow for proper penetration and fusion of the root. - What are the ideal amperage settings for welding pipe with a 7018 electrode?

Amperage settings can vary based on the electrode diameter and the thickness of the pipe. Generally, a 1/8-inch 7018 electrode operates well between 90-120 amps for root passes, but always refer to the electrode manufacturer’s recommendations. - How do I strike and maintain an arc with a 7018 electrode?

Striking an arc with a 7018 electrode involves lightly tapping the electrode against the workpiece then quickly pulling it back to establish the arc. Maintain a consistent arc length, roughly the thickness of the electrode’s metal core, throughout the weld. - What techniques are recommended for welding the root pass with a 7018 electrode?

For the root pass, a slight drag technique with a tight arc length helps ensure deep penetration and a strong foundation. Focus on maintaining a steady, consistent travel speed to ensure uniform bead appearance. - How can I avoid common defects like porosity or lack of fusion when welding with a 7018 electrode?

To avoid defects, ensure the pipe is clean and dry, maintain proper arc length, and select appropriate amperage settings. Proper technique and travel speed are also crucial to avoid porosity and ensure good fusion. - Can the 7018 electrode be used for all positions in pipe welding?

Yes, the 7018 electrode is versatile and can be used for welding in all positions, including flat, horizontal, vertical, and overhead, making it ideal for pipe welding applications. - What are the tips for welding the cap pass with a 7018 electrode?

For the cap pass, use a weave or oscillation technique to ensure even coverage and penetration. Monitor your travel speed to avoid excessive build-up and ensure a smooth, even cap appearance. - How do I inspect my weld for quality assurance?

Inspect your weld visually for uniformity, absence of surface defects like cracks or porosity, and proper penetration and fusion. Non-destructive testing methods, such as ultrasonic or radiographic inspection, can further assess weld quality. - What safety precautions should I take when welding pipe with a 7018 electrode?

Always wear appropriate personal protective equipment, including a welding helmet with the correct shade, fire-resistant clothing, gloves, and boots. Ensure good ventilation to avoid inhaling fumes, and be aware of your surroundings to prevent fire hazards.

We’re eager to connect with you! If you’ve ventured into the world of welding, particularly learning to weld pipe root and cap with a 7018 electrode, we’d love for you to share your journey and insights in the comments section below. Your personal experiences and tips could greatly assist fellow enthusiasts in mastering this skillful art. Your feedback is invaluable in helping others navigate their learning path and make knowledgeable choices.

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

3 comments

You are the first welder. Give a very good overview . One technique I used a rythm could be a song , or you could count.

Mackie

March 9, 2024 11:01 pmYou have been doing a good job,but 6010 rod is recommended for xray

Yes. 6010 . Is used for xray.But sometime you are given specific rod and technique to used .by the way I am 6g certified but retire.

Mackie

March 9, 2024 11:09 pm