Mastering Chainsaw Milling: Essential Tips for Perfect Cuts

- May 27, 2024

- 0 comment

Chainsaw milling transforms ordinary logs into valuable lumber, providing a deeply satisfying and productive experience. Whether you engage in this activity as a hobby or for professional purposes, perfecting your milling techniques is crucial for producing smooth and precise cuts. This guide offers 17 essential tips designed to refine your skills and elevate your chainsaw milling to the next level.

Tip 1: Start and Finish Cuts Smoothly

When using a chainsaw for milling, it’s crucial to begin and end each cut with care to ensure the best results and avoid damaging the wood. Start your cuts not at full throttle but by gently easing into the wood with partial throttle.

Only increase to full throttle once the chainsaw is fully engaged in the cut. This technique helps prevent gouging, particularly at the critical starting and ending points of your cut, where precision is vital and errors are most likely to occur. By managing the throttle carefully, you can achieve a smoother, cleaner cut and prolong the life of your chainsaw blade.

Tip 2: Let the Chain Do the Work

For efficient and smooth chainsaw milling, it’s essential to trust the equipment. A well-sharpened chain is designed to pull itself into the cut, reducing the need for you to exert extra force. Pushing the saw not only requires more effort but can also cause the chainsaw to bog down, disrupting the cutting process.

If you find the saw struggling or slowing down, don’t push harder. Instead, ease off the throttle, carefully reposition, and slowly re-engage the chain into the wood. This approach allows the chainsaw to operate at its best, maximizing cutting efficiency and minimizing wear on the chain.

Tip 3: Proper Use of Wedges

Wedges are invaluable tools in chainsaw milling for maintaining the integrity of your cuts and preventing the saw from becoming pinched. When selecting wedges, opt for those with a gentle taper. This shape ensures they stay securely in place without slipping out during the cut.

Hardwood wedges are highly recommended due to their durability, and painting them red enhances visibility, making them easy to find and less likely to leave marks on your lumber. Importantly, avoid hammering the wedges into the wood. Hammering can damage both the wedge and the wood you are cutting, potentially affecting the quality of your millwork. Instead, insert them gently but firmly to support the cut without causing harm.

Tip 4: Maintain a Consistent Cut Angle

Achieving a smooth and even cut in chainsaw milling greatly depends on maintaining a consistent angle throughout the process. Aim to keep your saw at an angle of about 45 degrees relative to the wood. This specific angle is beneficial as it aligns better with the grain of the wood, reducing the creation of fine, dusty sawdust.

Instead, it produces cleaner, stringier debris, which is much easier to manage and clear away. Keeping a consistent angle not only enhances the quality of your cuts but also improves the efficiency of your milling by ensuring smoother, faster sawing with less strain on both the chainsaw and the operator.

Tip 5: Utilize a Ladder as a Straightedge

When chainsaw milling, ensuring straight and accurate cuts is paramount. An innovative way to achieve this is by using a ladder as a straightedge. This approach is particularly handy for correcting minor deviations that can occur during the milling process.

By aligning the ladder along the length of the log, you can guide your chainsaw to follow a straight path, enhancing the precision of your cuts. Additionally, a ladder provides extra stability, which is especially beneficial when working solo. This method not only improves the quality of your cuts but also adds an element of safety and control, making the milling process smoother and more efficient.

Tip 6: Wear the Right Protective Gear

Safety should always be your top priority when operating a chainsaw, especially during milling. To protect yourself effectively, make sure you’re equipped with the right gear. A visor with built-in vapor filters is crucial to shield your eyes and respiratory system from sawdust and fumes. Additionally, ear defenders that incorporate a radio not only protect your hearing but also make the milling experience more enjoyable by allowing you to listen to music or radio broadcasts.

For those engaged in prolonged milling sessions, it’s advisable to use ear plugs in addition to the ear defenders for enhanced noise protection. This dual protection helps safeguard against long-term hearing damage from the chainsaw’s loud noise. Ensuring you have adequate protective gear not only keeps you safe but also enhances your comfort and focus, leading to better milling results.

Tip 7: Preparation is Key

Before diving into any chainsaw milling project, thorough preparation can make the difference between a smooth operation and unnecessary interruptions. To ensure everything runs seamlessly, create a checklist of all the essential items you’ll need.

This list should include:

- Fuel: Confirm you have enough fuel for the entire project to avoid mid-task refueling.

- Chainsaw: Ensure your chainsaw is in good working order, with the chain sharpened and all components functioning properly.

- Brushes for Cleaning: Keep brushes on hand to clean away debris and sawdust, which can accumulate and hinder your saw’s performance.

- Safety Gear: Double-check that all your safety equipment, such as gloves, goggles, ear protection, and a visor, is ready and in good condition.

Having a checklist and gathering all necessary items beforehand helps prevent mid-task pauses, maintaining your focus and efficiency throughout the milling process. This preparation not only saves time but also enhances safety and the quality of your work.

Tip 8: Keep a Brush Handy

While milling, it’s essential to keep your workspace clean and free of debris. A simple brush proves invaluable for this purpose. Throughout the milling process, sawdust and wood chips can accumulate quickly, potentially obscuring your cutting line or causing the chainsaw to slip.

Regularly using a brush to sweep away this debris ensures your work area remains clear and safe. This practice not only minimizes the risk of accidents but also allows for more accurate and efficient cuts. Always have a brush within easy reach to promptly manage sawdust and maintain optimal working conditions.

Tip 9: Check Fuel Levels Regularly

Before initiating each new cut, particularly when starting on a fresh slab, it’s crucial to check the fuel levels of your chainsaw. Running out of fuel mid-cut isn’t just inconvenient—it can lead to serious damage to your equipment. When a chainsaw runs low on fuel, it may begin to run lean, which means the fuel-to-air mixture is too light.

This condition can cause the saw to overheat, increasing wear on the engine and potentially leading to a breakdown. To avoid these risks and maintain your chainsaw in optimal working condition, make it a routine to verify the fuel level before you begin sawing. This simple check helps ensure a continuous, smooth operation and prolongs the life of your chainsaw.

Tip 10: Use an Auxiliary Oiler

When undertaking wide cuts, maintaining adequate lubrication of your chainsaw’s chain is essential for both the quality of the cut and the longevity of your saw. An auxiliary oiler can be a critical addition in these scenarios, ensuring that the chain remains well-lubricated throughout extended cuts. This continuous lubrication helps reduce friction and wear on the chain, enhancing both the performance and the durability of the saw.

For the lubricant, consider using a lightweight vegetable oil. This type of oil provides sufficient lubrication without the excessive stickiness associated with traditional bar oils. Vegetable oil is not only effective but also more environmentally friendly, making it a great choice for outdoor cutting tasks. Remember to set up your auxiliary oiler to deliver a steady, manageable flow of oil, and ensure to turn it off at the end of each cut to conserve your oil and keep the workspace clean.

Tip 11: Dampen Vibrations

Extended use of a chainsaw, especially during milling operations, can lead to significant hand and arm fatigue due to vibrations. To mitigate this, a simple yet effective solution is to wrap the saw handle with rubber. This additional cushioning absorbs much of the vibration that would otherwise transfer directly to your hands and arms.

Using rubber grips or even purpose-made anti-vibration wraps can make a big difference in comfort and control. This adjustment not only reduces the physical strain experienced during long milling sessions but also helps prevent long-term health issues such as hand-arm vibration syndrome (HAVS), which can be a serious concern for frequent chainsaw users. By damping vibrations, you’ll find you can work longer and more comfortably, improving both your productivity and the enjoyment of your milling projects.

Tip 12: Saw Maintenance

Proper maintenance of your chainsaw is crucial for ensuring its longevity and optimal performance. After completing a long cut, it’s important to let the saw idle for about 30 seconds before turning it off. This cooling period helps to stabilize the engine temperature and prevents the internal components from overheating, which can cause damage over time.

Additionally, regular maintenance should include flipping the bar of the chainsaw. This practice ensures that the bar wears evenly on both sides, extending its lifespan and maintaining the efficiency of your cuts. Regularly check and clean the air filter, sharpen the chain, and ensure that all nuts and bolts are tightened. These simple maintenance steps can significantly enhance the performance and durability of your chainsaw, making it a reliable tool for all your milling needs.

Tip 13: Moving Slabs Safely

Transporting large slabs of wood, especially after a successful milling session, requires careful planning and attention to safety. Large slabs can be unwieldy and heavy, posing significant risks during movement. To ensure safety, start by conducting a thorough risk assessment of your environment and personal capabilities. Evaluate factors such as the terrain over which you will be moving the slab, potential obstacles, and whether the path is sufficiently clear of hazards like rocks or uneven ground, which could cause trips or falls.

Consider your physical capabilities and the help available. Assess whether the slab’s weight and size are manageable or if additional help is needed to safely move it. Utilize proper lifting techniques—bending at the knees and keeping the back straight—to avoid injury. Additionally, equipment such as dollies, lifting straps, or even machinery like a forklift or a tractor with appropriate attachments can be indispensable in safely handling heavy slabs. Always prioritize safety over speed or convenience to prevent accidents and ensure that both you and your milling projects are protected.

Tip 14: Adapt to Setbacks

Woodworking and chainsaw milling often come with their share of unexpected challenges, such as discovering cracks in the wood during the milling process. When these setbacks occur, flexibility and adaptability are your best assets. Rather than viewing these issues as failures, consider them opportunities for creativity and innovation. A crack in a slab, for example, doesn’t necessarily render the wood unusable. Instead, it can provide a unique character to the piece, potentially making it suitable for smaller, more artistic projects like furniture, decorative panels, or even sculpture.

Adjust your plans according to the condition of the wood. Sometimes, what seems like a flaw can become a feature that adds beauty and interest to a piece. Embrace the natural imperfections of the wood and let them guide your creative process. This mindset not only salvages materials that might otherwise be wasted but also enriches your experience and expands your repertoire as a craftsman.

Tip 15: Keep Your Workspace Clean

Maintaining a clean workspace is essential for safe and efficient chainsaw milling. Before you begin your work, take preventative measures to ensure that your tools and equipment remain clean and functional. One simple yet effective practice is to close your toolbox. This prevents sawdust and debris from entering, which could potentially damage your tools or affect their performance.

Additionally, strategically place your gear upwind of where you’re working. By situating your equipment upwind, you minimize the amount of sawdust and debris that blows toward and accumulates on your tools and gear. This not only helps in keeping your workspace tidy but also reduces the time you spend cleaning after the job is done. A clean workspace enhances safety by reducing the risk of slips, trips, and equipment malfunctions. It also contributes to a more organized and efficient work environment, helping you stay focused and productive.

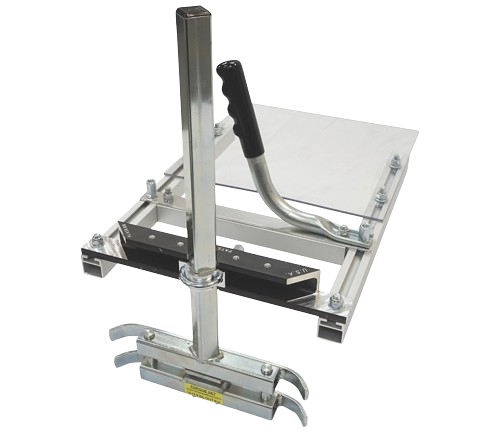

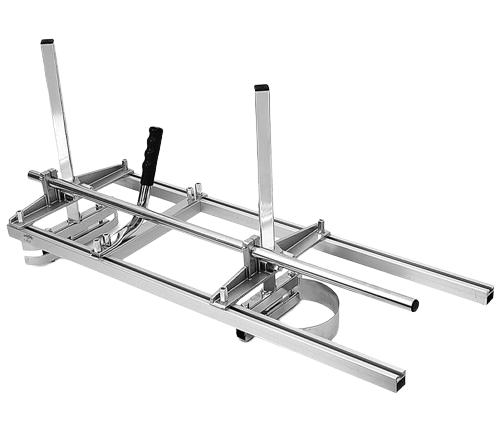

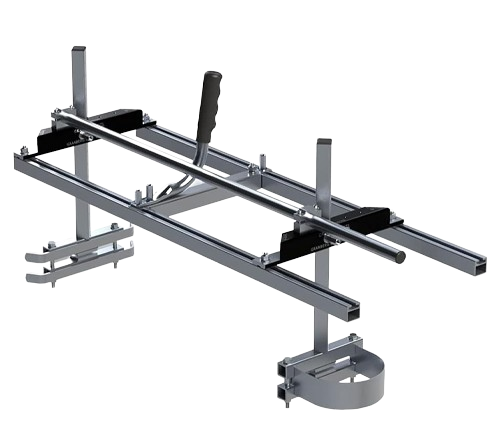

Tip 16: Cost and DIY Milling

Building your own chainsaw mill is a practical and affordable solution for those who enjoy custom woodworking. By using extruded aluminum, you can create a chainsaw mill that is strong, lightweight, and resistant to corrosion. The cost of constructing a basic setup can start at around 100 pounds, varying based on the design and size you choose. This DIY approach can save you money compared to buying commercial mills and allows for customization to meet your specific needs.

For those who love DIY projects, making your own mill brings added satisfaction and flexibility. You can tailor the mill to accommodate different sizes of chainsaws and logs, enhancing your woodworking capabilities. Tackling a project like this also sharpens your skills and deepens your understanding of milling techniques. To ensure success, thoroughly research and carefully plan your design. Utilize online tutorials, forums, and guides focused on chainsaw milling. These resources offer valuable tips and detailed instructions that can help you build an efficient and durable chainsaw mill.

Tip 17: Enjoy the Milling Experience

Chainsaw milling is more than just cutting wood; it’s a chance to connect deeply with nature. As you work outdoors, take a moment to enjoy the sounds of wildlife, the fresh air, and the feel of wood in your hands. Each log has its own unique story and character, shaped by where it grew. This makes milling a special experience, deepening your appreciation for the wood and the crafting process.

Enjoy the challenges of mastering chainsaw milling. Turning a rough log into smooth lumber is rewarding and something to be proud of. Remember to take breaks, drink water, and occasionally step back to appreciate your progress and the beauty around you. By embracing both the joys and challenges of milling, you make your work more meaningful and enjoyable, turning each session in the woods into a memorable adventure.

Product Recommendations for Chainsaw Milling

| Category | Chainsaw | Details | Milling Attachment | Details |

|---|---|---|---|---|

| Budget-Friendly | Poulan Pro PR5020 | Reliable and affordable with a 50cc engine. Ideal for smaller tasks. Offers lower fuel consumption and reduced emissions. | Granberg G777 | Light-duty, portable. Compatible with 16 to 20-inch bars. Suitable for occasional milling and smaller projects. |

| Mid-Range Options | Husqvarna 460 Rancher | More robust with a 60cc engine, suitable for mid-sized milling jobs. Features enhance ease of use during extended milling. | Carmyra Portable Chainsaw Mill | Versatile, easy to use. Handles bars from 14″ to 36″. Great for serious hobbyists or semi-professional woodworkers. |

| Professional-Grade | Stihl MS 661 C-M | High-performance, designed for professional use with a 91cc engine. Offers exceptional power and efficiency. | Granberg MK-IV Alaskan Chainsaw Mill | Advanced, can handle up to a 36-inch bar. Built for heavy use and large logs. |

Troubleshooting Common Problems in Chainsaw Milling

During chainsaw milling, encountering issues is not uncommon, especially as you handle various types and sizes of logs. Below, you’ll find troubleshooting tips for some of the most frequent challenges: a stuck saw, uneven cuts, and excessive vibration.

1. Stuck Saw

- Problem: The chainsaw gets stuck in the log during a cut.

- Solution: First, turn off the chainsaw to prevent damage or injury. If possible, gently wiggle the saw back and forth without forcing it. If this doesn’t work, use wedges to carefully open the cut and relieve the pressure on the saw. Insert the wedges into the cut above the saw, then gently tap them to widen the gap.

2. Uneven Cuts

- Problem: The cuts are not straight or level, resulting in uneven lumber.

- Solution: Ensure your chainsaw bar is not bent or damaged and that the chain is sharp and properly tensioned. Check the milling guide bar to make sure it’s securely attached and level. Adjust the depth and angle settings on your milling attachment for consistency. Practice maintaining steady pressure and a uniform feed rate during the cut.

3. Excessive Vibration

- Problem: The chainsaw produces uncomfortable or unmanageable vibrations.

- Solution: Excessive vibration can often be attributed to a loose or worn chain, an unbalanced bar, or a malfunctioning engine. Check the tightness of the chain and the condition of the bar. Replace any worn parts. Ensure that the chainsaw’s anti-vibration mounts are in good condition and secure. Regular maintenance checks can help mitigate this issue before it affects your milling.

Conclusion

In conclusion, mastering chainsaw milling is an invaluable skill for anyone looking to transform raw logs into usable lumber with precision and ease. By following the 17 tips outlined in this guide, you can enhance your milling techniques, ensure your safety, and optimize the quality of your cuts. Whether you’re a seasoned woodworker or a novice, these tips will help you work more efficiently and enjoyably, allowing you to fully appreciate the art of chainsaw milling and the natural beauty of the wood you work with. Embrace the challenges and rewards of this unique craft and let each milling session enrich your woodworking journey.

FAQ

- What size chainsaw do I need for milling?

The size of the chainsaw you need depends on the size of the logs you plan to mill. For smaller projects or occasional milling, a chainsaw with a 50cc to 60cc engine and a bar length of 16-20 inches is sufficient. For larger logs and more frequent milling, consider a chainsaw with at least a 70cc engine and a bar length of 24 inches or more. - How do I maintain my chainsaw for milling?

Proper maintenance is crucial for optimal performance and longevity. Keep your chain sharp, ensure the chain tension is correct, regularly check and replace the bar oil, and clean the air filter and cooling fins to prevent overheating. Also, flip the bar regularly to ensure even wear. - Can any chainsaw be used with a milling attachment?

Most chainsaws can be used with a milling attachment, but it’s essential to check the compatibility in terms of power and bar length. The chainsaw needs to have enough power to handle the extra strain of milling, and the bar must be long enough to extend beyond the width of the milling attachment. - What are the safety precautions I should take while chainsaw milling?

Always wear appropriate safety gear, including gloves, ear protection, eye protection (visor or goggles), and sturdy boots. Ensure the area is secure, and there are no tripping hazards. Never mill alone – having a partner can increase safety. Also, be aware of the kickback zone and maintain a firm grip on the saw at all times. - How do I ensure my cuts are straight when using a chainsaw mill?

Using a guide system such as a ladder or a custom-made guide rail can help keep your cuts straight. Ensure the guide is securely fastened and aligned with your intended cut line. Start the cut slowly to establish a groove, and keep the chainsaw steady and move at a consistent speed.

We hope this guide has armed you with the knowledge and confidence to tackle chainsaw milling more effectively. Whether you’re refining your skills or just starting out, we’d love to hear about your experiences and any tips you might have discovered along the way. Please share your thoughts and questions in the comments below—let’s keep the conversation going and learn from each other’s experiences. Happy milling!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment