Chainsaw Kickback: Causes, Dangers, and Safety Tips

- January 5, 2024

- 1 comment

Chainsaw kickback, a term that often brings a shudder to both novice and experienced users alike, refers to the sudden and often dangerous upward motion of a chainsaw’s guide bar, sometimes referred to as the “kickback bar.” It’s a leading cause of chainsaw accidents, capable of causing serious injuries. In this comprehensive guide, we delve into the causes, dangers, and crucial safety tips to minimize the risk of kickback incidents.

Understanding Chainsaw Kickback

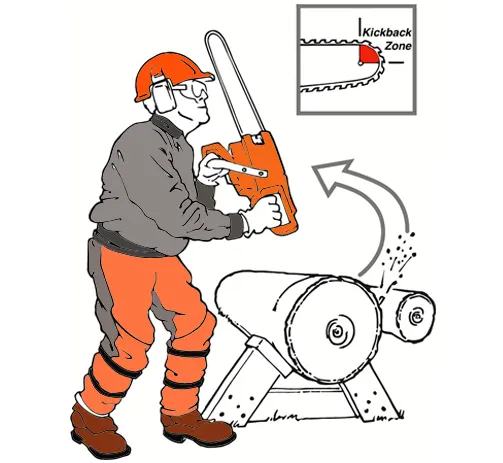

Chainsaw kickback, a critical concern for both seasoned loggers and weekend woodcutters, manifests primarily in two high-risk scenarios. The first, often termed as a ‘nose contact’ kickback, transpires when the swiftly moving chain at the extremity of the chainsaw’s guide bar, commonly known as the kickback bar, inadvertently strikes a solid object. This object could be anything from a hidden nail embedded in the wood to an unnoticed rock or a hard knot in the tree.

The second scenario, sometimes referred to as ‘pinch’ kickback, occurs during the act of cutting when the wood unpredictably clamps down on the chainsaw’s chain. This pinching effect is often a result of internal tensions within the wood being released as cuts are made, particularly in tree felling or when slicing through large logs.

Both these scenarios set off a rapid and forceful reaction from the kickback bar. In a fraction of a second, the bar can jerk upwards and backwards, creating a potentially dangerous situation. This abrupt motion is not only startling but can also wrest control of the chainsaw away from the user. The speed and force of this reaction are such that even experienced users can find it challenging to maintain a firm grip on the chainsaw, leading to a significant risk of injury.

It’s crucial to understand that kickback is an instantaneous and violent response of the chainsaw, often leaving little to no time for the operator to react. This underscores the importance of preventative measures, such as proper handling techniques, usage of safety features on the chainsaw, and wearing appropriate protective gear. Being aware of the kickback bar’s position relative to the workpiece at all times is fundamental in reducing the likelihood of these dangerous kickback scenarios.

Factors Increasing the Risk of Kickback

Kickback in chainsaws, a phenomenon that poses a significant safety risk, can be exacerbated by a variety of factors. Understanding these contributing elements is essential for both professional lumberjacks and casual users to ensure safe operation.

- Improper Saw Maintenance: Regular and proper maintenance is crucial. Neglect in this area can lead to a host of issues that elevate kickback risk. This includes not only the cleaning and oiling of the chainsaw but also ensuring all parts are functioning correctly.

- Dull or Incorrectly Sharpened Chains: A dull chain requires more force to cut through wood, which can lead to unpredictable saw behavior. Similarly, incorrect sharpening alters the angle of the teeth, affecting the chain’s cutting action and potentially increasing kickback risk.

- Loose Saw Chain Tension or Parts: Proper tension in the saw chain is essential for controlled and safe cutting. A chain that’s too loose can easily come off the bar or snag in the wood, causing kickback. Similarly, any loose parts can alter the balance and stability of the chainsaw during operation.

- Bent, Cracked, or Broken Chain Components: Damaged components can dramatically alter the chainsaw’s operational integrity. Even minor bends or cracks can lead to unexpected movements during use, significantly increasing the likelihood of kickback.

- Excessive or Incorrect Chain Depth Gauge Settings: The depth gauge determines how deep the teeth cut into the wood. Incorrect settings can either make the saw too aggressive or too timid in its cutting action, both of which can contribute to kickback.

- Larger Guide Bar Noses: The size of the guide bar’s nose plays a critical role. Larger noses have a more extensive kickback danger zone. This increased area heightens the probability of the bar nose striking an object, leading to kickback.

Understanding the Kickback Danger Zone

The top portion of the tip of the chainsaw’s guide bar, often referred to as the “kickback bar,” encompasses a critical area known as the “kickback danger zone.” This specific zone demands heightened attention due to its propensity to initiate kickback. The need to avoid using this part of the bar for cutting is paramount, as engaging in cutting activities with this zone significantly elevates the risk of experiencing kickback. This risk intensifies particularly when this zone comes into contact with external objects, such as logs or branches, during sawing operations.

To fully grasp the concept of the kickback danger zone, it is essential to understand what kickback entails. As per the standards set out in CSA Z62.3-11 (R2021), kickback is defined as the swift upward motion of the chainsaw’s guide bar. This phenomenon manifests in two distinct forms:

- Rotational Kickback: This type occurs when the saw chain near the nose of the guide bar – within the kickback danger zone – makes contact with an object. The unexpected contact can cause the chainsaw to rotate upwards and towards the operator, creating a hazardous situation.

- Pinch Kickback: Pinch kickback happens during the cutting process when the wood being cut unexpectedly pinches the saw chain. This pinching can result in the chainsaw moving rapidly upwards, potentially leading to loss of control and increased danger for the operator.

Both rotational and pinch kickbacks pose significant risks and underscore the importance of avoiding contact in the kickback danger zone. Understanding these dynamics is crucial for anyone operating a chainsaw, as it directly relates to the safe and effective use of this powerful tool.

Reducing the Risk of Chainsaw Kickback

- Before operating a chainsaw, invest time in understanding its mechanics and safety features. Familiarize yourself with the manufacturer’s guidelines to ensure you’re well-prepared for its use.

- Operating a chainsaw requires full concentration. Avoid using it when fatigued or distracted, as mental sharpness is key to reacting promptly to potential kickback scenarios.

- Limbing, the process of cutting branches off a fallen tree, is particularly prone to causing kickback. Be vigilant when the nose of the kickback bar chainsaw is near objects that could trigger a kickback.

- Proper cutting methods can significantly reduce kickback risk. This includes using the lower part of the bar for cutting and avoiding operations above shoulder height where control is less and kickback potential is higher.

- Avoid allowing the tip of the kickback bar to make contact with any surface during cutting. This practice is crucial in mitigating the risk of kickback.

- Regularly test the chainsaw’s chain brake, a critical safety component designed to stop the chain’s movement during a kickback, to ensure it’s working correctly.

- Always be aware of the position of the bar nose, particularly in the kickback danger zone. This vigilance is essential for preventing accidental contact leading to kickback.

- When selecting a chain, choose one specifically engineered to reduce kickback. These chains are designed with safety in mind and can be a significant factor in preventing accidents.

- Narrow-nose bars have a smaller kickback danger zone, thereby reducing the likelihood of kickback. They are an excellent choice for enhancing overall chainsaw safety.

- Protective equipment is non-negotiable. This includes chainsaw chaps or pants, sturdy gloves, safety glasses or a face shield, a hard hat for overhead protection, and hearing protection, and sturdy, non-slip boots.

- Wear clothing that fits well – not too tight that it restricts movement, nor too loose that it could get caught in the chainsaw. Proper fit contributes to both safety and ease of movement.

- A secure grip on the chainsaw is essential. Wrap your thumbs and fingers fully around the handles, maintaining control and balance, which is critical for reacting to any kickback.

- Regular and correct maintenance of your chainsaw is vital. This includes chain sharpening, tension adjustments, and general upkeep as per the manufacturer’s instructions, ensuring the chainsaw operates safely and efficiently.

Guidance for Novice and Experienced Chainsaw Users: Navigating Kickback Risks

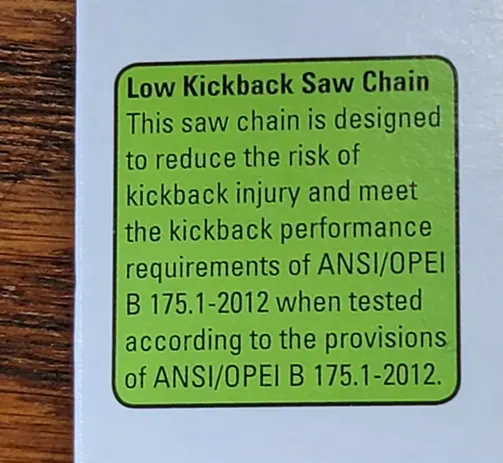

For Novice Users: Choosing the Right Chain

If you’re new to using chainsaws, it’s crucial to start with a chain that’s designed to minimize kickback. Look for chains marked with a green label from the American National Standards Institute (ANSI), which signifies a low kickback chain suitable for less experienced users. Be aware that some older models from brands like Oregon may use a blue label instead. These chains are engineered to reduce the intensity and likelihood of kickback, offering an added layer of safety for those still developing their chainsaw handling skills.

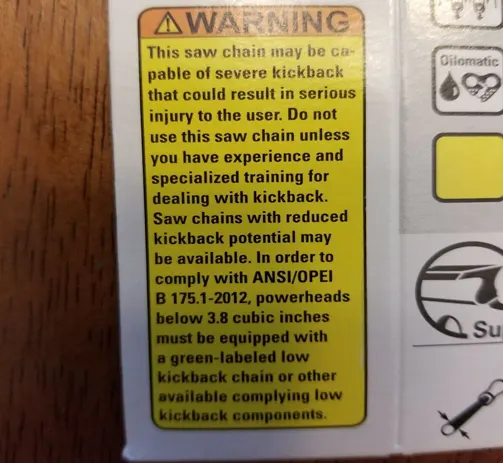

Safety Tips for Experienced Users: Handling Professional Chains

For seasoned chainsaw operators, professional saw chains are an option. These are typically marked with a yellow label and are not low kickback chains. They require skilled handling and are intended for users who have ample training and experience. These chains offer efficiency and power needed for demanding tasks but come with a higher risk of kickback due to their aggressive cutting capabilities.

Conclusion

Understanding and respecting the power of a chainsaw, especially the dynamics of the kickback bar Chainsaw, is vital for safe operation. By adhering to these guidelines, reading the operating instructions, staying alert, and using the right protective gear, the risk of kickback can be significantly reduced, making chainsaw use safer for everyone involved. Remember, safety is not just a guideline but a vital practice in every chainsaw operation.

Related Articles:

- Types of Chainsaw Chains and How to Choose

- How Tight Should A Chainsaw Chain Be

- Best Chainsaw Mill Attachments

- Best ATV Chainsaw Holder

- Common Reasons Your Chainsaw Is Smoking

- Best Chainsaw for the Money: Top Picks for Every User

- Top 5 Causes of a Loose or Detached Chainsaw Chain: How to Identify and Fix

- Chainsaw Safety Guide Tips

FAQs

- What is a kickback bar on a chainsaw, and how does it relate to safety?

A kickback bar refers to the guide bar of a chainsaw, particularly highlighting its role in kickback incidents. Understanding its dynamics and risks is crucial for safe chainsaw operation. - Can kickback happen even with a low kickback chain?

Yes, while low kickback chains reduce the risk, they do not eliminate it entirely. Kickback can still occur if the chainsaw is used improperly or if the kickback bar’s tip strikes an object. - Is there a particular technique to hold the chainsaw to prevent kickback?

Yes, always hold the chainsaw firmly with both hands, keeping your thumbs and fingers wrapped around the handles. This grip aids in controlling the saw during a potential kickback. - Why is the size of the guide bar’s nose important in kickback prevention? The larger the nose of the guide bar, the greater the area of the kickback danger zone. Using a bar with a smaller nose reduces the likelihood of kickback.

- How often should I check my chainsaw for features that prevent kickback?

Before each use, inspect your chainsaw for safety features like the chain brake and ensure they are functioning properly. Regular maintenance checks are also essential. - Can professional chainsaw users ignore kickback safety measures?

No. Regardless of experience, all chainsaw users should adhere to kickback safety measures. Professionals often use more powerful saws, which can increase kickback risks. - Are electric chainsaws less prone to kickback than gas-powered ones?

Electric chainsaws can still experience kickback, but their generally smaller size and lower power can reduce the severity compared to gas-powered models. - Does wearing protective gear really help in a kickback scenario?

Absolutely. Protective gear like chainsaw chaps, gloves, and helmets can provide crucial protection in the event of kickback, potentially preventing serious injuries. - What is the ‘kickback danger zone,’ and how can I identify it?

The kickback danger zone is located at the top quarter of the chainsaw bar’s nose. Avoid using this area for cutting, as it’s most prone to causing kickback. - How can a beginner practice safe chainsaw use to avoid kickback?

Beginners should start with a low kickback chain and bar, read the chainsaw’s operating manual thoroughly, practice under supervision if possible, and always stay alert and focused while using the saw.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

181se or 394xp 266xpw 288xp I think all good models forsure 288 case 181 jug 52mm piston primary and secondary transfers cleaned up for faster fiel and air

Kenneth

January 7, 2024 9:31 am