Best Sawmill Blades for Hardwood

- July 4, 2023

- 2 comment

Hardwood has been a staple in construction and furniture making for centuries. To work with this tough material, you need tools that are precise, strong, and durable—especially when it comes to sawmill blades. These blades are crucial for turning rough hardwood into fine, usable lumber.

However, not all sawmill blades are up to the task. Choosing the right blade is key to cutting through hardwood effectively and keeping it sharp for many uses. In this article, we’ll explore the Top Four Sawmill Blades that are ideal for slicing through hardwood effortlessly.

Best Sawmill Blades List:

- Ripper37 Blades

- Wood-Mizer Turbo 747 Blades

- Lenox Woodmaster C Sawmill Blades

- Simonds Red Streak Carbon Bandsaw Blade

Things To Consider When Choosing A Sawmill Blade

- Type of Wood: The type of wood you’re cutting is a crucial factor. Different woods have different hardness levels, and your blade needs to be able to handle that. Hardwoods typically require stronger, more durable blades than softwoods.

- Blade Material: Blades can be made from a variety of materials, each with its own pros and cons. Steel blades are quite common, but you may also find carbide-tipped blades that offer a longer lifespan and can endure tougher cutting tasks.

- Tooth Design: The design and arrangement of the teeth on a blade can have a significant impact on its cutting efficiency. The tooth count, angle, and size all play roles in how cleanly and quickly a blade cuts through wood.

- Blade Thickness (Kerf): The thickness of a blade, or its kerf, influences how much material is removed during each cut. Thinner blades remove less material, making them more efficient, especially when precision is needed.

- Band Wheel Diameter: The size of the wheels on your sawmill can determine the blade length and width you should use. Larger band wheels typically require wider and longer blades.

- Feed Speed: This refers to how quickly you can feed the wood into the sawmill during cutting. Some blades are designed to handle higher feed speeds than others.

- Maintenance and Sharpening: Over time, any blade will dull and require sharpening. Some blade materials and designs are easier to sharpen than others, and the ease and frequency of required sharpening could influence your blade choice.

Once you have considered all of these factors. Here is the Best Sawmill Blade on the Market:

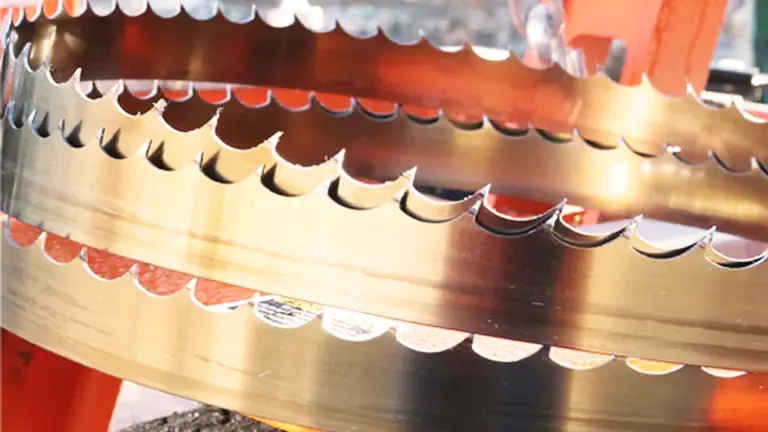

1. Ripper37 Blades

Product Specifications

- Size: 37 inches long, 1/4 inch thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: 6 teeth per inch, alternate hook, and rake

- Ideal for: Ripping through hardwoods and softwoods

Ripper37 blades stand out in the woodworking and sawmill industries for their remarkable durability, versatility, and longevity. Crafted from high-grade, carbon-rich Western European steel, these blades are designed to last up to 37% longer than conventional bandsaw blades. The steel used is not only robust but also incorporates unique metallurgical properties that boost the blade’s cutting performance. This makes them a sound investment for any woodworker or sawmill operator looking for reliability and efficiency.

These blades excel at cutting through tough hardwoods with ease, thanks to their unique tooth profile that minimizes cutting strain. This design allows for smoother cuts, reduces wood wastage, and extends the sharpness of the blade. Additionally, each blade is precision hardened and tempered to achieve the perfect balance of strength and flexibility, enabling them to endure rigorous use while maintaining top performance. The consistent and durable nature of Ripper37 blades ensures they are a preferred choice for professionals engaged in primary wood processing, timber-ripping, and resaw applications, enhancing productivity and cost-efficiency in sawmill operations.

Pros

- Known for lasting 37% longer than other comparable sawmill bands.

- Crafted from carbon-rich Western European steel for enhanced flexibility and longevity.

- Features a tooth set that reduces the frequency of sharpening needed, extending run time and reducing maintenance.

- Versatile for different sawing needs, including handling logs with embedded nails.

Cons

- Higher initial cost compared to standard sawmill blades.

- May not be compatible with all types of sawmills, requiring checks for specific compatibility.

- Not as readily available in some regions, potentially necessitating orders from specific suppliers.

- Proper sharpening requires specialized tools and expertise to maintain optimal efficiency.

2. Wood-Mizer Turbo 747 Blades

Product Specifications

- Size: 747 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 7 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

The Wood-Mizer Turbo 747 blades have established themselves as a top choice in the woodworking industry, especially noted for their superior performance, speed, and cut quality when dealing with hardwood. Designed specifically for high-speed and efficient cutting, these blades feature a distinctive seven-tooth pattern and wide gullet design. This combination not only enables faster, cleaner cuts but also helps in effectively evacuating sawdust, thus maintaining optimal cutting efficiency even when slicing through dense hardwoods.

Built from high-grade steel and equipped with induction-hardened teeth, the Turbo 747 blades are crafted for durability and consistent performance over time. This robust construction ensures that the blades can withstand the demands of heavy and continuous use without compromise, making them ideal for any serious woodworking or milling operation looking to enhance productivity and achieve precise results in their projects.

Pros

- Designed with a deep capacity gullet and extreme back angle for efficient cutting.

- Sharp penetrating points make it the sharpest blade on the market, improving cut quality.

- High-performance blade engineered for all band sawmill and resaw makes and models.

- Available in SilverTip Carbon and DoubleHard High-Alloy steel material for extended blade life.

Cons

- Premium pricing due to specialized design and materials.

- The specific design may not be suitable for all types of woodworking, limiting its versatility.

- Requires precise maintenance to keep the blade in optimal condition.

- May require specialized resharpening techniques due to the unique tooth design.

3. Lenox Woodmaster C Sawmill Blades

Product Specifications

- Size: 72 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 6 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

Lenox Woodmaster C Blades are highly regarded in the woodworking industry for their exceptional quality and durability. These premium carbide-tipped blades are specially designed for cutting hardwoods, which demand a blade that can maintain its sharpness and handle the high temperatures generated by friction during cutting.

The carbide tips on the Woodmaster C Blades enable them to produce a clean, smooth cut, which greatly reduces the need for post-cut finishing. They are renowned for their ability to stay sharp for extended periods, even when continuously cutting through the toughest hardwoods. This durability not only minimizes the frequency of blade replacements but also reduces maintenance costs and increases productivity by ensuring more operational uptime for sawmills.

Pros

- Lenox Woodmaster C Blades are designed for longevity, offering extended life in demanding sawmill applications.

- The blades deliver straight cuts at high band speeds, ensuring precise cutting for various wood applications.

- These blades are optimized for fast cutting rates, enhancing productivity in sawmill operations.

- Ideal for cutting specialty wood applications such as moulding, hardwood flooring, wood siding, and paneling.

Cons

- While offering significant performance benefits, these blades can be more expensive compared to other band saw blades.

- Primarily designed for professional sawmill use, which may not be suitable for casual or smaller-scale projects.

- Requires consistent maintenance to ensure longevity and optimal performance.

- May not be as readily available in local stores, often requiring purchase from specialized suppliers or online platforms.

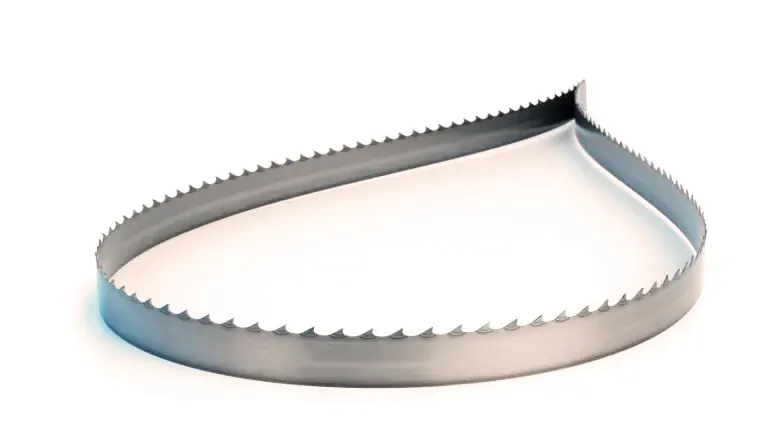

4. Simonds Red Streak Carbon Bandsaw Blade

Product Specifications

- Size: 102 inches long, 0.025 inches thick

- Construction: High-carbon steel

- Tempering: Tempered and hardened

- Teeth: Triple ground, 7 teeth per inch

- Ideal for: Resawing hardwoods and softwoods

The Simonds Red Streak Carbon Bandsaw Blade exemplifies what happens when durability and efficiency converge. Constructed from high carbon steel, this blade is built to last, providing both strength and enduring performance. Its hardened teeth maintain a sharp, consistent cut, essential for handling demanding sawing tasks.

What sets the Red Streak blades apart is their exceptional ability to produce straight and accurate cuts, crucial when working with high-value hardwood. This precision not only ensures quality results but also reduces the strain on sawmill equipment, extending the lifespan of both the blade and the machinery. With a compelling combination of affordability, performance, and longevity, the Red Streak Carbon Bandsaw Blade is a top choice for those specializing in hardwood applications, delivering reliability without compromising on quality.

Pros

- Designed for high performance, particularly on hardwoods.

- Features premium saw steel with superior flexing and heat treating capabilities.

- Specially heat-treated teeth ensure long runs, straight cuts, and extended blade life.

- Supports a convenient set sequence for efficient cutting.

Cons

- May require a higher initial investment compared to standard blades.

- Specialized nature means it might not be as versatile for non-wood materials.

- Potential for limited availability in certain regions.

- Requires proper maintenance and sharpening to maintain optimal performance.

Conclusion

Cutting hardwood requires sawmill blades that are tough, sharp, and durable. The Ripper37, Wood-Mizer Turbo 747, Lenox Woodmaster C, and Simonds Red Streak Carbon Bandsaw Blade each bring unique strengths to the table, allowing you to select the one that best fits your specific needs.

Whether you are dealing with the density of oak, the hardness of maple, or the uniqueness of exotic woods, these blades are equipped to handle the challenge. Each of these options offers a blend of speed, precision, and durability, providing you with the tools needed to transform raw hardwood into pieces of art. Their advanced designs and robust materials make them invaluable assets in the realm of hardwood cutting.

FAQs

- What’s the difference between carbide-tipped and Stellite-tipped blades? Carbide-tipped blades have tips made from carbide, a material known for its exceptional hardness and wear resistance. Stellite-tipped blades have tips made from Stellite, a cobalt-chromium alloy. Both materials are known for their durability and the ability to maintain sharpness over extended periods. The choice between the two often comes down to specific application requirements and personal preference.

- How often should I replace my sawmill blade? The frequency of blade replacement depends on several factors including the type of wood being cut, the volume of wood, and the blade’s quality. High-quality blades like the Ripper37 or the Lenox Woodmaster C can last longer than typical blades.

- Why is my sawmill blade dulling quickly? Several factors can cause a sawmill blade to dull quickly. These include cutting highly abrasive wood species, improper blade tension, inadequate lubrication, and feeding wood into the blade at an incorrect rate.

- How do I maintain my sawmill blades? Proper maintenance of sawmill blades involves regular cleaning to remove sap and resin buildup, proper tensioning to avoid overheating and warping, and regular inspection for any signs of wear or damage. Some blades may also require occasional sharpening.

- What does the tooth profile on a sawmill blade do? The tooth profile on a sawmill blade impacts how the blade cuts through the wood. For example, a tooth profile with more teeth or a more aggressive angle can cut through wood faster but might leave a rougher finish.

- What is the impact of blade width on the cutting process? Blade width can impact the stability of the cut and the minimum radius the blade can cut. Wider blades can provide more stability for straight cuts and are often used for resawing, while narrower blades can make tighter radius cuts.

- Why are some sawmill blades coated? Some sawmill blades have a special coating to reduce friction and heat build-up, which can prolong the life of the blade. The coating can also reduce resin and sap build-up, making the blades easier to clean.

- What type of sawmill blade is best for hardwood? High-quality blades, such as the Ripper37, Wood-Mizer Turbo 747, Lenox Woodmaster C, and Simonds Red Streak Carbon Bandsaw Blade, are all excellent choices for cutting hardwood due to their durability, sharpness, and design features that increase their cutting efficiency and lifespan.

Share Your Insights on the Best Sawmill Blades for Hardwood! At Chainsaw Length Guide, your expertise matters. We encourage you to take a moment and share your thoughts by leaving a comment. Your firsthand experiences and insights about the best sawmill blades for handling hardwood could be invaluable to others in our community. Let’s work together to create a valuable resource that assists those searching for optimal sawmill blade solutions for hardwood projects. Your input holds the power to shape the success of fellow sawmill enthusiasts.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

2 comments

Ripper37 is the best!

I am after a suitable bandsaw blade that will handle Gidgee hardwood

Rob

December 23, 2023 4:18 am