When to Replace Your Chainsaw Chain: Key Indicators and Tips

- February 15, 2024

- 2 comment

Chainsaws are indispensable tools for anyone involved in wood cutting, forestry, landscaping, or even general property maintenance. However, like any tool, they require regular maintenance and, at times, part replacements to ensure they operate efficiently and safely. One of the most critical components that need periodic replacement is the chainsaw chain. Knowing when to replace your chainsaw chain is essential for keeping your cutting tasks effective and safe. Here are key indicators and tips drawn from extensive experience and practical insights.

Understanding Chainsaw Chain Wear

The lifespan of a chainsaw chain can vary significantly based on several factors, including the type of wood you’re cutting, the conditions under which you’re cutting (e.g., winter vs. summer), and whether the wood has been contaminated with materials like mud or rocks. For example, cutting wood that has rocks embedded in its bark will dull a chain much faster than cutting clean, green wood.

An experienced woodcutter might go through 15 to 20 chains a year, indicating just how variable chain life can be. It’s also worth noting that different cutting conditions, such as tall grass or deep snow, can increase the risk of chain damage.

Key Indicators That It’s Time to Replace Your Chainsaw Chain

1. Worn Teeth and Excessive Deterioration

The clearest indication that your chainsaw chain needs replacement is noticeably worn-down teeth. Designed for efficiency, chainsaw chains feature sharp, defined teeth for optimal cutting. Once these teeth are reduced to mere nubs, your chain’s ability to effectively engage and cut through wood diminishes, leading to decreased productivity and increased effort.

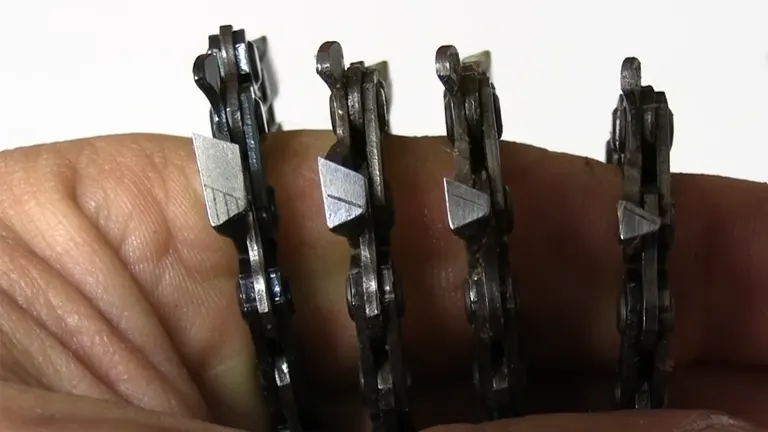

2. Disparity in Teeth Length

Frequent sharpening can lead to uneven tooth lengths across the chain. When you observe a significant variance, with some teeth considerably shorter than others, this uneven wear not only compromises the chain’s cutting performance but also signals the need for a replacement. Uniform tooth length is critical for balanced, effective cutting.

3. Challenges in Cutting Performance

An optimal chain will seamlessly draw itself into the wood, facilitating a smooth cutting process. If cutting becomes laborious, requiring extra force to push the chainsaw through the material, or if the saw generates more fine sawdust than larger wood chips, it’s a sign your chain may be dull or overly worn. This inefficiency can slow down your work and increase the physical strain on both the operator and the chainsaw.

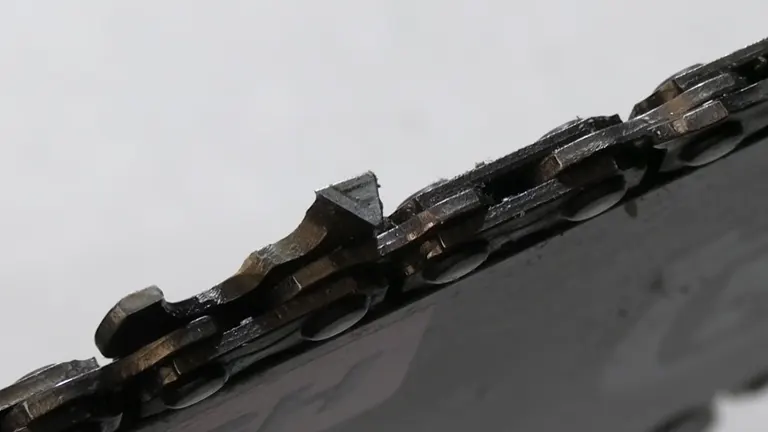

4. Visible Chain Damage

Encountering hard materials such as rocks, metal, or even dirt can severely damage your chain, leading to worn, bent, or broken teeth and compromised chain links. Such damage not only affects the chain’s functionality but also poses a safety risk. In most cases, replacing a damaged chain is more economical and safer than attempting repairs, ensuring your chainsaw operates reliably and efficiently.

5. Chain Elongation

With regular use, a chainsaw chain can stretch due to the mechanical stress of cutting and the heat generated from operation. A telltale sign of an overstretched chain is its inability to be properly tensioned using the chainsaw’s built-in adjustment features. If the chain hangs loosely on the bar or slips easily, indicating it has reached its tension limit, a replacement is due to maintain optimal performance and safety.

Environmental Considerations for Chainsaw Chain Disposal and Recycling

Integrating environmental responsibility into the lifecycle of a chainsaw chain not only addresses the practical aspects of maintenance and replacement but also aligns with a growing commitment to sustainability among readers. As chainsaw chains are primarily made of metal, it’s paramount to avoid disposing of them in regular household waste to prevent environmental contamination and the squandering of valuable resources. Recycling becomes a crucial step in this process, where old chains can be taken to local recycling centers to ensure the metal is repurposed, reducing landfill waste and supporting the circular economy. Additionally, some chainsaw manufacturers may offer take-back programs, rewarding customers for recycling old chains with discounts on future purchases, thereby promoting a cycle of responsible consumption and waste management.

For the creatively inclined, repurposing or ‘upcycling’ old chainsaw chains into art, tools, or jewelry presents an innovative way to extend the life of these materials beyond their intended use. This not only diverts waste from landfills but also adds value through new creations. Community initiatives, such as organized clean-up events, can further reinforce the importance of recycling and responsible disposal, fostering a collective effort toward environmental stewardship. Highlighting the negative impact of improper metal disposal, such as soil and water pollution, underscores the broader environmental implications of our choices and can motivate readers to adopt more sustainable practices. By addressing these environmental considerations, the article transcends its immediate subject, framing chainsaw chain replacement within a larger narrative of ecological responsibility and sustainable living.

Tips for Replacing Your Chainsaw Chain

- The key to optimal chainsaw performance begins with choosing the correct chain. It’s imperative to match the chain to your saw’s specific requirements, including gauge, pitch, and the exact number of drive links. Incorrectly matched chains not only hinder performance but can also pose significant safety risks. Refer to your saw’s manual or consult with a professional to ensure you’re making the right choice.

- Consistent inspection of your chainsaw chain is crucial for identifying wear, damage, or stretching at early stages. By catching these issues promptly, you can mitigate further damage to your chainsaw, ensuring that it remains a reliable and efficient tool for your cutting needs. This proactive approach to maintenance helps extend the lifespan of both your chain and the chainsaw itself.

- Regular sharpening is essential to maintain your chain’s cutting edge, literally. With proper technique, a chain can be sharpened between six to ten times before it requires replacement. Sharpening must be done with precision to prevent uneven wear, which can diminish the chain’s effectiveness. Investing time in learning the correct sharpening methods will pay dividends in the longevity and performance of your chainsaw chain.

- The durability of your chainsaw chain can greatly vary based on the materials you’re cutting and the environmental conditions. For instance, cutting clean, softwood under ideal circumstances puts less strain on the chain compared to working with dirty, hardwood or operating in challenging conditions. Adjust your maintenance and replacement schedule according to the demands of your cutting tasks to optimize chain lifespan.

- When it comes time to replace your chainsaw chain, safety should be your foremost concern. Always wear protective gloves to guard against the chain’s sharp edges. Before performing any maintenance or replacement tasks, ensure that the chainsaw is completely powered off and has had time to cool down. This preventive measure safeguards against accidental starts and potential burns from a hot engine, ensuring a safe maintenance environment.

Conclusion

Replacing your chainsaw chain at the right time is crucial for maintaining the efficiency, effectiveness, and safety of your cutting tasks. By paying attention to the key indicators of wear and following the tips for replacement, you can ensure that your chainsaw remains a valuable asset in your tool arsenal. Remember, a well-maintained chainsaw is not only more efficient but also safer to use.

FAQs

- Can I use any chain brand on my chainsaw, or should it be specific to the chainsaw brand?

While many chains can be cross-compatible across different chainsaw brands, it’s crucial to select a chain that matches your saw’s specific requirements for gauge, pitch, and length. Using the wrong chain can lead to poor performance, increased wear on the chainsaw, or dangerous situations. It’s often best to consult your chainsaw’s manual or a professional to ensure compatibility. - How can I tell if my chainsaw chain is stretched beyond usable limits?

A stretched chain will sag or hang loose on the guide bar, and you won’t be able to tighten it using the chainsaw’s adjustment mechanism. Additionally, a stretched chain may skip or come off the bar during operation, which can be dangerous. - Is it better to sharpen my chainsaw chain or just replace it when it becomes dull?

Sharpening your chainsaw chain is cost-effective and can extend its life, provided that the teeth are not too worn or damaged. Generally, a chain can be sharpened multiple times before it needs to be replaced. However, if the chain is severely damaged, excessively worn, or has uneven tooth wear, replacing it is the better option. - How often should I replace my chainsaw chain?

The frequency of chain replacement depends on how often and under what conditions you use your chainsaw. Heavy users cutting in dirty conditions may need to replace their chains several times a year, while occasional users might only need to replace their chains every few years. Monitor your chain’s condition and performance regularly to determine when a replacement is needed. - Can hitting a single rock really ruin my chainsaw chain?

Yes, hitting a rock, metal, or other hard materials can cause immediate damage to the teeth of your chainsaw chain, making it dull or even breaking the teeth. While some damage can be repaired with sharpening, severe damage often necessitates chain replacement. - How do I dispose of an old chainsaw chain responsibly?

Since chainsaw chains are made of metal, they can be recycled at a local metal recycling facility. Avoid throwing them in the trash due to their potential to harm wildlife and the environment. Some chainsaw retailers or repair shops also offer recycling programs. - Can a new chainsaw chain affect the performance of my chainsaw?

Absolutely! Installing a new chain can significantly improve your chainsaw’s cutting efficiency, reduce the effort required to cut through wood, and enhance the overall safety of your cutting operations. A new chain ensures that your chainsaw operates at its peak performance. - Is there a way to extend the life of my chainsaw chain?

Yes, proper maintenance can extend the life of your chain. This includes regular sharpening, ensuring your chainsaw has the correct tension, using the chainsaw for appropriate tasks (avoiding dirt and rocks), and storing the chain and saw properly when not in use. Additionally, flipping your guide bar at regular intervals can promote even wear, further extending the life of your chain.

We hope this guide has armed you with the knowledge you need to keep your chainsaw in top-notch condition. But we know that real wisdom often comes from shared experiences. Have you encountered any telltale signs it was time to change your chain? Maybe you’ve got a tip or two on maintaining your chainsaw chain we didn’t cover.

Whatever your story or question, we’d love to hear from you! Drop us a comment below, share your thoughts, and let’s keep the conversation going. Sharing is caring, and your insights might just be the nugget of wisdom someone else needs. Don’t forget to share this article with fellow chainsaw enthusiasts – let’s spread the knowledge and keep our cutting tools in their best shape, together!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

2 comments

totally useful to me.

I have been using chainsaws all my life but you covered some things I never knew.thanks

Armando Villarreal

February 20, 2024 4:25 am