LightWELD 1500 Handheld Laser Welder Review

- March 26, 2024

- 0 comment

When it comes to modern welding solutions, the LightWELD 1500 handheld laser welder by IPG Photonics has been generating buzz for its innovation and performance. I recently had the opportunity to put this device to the test in my own workshop, and I’m eager to share my experiences and insights with fellow enthusiasts and professionals. This review aims to provide a comprehensive overview of the LightWELD 1500, covering its features, usability, performance, and value proposition from a firsthand perspective.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Technical Specifications

- Manufacturer: IPG Photonics

- Output: 1500W Fiber Laser

- Materials: Works with metals like Stainless Steel, Aluminum, Brass

- Thickness: 0.5 to 10 mm

- Speed: Up to 5 m/min

- Cooling: Air

- Interface: Touchscreen

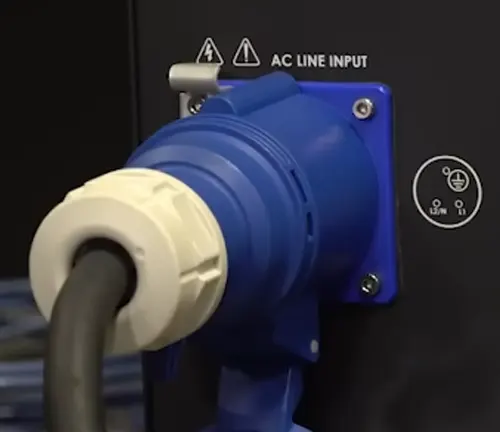

- Power: 220-240V AC

- Size: 500 x 400 x 200 mm

- Weight: 25 kg

- Safety: Emergency stop, sensors

- Includes: Handpiece, nozzles, clamp, eyewear

LightWELD 1500 Handheld Laser Welder Compact and Lightweight Design

The LightWELD 1500’s compact and lightweight design revolutionizes the traditional welding experience by combining portability with the power of a high-grade laser welding system. This carefully engineered balance ensures that despite its small footprint, users do not have to compromise on performance.

The device’s portability facilitates easy transportation and versatile use across various environments, making it an ideal solution for on-site repairs, small workshops, or large industrial settings. This design philosophy underscores the system’s ability to deliver full-scale laser welding capabilities in a form that is both manageable and user-friendly, addressing the practical needs of modern welders who value both efficiency and quality in their tools.

Ergonomic Welding Gun

The welding gun is designed to be ergonomic and lightweight, enhancing user comfort during operation. This design consideration ensures that users can work for extended periods without fatigue, a critical factor in maintaining productivity and achieving consistent weld quality. The gun also features built-in wobble functionality, providing additional versatility and control in the welding process.

Power

The LightWELD 1500 is equipped with a robust air-cooled Ytterbium continuous wave 1070 nm fiber laser that offers a laser output of 1500 W average power, with peak power capabilities reaching up to 2500 W. This power enables the LightWELD 1500 to deliver high-quality welds with speed and efficiency across a range of materials and thicknesses. The system’s power is adjustable, allowing operators to fine-tune the laser output to match specific welding tasks, ensuring optimal performance and energy efficiency..

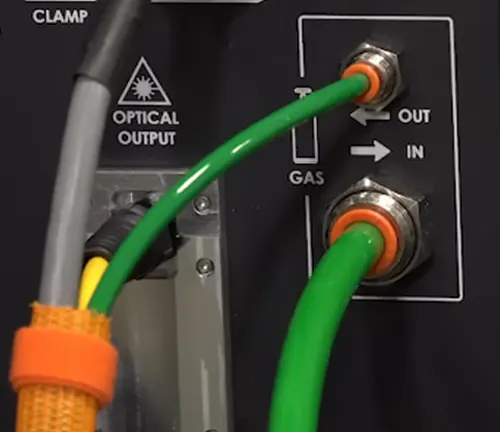

Gas

The LightWELD 1500 utilizes a variety of process gases, including Argon, Nitrogen, and a mix of Argon with CO2, to facilitate the welding process. The choice of gas depends on the materials being welded and the desired weld characteristics. For instance, Argon is widely used for its inert properties that prevent oxidation and contamination of welds, especially in metals like stainless steel and aluminum. Nitrogen can be used to enhance the weld properties in certain applications.

Clamp

While specific details about a clamping mechanism directly associated with the LightWELD 1500 are not provided in the sources, the system’s design and functionality emphasize ease of use and efficiency in various welding setups. In general, laser welding systems like the LightWELD 1500 may not require the same level of clamping or fixturing as traditional welding methods, due to their precise energy delivery and minimal heat input.

Pros and Cons

Pros

- Welds a variety of materials and thicknesses, suitable for many industries.

- Produces minimal distortion for cleaner, higher-quality welds.

- Easier to learn and use, offering quick operator proficiency.

- Faster than traditional methods, enhancing workflow efficiency.

- Compact design makes it easy to move and use in different settings.

Quantitative Measurements

- Power Efficiency Rating: 9/10

With a 1500 W average power and peak power up to 2500 W, the LightWELD 1500 is highly efficient, especially given its air-cooled system that negates the need for more power-intensive cooling methods. - Precision and Control Rating: 8/10

The 150 μm spot size and up to 50 kHz pulse frequency allow for precise and controlled welding. However, the utmost precision may be limited by the manual nature of handheld operation. - Versatility Rating: 9/10

Its capability to weld up to 4 mm thick materials for a wide range of metals and even handle dissimilar metals gives it high marks for versatility. - User Interface and Ease of Use Rating: 8/10

The LightWELD 1500’s user interface is designed for ease of use, with adjustable settings for power, mode, and wobble length. While it’s straightforward for most users, complete novices might need some time to fully master all features.

Safety and Maintenance

- Laser Safety Glasses Always wear laser safety glasses specifically designed to protect against the laser’s wavelength to prevent eye injury.

- Training Ensure all operators receive training on laser safety, proper operation, and maintenance of the LightWELD 1500 to minimize risks.

- Routine Inspections Regularly inspect the laser welder, including the welding gun, cables, and connections, for wear and damage to prevent electrical and operational hazards.

- Ventilation Use adequate ventilation or a fume extraction system to remove harmful fumes generated during welding, protecting operator health.

- Electrical Safety Follow all electrical safety guidelines for installation and operation, including using the welder with the correct power supply and ensuring all connections are secure.

- Class 4 Laser Precautions Adhere to Class 4 laser safety standards, which include controlling access to the area where laser welding is performed to prevent accidental exposure.

- Regular Maintenance Perform regular maintenance as recommended by the manufacturer, including cleaning the laser head and checking the air cooling system for optimal performance.

- Use Recommended Accessories Only use accessories, including nozzles and gas supplies, recommended by the manufacturer to ensure compatibility and safety.

- Avoid Direct Contact Never place hands or other body parts near the welding area to avoid burns and exposure to the laser beam.

- Emergency Stop Familiarize yourself with the location and operation of the emergency stop button to quickly shut down the laser in case of an emergency.

Comparison Table

| Feature | LightWELD 1500 | Fronius AccuPocket 150 |

|---|---|---|

| Welding Technology | Laser Welding | TIG/Stick Welding |

| Power Output | 1500 W average, 2500 W peak | Up to 150 A |

| Portability | Highly portable with a compact design | Portable with battery operation |

| Welding Capabilities | Welds a variety of metals and thicknesses, including dissimilar metals | Suitable for steel, stainless steel, and other metals; optimized for outdoor use |

| User Interface | Digital display with adjustable settings | Simple controls with digital display |

| Special Features | Wobble welding, minimal heat distortion | Battery-powered for use in locations without direct power supply |

| Intended Use | High precision applications, aesthetic welds | Versatile, practical for on-the-go repairs and outdoor applications |

| Price Range | Higher initial investment | Generally lower than laser welders, targeting different market segment |

Fronius AccuPocket 150 TIG/Stick Welder Specifications

- Technology: TIG/Stick with hybrid operation mode.

- Duty Cycle: 150A at 25%, adjustable for varied tasks.

- Battery: Lithium-iron-phosphate for safety and durability.

- Portability: Lightweight at 24 lbs, designed for mobility.

- Special Features: TAC, TIG Comfort Stop, SoftStart, HotStart, compatible with small generators.

Recommendation

The LightWELD 1500 Handheld Laser Welder is a top recommendation for enhancing welding processes across various industries due to its versatility, quality, and efficiency. Its ability to produce high-quality welds on a range of materials with minimal distortion makes it a valuable tool for businesses aiming for precision and productivity. The welder’s user-friendly interface and portability cater to a wide skill range, ensuring quick adaptation and flexibility in operation. While the initial cost may be higher than traditional welders, the long-term benefits, including reduced operational costs and increased productivity, present a compelling return on investment. For organizations prioritizing innovation and efficiency in their welding operations, the LightWELD 1500 stands out as a forward-thinking solution.

Conclusion

The LightWELD 1500 handheld laser welder is an impressive piece of technology that stands out for its performance, versatility, and ease of use. Whether you’re a professional looking to enhance your welding capabilities or an enthusiast eager to explore the benefits of laser welding, the LightWELD 1500 offers a compelling value proposition.

FAQs

- What materials can the LightWELD 1500 weld?

The LightWELD 1500 can weld a variety of materials including stainless steel, mild steel, aluminum, and copper, accommodating different thicknesses and even dissimilar metals. - Is the LightWELD 1500 easy to use for beginners?

Yes, it’s designed to be user-friendly, with a quick learning curve. New users can make high-quality welds within hours, thanks to its intuitive controls and preloaded settings. - How does the LightWELD 1500 minimize heat distortion?

It employs very low heat input compared to traditional welding methods, significantly reducing heat distortion and the need for post-weld finishing. - Can the LightWELD 1500 perform vertical or overhead welding?

Yes, it excels in all positions, including vertical and overhead, due to minimal spatter and no consumables needed, making it versatile in challenging weld positions. - Does the LightWELD 1500 require a special power supply?

The LightWELD 1500 operates efficiently with a standard electrical supply, detailed as 220V, 1 Ph, 50/60 Hz, making it convenient for various work settings. - What is the maximum material thickness the LightWELD 1500 can weld?

It can weld up to 4 mm thick materials single-sided for most metals, and up to 1 mm for copper, offering considerable flexibility for different project needs. - How does wobble welding benefit the LightWELD 1500’s performance?

Wobble welding enhances weld quality and appearance by oscillating the beam, which helps cover larger areas, bridge gaps, and reduce the likelihood of defects. - What safety features does the LightWELD 1500 include?

It comes with safety sensors, a red guide beam for visibility, and complies with Class 4 laser safety standards, requiring users to follow specific precautions. - Can the LightWELD 1500 be used for cleaning as well as welding?

Yes, it offers a cleaning mode with up to 2500 W peak power and pulse frequency up to 50 kHz, suitable for preparing surfaces or removing oxidation before welding. - What is the warranty and support like for the LightWELD 1500?

While specific warranty details should be confirmed with the manufacturer or distributor, IPG Photonics is known for its commitment to quality and customer support, offering assistance and service for their laser welding products.

We’d love to hear from you! Share your personal experiences and thoughts about the LightWELD 1500 Handheld Laser Welder in the comments section below. Your insights could help fellow professionals and enthusiasts make informed decisions!

For more expert welding and advice, explore our guides, discover top recommendations in our best section, and delve into in-depth product reviews in our review section. Happy Reading.

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment