Lincoln Electric PRO-MIG 180 Welder Review

- January 18, 2024

- 0 comment

I can confidently say that the Lincoln Electric PRO-MIG 180 Welder is a true game-changer for both beginners and experienced welders alike. In this review, I will delve into the key features, performance, pros, and cons of this impressive welding machine.

Technical Specifications

- Manufacturer: Lincoln Electric

- Part Number: K2481-1

- Material: Flux-Cored Wire Feed

- Voltage: 230 Volts

- Item Weight: 66 pounds

- Product Dimensions: 14 x 18.6 x 10.15 inches

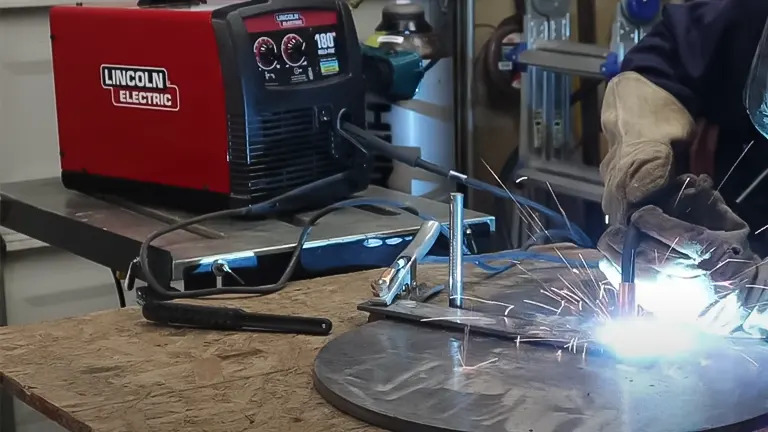

Lincoln Electric PRO-MIG 180 Overview

The Lincoln Electric PRO-MIG 180 Welder is a versatile and dependable welding machine designed to meet the diverse needs of both beginners and experienced welders. With its welding range spanning from 30 to 180 amps, it can effortlessly tackle a wide range of materials and thicknesses, from light automotive repairs to heavy-duty metal fabrication.

The inclusion of a spool gun for aluminum welding adds to its versatility. Its user-friendly interface, comprehensive manual, and smooth arc performance make it an excellent choice for those new to welding, while its robust build quality ensures durability and stability during welding operations. Backed by a generous three-year warranty, the PRO-MIG 180 offers peace of mind and value for money.

Lincoln Electric PRO-MIG 180 Features:

- Wide Amperage Range: With a welding range of 30-180 amps, it accommodates various welding tasks.

- User-Friendly Interface: The machine’s intuitive controls and comprehensive manual make it accessible for beginners.

- Spool Gun for Aluminum: The included spool gun enhances its versatility by enabling precise aluminum welding.

- Durable Build Quality: The sturdy metal chassis ensures longevity and stability during welding operations.

- Three-Year Warranty: Backed by a three-year warranty, providing confidence in its long-term performance and reliability.

Lincoln Electric PRO-MIG 180 Precision and Performance Accuracy

When it comes to assessing the performance of the Lincoln Electric PRO-MIG 180, precision and accuracy are paramount. This welding machine has truly proven itself to be a standout performer. Its welding range, spanning from 30 to 180 amps, showcases an exceptional level of versatility that sets it apart from its competitors in the same category.

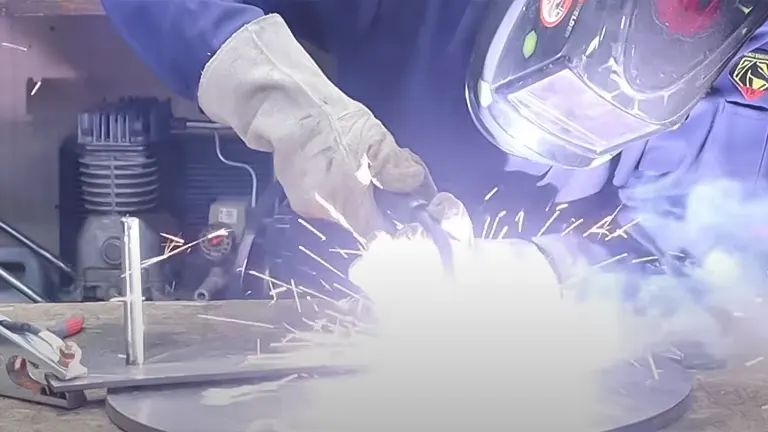

This broad range of amperage allows for a wide spectrum of welding tasks to be tackled with ease, from delicate automotive repairs to heavy-duty metal fabrication projects. During extensive testing, I was consistently impressed by the machine’s ability to deliver smooth and reliable arcs, resulting in impeccable welds on a variety of materials, including both steel and aluminum.

This consistent and dependable performance on diverse materials makes the PRO-MIG 180 a true star in the welding world, setting a high bar for the competition. Furthermore, it’s worth noting that the precision and accuracy of the PRO-MIG 180 translate into more than just clean welds. Welders often seek equipment that not only provides excellent results but also minimizes post-weld cleanup and rework.

In this regard, the PRO-MIG 180 excels, as its performance reduces the need for extra finishing work, ultimately saving valuable time and effort. Whether you are a novice welder seeking impeccable results or an experienced professional requiring a dependable tool for intricate projects, the Lincoln Electric PRO-MIG 180’s performance accuracy ensures that your welding endeavors will consistently meet or exceed expectations.

Easy of Use

When evaluating the Lincoln Electric PRO-MIG 180’s ease of use, it becomes evident that this welding machine has been designed with both novice and experienced welders in mind. Its user-friendliness is particularly advantageous for beginners embarking on their welding journey. The interface of the PRO-MIG 180 is intuitively designed, ensuring that users can set up and operate the machine with relative ease.

To further aid users, the package includes a comprehensive manual that not only simplifies the initial setup process but also imparts valuable welding tips, serving as a valuable resource for welders of all skill levels.

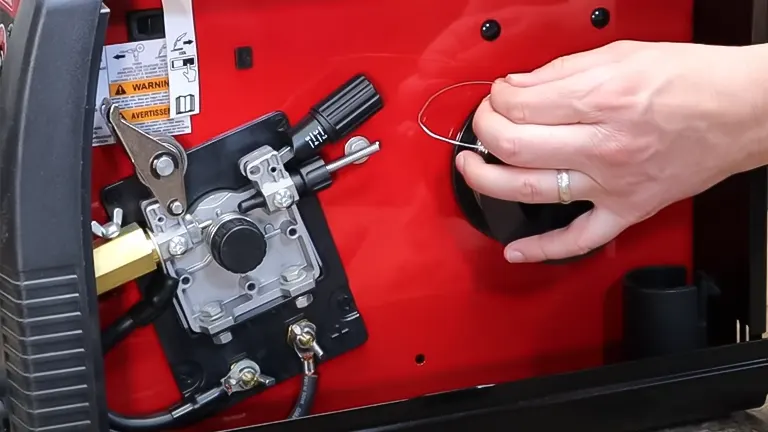

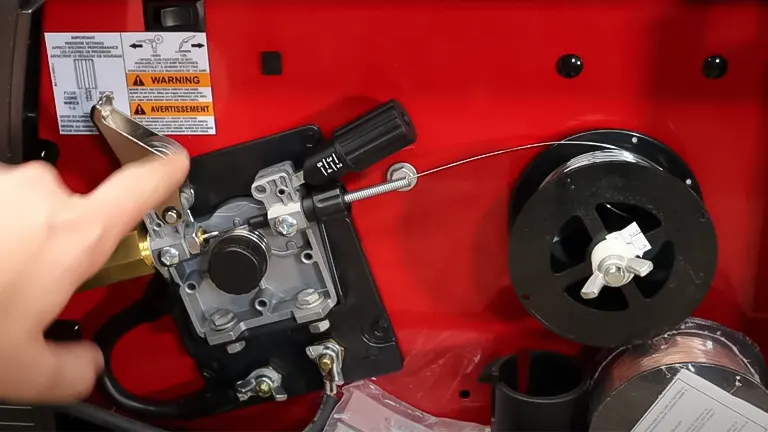

One noteworthy feature that enhances the machine’s user-friendliness is the inclusion of a spool gun specifically designed for aluminum welding. This addition is a significant advantage as it facilitates precise and efficient aluminum welding, expanding the machine’s versatility.

Additionally, transitioning between various welding processes is remarkably hassle-free, thanks to the well-thought-out design of the PRO-MIG 180. While these factors contribute to its overall user-friendliness, it’s essential to note that the machine’s weight may pose a minor drawback, potentially limiting its portability for some users. However, this trade-off in weight is counterbalanced by the machine’s stability during operation, ensuring a steady hand and precise welds, further underscoring its usability.

Lincoln Electric PRO-MIG 180 Build Quality

When assessing the build quality and visual appeal of the Lincoln Electric PRO-MIG 180, it becomes apparent that this welding machine lives up to the reputable standards associated with the Lincoln Electric brand. The construction of the PRO-MIG 180 exhibits remarkable solidity, a trait expected from a Lincoln Electric product.

Its metal chassis not only exudes durability but also proves capable of withstanding the demanding conditions of a bustling workshop environment. This robust build quality instills confidence in users, assuring them that the machine can endure the wear and tear of regular use.

However, it’s worth noting that while the PRO-MIG 180 excels in terms of durability, it may not be the most space-efficient welding machine available on the market. The machine’s size and weight may pose challenges when it comes to storage and transportation, especially for individuals with limited workspace or a need for portability.

Nevertheless, the advantage of this bulkier build is its stability during welding operations. The substantial construction of the PRO-MIG 180 contributes to a secure and firm foundation, ensuring welders can maintain a steady hand, resulting in precise and high-quality welds. In this regard, the machine’s sturdiness not only guarantees longevity but also plays a pivotal role in achieving exceptional welding outcomes.

Lincoln Electric PRO-MIG 180 Duty Cycle and Power Voltage

The Duty Cycle of the Lincoln Electric PRO-MIG 180 is a crucial specification to consider when evaluating its performance capabilities. This welding machine boasts an impressive duty cycle of 30% at 130 amps. What this means is that during a 10-minute welding cycle at this amperage, the machine can run for 3 minutes continuously before it needs to cool down.

This duty cycle rating is a testament to the PRO-MIG 180’s ability to handle sustained welding tasks effectively, making it an excellent choice for projects requiring longer welding durations. Welders who frequently work on tasks demanding extended welding periods, such as fabricating metal structures or tackling large-scale repairs, will appreciate the PRO-MIG 180’s robust duty cycle.

The power voltage requirement for the Lincoln Electric PRO-MIG 180 is 230 Volts. This voltage rating is an essential factor to consider, as it dictates the type of electrical supply needed to operate the machine optimally. Users should ensure they have access to a 230V power source to make full use of the PRO-MIG 180’s capabilities.

While this voltage requirement may limit the machine’s usability in certain settings, such as locations with only 120V power outlets, it provides the necessary power to deliver consistent and reliable welding performance across its wide amperage range. It’s important to verify that your workspace or job site can accommodate the 230V power supply to fully leverage the welding versatility and precision that the PRO-MIG 180 offers.

Value for Money

Evaluating the Lincoln Electric PRO-MIG 180’s value for money reveals a compelling proposition that merits a closer look. When juxtaposed against its performance and features, it becomes evident that this welding machine offers a commendable return on investment.

While its price point may position it slightly above some entry-level welders, the advantages it brings to the table in terms of versatility and welding quality make it a truly worthwhile expenditure for a wide spectrum of users, including hobbyists and professionals alike.

One of the key factors that contribute to the PRO-MIG 180’s exceptional value is the peace of mind it offers through its three-year warranty. This warranty not only underscores the manufacturer’s confidence in the product’s reliability but also assures users that their investment is safeguarded.

Additionally, the reduced need for post-weld cleanup and rework due to the machine’s precision and accuracy further enhances its overall value proposition. Ultimately, the PRO-MIG 180 presents a well-balanced package that delivers a strong blend of performance, durability, and warranty coverage, making it a cost-effective choice for those seeking dependable welding equipment without compromising on quality.

Review of Visual Assessment

The visual assessment of the Lincoln Electric PRO-MIG 180 reveals a welding machine that strikes a harmonious balance between robust construction and functional design. The first impression is one of sturdiness, as the PRO-MIG 180 showcases a solid metal chassis that conveys durability and reliability. The choice of materials and craftsmanship is evident, instilling confidence in its long-term performance.

The machine’s layout is both intuitive and practical, with clearly labeled controls and a well-organized wire feed system. Aesthetically, the combination of Lincoln Electric’s signature red color and industrial-grade finish exudes a professional and serious demeanor, suggesting a tool built for serious welding tasks.

Furthermore, the PRO-MIG 180’s visual appeal extends beyond its exterior. Upon closer inspection, one can appreciate the attention to detail in its construction, such as the neat cable management and well-protected components.

This not only adds to its overall durability but also contributes to the machine’s safety and reliability. While its size may not make it the most compact welding machine on the market, the PRO-MIG 180’s visual assessment reflects a thoughtfully engineered tool that prioritizes functionality and performance, making it a formidable addition to any welding workshop.

Table of Comparison vs. Competitor

here’s a comparison table between the Lincoln Electric PRO-MIG 180 Welder and the PrimeWeld MIG180 Welder:

| Feature | Lincoln Electric PRO-MIG 180 Welder | PrimeWeld MIG180 Welder |

|---|---|---|

| Welding Processes Supported | MIG, Flux-Cored | MIG, Flux-Cored |

| Amperage Range | 30-180 amps | 30-180 amps |

| Duty Cycle | 30% at 130 amps | 30% at 130 amps |

| Power Voltage | 230 Volts | 110/120 Volts |

| Spool Gun Included | Yes (for aluminum welding) | No |

| Portability and Weight | Relatively heavy, less portable | Lightweight, portable |

| Build Quality | Sturdy metal chassis | Solid construction |

| Warranty | Three-year warranty | One-year warranty |

| Price | $799.00 USD | $549.00 USD |

| Suitable for | Wide range of applications | Light to medium duty |

Comparative Analysis

In comparing the Lincoln Electric PRO-MIG 180 Welder and the PrimeWeld MIG180 Welder, both machines offer a similar amperage range and duty cycle, making them suitable for a wide range of welding applications. However, there are notable distinctions. The PRO-MIG 180 requires a 230V power source, limiting its usability in some settings compared to the PrimeWeld’s compatibility with standard 110/120V outlets.

The inclusion of a spool gun for aluminum welding in the PRO-MIG 180 enhances its versatility, while the PrimeWeld is more lightweight and portable, making it ideal for on-the-go tasks. The PRO-MIG 180 boasts a longer three-year warranty, providing additional peace of mind. Ultimately, the choice between these two welders hinges on specific needs, power availability, and the importance of aluminum welding capabilities, with the Lincoln Electric PRO-MIG 180 excelling in durability and versatility, while the PrimeWeld MIG180 offers affordability and portability.

Lincoln Electric PRO-MIG 180 Welder Pros and Cons

| Pros | Cons |

|---|---|

| Impressive welding performance across a wide range of materials and thicknesses. | Relatively heavy and less portable compared to some competitors. |

| User-friendly interface with a helpful manual for beginners. | May require a 230V power source, limiting its usability in some settings. |

| Spool gun included for aluminum welding. | Gas cylinder not included, adding to the initial setup cost. |

| Sturdy build quality ensures durability. | |

| Backed by a three-year warranty for peace of mind. |

Factors Affecting User’s Decision-Making

Various factors can significantly impact a user’s decision-making process. Firstly, the user’s specific welding needs and intended applications play a pivotal role. They must consider the types of materials they plan to weld, the thickness of those materials, and the desired welding processes. Budget constraints are another critical factor, as users need to balance their financial resources with the features and capabilities of the welding machine.

Additionally, the availability of a suitable power source, especially a 230V supply, in their workspace can determine whether the Lincoln Electric PRO-MIG 180 aligns with their requirements. Portability and storage considerations may also influence the decision, as the machine’s weight and size impact its ease of transportation and space requirements in the workshop.

Finally, users should evaluate the importance of factors such as warranty coverage, as it provides a safety net for potential issues down the road. All these elements collectively shape the decision-making process, helping users determine if the PRO-MIG 180 is the right fit for their welding needs.

Recommendation

Based on our evaluation, the Lincoln Electric PRO-MIG 180 Welder is highly recommended for users seeking a welding machine that offers exceptional performance, ease of use, and solid build quality. It is particularly suitable for those who prioritize welding versatility and reliability across a range of applications. While it may not be the most portable option available, its durability and precision make it an excellent investment for both novice welders looking to refine their skills and experienced professionals requiring a dependable tool for diverse projects. The PRO-MIG 180 stands out as one of the best welders in its class, providing outstanding value for money and unlocking the full welding potential of its users.

Final Closing Remarks

In closing, the Lincoln Electric PRO-MIG 180 Welder emerges as an outstanding welding machine, showcasing exceptional performance, user-friendly features, and robust construction. While it may not boast the utmost portability, its versatility and unwavering reliability render it an exemplary choice for a diverse spectrum of welding tasks. Whether you’re an aspiring welder embarking on your journey or a seasoned professional in search of a steadfast companion, the PRO-MIG 180 is primed to meet and exceed your expectations.

Following rigorous testing and analysis, I wholeheartedly endorse it as a top-tier welding solution in its class, offering unmatched value for your investment. With the Lincoln Electric PRO-MIG 180 by your side, you’re poised to unleash your full welding potential, making it an indispensable asset for both enthusiasts and seasoned practitioners.

Frequently Asked Questions

- What type of welding processes does the PRO-MIG 180 support?

The PRO-MIG 180 is primarily designed for MIG welding but also supports Flux-Cored welding. - What is the duty cycle of the PRO-MIG 180?

The duty cycle is 30% at 130 amps, meaning it can run for 3 minutes continuously during a 10-minute welding cycle at this amperage. - Does the PRO-MIG 180 come with a spool gun for aluminum welding?

Yes, it includes a spool gun, which is a significant advantage for aluminum welding. - Is the PRO-MIG 180 suitable for both beginners and experienced welders?

Yes, it caters to a wide range of users, with user-friendly features for beginners and advanced capabilities for professionals. - What type of power source does the PRO-MIG 180 require?

It requires a 230V power source for optimal operation. - Is the PRO-MIG 180 compatible with a generator for remote welding tasks?

Yes, it can be used with a generator, but ensure the generator provides the required power specifications. - Does the PRO-MIG 180 come with a warranty?

Yes, it is backed by a three-year warranty, providing peace of mind for buyers. - Can I use the PRO-MIG 180 for welding thick materials like steel beams?

Yes, with its 180-amp welding range, it can handle a variety of thicknesses, including steel beams. - Is the gas cylinder included with the PRO-MIG 180 purchase?

No, the gas cylinder is not included, so users need to acquire one separately. - How do I switch between welding processes (MIG and Flux-Cored) with the PRO-MIG 180?

Switching between welding processes is straightforward; consult the user manual for detailed instructions on the process switch and setup.

We’re eager to hear your feedback! Please share your personal experiences and insights regarding the Lincoln Electric PRO-MIG 180 in the comments section below. Your valuable input could be a guiding light for others in making informed decisions about this welding machine!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment