How To Sharpen A Chainsaw Properly: Tips and Tricks

- November 30, 2023

- 7 comment

Unlock the secrets of effective chainsaw chain sharpening with our in-depth guide. Learn the techniques that ensure a sharp, efficient cut every time. Chainsaw chain sharpening can often seem like a daunting task, especially for hobbyists and home users. However, understanding the basics of how a chain works and how to sharpen it effectively can transform even an old, worn-out chain into a cutting powerhouse. This guide will take you through the essential steps and techniques of how to sharpen a chainsaw chain like a pro.

Understanding Chainsaw Chains

Understanding the components of a chainsaw chain is essential for mastering chain sharpening. The chain comprises several cutting teeth, which are the primary focus during sharpening. These teeth need to be sharp for effective cutting, as they are responsible for slicing through wood fibers. Most of the cutting action occurs at the bottom of the chain, although the chain is designed to cut on both sides of the bar. This design allows for versatility in cutting directions and techniques.

The sharpness of the teeth is crucial; dull teeth not only make cutting more challenging but also increase the risk of accidents. Chainsaw chains come in various designs, each suited for different cutting tasks, and understanding these can help in selecting the right chain for specific jobs. Regular maintenance, which includes sharpening the teeth, ensuring proper chain tension, and checking the condition of the bar, is vital for the chainsaw’s effective operation and longevity. This comprehensive understanding of the chainsaw chain’s components and their functions enhances not only the efficiency of cutting tasks but also ensures safety during use.

The Art of Sharpening

Sharpening a chainsaw chain, initially a seemingly complex task, is in fact quite straightforward when understood and practiced with the correct tools and techniques. The art and basics of sharpening a chainsaw chain combine to form a crucial aspect of chainsaw maintenance.

The most effective and widely recommended method for sharpening is using a hand file, a technique favored by professionals for its precision. This approach allows for accurate and controlled sharpening of each tooth, ensuring effective and efficient cutting. A hand file is also gentle on the chain, removing just enough metal to create a sharp edge without shortening the chain’s lifespan, an important consideration for frequent users.

Selecting the correct file diameter is crucial. Chainsaw files typically come in sizes like 5/32 and 7/32 of an inch, designed to fit the curved bevel of the chainsaw’s cutter. Consulting the owner’s manual for specifics about your chainsaw’s chain and bar is advisable, or you can follow a tutorial to identify the correct chain. In cases of uncertainty, seeking professional advice from a servicing dealer is recommended.

The technique of filing involves aligning the file at the right angle and applying the correct amount of pressure, ensuring uniform filing of each tooth for balanced cutting performance. It’s essential to understand that filing changes the geometry of each cutter. Sharpening the beveled surface alters its relationship with the depth gauge (or raker), which limits the wood amount removed. After several sharpening sessions, it’s necessary to adjust the depth gauge to maintain efficient cutting. However, caution is needed to avoid over-filing the depth gauge, as this can lead to dangerous aggressiveness in cutting.

Mastering the art of sharpening a chainsaw chain lies in meticulous attention to detail and understanding the chain’s anatomy. This skill enhances the chainsaw’s performance and extends the life of the chain, making it an invaluable competency for professionals and frequent users alike. With practice, the process of sharpening becomes an integral part of efficient and safe chainsaw operation.

Equipment Required for Chainsaw Chain Sharpening and Maintenance

To effectively sharpen and maintain your chainsaw chain and bar, you will need specific tools and equipment. Here’s a list of the essential items:

- Hand File: For sharpening the teeth of the chainsaw chain. Ensure the file size matches the chain’s specifications.

- Flat File: Used for adjusting the height of the rakers or depth gauges on the chain.

- Filing Guide: This helps maintain the correct angle while sharpening the teeth. Some guides include markings for different angles.

- Depth Gauge Tool: A tool for measuring and setting the correct height of the rakers.

- Vise: To secure the chainsaw during sharpening, ensuring stability and safety.

- Gloves and Safety Glasses: Essential for personal protection during the sharpening process.

- Cleaning Brush or Cloth: For cleaning the chain and bar before and after sharpening.

- Bar Groove Cleaner: To clear debris and sawdust from the bar groove.

- Compressed Air or Pin (optional): For unclogging the oiler hole on the bar.

- Straight Edge or Level: For checking the straightness of the bar.

- Burr File or Metal File: For removing burrs from the edges of the bar.

- Lubricant (Chain Oil): For lubricating the chain after maintenance.

Each of these tools plays a specific role in the maintenance process, contributing to the overall effectiveness and safety of your chainsaw. Ensuring you have the right equipment on hand will make the maintenance process smoother and more efficient, helping to keep your chainsaw in top working condition.

Step-by-Step Sharpening Chainsaw Chain

Step 1: Sharpening the Teeth

Sharpening the teeth of your chainsaw is a critical skill for ensuring efficient and effective cutting. The key to this process is using the right tool and technique.

Choosing the Right Tool

The hand file stands out as the best tool for sharpening chainsaw teeth. Its advantages are manifold – it’s affordable, easily portable, and offers superior control and precision over electric grinders. With practice, a hand file can deliver exceptional results, preserving the integrity of the teeth while ensuring sharpness.

Securing the Chainsaw

Stability is crucial for effective sharpening. Secure your chainsaw in a vise. This stability is not just for safety; it also allows for more accurate and consistent sharpening as you work on the chain.

Finding the Angle

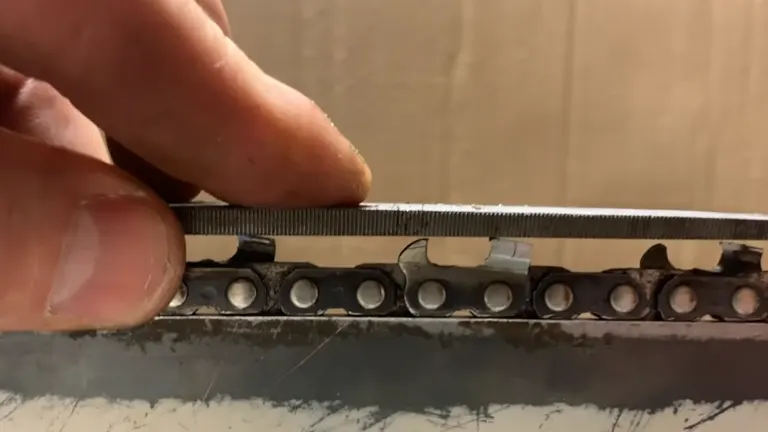

Accurate sharpening hinges on maintaining the correct angle. Most chainsaw chains feature a mark on each tooth, indicating the angle at which you should hold your file. Carefully align your file with this angle for each tooth. This alignment is crucial for ensuring that each tooth is sharpened effectively for optimal cutting performance.

The Sharpening Process

With the file at the correct angle, hold it firmly at both ends. Then, with consistent pressure, push it across the tooth, sharpening both the top and side edges. It’s important to work systematically – sharpen all the teeth on one side of the chain before switching to the other side. This methodical approach ensures you don’t miss any teeth and maintains a rhythm that can enhance the precision of your sharpening.

Consistency in Length

One of the key aspects of effective sharpening is ensuring that all teeth are of the same length. This uniformity is essential for balanced cutting. If some teeth are shorter than others, it can lead to uneven cutting and increased wear on the chain. Take the time to inspect each tooth after sharpening, ensuring they are of uniform length.

Step 2: Adjusting the Rakers

Once the teeth of your chainsaw chain are sharpened, the next crucial step is to adjust the rakers, also known as depth gauges. The rakers play a pivotal role in determining how deep the teeth cut into the wood. Proper adjustment of the rakers is essential for efficient and safe chainsaw operation.

Using a Flat File for Raker Adjustment

After sharpening the teeth, use a flat file to adjust the height of the rakers. This process requires a gentle touch, as removing too much material from the rakers can lead to the chain cutting too aggressively, which can be dangerous. Conversely, if too little is removed, the chain will cut inefficiently. Gently file the top of each raker, ensuring you maintain a consistent pressure and angle.

Measuring Raker Depth

The objective is to achieve the correct depth for your rakers, which is typically 0.6 mm (or 25 thousandths of an inch). To accurately measure this, use a special depth gauge tool designed for chainsaw chains. These tools are straightforward to use and take the guesswork out of the process, ensuring that each raker is filed to the correct height.

Testing and Adjusting

After adjusting the rakers, it’s a good practice to test the saw on a piece of wood. If the saw cuts efficiently without being overly aggressive, the rakers are likely set correctly. If the cut feels too shallow or the saw isn’t cutting as effectively as it should, some additional adjustments to the rakers may be necessary.

Consistency Across the Chain

Ensure that each raker is filed to the same height. Inconsistent raker heights can lead to uneven cutting and can place unnecessary strain on the chainsaw.

Step 3: Bar Maintenance

The final step in maintaining your chainsaw for peak performance involves careful attention to the bar. A chainsaw bar in good condition is crucial for the smooth operation of the chain and for effective cutting.

Rotating the Bar for Even Wear

Regularly rotating your chainsaw bar is a simple yet effective way to promote even wear. Each time you sharpen the chain or perform maintenance, flip the bar over. This practice balances the wear on both sides of the bar, extending its life and maintaining its performance.

Checking for and Removing Burrs

Over time and with regular use, the edges of your chainsaw bar can develop burrs. These small metal protrusions can impede the smooth movement of the chain around the bar. To check for burrs, run your fingers carefully along the edges of the bar. If you feel any roughness or small protrusions, use a flat file to gently smooth them down. This step ensures that the chain glides seamlessly around the bar, reducing wear on both the chain and the bar.

Ensuring the Bar’s Straightness

A bent or twisted bar can severely impact the performance of your chainsaw. It can lead to uneven cuts, increased wear on the chain, and can even be a safety hazard. Inspect the bar regularly for any signs of bending or twisting. Lay the bar on a flat surface to check for any warping. If you find that the bar is bent or twisted, it is essential to replace it. Continuing to use a damaged bar can lead to further complications and may potentially be dangerous.

Troubleshooting Common Issues

Troubleshooting common issues with a chainsaw is an essential skill for ensuring both the efficiency and safety of your cutting tasks. Here are some common problems and their likely causes:

Chain Not Cutting Straight

If you find that your chainsaw is not cutting in a straight line, the issue may lie in the uneven length of the teeth. When some teeth are longer or shorter than others, they can cause the chain to veer off to one side. Another possible cause of this issue could be a bent bar. A bar that’s not straight will affect the direction of the cut, making it difficult to maintain a straight line.

Chain Producing Only Sawdust

In a well-functioning chainsaw, the chain should produce small chips of wood. If you’re only seeing sawdust, this might indicate that the rakers (depth gauges) are set too high. When the rakers are too high, they limit the depth of the cut each tooth can make, resulting in fine sawdust instead of chips. Adjusting the height of the rakers can resolve this issue.

Overheating and Quick Dulling of the Chain

If you notice that your chainsaw is overheating and the chain is dulling more quickly than usual, the problem might be a clogged oiler hole in the bar. The oiler hole is responsible for delivering lubrication to the chain during operation. If it’s clogged, the chain won’t receive enough lubrication, leading to increased friction, overheating, and rapid dulling of the teeth. Cleaning the oiler hole and ensuring proper lubrication can help mitigate this problem.

Conclusion

Sharpening a chainsaw chain is a skill that can significantly enhance your cutting efficiency and prolong the life of your chain. By following these steps and understanding the mechanics of your chainsaw, you can ensure that your chainsaw remains a reliable tool for all your cutting needs. Remember, regular maintenance and proper sharpening techniques are the keys to keeping your chainsaw in top condition.

Looking for the Best Chainsaw Chains? Check it out Here! Best Top 5 Chainsaw Chains: A Hands-On Comparison

FAQs

- Can the type of wood I’m cutting affect how often I need to sharpen my chainsaw chain?

Absolutely! Softer woods like pine can cause the chain to become gummed up with resin, requiring more frequent cleaning and sharpening. Harder woods, on the other hand, can dull the teeth faster due to their density. - Is it possible to sharpen a chainsaw chain too much?

Yes, over-sharpening can occur. Each time you sharpen, you remove some of the metal from the teeth, which can eventually lead to reduced effectiveness and the need for a chain replacement. - How can I tell if my chainsaw chain is sharp enough?

A sharp chain will pull itself into the wood without much pressure and create large, even wood chips. If you’re exerting a lot of force or only getting fine sawdust, it’s likely time to sharpen. - Does the weather or temperature affect how I should sharpen my chainsaw chain?

Extreme temperatures can affect metal, so it’s important to ensure your chainsaw chain isn’t too hot or too cold when you sharpen it. Cold can make the metal brittle, and excessive heat can cause it to soften. - Can I use any file to sharpen my chainsaw chain, or does it need to be a specific type?

It’s important to use the correct size and type of file for your chain. The file size must match the chain’s pitch, and using the wrong file can damage the chain or lead to ineffective sharpening. - Is there a difference in sharpening technique for different types of chainsaw chains?

Yes, different chains, such as chisel chains and semi-chisel chains, have different tooth designs and may require slightly different sharpening angles and techniques. - How do I maintain the correct angle while sharpening each tooth?

Many sharpening kits come with guides that help maintain the correct angle. Consistency is key, so using a guide or jig can be very helpful, especially for beginners. - Can sharpening a chainsaw chain affect its balance?

If sharpening is done unevenly, it can cause the chain to become unbalanced, which can lead to uneven cutting and increased wear on the chainsaw.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

7 comments

Great information. I knew very little about adjusting the rakes on the chain. This article was very helpful. I'm a 40 year veteran using a saw and never adjusted the rakes. Many thanks.

Tony Pegues

December 4, 2023 9:06 pmBrilliant,new tips and tricks keep it going

Scott Sippel

December 4, 2023 5:55 pmVery helpful

John Windeatt

December 3, 2023 9:10 pmVery interesting to read . I have used and sharpened chainsaws for over 50 years. However I have probably never done it quite right obviously. I will try some of the points raised and no doubt my chains will cut better and last longer.

Mike Smith

December 3, 2023 2:50 pmDo you push the file across the tooth from the inside pushing out, or from the outside pushing in? And do you twist the file while pushing?

Michael Helvey

December 3, 2023 2:31 pmWow, great info! I’ve been running saws for 40+ years and learned to sharpen my own chains early on. Each and every item you discuss here is crucial and a sharp chain is not only more effective but much safer! I run Huskies and use a jig to ensure correct angles; saves time and money to touch up the chains with each use! Thanks for this awesome info!

Thank yoy for the info. I'm new to the chainsaw world therefore please excuse me if the following question is irrelevant. Can a chainsaw be used to cut dry wood?

Louis

December 5, 2023 10:52 am