Fronius TransSteel 2200 MIG/TIG Welder Review

- January 4, 2024

- 0 comment

I recently acquired the Fronius TransSteel 2200, a MIG/TIG welding machine poised to revolutionize the welding industry. In this review, I’ll provide insights from my firsthand experiences, explore its features in detail, assess performance metrics, and guide you in determining whether it suits your specific welding requirements.

Brief Specifications

- Mains Voltage: 230V / 120V

- Mains Voltage Tolerance: -20% / +15%

- Mains Frequency: 50-60Hz

- Welding Current: Min: 10 A – Max: 230 A

- Welding Current / Duty Cycle [10min/40°C]: 230A / 35% TIG – 170A / 60% MIG

- Operating Voltage Min.: 14.5 V

- Open-Circuit Voltage: 90 V

- Protection Class: IP23

- Dimensions: Length: 1.84 ft x Width: 8.46 in x Height: 1.21 ft

- Weight: 34.17 lbs

Overview of the Fronius TransSteel 2200

The Fronius TransSteel 2200 stands out as a versatile and reliable multi-process welding machine, seamlessly accommodating both MIG and TIG welding methods. From the moment it’s unboxed, the TransSteel 2200 leaves a lasting impression with its robust construction, indicative of Fronius’s commitment to quality.

The machine’s sleek design not only adds an aesthetic touch but also underscores the meticulous attention to detail that Fronius, as a reputable brand, is recognized for. This welding powerhouse is not only about functionality but also about a combination of durability and style, making it a compelling choice for welders seeking a tool that not only performs exceptionally but also looks the part.

Key Features:

- Multi-Process Capability: The TransSteel 2200 supports both MIG and TIG welding processes, providing versatility for a wide range of welding applications.

- Synergic MIG/MAG Modes: The machine features synergic MIG/MAG modes, automatically optimizing welding parameters to achieve high-quality welds with minimal spatter.

- Seamless Transition Between Processes: With the ability to seamlessly switch between MIG and TIG processes, the TransSteel 2200 offers unparalleled flexibility for different welding requirements.

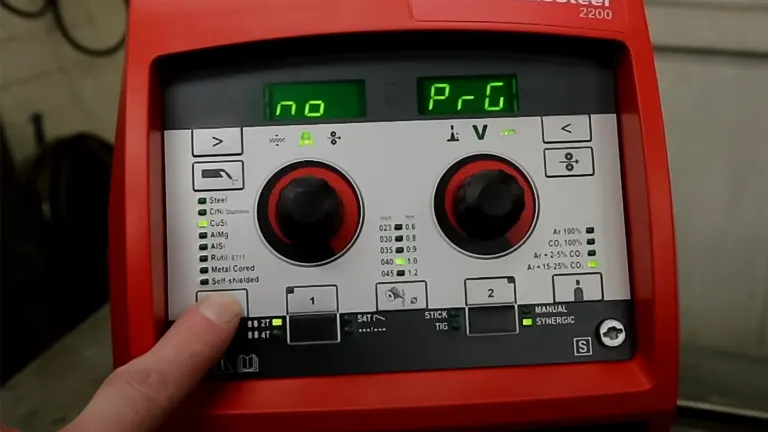

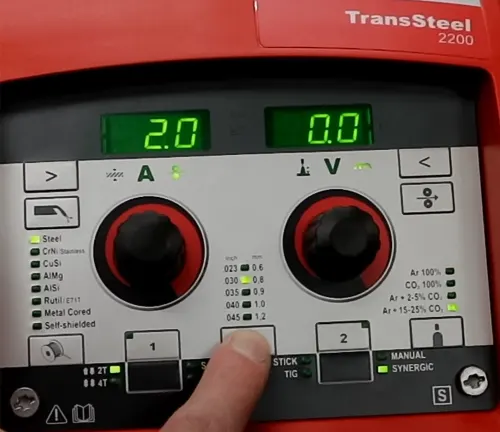

- Intuitive User Interface: The user interface is designed for ease of use, featuring a color display that provides clear information and simple menu navigation for adjusting settings.

- Quick-Change Torch System: Enhancing efficiency, the quick-change torch system allows for swift transitions between different welding tasks without compromising on performance.

- Robust Build Quality: The welding machine boasts a robust construction, ensuring durability and reliability even in demanding welding environments.

- Impressive Welding Speed: The TransSteel 2200 delivers a remarkable welding speed, reducing downtime and allowing for the completion of projects promptly.

- High Duty Cycle: With a high duty cycle, the machine maintains consistent performance during prolonged welding sessions, minimizing the risk of overheating.

- Wide Range of Welding Currents: Supporting a welding current range from 10 A to 230 A, the TransSteel 2200 caters to various welding needs, from intricate work to heavy-duty applications.

- Compact and Portable Design: Despite its powerful capabilities, the machine features compact dimensions and a manageable weight of 34.17 lbs, ensuring portability and ease of transport to different job sites.

Build Quality and Visual Appeal

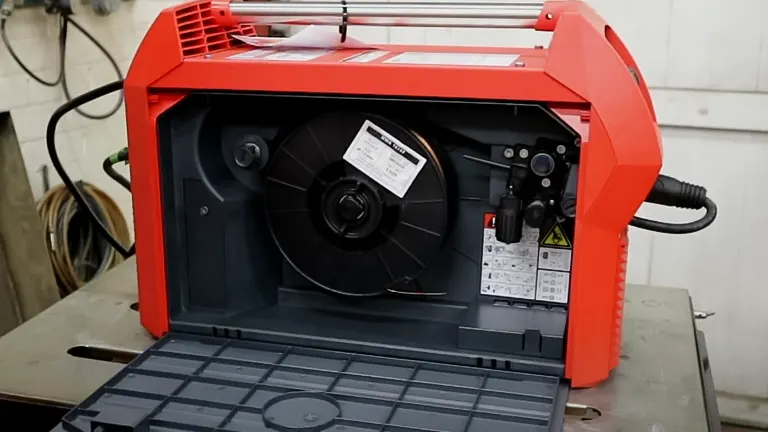

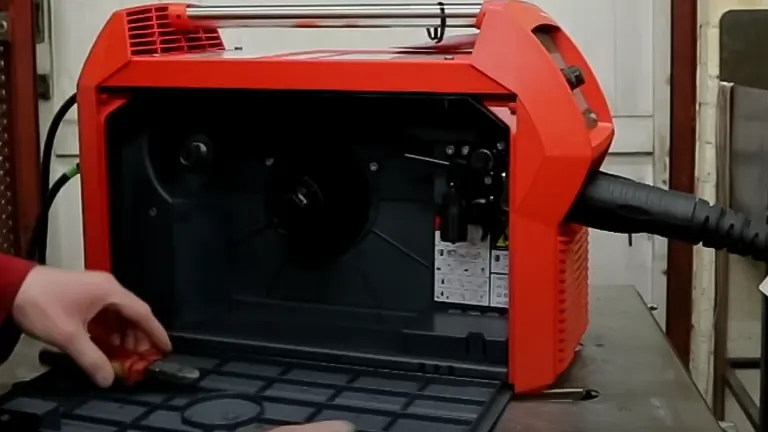

The Fronius TransSteel 2200 excels in both build quality and visual appeal, making it a standout choice for welders who value durability and aesthetics in their equipment. The machine’s robust construction is immediately evident upon inspection. Built with high-quality materials, it exudes a sense of durability that instills confidence in its ability to withstand the rigors of demanding welding environments.

The sturdy chassis and components contribute to a machine that not only performs exceptionally but also endures the challenges presented by heavy-duty welding tasks. The attention to detail in the build quality is apparent, reflecting Fronius’s commitment to manufacturing welding equipment that goes beyond functionality to deliver a reliable and long-lasting tool for professionals.

In addition to its impressive build, the Fronius TransSteel 2200 boasts a sleek and modern design that enhances its visual appeal. The thoughtful design elements not only contribute to the machine’s aesthetics but also serve practical purposes, such as efficient heat dissipation and user-friendly features. The color display on the user interface provides a modern touch, offering clear visibility of welding parameters and settings.

The compact and well-organized layout adds to the overall visual appeal, making the TransSteel 2200 not just a tool but a piece of equipment that welders can take pride in using. Whether in a workshop or on a job site, the combination of robust build quality and contemporary design makes the Fronius TransSteel 2200 a top choice for welders who appreciate a balance of durability and visual sophistication in their welding equipment.

Performance Metrics

- Welding Speed and Efficiency 10/10: With an impressive welding speed, the TransSteel 2200 minimizes downtime, allowing me to complete projects swiftly. The synergic MIG/MAG modes optimize welding parameters automatically, resulting in high-quality welds with minimal spatter.

- Versatility 9.5/10: One of the standout features is its ability to seamlessly transition between MIG and TIG processes. Whether I’m working on heavy structural steel with MIG or intricate stainless steel with TIG, the machine adapts effortlessly, showcasing its versatility.

- User-Friendliness 9/10: The user interface is intuitive, even for those new to welding. The color display provides clear information, and the simple menu navigation makes adjusting settings a breeze. The quick-change torch system further enhances user convenience.

- Power and Duty Cycle 10/10: The TransSteel 2200 boasts a commendable power output, making it suitable for various applications. The high-duty cycle ensures sustained performance even during prolonged welding sessions, reducing the risk of overheating.

What Sets Apart

What sets the Fronius TransSteel 2200 apart is its exceptional combination of versatility and user-friendly features. Unlike traditional welding machines, this model seamlessly integrates both MIG and TIG processes, providing a comprehensive solution for various welding needs. The quick-change torch system is a standout feature that distinguishes it from competitors.

This innovation enables welders to transition between different welding tasks effortlessly, saving valuable time and enhancing overall productivity. The intuitive user interface, complete with a color display, adds another layer of distinction. The machine’s design prioritizes ease of operation, making it accessible to welders of all experience levels.

This amalgamation of advanced functionalities and user-centric design sets the TransSteel 2200 apart as a top-tier welding machine in the market. Furthermore, the robust build quality of the TransSteel 2200 reinforces its position as an industry leader. The durability of the machine is evident in its construction, ensuring reliable performance even in demanding work environments.

The welding speed and high duty cycle contribute to its exceptional performance, allowing users to tackle projects with efficiency and precision. The TransSteel 2200’s ability to strike a balance between power and finesse, coupled with its innovative features, firmly establishes it as a standout choice for welders seeking a reliable, versatile, and durable welding machine that goes beyond conventional capabilities.

Visual Assessment

The Fronius TransSteel 2200 makes a striking visual impression with its sleek and modern design, marrying functionality with aesthetic appeal. The machine’s thoughtfully laid-out interface, featuring a vibrant color display, not only adds a contemporary touch but also enhances user experience. The compact and well-organized layout of controls contributes to an overall visually pleasing appearance.

Beyond its exterior, the robust build quality is evident, instilling a sense of durability and reliability. The combination of visual sophistication and practical design makes the TransSteel 2200 a standout in the welding equipment landscape, embodying Fronius’s commitment to delivering tools that not only perform exceptionally but also reflect a high standard of craftsmanship.

Comparative Analysis and Consideration

In comparing the Fronius TransSteel 2200 MIG/TIG Welding Machine with the MATRIX 2200 HF TIG/ARC Welding Machine, several key factors come into play. Firstly, the TransSteel 2200’s standout feature is its multi-process capabilities, accommodating both MIG and TIG welding techniques seamlessly. This versatility makes it a compelling choice for welders who require flexibility in their projects.

On the other hand, the MATRIX 2200 HF focuses primarily on TIG and ARC welding, offering precision and control in these specific processes. The decision between the two would hinge on the user’s specific welding needs; if a broad range of applications is anticipated, the TransSteel 2200 might be more suitable, while the MATRIX 2200 HF would be preferred for those primarily engaging in TIG and ARC welding.

Secondly, the user interfaces of both machines play a crucial role in the comparative analysis. The TransSteel 2200 boasts an intuitive interface with a color display, ensuring ease of use for welders of varying skill levels. This is particularly advantageous for those who value a straightforward operating experience.

On the other hand, the MATRIX 2200 HF may cater to users who prefer a more intricate control system, potentially offering more detailed adjustments for TIG and ARC welding enthusiasts. Ultimately, the choice between these two welding machines depends on the user’s specific requirements, weighing the importance of multi-process capabilities, user interface preferences, and the nuances of welding techniques they engage in most frequently.

Table of Comparison vs. Competitive

Here’s a simplified comparison table for the Fronius TransSteel 2200 MIG/TIG Welding Machine and the MATRIX 2200 HF TIG/ARC Welding Machine:

| Feature | Fronius TransSteel 2200 | MATRIX 2200 HF |

|---|---|---|

| Welding Processes | MIG, TIG | TIG, ARC |

| Multi-Process Capabilities | Yes | Limited to TIG and ARC |

| Quick-Change Torch System | Yes | Feature may vary |

| User Interface | Intuitive with Color Display | May offer intricate controls |

| Versatility | Broad range of applications | Primarily TIG and ARC welding |

| Build Quality | Robust and durable | Quality build for precision work |

| Welding Speed and Duty Cycle | Impressive for various applications | Optimized for TIG and ARC welding |

| Application Focus | Versatile applications | TIG and ARC welding |

| Weight and Portability | Compact and portable design | Varies depending on the model |

Pros and Cons

Pros

- Versatile Multi-Process Capabilities (MIG/TIG): The TransSteel 2200 supports both MIG and TIG welding processes, providing versatility for various welding applications.

