How To Fix A Chainsaw If It Won’t Oil The Bar And Chain

- February 8, 2024

- 0 comment

Have you ever found yourself halfway through a cut, only to notice your chainsaw struggling more than it should? A well-oiled chainsaw isn’t just a convenience; it’s a necessity. In this comprehensive guide, we’ll walk you through the steps to diagnose and fix a chainsaw that isn’t oiling the bar and chain correctly, ensuring your tool remains in top condition for any task.

Understanding the Chainsaw Oiler Mechanism and the Importance of Lubrication

At its core, the chainsaw oiler mechanism is ingeniously straightforward, functioning as a vital pump designed to keep the bar and chain amply lubricated, thus ensuring they operate smoothly and without overheating. This mechanism efficiently transfers oil from the tank, directing it through oiler holes in the bar onto the moving chain. This process is crucial, as both the chain and bar, being made of steel, are susceptible to generating significant heat due to friction during use.

Without this essential lubrication, the risk of overheating becomes imminent, potentially leading to damage to these critical components. Furthermore, some chainsaws are outfitted with manual oilers, adding a layer of maintenance by requiring the operator to periodically pump oil manually, ensuring consistent lubrication. The significance of this lubrication extends beyond preventing damage; it plays a pivotal role in the chainsaw’s performance and longevity. A well-oiled chainsaw not only prevents the chain and bar from overheating but also facilitates better cutting performance and extends the lifespan of the chainsaw, showcasing the indispensable nature of the oiler mechanism in the maintenance of the chainsaw’s efficiency and durability.

Signs Your Chainsaw Isn’t Oiling Properly

- Chain loosens quickly: A lack of oil causes the chain to heat up, stretch, and become loose.

- Saw produces smoke: Indicates overheating due to insufficient lubrication.

- Chain gets stuck: Can occur if the saw isn’t oiling properly, leading to the saw getting pinched or stuck.

- Bar shows “burned” marks: Bluish marks along the edge of the bar are a clear indication of overheating.

- Excessive vibration and unusual noises: These signs can also indicate a lack of proper lubrication.

Troubleshooting and Fixing the Oiling Issue: Step-by-Step Solution

Step 1: Remove the Bar and Chain

Start by disassembling your chainsaw to gain access to the components that might be causing the oiling issue. This involves carefully removing the bar and chain. It’s crucial to check that the oil tank is filled with the appropriate chainsaw bar oil and that the chain brake is disengaged. This ensures that the clutch drum is free to rotate, facilitating a thorough inspection and cleaning process.

Step 2: Test the Chainsaw’s Oiling Mechanism

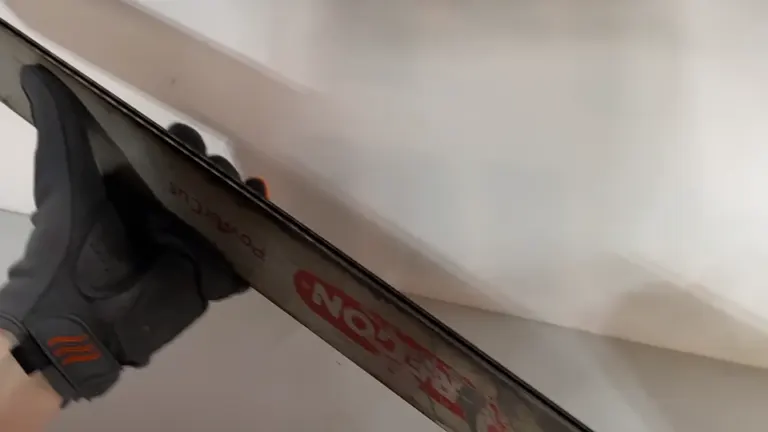

With the bar and chain removed, proceed to safely start the chainsaw in an open area to observe if oil is being ejected from the oil port where the bar connects to the saw. Observing oil indicates that the internal oiling system and oil pump are likely functioning correctly, suggesting that the problem lies elsewhere.

Step 3: Inspect and Clean the Guide Bar

If oil is present without the bar and chain, the guide bar, specifically the oil hole, is likely the culprit. Utilizing either specialized bar maintenance tools or household items like a putty knife, hacksaw blade, or a small screwdriver, clean the groove and the oil hole on the guide bar thoroughly. This is a critical step to ensure the unobstructed flow of oil necessary for lubricating the bar and chain. An air compressor can be exceptionally useful here to blow out any lingering debris, guaranteeing that the pathway for the oil is completely clear.

Step 4: Reassemble and Test

After cleaning, reattach the bar and chain to the chainsaw, taking care to align the oil hole with the oil port on the saw accurately. If there’s any uncertainty about reattaching the bar, adjusting the chain’s tension, or if you need a refresher, consult the chainsaw’s user manual tailored to your model for guidance.

Final Testing

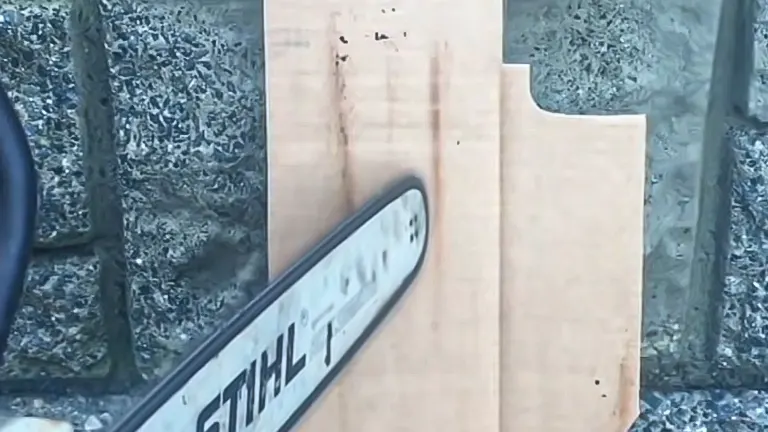

To confirm the success of your maintenance efforts, prepare a clean piece of cardboard or a fresh piece of wood as a test material. Run the chainsaw close to this material, allowing the chain to move at operational speed. A consistent spray of oil on the test material, especially noticeable coming off the tip of the bar, is a reliable indicator that your chainsaw is now properly oiling the bar and chain. This not only signifies that you’ve effectively resolved the oiling issue but also that your chainsaw is ready for efficient and safe operation.

Maintaining Your Chainsaw

- After each use, take a moment to clean the guide bar. Focus on the oil hole and the groove, as these areas are critical for the lubrication system’s efficiency. Sawdust and debris can easily clog these parts, preventing oil from reaching the chain and bar, leading to increased friction and wear.

- It’s essential to use the appropriate oil for your chainsaw, considering both the model of your chainsaw and the environmental conditions in which you’re working. Chainsaw oil is specially formulated to adhere to the chain and bar, providing optimal lubrication and protection against wear. In colder climates, you might need a winter-grade oil to ensure smooth operation.

- Beyond cleaning, regularly inspect your chainsaw for any signs of wear or damage, such as cracks in the chain, dullness of the teeth, or damage to the bar. Adjust the chain tension as needed; a chain that’s too loose or too tight can lead to problems during operation.

- Properly storing your chainsaw can also prevent many issues. Store it in a clean, dry place and cover the bar and chain to protect them from dust and moisture.

Safety Tips and Best Practices for Chainsaw Maintenance

Maintaining your chainsaw is critical for ensuring its longevity and performance. However, it’s paramount that safety takes precedence during any maintenance activity. Here are fundamental safety tips and best practices you should adhere to when handling chainsaw maintenance:

- The importance of wearing appropriate protective equipment cannot be overstated. Before you begin any maintenance work on your chainsaw, ensure you’re equipped with gloves to safeguard your hands against sharp edges. Additionally, safety glasses are a must to protect your eyes from potential flying debris. These simple precautions can significantly reduce the risk of injury.

- Prior to performing any maintenance tasks, it’s crucial to verify that the chainsaw is completely powered off and has had sufficient time to cool down. This precautionary step is essential to prevent the risk of accidental starts, which could lead to injuries, and to avoid burns from handling components that may remain hot after use.

- Each chainsaw model comes with its own set of specifications and maintenance instructions. By adhering to the manufacturer’s guidelines, you ensure that you’re applying the correct maintenance procedures, which not only keeps your chainsaw in prime condition but also preserves any existing warranties. These guidelines are designed to help you understand your chainsaw’s requirements and avoid common maintenance mistakes.

- Like any power tool, chainsaws require regular inspections to ensure they remain in good working order. Make it a habit to give your chainsaw a thorough check-up regularly. Look for signs of wear, ensure that all parts are functioning correctly, and confirm that the chainsaw is clean and properly lubricated. If you encounter any issues that you’re not comfortable addressing on your own, or if the task requires specialized knowledge, seeking professional assistance is the best course of action. Professionals can provide the necessary repairs or maintenance, ensuring your chainsaw’s safety and reliability.

Related Articles:

- What is the Fuel Mixture for a STIHL Chainsaw?

- How To Replace Echo Chainsaw Chain: 15 Easy Steps

- Can a Chainsaw Chain Be Put on Backwards? How to Fix

- How To Switch From Winter Mode To Summer Mode: STIHL Hidden Feature

- How To Get A Chainsaw Unstuck? Expert Tips for a Quick Solution

- How To Use A Chainsaw Depth Gauge

FAQs

- Can I use vegetable oil as a lubricant for my chainsaw’s bar and chain?

While some users have experimented with vegetable oil as an eco-friendly alternative to petroleum-based oils, it’s essential to consult your chainsaw’s manual first. Some manufacturers may advise against it due to potential issues with viscosity, oil flow, and the risk of damage to the oil pump or oiler system, especially in colder weather. - How can I tell if my chainsaw chain is too tight or too loose?

A properly tensioned chain should snugly fit against the guide bar but still be able to rotate freely by hand (with gloves on and the chainsaw off). If the chain sags away from the bar or is difficult to move, adjustments are necessary. Too tight, and it risks breaking; too loose, and it could jump off the bar. - Is it necessary to sharpen the chainsaw’s chain after every use?

The frequency of sharpening depends on how much you use the chainsaw and what materials you’re cutting. If you notice the chainsaw is producing sawdust instead of chips, it’s a sign the chain needs sharpening. Regular inspection and maintenance will help determine the optimal sharpening schedule. - How often should I replace the spark plug in my chainsaw?

The spark plug’s condition can significantly affect your chainsaw’s performance. A general recommendation is to check the spark plug annually and replace it if it’s fouled, damaged, or after 100 hours of use, whichever comes first. Refer to your chainsaw’s manual for specific recommendations. - What’s the best way to store my chainsaw long-term?

For long-term storage, first, ensure your chainsaw is clean and dry. Drain the fuel tank and run the engine until it stops to clear remaining fuel from the carburetor. Remove the chain and bar, lightly oil them to prevent rust, and store them separately. Keep the chainsaw in a dry, cool place, away from direct sunlight. - Can dull chains increase the risk of chainsaw accidents?

Yes, using a dull chain can significantly increase the risk of kickback, one of the most common chainsaw accidents. A sharp chain cuts efficiently, while a dull chain requires more force, making the chainsaw harder to control and more likely to kick back. - Are there any signs that indicate my chainsaw’s air filter needs cleaning or replacing?

Signs that your chainsaw’s air filter may need attention include difficulty starting, a noticeable drop in power, and excessive fuel consumption. A dirty air filter restricts airflow to the engine, affecting performance. Regularly check and clean the air filter, and replace it as needed according to your chainsaw’s manual.

We hope this guide has helped you solve the tricky issue of a chainsaw that won’t properly oil its bar and chain. Remember, keeping your chainsaw in top shape is key to smooth, safe cutting adventures!

Got any chainsaw maintenance tips or stories of your own? We’d love to hear from you in the comments below. Your advice and experiences can really help out fellow chainsaw buffs, making our community a richer place.

Thanks for reading, and happy chainsawing! Keep those chains running smoothly and safely.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment