SuperSplit Log Splitter Review

- February 19, 2024

- 3 comment

In the world of log splitting, efficiency, reliability, and power are paramount. The Super Split Heavy Duty (HD) Log Splitter promises to deliver on all these fronts with its unique design and robust features. This review dives into the heart of what makes the SuperSplit HD a contender for those looking to streamline their wood splitting process, highlighting its performance, design upgrades, and practicality in real-world use.

Wondering How SuperSplit Log Splitter Works?

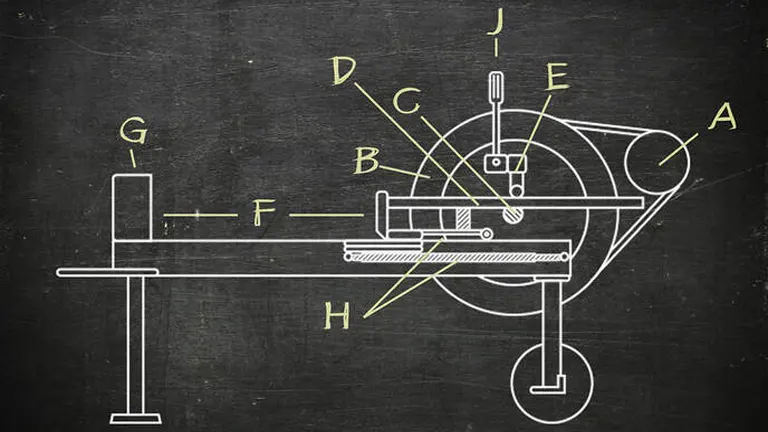

After power is turned on (either gas or electric [ A ] ), the kinetic energy is stored in two revolving flywheels [ B ]. These flywheels are firmly secured to a one-piece pinion gear [ C ]. Because of the flywheel weight and RPM, as well as being mounted on ball bearings and secured to the frame, the pinion gear has tremendous power advantage.

To transmit power from pinion gear to log, a rack gear [ D ] is engaged by a cam-lock assembly [ E ]. The rack gear, now fully engaged and locked in the pinion gear, moves out with a 12 to 24 ton force across the log bed [ F ] into the alloy heat-treated steel blade [ G ]. At the end of the full 24” stroke, the rack is spring loaded upward and backward [ H ], which disengages the cam lock and immediately returns to start position.

For safety reasons, the SuperSplit log splitter is a semi-automatic machine. This means every cycle must be manually activated by lowering and raising the operation lever [ J ] that engages the cam-lock; but after activation, the rack will complete a full cycle. The cycle, however, can at any time be interrupted by simply returning the operating lever to the up position. The flywheel will also stall on overload. Successive cycles may be engaged if necessary in order to drive through particularly large, hard or knotty logs. Flywheel recovery time is about 1/2 second. (If you have ever used a rack type arbor press or swung a heavy maul, you will better understand why the SuperSplit kinetic log splitter principle works so well.

Power and Performance

At the core of the SuperSplit HD are two 90-pound flywheels that store an immense amount of kinetic energy. This energy is unleashed via a pusher arm, which, when engaged, forcefully drives wood through a wedge, splitting it efficiently. The action is initiated by actuating a control arm, which in turn moves a rack gear to interact with the flywheels, demonstrating a seamless integration of mechanics for optimal splitting performance.

Design and Durability

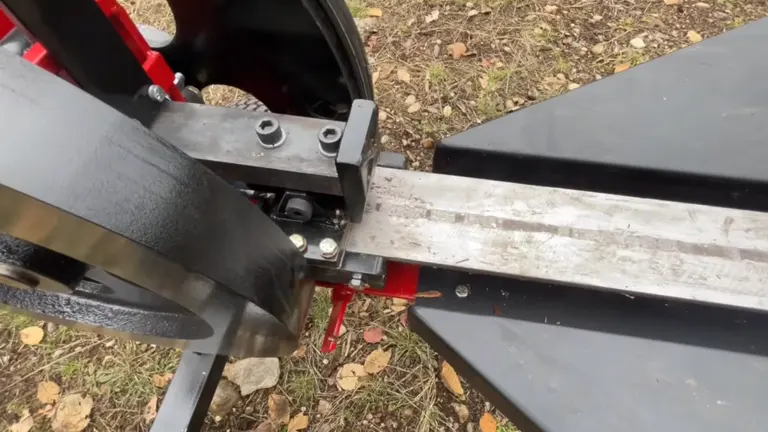

The HD model has seen significant upgrades from its predecessors, most notably in its pusher design. It boasts a two-and-a-quarter-inch wide rack gear and a pivoting pusher mechanism supported by four bearings, ensuring minimal space between the pusher plate and the I-beam. This design reduces debris interference and improves the return stroke’s smoothness—a crucial factor in maintaining consistent operation and minimizing maintenance hassles.

Ease of Use and Maintenance

One of the HD model’s standout features is its ease of maintenance. Regular cleaning of the I-beam surface is necessary to prevent the roller bearings from developing flat spots, which could impede the pusher arm’s return stroke. This maintenance is straightforward, requiring only a spray solvent to keep the area clean and functional.

Mobility and Versatility

The SuperSplit HD is designed with mobility in mind, equipped with a tow hitch and off-road tires suited for transportation around your wood yard but not recommended for road travel. The addition of an extra-wide production table with telescoping support legs enhances its versatility, allowing for easier handling of larger wood rounds and reducing the need for constant bending during operation.

Pros of the SuperSplit HD Log Splitter

- The twin 90-lb flywheels store a significant amount of kinetic energy, making the splitting process faster and more efficient compared to traditional hydraulic splitters. This means you can split more wood in less time.

- With four bearings under the top flange of the I-beam and a pivoting pusher design, the SuperSplit HD offers smoother operation and reduces wear and tear on the machine, enhancing its longevity.

- Equipped with off-road tires and a tow hitch, the SuperSplit HD is designed for easy movement around your property, though it’s not intended for highway use. This makes it convenient for splitting wood in various locations.

- The upgraded production table features telescoping support legs, allowing for adjustments to accommodate larger logs and reduce physical strain during prolonged splitting sessions.

- The HD model’s increased impact force means it can handle tougher woods and larger log sizes up to 24 inches in length, making it versatile for different types of wood splitting needs.

- Regular cleaning of the I-beam surface and a simple check of the bearings and gears can keep the SuperSplit HD running smoothly, highlighting its ease of maintenance compared to more complex machinery.

Cons of the SuperSplit HD Log Splitter

- Despite its mobility features, the SuperSplit HD cannot be legally towed on public roads without a trailer, which might be a limitation for those needing to transport it to different locations.

- New users may need some time to get accustomed to the operation and safety features of the SuperSplit HD, especially the kinetic energy mechanism which differs from hydraulic splitters.

- While generally low maintenance, keeping the I-beam clean and ensuring the bearings do not develop flat spots requires regular attention, which might be overlooked by some users.

- The SuperSplit HD, with its advanced features and heavy-duty design, may come at a higher price point compared to simpler or smaller capacity log splitters, which could be a significant factor for hobbyists or occasional users.

- Due to its robust design and larger size, the SuperSplit HD may require more storage space, which could be a consideration for those with limited room.

Maintenance of SuperSplit Log Splitter

- It’s essential to keep the I-beam and pusher area clean after every use to prevent debris from impeding the pusher arm’s movement and causing wear on the roller bearings. Periodically check the flywheels for debris and buildup, ensuring they remain in good condition for efficient operation.

- Maintain smooth operation by lubricating the bearings, gears, and pivot points of the pusher and control arms regularly. Use the manufacturer-recommended grease or lubricant. This routine should be based on usage frequency but generally revisited every few months.

- Conduct regular inspections of the bearings, flywheels, and gear mechanisms for signs of wear or damage. Any wear on the bearings or cracks in the flywheels can significantly affect the machine’s performance and safety. Also, inspect the structural components, including the frame and I-beam, for integrity.

- Ensure the control arm mechanism operates smoothly and that all bolts and fasteners are secure to prevent safety hazards. Check the alignment of the pusher plate with the I-beam to avoid inefficient splitting and uneven wear.

- Protect the log splitter from the elements by covering it when not in use, especially if stored outdoors. For long-term storage, place it in a dry area and perform a thorough lubrication of all moving parts to prevent rust and ensure readiness for future use.

Conclusion

The SuperSplit Heavy Duty Log Splitter stands out as a robust and efficient solution for those with substantial wood splitting needs. Its innovative design, focusing on power delivery and efficiency, combined with the ease of maintenance and mobility, makes it a compelling choice. Whether tackling tough woods or managing larger logs, the HD model’s upgraded features and reliable performance ensure it’s a worthy investment for both seasoned and amateur woodworkers alike. With a legacy dating back to 1978, the SuperSplit brand continues to embody durability and excellence, and the HD model is no exception, promising to be a reliable partner in your wood splitting tasks for years to come.

FAQs

- What sets the SuperSplit HD model apart from the J model in terms of performance and durability?

The SuperSplit HD is enhanced with twin 90-lb flywheels (up from 75-lb in the J model), offering more kinetic energy for splitting tougher wood. Its pivoting pusher design, with four bearings under the top flange of the I-beam, ensures smoother operation and less wear over time, making it ideal for those who need to split wood closer to the 24-inch maximum length consistently. - Can the SuperSplit HD handle green wood or only dry, seasoned wood?

Thanks to its powerful twin 90-lb flywheels and upgraded pusher design, the Super Split HD can tackle both green and seasoned wood effectively. The kinetic energy stored in the flywheels provides ample force to split even the toughest green wood, although the ease of splitting may vary depending on wood species and moisture content. - How often should I clean the I-beam surface, and what’s the best method to prevent maintenance issues?

Regular cleaning of the I-beam surface is crucial for maintaining the SuperSplit HD’s efficiency. The frequency depends on usage but checking after each splitting session is advisable. Use a spray solvent to remove debris and ensure the roller bearings remain in good condition. This simple maintenance step prevents the pusher arm’s return stroke from being impeded. - Is the SuperSplit HD mobile, and can it be towed to different locations?

While the Super Split HD is designed with off-road tires for mobility around your wood yard or trails, it’s not intended for road towing. For transportation to off-site locations, it’s recommended to use a trailer. The addition of a tow hitch enhances its mobility for easy relocation around your property. - Can the production table be adjusted to accommodate larger logs or different splitting tasks?

Yes, the Super Split HD features an upgraded production table with telescoping support legs, allowing for adjustments to handle larger logs and reduce the need for bending during re-splits. This ergonomic feature enables more efficient and comfortable operation, especially when dealing with varied log sizes. - What should I do if the flywheels stall on a particularly tough piece of wood?

Stalling is a built-in safety feature, not a flaw. If the flywheels stall, it means the wood is offering significant resistance. The SuperSplit HD is designed to give the wood a “Round One” attempt, then use the full momentum of the flywheels for a subsequent attempt, ensuring the wood is split without overexerting the operator or damaging the machine. - How does the SuperSplit HD ensure consistent performance over years of use?

The SuperSplit HD’s design, featuring a two-and-a-quarter-inch wide rack gear and a pivoting pusher with four bearings, ensures consistent space between the I-beam and pusher plate, minimizing debris interference. Regular maintenance and cleaning further enhance its longevity, with many units remaining operational for decades due to their robust construction and thoughtful design.

We hope this review of the SuperSplit Heavy Duty Log Splitter has been insightful and helpful! Whether you’re a seasoned wood splitter or considering your first purchase, we’d love to hear from you. Have you used the SuperSplit HD before? Do you have any tips or questions about log splitting? Share your thoughts and experiences in the comments below. Your input not only enriches our community but also helps others make informed decisions. Happy splitting, and don’t forget to share this review with fellow wood enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

3 comments

What is the cost?

Fritz Duclos

February 23, 2024 6:46 amAround $2,295, or you can Read our post on Best log splitter for the money

Where can they be viewed

Ron Potter

February 23, 2024 6:23 pm