- Intuitive User Interface for Easy Operation: The machine features an easy-to-use interface with a color display, ensuring a user-friendly experience for both beginners and experienced welders.

- Quick-Change Torch System Enhances Efficiency: Equipped with a quick-change torch system, the TransSteel 2200 facilitates swift transitions between different welding tasks, optimizing workflow efficiency.

- Robust Build Quality Ensures Durability: With a durable construction and high-quality materials, the machine is built to withstand the rigors of demanding welding environments, ensuring long-lasting performance.

- Impressive Welding Speed and High Duty Cycle: The TransSteel 2200 delivers exceptional welding speed and a high duty cycle, allowing for efficient completion of projects and sustained performance during extended welding sessions.

Cons

- Initial Cost May Be Higher Compared to Some Competitors: While the TransSteel 2200 offers advanced features, the initial investment could be comparatively higher than some competing welding machines. However, the long-term benefits often justify the upfront cost.

- Some Users May Find the Interface Overwhelming Initially: The feature-rich interface, though intuitive, may be overwhelming for users new to the machine. However, with familiarization, it becomes a powerful tool for precise control over welding parameters.

Suggested Applications

The Fronius TransSteel 2200 MIG/TIG Welding Machine proves its worth across a spectrum of welding applications. Its versatile nature makes it an ideal choice for both professional welders and enthusiasts. For heavy-duty tasks, such as structural welding, the machine’s robust build and high welding currents deliver exceptional results. In intricate and precise welding work, its ability to handle low welding currents starting from 10 A ensures finesse.

The seamless transition between MIG and TIG processes caters to diverse welding needs, from automotive repairs to stainless steel fabrication. Its portability, coupled with a quick-change torch system, makes it suitable for on-site projects. Whether you’re working with thick materials or require precision in your welds, the TransSteel 2200 emerges as a reliable companion, showcasing its adaptability across a myriad of welding applications.

Final Conclusion

Having extensively used the Fronius TransSteel 2200, I can confidently say it’s a welding powerhouse that caters to the diverse needs of both amateur enthusiasts and professional welders. Its versatility, efficiency, and user-friendly design make it a top choice for those looking to invest in a high-performance welding machine. While the initial cost may be a consideration, the long-term benefits and superior performance justify the investment. If you’re seeking a welding companion that excels in both MIG and TIG applications, the Fronius TransSteel 2200 should be at the top of your list.

Frequently Asked Questions

- What welding processes does the Fronius TransSteel 2200 support?

The TransSteel 2200 is a multi-process welding machine that supports both MIG and TIG welding techniques. - Is the user interface beginner-friendly?

Yes, the machine features an intuitive user interface with a color display, designed to facilitate easy operation for both novice and experienced welders. - How quickly can I switch between MIG and TIG processes?

The TransSteel 2200 allows for seamless transitions between MIG and TIG processes, providing versatility without significant downtime. - Does it come with a quick-change torch system?

Yes, the welding machine is equipped with a quick-change torch system, enhancing efficiency by allowing users to switch between different welding tasks with ease. - What is the duty cycle of the TransSteel 2200?

The machine offers a high duty cycle, ensuring sustained performance even during prolonged welding sessions. Specific duty cycle values for various welding processes are detailed in the product specifications. - Is the TransSteel 2200 suitable for heavy-duty welding tasks?

Absolutely, the robust build quality and a wide range of welding currents make the TransSteel 2200 well-suited for heavy-duty welding applications. - How portable is the TransSteel 2200?

Despite its powerful capabilities, the machine is designed with compact dimensions and a manageable weight of 34.17 lbs, ensuring portability and ease of transport to different job sites. - Can the TransSteel 2200 handle intricate welding work?

Yes, the machine supports low welding currents, starting from 10 A, making it suitable for intricate and precise welding tasks. - What is the IP23 protection class?

The TransSteel 2200 carries an IP23 protection class, indicating its resistance to water spray from up to 60 degrees vertical. - Is there a warranty included with the TransSteel 2200?

Warranty details may vary, but Fronius typically provides a warranty for their welding machines. It is advisable to check the specific warranty terms and conditions provided by the manufacturer.

We invite you to share your firsthand experiences and insights on the Fronius TransSteel 2200 MIG/TIG Welding Machine in the comments section below. Your valuable feedback can provide valuable guidance for fellow welders looking to make informed decisions. Whether it’s about the machine’s performance, usability, or any tips and tricks you’ve discovered, your input can contribute to a community of informed users. We look forward to hearing from you and fostering a discussion that benefits the welding community!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment