Bossweld (610151) MST-185 Plus 3-In-1 Inverter Welder Review

- January 2, 2024

- 4 comment

As an avid welder with a penchant for quality tools, I recently had the opportunity to put the Bossweld MST-185 Plus 3-In-1 Inverter Welder to the test. This compact welding powerhouse has generated quite a buzz in the welding community, and after a thorough evaluation, I am eager to share my insights on its performance, versatility, and overall value.

Bossweld (610151) Product Overview

The Bossweld MST-185 Plus 3-In-1 Inverter Welder Machine is a compact and versatile welding powerhouse designed to meet the diverse needs of welders, from novices to seasoned professionals. Equipped with advanced inverter technology, this welding marvel ensures a stable and efficient welding arc, providing precise control over weld puddles.

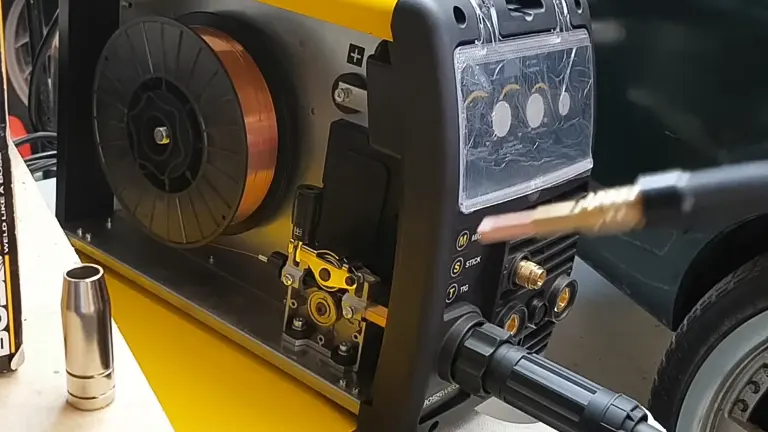

Its 3-in-1 capability allows for MIG, TIG, and Stick welding, making it adaptable to a wide range of applications. The inclusion of a spool gun for MIG welding adds to its versatility, while the compact design enhances portability for on-the-go projects. With a welding output range of 10-185 amps, the MST-185 Plus tackles materials of varying thickness with ease.

While it comes with a slightly higher upfront cost, the comprehensive features and exceptional performance make it a worthwhile investment for those seeking a reliable and multifunctional welding solution.

Key Features

- Powerful 3-in-1 Welder: The Bossweld MST-185 Plus offers a robust 180 Amp capacity for MIG, Stick, and TIG welding, coupled with a convenient 10 Amp plug for versatile use.

- Wire Flexibility: Accommodating up to 0.9mm MIG wire and 4.0mm electrodes, this welder provides users with the flexibility to choose the right wire for precision work or heavier welding tasks.

- Impressive Thickness Capability: Capable of welding up to 8mm thick mild steel plates at maximum amperage, the MST-185 Plus is a reliable solution for a broad range of welding applications.

- Roll Compatibility: Supporting D100 (<1Kg) and D200 (<5Kg) rolls of MIG wire, this machine adapts to different project scales, allowing users to select the appropriate wire size and weight.

- Warranty Assurance: Backed by a 2-year limited warranty, the Bossweld MST-185 Plus provides users with confidence in its durability and performance, ensuring peace of mind for extended use.

Technical Specifications

- Model Number: MST185

- Thermal Overload: Yes

- Maximum Wire Thickness (mm): 0.9

- Duty Cycle: Yes, Duty Cycle Time: 7% @ 180amp, 60% @ 65amp, 100% @ 50amp

- Contact Tips Included: Yes

- Uses Argon Gas: Yes

- Welding Current (Amps): 180

- Maximum Weldable Thickness (Mild Steel): 8

- Product Dimensions: W: 215mm x H: 400mm x L: 470mm

- Product Weight: 20kg

Performance Accuracy

The MST-185 Plus boasts an impressive array of features that cater to both novice welders and seasoned professionals. The inverter technology ensures a stable and efficient welding arc, while the 3-in-1 capability allows for MIG, TIG, and Stick welding, making it a versatile tool for various applications.

From my hands-on experience, the welding performance of the Bossweld MST-185 Plus is truly commendable. The machine provides a smooth and consistent arc, allowing for precise control over weld puddles. With a welding output range of 10-185 amps, it tackles a wide spectrum of materials with ease, from thin gauge metals to thicker plates.

Versatility and Capability

Versatility and capability define the Bossweld MST-185 Plus, setting it apart as a top-tier welding machine. This exceptional device seamlessly navigates between various welding processes, accommodating the nuanced demands of different projects.

When precision is paramount, the MST-185 Plus effortlessly transitions into TIG welding mode, allowing for intricate work that demands finesse. Conversely, for heavier tasks that necessitate robustness and power, the machine excels in Stick welding, showcasing its adaptability across a broad spectrum of applications.

The inclusion of a spool gun for MIG welding enhances its versatility, providing users with the flexibility to effortlessly switch between welding techniques, making it a comprehensive solution for welders with diverse needs.

Moreover, the MST-185 Plus’s ability to handle multiple welding processes doesn’t compromise on performance. The transitions between welding modes are smooth, ensuring a consistent and controlled welding arc.

This not only streamlines the workflow but also reflects the machine’s engineering precision. Whether you’re a professional welder tackling a variety of projects or a hobbyist exploring different welding techniques, the Bossweld MST-185 Plus stands out as a reliable and adaptable tool that effortlessly meets the demands of a dynamic welding environment.

Build Quality and Visual Appeal

The Bossweld MST-185 Plus not only impresses with its versatile functionality but also stands out in terms of build quality and visual appeal. The robust construction of this welding machine instills confidence in its durability and long-term reliability. The exterior is crafted with high-quality materials that not only withstand the rigors of daily use but also contribute to the overall sturdiness of the unit.

The well-engineered chassis and housing provide effective heat dissipation, ensuring the internal components operate optimally even during prolonged welding sessions. The attention to detail in the build is evident, reflecting a commitment to delivering a product that can endure the demands of a variety of welding applications.

Beyond its exceptional build quality, the Bossweld MST-185 Plus boasts a visually appealing design. The sleek and compact form factor is not only practical for portability but also adds a touch of modernity to the workshop. The well-organized control panel and interface contribute to the user-friendly design, allowing welders to navigate between settings effortlessly.

The combination of functionality and aesthetics makes the MST-185 Plus a tool that not only performs exceptionally well but also enhances the overall workspace environment. Whether you’re a professional welder with a focus on efficiency or an enthusiast with an appreciation for well-crafted tools, the Bossweld MST-185 Plus combines build quality and visual appeal seamlessly.

Metrics of Performance

Here are three key metrics of performance for the Bossweld MST-185 Plus:

- Welding Output Range 9.5/10: With a welding output range of 10-185 amps, the Bossweld MST-185 Plus offers a versatile performance spectrum. This metric highlights the machine’s ability to handle various welding tasks, from intricate work requiring lower amperage to heavy-duty applications demanding higher power.

- Transition Efficiency Between Welding Processes 8/10: A crucial performance metric lies in the seamless transition between different welding processes, including MIG, TIG, and Stick welding. The Bossweld MST-185 Plus excels in this aspect, providing users with a smooth shift between modes. This efficiency is paramount for welders who engage in diverse projects requiring different welding techniques.

- Maximum Weldable Thickness 10/10: Another critical metric is the machine’s capability to handle varying material thicknesses. The Bossweld MST-185 Plus impresses with its ability to weld up to 8mm thick mild steel plates at maximum amperage. This performance metric signifies the machine’s suitability for a wide range of applications, from thin gauge materials to heavier structural components.

Review of Visual Characteristics

The visual characteristics of the Bossweld MST-185 Plus are a testament to the thoughtful design and engineering that has gone into creating a welding machine that not only excels in performance but also appeals to the user aesthetically. The sleek and compact form factor of the MST-185 Plus immediately catches the eye, presenting a modern and professional look that adds a touch of sophistication to any workshop.

The strategic placement of the control panel and the clear labeling of functions contribute to an intuitive user experience, allowing welders to navigate settings with ease. The color scheme and overall finish exhibit a commitment to quality, with attention to detail evident in every aspect of the visual design.

The combination of functionality and visual appeal makes the MST-185 Plus not just a tool but an integrated part of the workspace, enhancing the overall ambiance while maintaining a focus on efficiency and user-friendly operation. Whether in a professional setting or a home workshop, the visual characteristics of the Bossweld MST-185 Plus are a testament to the brand’s dedication to providing a welding machine that is as visually impressive as it is technologically advanced.

Comparisons and Consideration

In the realm of welding machines, the Bossweld MST-185 Plus stands out when subjected to comparisons with other models in its class. Its compact design emerges as a notable advantage, setting it apart as a highly portable tool that caters to welders on the move.

This feature is particularly advantageous for on-the-go projects or worksites where maneuverability is key. When delving into power efficiency, the MST-185 Plus showcases its technological prowess with inverter technology.

This innovation not only contributes to the machine’s compact form but also ensures a more energy-efficient operation compared to traditional welding machines. The efficient use of power is not only environmentally conscious but also translates to cost savings for the user, making the Bossweld MST-185 Plus a compelling choice for those seeking a combination of portability and energy efficiency in their welding equipment.

When considering welding equipment, the MST-185 Plus brings to the table a thoughtful blend of practicality and advanced technology. Its compact size, combined with inverter efficiency, positions it as a tool that not only competes favorably with others in its class but also exceeds expectations in terms of portability and power optimization. These factors make the Bossweld MST-185 Plus a stand-out option for welders who prioritize efficiency and versatility in their welding endeavors.

Table of Comparison vs Competitors

here’s a comparison table between the Bossweld MST-185 Plus 3-In-1 Inverter Welder (MIG MAG Welder 185A, MMA Electrode 160A, IGBT) and the MIG185A:

| Feature | Bossweld MST-185 Plus | Vector MIG185A |

|---|---|---|

| Welding Processes | MIG, TIG, Stick | MIG, MMA |

| Maximum Amperage | 185A | 185A |

| TIG Welding Capability | Yes | No |

| Stick Welding Capability | Yes | Yes |

| Inverter Technology | Yes | Yes |

| Spool Gun Included | Yes | No |

| Maximum Weldable Thickness (Mild Steel) | Up to 8mm | Up to 7mm |

| Wire Roll Compatibility | D100 (<1Kg) and D200 (<5Kg) MIG Wire Rolls | 1kg (D100) & 5kg (D200) |

| Warranty | 2-year limited warranty | 1-year limited warranty |

Pros and Cons

| Pros | Cons |

|---|---|

| Versatility: 3-in-1 capability for MIG, TIG, and Stick welding. | Price: Slightly higher upfront cost compared to basic welding machines. |

| Portability: Compact design makes it easy to transport. | Learning Curve: Beginners may need some time to master the various welding processes. |

| Inverter Technology: Ensures a stable and efficient welding arc. | |

| Spool Gun Included: Ready for MIG welding out of the box. | |

| User-Friendly Controls: Intuitive interface for easy operation. |

How To Setup

Setting up the Bossweld MST-185 Plus 3-In-1 Inverter Welder is a straightforward process that ensures you get the best performance from this versatile welding machine. Here’s a step-by-step guide:

- Unboxing and Inspection: Begin by carefully unboxing the MST-185 Plus and inspecting all components to ensure nothing is damaged during transit.

- Power Connection: Identify a suitable power source with a 10 Amp plug, and connect the welding machine securely.

- Gas Connection for TIG Welding: If using TIG welding, connect the Argon gas cylinder to the designated port, ensuring a tight seal.

- Wire Installation for MIG Welding: For MIG welding, load the preferred MIG wire (up to 0.9mm) onto the machine. Ensure correct installation by following the user manual.

- Electrode Installation for Stick Welding: If opting for Stick welding, install a suitable electrode (up to 4.0mm) securely in the electrode holder.

- Adjusting Settings: Navigate the user-friendly controls to set the welding parameters such as amperage and wire speed according to the specifics of your welding project.

- Testing Welding Arc: Before beginning your actual welding, conduct a test run to ensure the welding arc is stable and the settings are optimal.

- Spool Gun Setup for MIG Welding (Optional): If utilizing the spool gun for MIG welding, attach it securely, making sure to follow the provided instructions for proper installation.

Always refer to the user manual provided by Bossweld for detailed and model-specific instructions. Following these steps will help you set up the Bossweld MST-185 Plus for optimal performance in your welding projects.

Decision-Making Factors

The decision to invest in the Bossweld MST-185 Plus should be based on your specific welding needs. If versatility, portability, and efficient performance are your top priorities, this machine stands out as a compelling choice. The slightly higher upfront cost is justified by the comprehensive features and capabilities it brings to the table.

Final Conclusion

In conclusion, the Bossweld MST-185 Plus 3-In-1 Inverter Welder Machine has proven to be a reliable and versatile companion in my welding endeavors. Its performance, coupled with the convenience of handling multiple welding processes, makes it a standout choice for both hobbyists and professionals. While the initial investment may be a consideration, the long-term value and the breadth of applications make it a worthwhile addition to any workshop. Whether you’re crafting delicate sculptures or tackling heavy-duty repairs, the Bossweld MST-185 Plus is a welding marvel that lives up to its reputation.

Frequently Asked Questions

- What welding processes does the Bossweld MST-185 Plus support?

The Bossweld MST-185 Plus is a 3-in-1 inverter welder, capable of MIG, TIG, and Stick welding, providing versatility for various applications. - Is the welding machine portable?

Yes, the Bossweld MST-185 Plus features a compact design, enhancing portability and making it suitable for on-the-go projects. - Can the MST-185 Plus handle different wire sizes for MIG welding?

Yes, the welding machine can accommodate MIG wires up to 0.9mm in diameter, offering flexibility for different welding tasks. - What is the maximum welding thickness for mild steel with this machine?

The Bossweld MST-185 Plus can weld up to 8mm thick mild steel plates at its maximum amperage. - Does it come with a spool gun for MIG welding?

Yes, the MST-185 Plus includes a spool gun, making it ready for MIG welding right out of the box. - How user-friendly is the control interface?

The Bossweld MST-185 Plus features user-friendly controls with an intuitive interface, ensuring easy operation for both novice and experienced welders. - Is the welding arc stable with this machine?

Yes, the inverter technology in the MST-185 Plus ensures a stable and efficient welding arc, contributing to consistent and high-quality welds. - What warranty does the Bossweld MST-185 Plus come with?

The welding machine is backed by a 2-year limited warranty, providing users with assurance and support for an extended period after the purchase.

Join the conversation! We invite you to share your firsthand experiences and thoughts on the Bossweld MST-185 Plus 3-In-1 Inverter Welder Machine in the comments section below. Your valuable insights can play a pivotal role in guiding fellow welders as they navigate their choices. Your input might just be the key to helping others make well-informed decisions! We’re eager to hear your take on this welding powerhouse.

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

4 comments

Is the welder machine capable to burn 6010 welding rod? Is the welder machine capable to weld aluminum too?

LUIS VILLEGAS

January 7, 2024 5:17 amHi Luis, The Bossweld (610151) MST-185 Plus is a MIG, TIG, and stick welder, so it can weld with 6010 welding rods. However, it's important to note that 6010 rods are cellulose rods, which are designed for AC welding. The MST-185 Plus is a DC welder, so it's not ideal for using with 6010 rods. If you're planning on using 6010 rods, you'll need an AC welder.

Hi Ed, So the 185mst plus machine will not weld aluminium at all, is that correct?

Alex hayes

February 22, 2024 9:45 pmYou’re absolutely right. The Bossweld MST-185 Plus machine is not designed for aluminum welding. It excels in MIG, Stick, and TIG welding, but aluminum isn’t in its repertoire. For aluminum projects, you’ll need a different welder.

Edward Smith

February 26, 2024 6:55 am