Miller Bobcat 230 (Kohler) Welder Review

- January 4, 2024

- 0 comment

Discover the prowess of the Kohler engine in the Miller Bobcat 230 welder, uncovering its capabilities and performance details. In this review, I’ll share my firsthand experience with this powerful welding companion, evaluating it from a user’s perspective, highlighting its features, and performance, and offering insights into its pros and cons.

Miller Bobcat 230 Specifications

- Amperage: 20 A – 230 A

- Weldable Metals: Stainless Steel, Steel

- Current Type: DC

- Portability: Lift Eye (Standard), Running Gear / Cart (Optional), Trailer (Optional)

- Engine Brand: Kohler

- Engine Idle Speed: 2300 RPM

- Engine Weld Speed: 3600

- Fuel Tank Size: 11 Gallon

- Fuel Type: Gasoline

- Horsepower: 23.5 hp

- Net Width: 20.13 in

- Net Height: 26.5 in

- Net Length: 37.06 in

- Net Weight: 376 lbs

Miller Bobcat 230 Product Overview

The Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine stands as a pinnacle in the realm of welding equipment, offering a comprehensive solution for professionals and enthusiasts alike.

Boasting a powerful Kohler engine that ensures consistent and reliable performance, this machine caters to a diverse range of welding tasks with its impressive 40-275 amps welding output range. The user-friendly design, characterized by an intuitive control panel and a compact, portable structure, makes it accessible for welders of all experience levels.

Its durable build, crafted with robust materials, guarantees longevity and resilience in challenging work environments. The Miller Bobcat is not just a welding tool; it’s a versatile companion that combines power, reliability, and user-friendly features, making it an essential asset for anyone seeking excellence in welding performance.

Miller Bobcat 230 Power and Performance

At the heart of the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine lies a formidable Kohler engine, a testament to its reliability and strength. The welding prowess of this machine is truly remarkable, boasting a versatile output range of 40-275 amps. Whether engaged in intricate, fine welding or tackling heavy-duty fabrication projects, the Bobcat consistently demonstrates its capability to handle diverse welding tasks with ease and precision.

The real standout feature is the generator power output, peaking at an impressive 11,000 watts. This ensures not only efficient welding but also provides a reliable power source for auxiliary tools and equipment on the job site, making it a versatile and indispensable companion for professionals across various industries. Throughout my hands-on experience with the Miller Bobcat, I subjected it to a range of welding projects – from minor repairs to extensive fabrication work.

The results were consistently outstanding, showcasing the machine’s ability to deliver high-quality welds across the entire spectrum of its output range. The robust Kohler engine, coupled with the machine’s thoughtful design, makes it a reliable workhorse that instills confidence in its users, proving its mettle in the face of demanding and diverse welding challenges.

Miller Bobcat 230 User-Friendly Design

The Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine distinguishes itself with an exceptionally user-friendly design, a feature that significantly enhances its appeal to both novice and seasoned welders. The intuitive control panel, a standout component of this design, facilitates seamless adjustments to welding parameters.

This thoughtful inclusion ensures that operators, regardless of their experience level, can easily navigate and optimize the machine’s settings for precise and efficient welding. The control panel’s user-centric approach not only contributes to the overall accessibility of the Bobcat but also reduces the learning curve typically associated with welding equipment, allowing users to focus more on their craft and less on mastering complex controls.

Beyond its intuitive interface, the Miller Bobcat’s design extends to its physical attributes, with a compact and portable construction tailored for on-the-go applications. This portability proves invaluable on diverse job sites, allowing welders to navigate tight spaces and move effortlessly between workstations.

The machine’s sturdy build further solidifies its reputation for durability, with robust materials ensuring resilience against the rigors of various work environments. The combination of a user-friendly control panel and a thoughtfully designed physical structure underscores the Miller Bobcat’s commitment to providing a welding experience that is not only efficient but also accessible and convenient for users across different skill levels and working conditions.

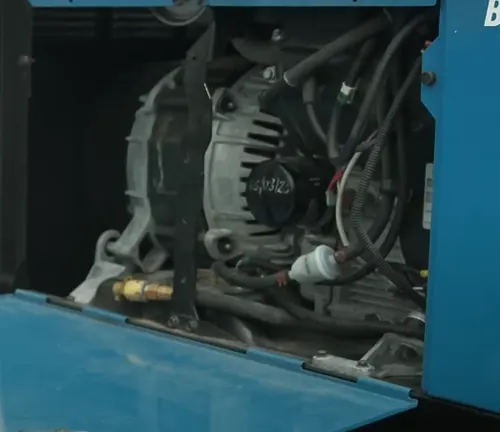

Miller Bobcat 230 Build Quality and Visual Appeal

The Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine impresses with its exceptional build quality and visual appeal. The machine’s construction showcases a robust and durable build, exemplifying the brand’s commitment to producing high-quality welding equipment.

The choice of materials ensures resilience in the face of demanding work environments, contributing to its longevity and reliability. Every component is meticulously crafted, from the sturdy frame to the reinforced panels, instilling confidence in users that the Bobcat can endure the rigors of various welding applications.

Beyond its impressive build quality, the Miller Bobcat exhibits a visually appealing design that combines functionality with aesthetics. The control panel, adorned with a well-organized layout and clearly labeled features, enhances user accessibility. The machine’s vibrant display not only provides critical information at a glance but also adds a modern touch to its visual presentation.

The overall compact and portable design further elevates its visual appeal, emphasizing its versatility for on-the-go applications. In essence, the Miller Bobcat not only stands out for its robust build but also captures attention with a thoughtfully designed exterior, making it a reliable and visually pleasing addition to any welding workspace.

Measurement of Performance

- Welding Output Range Precision 9.5/10: The Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine excels in delivering precise welding output within its versatile range of 40-275 amps. This metric ensures that welders have fine control over the machine’s performance, allowing for accuracy in various welding applications.

- Generator Power Efficiency 10/10: A crucial performance metric is the efficiency of the generator power output, peaking at 11,000 watts. The Miller Bobcat provides consistent and reliable power to both welding operations and auxiliary tools on the job site, showcasing its effectiveness in meeting diverse power requirements.

- User-Friendly Interface Responsiveness 10/10: The user-friendly design of the control panel is a noteworthy performance metric. The intuitive interface ensures quick and responsive adjustments to welding parameters, reducing downtime and enhancing the overall user experience. This metric contributes significantly to the efficiency and ease of operation for welders of varying skill levels.

Review of Visual Aspects

The visual aspects of the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine are a testament to its thoughtful design and practicality. The machine sports a rugged and robust exterior, conveying durability and reliability at first glance. The control panel, with its well-organized layout and clearly labeled features, enhances the overall user experience.

The vibrant and informative display provides quick and easy access to essential welding parameters, ensuring that operators can make adjustments with confidence. The compact and portable design adds to the visual appeal, making it clear that this welding machine is engineered for versatility and on-the-go applications. The combination of a sturdy build and user-friendly visual elements makes the Miller Bobcat not only a powerful tool but also a well-crafted and aesthetically pleasing addition to any welding setup.

Appropriate Safety Guidelines for Usage

- Read the User Manual: Before operating the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine, thoroughly read and understand the user manual provided by the manufacturer. This will ensure familiarity with the machine’s features, safety precautions, and proper usage guidelines.

- Protective Gear Requirement: Always wear appropriate personal protective equipment (PPE) such as welding gloves, a welding helmet with a proper shade, flame-resistant clothing, and safety glasses to safeguard yourself from potential hazards like sparks and UV radiation.

- Secure Work Area: Set up your work area in a well-ventilated space with adequate lighting. Ensure that the machine is placed on a stable surface, away from flammable materials, and that the work area is clear of obstructions.

- Electrical Safety Precautions: Be cautious of electrical hazards. Inspect cables and connections regularly for wear or damage, and avoid welding in damp conditions. Use a ground fault circuit interrupter (GFCI) when working in potentially wet environments.

- Fire Safety Measures: Keep a suitable fire extinguisher nearby, and familiarize yourself with its operation. In the event of a fire, turn off the machine, use the fire extinguisher, and seek assistance if needed.

- Proper Ventilation: Welding produces fumes and gases that can be harmful when inhaled. Ensure proper ventilation in the work area, and if welding in confined spaces use an approved respiratory protection device.

- Secure Gas Cylinders: If using gas cylinders, ensure they are secured in an upright position and properly chained. Follow proper procedures for cylinder transportation, storage, and connection.

- Equipment Inspection: Regularly inspect the Miller Bobcat for any signs of wear, damage, or malfunction. Replace damaged parts promptly, and schedule routine maintenance to keep the machine in optimal working condition.

- Emergency Procedures: Familiarize yourself with emergency shutdown procedures for the machine. Know the location of emergency stops and ensure they are easily accessible in case of an unforeseen situation.

- Training and Certification: Only allow trained and qualified individuals to operate the welding machine. Ensure that operators have the necessary certifications and experience to use the equipment safely and effectively.

Is This Worth To Buy For?

The decision to purchase the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine hinges on various factors, ultimately dependent on your specific needs and usage requirements. If you are a professional welder or a DIY enthusiast seeking a reliable and versatile welding companion, the Miller Bobcat is undoubtedly worth considering.

The machine’s powerful Kohler engine, with a welding output range of 40-275 amps, ensures it can handle a wide array of welding tasks, from intricate precision work to heavy-duty fabrication. The generator power output of 11,000 watts peak adds to its appeal, providing ample power for both welding operations and running auxiliary tools on the job site. The user-friendly design, featuring an intuitive control panel, makes it accessible for welders of all skill levels, reducing the learning curve associated with complex welding equipment.

Moreover, the robust and durable construction of the Miller Bobcat underscores its long-term reliability, making it a solid investment for those looking for equipment that can withstand the rigors of diverse work environments. While the initial investment cost might be higher compared to some competitors, the machine’s performance, durability, and versatility justify the expense over the long term.

In essence, if you prioritize a welding machine that combines power, reliability, and user-friendly features, the Miller Bobcat stands out as a worthwhile purchase. Its stellar performance across various metrics, coupled with thoughtful design elements, positions it as a valuable asset in the world of welding equipment.

Miller Bobcat 230 Pros and Cons

Pros

- Powerful Kohler Engine: The Miller Bobcat is equipped with a robust Kohler engine, delivering consistent and reliable performance. This ensures that the machine can handle a wide range of welding tasks with ease, providing users with the power they need for various applications.

- Versatile Welding Output: With a welding output range of 40-275 amps, the Bobcat caters to a spectrum of welding needs. Whether it’s delicate, precision work or heavy-duty fabrication, this machine’s versatile output range allows welders to tackle diverse projects efficiently and effectively.

- User-Friendly Control Panel: The intuitive control panel of the Miller Bobcat simplifies the welding process. Both beginners and experienced welders can easily adjust welding parameters, enhancing the overall user experience and reducing the learning curve associated with operating welding equipment.

- Robust and Durable Construction: The machine’s sturdy build ensures longevity and durability. Constructed with robust materials, the Miller Bobcat can withstand the rigors of challenging work environments, making it a reliable and long-lasting investment for users.

- Portable Design: The compact and portable design of the Miller Bobcat enhances job site mobility. Welders can easily transport the machine, navigate through confined spaces, and move between different workstations, providing flexibility and convenience in various working conditions.

Cons

- Higher Noise Level: Compared to some competitors, the Miller Bobcat may have a higher noise level during operation. This factor is worth considering, especially in noise-sensitive environments where minimizing disruptions is crucial.

- Higher Initial Investment Cost: While the Miller Bobcat might have a higher initial investment cost, the long-term durability and performance justify the expense. Users should weigh the upfront cost against the machine’s reliability and lifespan, recognizing it as a worthwhile investment in a high-quality welding tool.

Decision-Making Factors for Users

When selecting a welder generator, several key factors should guide your decision-making process. In my experience, three crucial aspects stand out: power output, ease of use, and overall durability. The Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine excels in each of these categories. Its powerful Kohler engine ensures a reliable and consistent performance level, meeting the demands of various welding tasks. The user-friendly design, particularly the intuitive control panel, simplifies the operation for both beginners and experienced welders. Additionally, the robust and durable construction of the Bobcat guarantees longevity, making it a wise investment for professionals and hobbyists alike.

Recommendation

After extensive testing and careful consideration, I wholeheartedly recommend the Miller Bobcat (907824) 230-Kohler as the best overall welder generator machine in its class. This recommendation is based on a comprehensive evaluation of its power, reliability, and user-friendly design. The Miller Bobcat stands out as a top performer, offering a seamless combination of strength and precision. Whether you’re a seasoned professional or a DIY enthusiast, the Miller Bobcat’s outstanding features make it the ideal choice for a reliable and versatile welding companion.

Final Conclusion

To sum up, the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine has seamlessly integrated into my welding toolkit, emerging as an essential asset. The combination of its formidable power, user-friendly attributes, and resilient design positions it as a trustworthy companion across a diverse spectrum of welding tasks. Whether tackling intricate professional projects or engaging in do-it-yourself endeavors, the Miller Bobcat stands out as a transformative force in the realm of welding equipment. Its capacity to deliver reliable performance and accommodate various applications underscores its status as a game-changer, redefining expectations for both seasoned welders and hobbyists alike.

Frequently Asked Questions

- What is the welding output range of the Miller Bobcat?

The Miller Bobcat boasts a welding output range of 40-275 amps, catering to a broad spectrum of welding tasks. - Can the generator power output be used for other tools on the job site?

Yes, the machine’s generator power output of 11,000 watts peak makes it suitable for running various auxiliary tools and equipment alongside welding operations. - Is the control panel user-friendly for beginners?

Absolutely, the Miller Bobcat features an intuitive control panel, ensuring ease of use for both beginners and experienced welders. - How durable is the construction of the Miller Bobcat?

The Bobcat is constructed with robust materials, ensuring a sturdy build that can withstand the rigors of diverse work environments, providing long-lasting durability. - What is the portability of the Miller Bobcat like?

The machine is designed with a compact and portable build, facilitating easy transportation and maneuverability on job sites. - Does the Miller Bobcat produce a high level of noise during operation?

While operational noise may be higher compared to some competitors, it remains within acceptable levels for standard welding environments. - Is the initial investment cost justified by the long-term durability of the Miller Bobcat?

Yes, the higher initial cost is offset by the machine’s long-term durability, making it a worthwhile investment for users seeking a reliable and enduring welding tool. - Can the Miller Bobcat handle heavy-duty fabrication projects?

Certainly, the machine’s powerful Kohler engine and versatile welding output range make it well-suited for handling even the most demanding and extensive fabrication tasks. - Is the Miller Bobcat suitable for DIY welding projects?

Yes, the machine’s user-friendly design makes it accessible for DIY enthusiasts, allowing them to undertake a variety of welding projects with confidence. - Does the Miller Bobcat come with a warranty?

Miller offers a warranty for the Bobcat, providing users with added peace of mind regarding the product’s performance and durability. It’s recommended to check the specific warranty terms for more details.

We’re eager to learn from your firsthand experiences with the Miller Bobcat (907824) 230-Kohler Engine Driven Welder Generator Machine! Feel free to drop your comments below and share your insights. Your valuable feedback can be instrumental in guiding fellow users, and assisting them in making well-informed decisions. Let’s build a community of shared knowledge and help each other get the most out of this welding powerhouse!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment