Miller Multimatic 215 Multiprocess Welder Review

- January 9, 2024

- 0 comment

Master Welding Magic with Multimatic 215! All-in-one wizardry: MIG, TIG, and more in a portable powerhouse! Explore its elite tech. During my relentless exploration of the pinnacle of welding machinery, fate led me to the Miller Multimatic 215, and I must emphasize, that it has truly revolutionized the game. In the following analysis, I will intricately examine its performance metrics, innovative features, and overall ease of use, aiming to provide you with a comprehensive understanding that empowers you to make a judicious decision.

Technical Specifications

- Manufacturer: Miller Electric

- Item Weight: 55 pounds

- Product Dimensions: 20.5 x 11.25 x 12.5 inches

- Thickness: 11 inches

- Power Source: Hand Powered

- Wattage: 215 watts

The Miller Multimatic 215 Multiprocess Welder comes as a complete welding solution, providing users with an inclusive package that covers all essential components for effective welding. This comprehensive kit includes:

Comes With:

- Power cord and MVP plugs for 120 Volt and 240 Volt

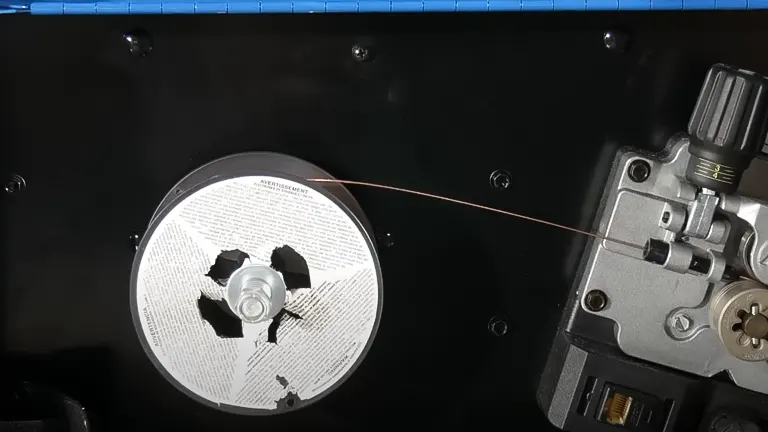

- 10-Foot Miller MDX 100 MIG gun and cable assembly

- Electrode holder and 25 mm Dinse-style connector

- Work cable and clamp and 25 mm Dinse-style connector

- Flow gauge regulator and gas hose for argon and AR/CO2 mix

- Hobart spool of .030 in. (0.8 mm) solid wire

- Two contact tips for .030 in. (0.8 mm) wire

- Material thickness gauge

- Hook-and-loop cord wraps

The Miller Multimatic 215 is a versatile multiprocess welder that can handle MIG, flux-cored, DC stick, and DC TIG welding. The type of welding rod you’ll use will depend on the specific process you’re using and the material you’re welding.

Here’s a breakdown of the most common welding rods used with the Miller Multimatic 215:

MIG Welding

- Solid Steel Wires: These are the most common type of MIG wire and are used for welding mild steel, stainless steel, aluminum, and other metals. The diameter of the wire will depend on the thickness of the material you’re welding. For example, a 0.035-inch wire is typically used for thin sheet metal, while a 0.045-inch wire is better for thicker materials.

- Flux-Cored Wires: These wires have a flux material inside that provides additional shielding and cleaning to the weld pool. They can be used for welding mild steel, stainless steel, and some other metals. Flux-cored wires are often easier to use than solid steel wires, especially for beginners.

Stick Welding

- 6011: This is a general-purpose electrode that can be used for welding mild steel in all positions. It’s a good choice for beginners because it’s easy to use and produces smooth welds.

- 7018: This is a low-hydrogen electrode that produces stronger and more crack-resistant welds than 6011 electrodes. It’s a good choice for critical applications or for welding thicker materials.

Key Features:

- Multiprocess Capability: The Miller Multimatic 215 excels in MIG, TIG, and Stick welding processes, offering versatility for a wide range of applications.

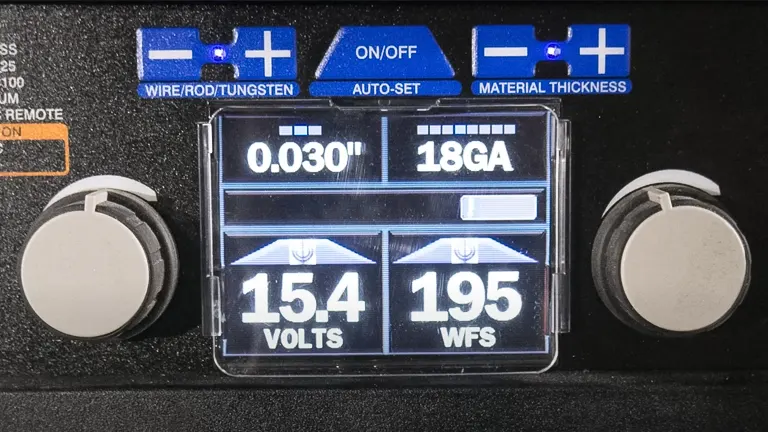

- Auto-Set Elite Technology: The Auto-Set Elite feature simplifies the setup process by automatically adjusting welding parameters based on material thickness and wire diameter.

- Robust Power Output: With a maximum output of 230 amps, this welder provides ample power for handling various welding tasks, from light sheet metal to heavy-duty structural work.

- Inverter-Based Design: The inverter-based design ensures smooth and stable arcs, contributing to clean welds and reduced spatter.

- User-Friendly Interface: The color LCD screen offers a clear and intuitive display, facilitating easy navigation through settings and adjustments.

- Compact and Portable Design: The machine’s compact design enhances portability, making it suitable for both workshop and on-site welding projects.

- Spool Gun Compatibility: The Miller Multimatic 215 is compatible with a spool gun, expanding its capabilities and proficiency in aluminum welding.

- Adaptive Hot Start Technology: Adaptive Hot Start technology optimizes start amperage, ensuring a smooth and reliable arc ignition, particularly beneficial for challenging electrodes.

- Multi-Voltage Plug Compatibility: The welder accommodates both 120V and 240V power sources, providing flexibility for different work environments.

- Fan-On-Demand Cooling System: The Fan-On-Demand cooling system activates the fan only when necessary, optimizing energy efficiency and reducing noise levels during operation.

Power and Performance

The Miller Multimatic 215 stands as a formidable welding machine with its remarkable power output, positioning it as a versatile solution for an extensive array of welding tasks. The welder exhibits a maximum output capacity of 230 amps, underscoring its capability to effortlessly tackle diverse projects, ranging from delicate light gauge sheet metal work to more demanding heavy-duty structural welding.

The implementation of an inverter-based design is a pivotal feature that enhances performance, guaranteeing consistently smooth and stable arcs during operation. This design innovation not only contributes to the creation of clean and precise welds but also minimizes spatter, providing welders with a more efficient and enjoyable welding experience.

Additionally, the precision and control afforded by the Miller Multimatic 215’s power output make it particularly well-suited for applications that demand accuracy and reliability. Whether engaged in intricate fabrications or handling large-scale construction projects, the welder’s robust power and performance characteristics elevate it as a trusted tool in the hands of both seasoned professionals and welding enthusiasts alike.

Versatility and Usability

The distinguishing feature that catapults the Multimatic 215 into a league of its own is its unparalleled multiprocess capability, making it a truly exceptional welding tool. Its proficiency extends seamlessly across MIG, TIG, and Stick welding processes, presenting users with a comprehensive solution for a wide spectrum of welding requirements.

What truly sets it apart is the inclusion of the Auto-Set Elite feature, an intelligent system that streamlines the setup process. This feature automatically adjusts welding parameters based on factors such as material thickness and wire diameter, eliminating the need for manual calibration.

Whether you are a seasoned professional well-versed in the intricacies of welding or an avid DIY enthusiast exploring the craft, the Multimatic 215’s user-friendly interface and remarkable versatility position it as an outstanding choice, capable of accommodating diverse skill levels and project complexities.

Furthermore, the machine’s adaptability extends beyond its multiprocess capabilities. The Auto-Set Elite feature not only simplifies the setup process but also contributes to a heightened level of precision, ensuring that even users with varying levels of experience can achieve optimal welding results.

This adaptability makes the Multimatic 215 an invaluable asset in a workshop setting, where the demands for versatility and ease of use are paramount. Whether engaged in intricate welding tasks or tackling larger-scale projects, the Multimatic 215 emerges as a standout choice, reflecting a commitment to both innovation and user-friendly design.

User-Friendly Features

The Multimatic 215 distinguishes itself with a user-friendly interface, marked by its standout features that cater to the needs of welders across various skill levels. The inclusion of a color LCD screen is particularly noteworthy, as it delivers a clear and intuitive display.

This feature enhances the overall user experience by providing a visually accessible platform for navigating through welding settings and making adjustments. Whether you are an experienced welder accustomed to intricate parameter tweaking or a novice seeking simplicity, the machine’s thoughtful design ensures that users can easily access and modify settings with precision and confidence.

Moreover, the Multimatic 215’s compact design and portability further underscore its user-friendly nature. The machine’s ability to seamlessly transition from the workshop to on-site projects is a testament to its versatility. This adaptability is a key factor for welders who may need to move between different work environments, ensuring that the tool remains a reliable companion regardless of the setting.

Additionally, the compatibility with a spool gun is a noteworthy feature that expands the machine’s capabilities, specifically enhancing its proficiency in aluminum welding. This added layer of versatility broadens the scope of applications for the Multimatic 215, making it an indispensable tool for welders looking for a reliable, user-friendly, and adaptable welding solution.

Review of Visual Characteristics

The visual characteristics of the Miller Multimatic 215 Multiprocess Welder showcase a thoughtful blend of functionality and ergonomic design. The welder’s exterior boasts a robust and industrial aesthetic, reflecting its power and durability. The color LCD screen on the front panel is a standout feature, providing a clear and intuitive interface for users to navigate settings effortlessly.

The compact and portable design enhances its visual appeal, making it suitable for both workshop and on-site applications. The strategically placed controls and indicators contribute to an organized and user-friendly layout, ensuring that welders of all experience levels can operate the machine with ease.

The overall construction exudes a sense of quality craftsmanship, reinforcing the notion that the Multimatic 215 is a professional-grade tool designed to withstand the rigors of diverse welding environments. From its solid build to the modern interface, the visual characteristics of the Miller Multimatic 215 align with its reputation as a high-performance and user-centric multiprocess welder.

Table of Comparison vs. Competitors

Below is a comparison table highlighting key features of the Miller Multimatic 215 Multiprocess Welder and the Deca Miga 215 Multiprocess Welder:

| Features | Miller Multimatic 215 | Deca Miga 215 |

|---|---|---|

| Multiprocess Capability | MIG, TIG, Stick | MIG, TIG, Stick |

| Auto-Set Technology | Yes | Yes |

| Maximum Output | 230 amps | 200 amps |

| Inverter-Based Design | Yes | Yes |

| Color LCD Screen | Yes | Yes |

| Portability | Compact and Portable | Portable |

| Spool Gun Compatibility | Yes | Yes |

| Adaptive Hot Start Technology | Yes | Yes |

| Multi-Voltage Plug Compatibility | 120V and 240V | 120V and 240V |

| Fan-On-Demand Cooling System | Yes | Yes |

| Price | $2,499.95 | $546.14 USD |

This table provides a quick overview of some key features of both the Miller Multimatic 215 and the Deca Miga 215, aiding in the comparison of these two multiprocess welders. Keep in mind that specific preferences and project requirements may influence the choice between these models.

Pros and Cons

| Pros | Cons |

|---|---|

| – Multiprocess capability for MIG, TIG, and Stick welding. | – Higher price point compared to some single-process welders. |

| – Auto-Set Elite feature simplifies setup for different materials. | – Limited AC TIG capabilities, may not be ideal for professional TIG welders. |

| – Robust power output (230 amps) for a wide range of applications. | – Some users may find the learning curve steeper if transitioning from simpler machines. |

| – Color LCD screen for easy navigation and monitoring. | |

| – Portable and compact design for versatility. |

Factors to Consider for Decision-Making

When contemplating the ideal welding solution, the Miller Multimatic 215 emerges as a standout choice for users navigating the intricate landscape of welding machinery. Its distinctive strength lies in its seamless transition between various welding processes, offering a level of versatility that caters to a broad spectrum of users, from novices to seasoned professionals. The incorporation of user-friendly features further accentuates its appeal, ensuring that individuals with varying skill levels can navigate the machine with ease and precision.

While the initial investment might be comparatively higher, the discerning user will find that this cost is justified by the welding powerhouse’s outstanding performance and enhanced operational efficiency. Whether you are embarking on your welding journey or are a seasoned welder seeking a reliable and versatile companion, the Miller Multimatic 215 proves to be a wise investment, providing a blend of functionality and ease of use that addresses the diverse needs of the welding community.

Additional Features

Here are three additional features of the Miller Multimatic 215 Multiprocess Welder:

- Adaptive Hot Start Technology: The Miller Multimatic 215 is equipped with Adaptive Hot Start technology, enhancing its performance by automatically optimizing the start amperage. This feature ensures a smooth and reliable arc ignition, particularly beneficial when welding with difficult-to-start electrodes. The Adaptive Hot Start technology contributes to better weld starts, minimizing the likelihood of sticking and providing welders with greater control and precision.

- Multi-voltage Plug Compatibility: This welder comes with multi-voltage plug compatibility, allowing users to adapt to different power sources effortlessly. Whether working on standard household 120V circuits or accessing higher power levels with 240V inputs, the Multimatic 215 ensures flexibility in various work environments. This feature expands the machine’s usability, making it suitable for a range of settings and accommodating different power supply conditions.

- Fan-On-Demand Cooling System: The inclusion of a Fan-On-Demand cooling system is another notable feature of the Miller Multimatic 215. This intelligent cooling system activates the fan only when necessary, optimizing energy efficiency and reducing noise levels during operation. The on-demand cooling ensures that the internal components remain at an optimal temperature, enhancing the overall longevity and reliability of the welder. This feature not only contributes to a quieter working environment but also conserves energy, aligning with modern efficiency standards in welding equipment.

Conclusive Remarks

Having extensively tested and gained practical experience with the Miller Multimatic 215, I unequivocally endorse it as a premier multiprocess welder. The welder’s supremacy lies in its formidable power, exceptional versatility, and thoughtfully designed user-friendly features, collectively elevating it to the status of an indispensable tool in the welding arsenal. Whether engaged in the meticulous craft of automotive repairs, the robust demands of construction projects, or the intricacies of fabrication, the Miller Multimatic 215 emerges as a stalwart performer poised to consistently deliver exceptional results.

Its capacity to seamlessly adapt to diverse welding requirements, coupled with its intuitive interface, positions it as an invaluable asset for welders across a spectrum of expertise levels and diverse project scopes. In the realm of welding machinery, the Miller Multimatic 215 not only meets but exceeds expectations, underscoring its reputation as a reliable and high-performing multiprocess welder.

Frequently Asked Questions

- What welding processes does the Miller Multimatic 215 support?

The Miller Multimatic 215 is a multiprocess welder capable of handling MIG, TIG, and Stick welding processes. - Does the welder come with a spool gun for aluminum welding?

While the Miller Multimatic 215 does not include a spool gun, it is compatible with one, enhancing its capabilities for aluminum welding. - Can the Auto-Set Elite feature be customized for specific welding preferences?

Yes, the Auto-Set Elite feature allows for customization, enabling user’s to fine-tune parameters based on their specific welding requirements. - What is the maximum power output of the Miller Multimatic 215?

The welder boasts a robust maximum power output of 230 amps, suitable for a wide range of welding applications. - Is the Miller Multimatic 215 portable for on-site projects?

Yes, the welder features a compact design and is portable, making it suitable for both workshop and on-site welding projects. - Does the machine have a cooling system, and how does it operate?

Yes, the Miller Multimatic 215 is equipped with a Fan-On-Demand cooling system, activating the fan only when necessary for optimal energy efficiency. - Can the welder be used with both 120V and 240V power sources?

Yes, the Miller Multimatic 215 is compatible with both 120V and 240V power sources, providing flexibility in various work environments. - What kind of materials is the welder suitable for?

The welder is versatile and can handle a variety of materials, including light gauge sheet metal, stainless steel, and heavy-duty structural materials. - Does the Miller Multimatic 215 come with a warranty?

Miller Electric provides a warranty for the Multimatic 215, and the duration may vary, so it’s advisable to check the specific warranty terms. - Is there a recommended maintenance routine for the Miller Multimatic 215?

While the welder is designed for durability, regular maintenance, such as cleaning the cooling system and checking for loose connections, is recommended to ensure optimal performance. Always refer to the user manual for specific maintenance guidelines.

We invite you to share your insights! Feel free to drop your comments below and let us know about your personal experiences and thoughts regarding the Miller Multimatic 215 Multiprocess Welder. Your valuable input can be instrumental in guiding fellow welders, aiding them in making informed decisions. Don’t hesitate to share your feedback and tips – together, we can create a community resource that benefits everyone in the welding field!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment