Understanding the LA Setting on STIHL Chainsaws

- February 14, 2024

- 12 comment

When it comes to maintaining and optimizing handheld equipment, especially those as indispensable as chainsaws, understanding the nuances of their operation is crucial. A common point of curiosity and sometimes confusion among users revolves around a small but significant detail found on the carburetor of these machines: a screw labeled “LA.” This feature is not exclusive to chainsaws but is a standard component across all Stihl equipment, a renowned brand originating from Germany.

The Meaning of LA on a STIHL Chainsaw

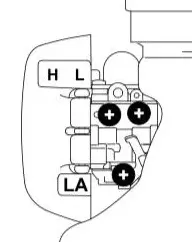

The “LA” marking stands for “Leerlauf Anschlag,” a German phrase that translates to “idle stop” in English. This designation is straightforward yet essential, providing insight into the function of this adjustment screw. Unlike the “L” (Leerlauf, meaning Idle) and “H” (Hauptdüse, meaning Main Jet) mixture screws that are concerned with fuel mixture ratios at different engine speeds, the LA screw serves a more singular purpose.

The Role of the LA Screw: Managing Idle Speed

The primary function of the LA screw is to regulate the engine’s idle speed. By adjusting this screw, users can increase or decrease the revolutions per minute (RPMs) of the engine when it is idling. This adjustment is vital for ensuring the engine runs smoothly when not actively cutting, preventing it from stalling or running too fast, which could lead to unnecessary wear or even pose a safety risk.

Practical Application: Adjusting Your Idle Stop

Adjusting the LA screw is a task that can significantly impact the performance and longevity of your Stihl equipment. To optimize idle speed, a slight adjustment to the LA screw may be required, depending on the machine’s behavior. If the engine stalls when idling, a clockwise turn (to increase RPMs) might be necessary. Conversely, if the engine runs too fast at idle, potentially engaging the chain or cutting tool, a counter-clockwise adjustment (to decrease RPMs) will lower the idle speed to a safer, more appropriate level.

Adjusting Carburetor on a STIHL Chainsaw

Adjusting the carburetor of your equipment is a crucial step in ensuring optimal performance and efficiency. The factory sets the carburetor with standard settings to achieve the best possible air-fuel mixture for most conditions. However, the high-speed screw (H) offers some room for adjustment, albeit within fine limits, to cater to specific operating conditions or changes in altitude.

The standard procedure for adjusting your carburetor begins with stopping the engine and attaching the cutting tool. It’s also essential to check the air filter and replace it if necessary, and ensure the spark arrestor is checked by a professional dealer. To adjust, you’ll need to turn the high-speed screw (H) counterclockwise until it stops and then dial it back by 3/4 of a turn. Similarly, adjust the low-speed screw (L) by turning it clockwise until it stops, then back it off by 1.5 turns. After these adjustments, start the engine, allowing it to warm up if necessary, and use the idle speed screw (LA) to ensure the cutting attachment remains stationary when the engine idles.

Fine-tuning might be required to achieve satisfactory engine power or to adapt to operating at different altitudes or with various cutting attachments. If you notice that engine power is lacking or if you’re working in conditions significantly different from sea level, slight corrections to the high-speed screw (H) can be made. A general rule of thumb for these adjustments is to alter the high-speed screw by about 1/4 turn for every 1000 meters (approximately 3300 feet) of altitude change. This adjustment is particularly relevant when using a mowing head with full-length cutting lines or a metal cutting attachment. Before making these adjustments, it’s advisable to warm up the engine for about three minutes at wide-open throttle.

For operations at high altitudes, turning the high-speed screw (H) clockwise will lean the mixture, enhancing the engine’s speed until no further noticeable increase can be achieved. Conversely, at sea level, turning the high-speed screw (H) counterclockwise enriches the mixture until reaching the optimal engine speed. It’s crucial to ensure that these adjustments do not push the engine beyond its maximum speed, which can be safely maintained with the standard settings under typical conditions.

Maintenance Tips for Stihl Equipment

Maintaining your Stihl equipment is crucial for ensuring its longevity and optimal performance. Regular care not only keeps your tools running efficiently but also safeguards your investment. Here are some essential maintenance tips, including the role of the LA screw adjustment in your overall equipment care routine:

- After each use, clean your equipment to remove dirt, debris, and sawdust. This prevents buildup that can impair performance and cause overheating.

- Keep the chain sharp for better cutting efficiency. A dull chain makes your work harder and can strain the engine. Replace the chain when necessary to maintain optimal cutting performance.

- Regularly check and clean the air filter, especially if you’re working in dusty conditions. A clean air filter ensures proper air flow, which is critical for the engine’s performance and longevity.

- Use the correct fuel-oil mix as recommended by Stihl for your equipment. Store fuel in a clean, airtight container and avoid storing it for more than a month to prevent fuel degradation.

- Check the spark plug periodically for signs of wear or fouling and replace it as needed. A properly functioning spark plug is essential for starting and running your equipment smoothly.

- The LA screw, which controls the idle speed, should be checked and adjusted regularly as part of your maintenance routine. Proper idle speed prevents the equipment from stalling and ensures it’s ready to perform when you need it. Adjustment of the LA screw is a simple process that keeps your engine running smoothly at idle, reducing wear and tear on the engine.

Conclusion: The Importance of Understanding Your Equipment

For enthusiasts, professionals, and casual users of Stihl equipment alike, knowing how to properly adjust the LA screw is a small but critical aspect of maintenance that ensures safety, efficiency, and the durability of your tools. This seemingly minor detail underscores the importance of understanding the intricacies of your equipment, enabling you to maintain optimal performance and extend the lifespan of your investments. Remember, a well-maintained machine is a reliable partner in your work, and knowledge of its components is key to achieving that reliability.

Related Articles:

- How To Clean A Chainsaw Chain: Easy Care and Maintenance

- Best Bar and Chain for Cutting Notches?

- How STIHL Chainsaw Protective Chaps Work

- What You Need to Know About Chainsaw Chain Brakes

- How To Fix A Chainsaw If It Won’t Oil The Bar And Chain

- What Size Chainsaw Do I Need?

FAQs

- What does the LA screw do?

The LA screw adjusts the idle speed of your Stihl equipment. It controls how fast the engine runs when it’s not cutting, ensuring the engine doesn’t stall or run too high, which could engage the chain. - How often should I adjust the LA screw?

You should check the idle speed of your equipment regularly and adjust the LA screw as needed. This might be necessary after replacing parts, cleaning the equipment, or noticing changes in idle performance. - Can improper adjustment of the LA screw damage my equipment?

Yes, incorrect idle speed can lead to engine problems. Too low an idle can cause the engine to stall, while too high an idle might engage the chain or cutting tool unexpectedly, posing a safety risk. - Do I need special tools to adjust the LA screw?

Typically, a small flathead or Phillips screwdriver is all you need to adjust the LA screw. Check your user manual for the specific tool required for your model. - Can I adjust the LA screw while the equipment is running?

Yes, the LA screw is meant to be adjusted while the engine is running at idle. Ensure the equipment is stable and that you’re wearing protective gear during adjustment. - What’s the sign that I’ve correctly adjusted the LA screw?

The engine should run smoothly at idle without stalling, and the chain or tool should not move. If the engine transitions smoothly from idle to full speed without hesitation, the LA screw is correctly adjusted.

Got tips, questions, or stories about maintaining your Stihl equipment? Whether you’re a seasoned pro or just starting out, we’d love to hear from you! Your experiences can help others, and we’re all about sharing knowledge and tips to keep our tools in top shape.

Drop a comment below to share your insights or ask a question. Found a clever way to adjust the LA screw? Stumbled upon a maintenance hack? Let’s make this space a cozy corner for all things Stihl, where we can learn from each other and enjoy our passion for great equipment.

Join the conversation and let’s grow together as a community!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

12 comments

Thanks for info. Question.... I use my Stihl infrequently. Once had to get shop to start it. Said the "carb" was dry. To start my Seadoos after sitting, I have to add a bottle cap of gas. How much should I add to my saw for a seasonal start up ? THANKS !

Charles Chambers

February 17, 2024 11:17 pmGood information on carb adjustment for Stihl saws. Thanks!

Gerald

February 17, 2024 10:48 pmI purchased a 250Stihl approximately 1.5 years ago. I started having trouble starting it the first time I used it. I place it in a case, then in my Argo . When i start using it, it will not start. My friend has a 250 and has no problems with his. Another guy has the same problem as me. I have returned to the dealer several times in regards to my problem. They have to pull it about 20 times to get it started. Is it flooding or just not working properly. This occurs on a regular basis after I transport the saw

George

February 17, 2024 5:53 pmbuy a new carb and fuel line there both very cheap cheap Im sure that will fix it good luck fellow woodsman

I have used saws for a while. Fire wood for back yard and on the quad incase a tree is down across a trail. No expert by any means. I learned that when saw is at idle if the chain is moving a bit its not just possibly your idle speed. Could be warn out clutch springs. Wich im getting replaced as i post this.

Chris

February 17, 2024 1:39 pmOr possibly your chain could be loose and in need of tightening. I have noticed that the saws I use almost daily when the chain gets to loose it will seem like it idles high causing the chain to engage. The only way to stop the chain from spinning is either set the brake or tighten bar and chain.

Billy

February 21, 2024 12:16 pmJust a note about the incredible longevity and reliability of Stihl. My 1987 AV Super Woodboss still going strong with only routine maintenance. Probably felled and cleaned up 1500 trees mostly hardwoods! Impressive!

Mike Petersen

February 16, 2024 9:39 pmMy Stihl chainsaw is very hard to start the first time after that it starts on the first pull. I'm not sure if the prime button is working or not.

Stan Knight

February 15, 2024 9:35 pmWhat is the correct octane fuel to be used in stihl chainsaws? What is the maximum?

Don ahlemeyer

February 15, 2024 5:51 pmGreat explanation, I didn't know that information, people should know about winter and summer mode switching, I just learned that recently, thanks, Dan

Daniel Webster

February 15, 2024 10:35 amThanks Dan!, you might want to read this article about conditions under summer and winter—When to Replace Your Chainsaw Chain.

Why don't we just use the word "idle" on the saw. The saws would be sold to MORE NON German speaking countries than German speaking countries.

Bruce G Tough

February 23, 2024 1:23 am