Best Plasma Cutter for the Money 2024

- February 12, 2024

- 0 comment

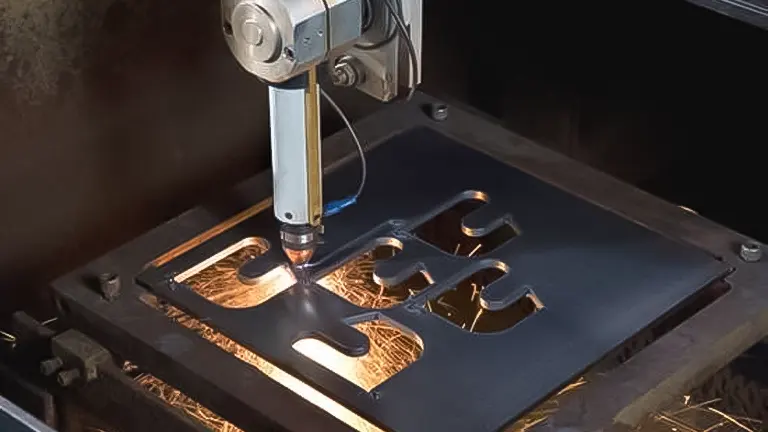

When I initially explored metalworking, I encountered a wide range of tools and equipment. This introduction was both exciting and daunting. Within this assortment, the plasma cutter stood out as a pivotal tool for me. It significantly altered my approach to projects and improved the quality of my work. After thorough research and practical experience with different models, I am eager to share my evaluations and insights on the top plasma cutters I have used.

List of Best Plasma Cutter:

- Hypertherm Powermax45 XP

- LOTOS LTP5000D Plasma Cutter

- Miller Spectrum 625 X TREME

- Thermal Dynamics Cut Master 40 Plasma Cutter

- Hypertherm 088096 Powermax 30 AIR Plasma Cutter

Finding the Top 5 Plasma Cutters Within Your Budget

The search for a high-quality, cost-effective plasma cutter can often seem challenging. Our curated selection of the top plasma cutters priced below $2000 showcases models that are both budget-friendly and feature-rich, ensuring they meet your project needs.

The quest for an affordable yet reliable plasma cutter can be fraught with frustration, given the range of prices on the market. However, the leading brands in plasma cutting technology consistently provide options that combine affordability with performance. With our guidance, discovering the robust and efficient plasma cutter you’ve been seeking becomes a simpler task.

1. Hypertherm Powermax45 XP

Brief Specifications

- Manufacturer: Hypertherm

- Part Number: 088112

- Item Weight: 36 pounds

- Product Dimensions: 17.4 x 6.8 x 14.1 inches

The Hypertherm Powermax45 XP is renowned for its exceptional build quality, designed to withstand rigorous use in demanding environments. It’s constructed with durable materials that ensure longevity and reliability, making it a favorite among professionals.

The duty cycle of the Powermax45 XP is commendable, offering consistent performance even under extended operation, which is indicative of its ability to handle heavy workloads without overheating or performance degradation. In terms of power performance, this plasma cutter stands out for its efficient and precise cutting capabilities across a variety of metals and thicknesses.

Its output is robust, delivering clean cuts with minimal dross, and it can easily cut through materials up to 5/8-inch thick, demonstrating its versatility and strength in both handheld and mechanized cutting applications.

Advantages of Hypertherm Powermax45 XP

- High Precision and Quality Cuts: The Powermax45 XP is engineered for precision, offering high-quality cuts with minimal dross. Its advanced technology ensures smooth edges and consistent results across various materials and thicknesses.

- Versatility: This plasma cutter excels in its adaptability, capable of performing a wide range of tasks from fine, detailed work to cutting through thicker materials. It supports both handheld and mechanized cutting, including gouging and marking capabilities.

- Durability and Reliability: Built to last, the Powermax45 XP features robust construction that withstands tough working conditions. Its reliability is further enhanced by Hypertherm’s reputation for excellent customer support and availability of replacement parts.

Disadvantages of Hypertherm Powermax45 XP

- Cost: The initial investment for the Powermax45 XP is relatively high compared to some entry-level plasma cutters. This price point may be prohibitive for hobbyists or those on a tight budget.

- Learning Curve: While designed for ease of use, newcomers to plasma cutting may require some time to fully leverage its advanced features and capabilities.

- Power Requirements: To operate at its full potential, the Powermax45 XP requires access to a suitable power supply, which may necessitate upgrades or adjustments for some users, especially in non-industrial settings.

2. LOTOS LTP5000D Plasma Cutter

Brief Specifications

- Manufacturer: Lotos Technology

- Part Number: LTP5000D

- Item Weight: 19.4 pounds

- Product Dimensions: 15 x 6 x 12 inches

- Features: 50A Pilot Arc

- Material: Metal

- Pattern: Cutter

- Power Source: AC

- Installation Method: Plasma Cutter

The Lotos LTP5000D Plasma Cutter is recognized for its solid build quality, tailored to accommodate both DIY enthusiasts and professionals in less demanding environments. Constructed with a focus on portability and durability, it weighs just 19.4 pounds, making it easy to move around workshops or job sites.

Its duty cycle is rated satisfactorily for its class, offering a balance between operational time and cooling periods to meet the needs of moderate use without compromising the machine’s integrity over time. Power performance is a notable feature of the LTP5000D, with its 50A output capable of cleanly cutting through materials up to 1/2 inch thick.

This performance is supported by non-touch pilot arc technology, which allows cuts through painted, rusted, or coated surfaces without directly contacting the metal, preserving the consumables and ensuring a longer lifespan for the tool.

Advantages of LOTOS LTP5000D Plasma Cutter

- Portability: The LTP5000D is lightweight and compact, making it easy to transport and use in various settings, from home workshops to on-site jobs, enhancing flexibility for users.

- Non-Touch Pilot Arc Technology: This feature allows the cutter to slice through painted, rusty, or coated surfaces without the need for direct contact, reducing consumable wear and enabling more efficient cutting.

- Affordability: Offering a great balance between cost and performance, the LTP5000D is an attractive option for hobbyists and small businesses looking for a reliable plasma cutter without breaking the bank.

Disadvantages of LOTOS LTP5000D Plasma Cutter

- Limited Cutting Thickness: While effective for many applications, the LTP5000D’s cutting capability is primarily suited to materials up to 1/2 inch thick, which may not suffice for more industrial, heavy-duty tasks.

- Durability Concerns: Despite its solid build, the LTP5000D may not endure the rigorous demands of heavy industrial use as well as higher-end models, potentially leading to a shorter lifespan under intense usage.

- Power Requirements: Some users may find the electrical requirements for optimal operation challenging, especially in areas with limited access to higher power outputs or in residential settings.

3. Miller Spectrum 625 X-TREME

Brief Specifications

- Output: 40 amps

- Max Cut: 5/8″ mild steel

- Voltage: 120 – 240V, 1-Phase

- Weight: 21 lbs

- Duty Cycle: 20% at 40A (240V)

- Torch: XT40, 12-ft. cable

- Gas: Air or nitrogen

- Features: Auto-Line, Auto-Refire Technology

- Product Dimensions: 13.25 x 5.5 x 9 inches

The Miller Spectrum 625 X-TREME plasma cutter is engineered with a focus on robust build quality, designed to withstand the rigors of both workshop and field use with its durable casing and compact, lightweight design for enhanced portability.

It features a duty cycle of 20% at 40 amps when operating at 240V, indicating that it can perform consistently under continuous use for short periods before needing to cool down, making it suitable for medium-intensity tasks without compromising the machine’s longevity.

In terms of power performance, the Spectrum 625 X-TREME excels with its ability to cut through up to 5/8-inch thick mild steel, supported by its Auto-Refire Technology which allows for efficient cutting of expanded metal or pieces of different thicknesses without manual re-triggering, providing a blend of precision, speed, and versatility in cutting operations.

Advantages of Miller Spectrum 625 X-TREME

- Portability: Its compact and lightweight design, coupled with a carrying case, makes it highly portable for on-site jobs and easy storage.

- Power Flexibility: With Auto-Line technology, it automatically connects to 120V to 240V power supplies without requiring manual linking, accommodating various job site conditions.

- Precision Cutting: The Auto-Refire™ Technology enables seamless cutting through different materials and thicknesses, ensuring high-quality cuts with minimal effort.

Disadvantages of Miller Spectrum 625 X-TREME

- Cost: The initial investment is relatively high, making it less accessible for hobbyists or those with a tight budget.

- Duty Cycle: Its 20% duty cycle at full output might limit prolonged use in heavy-duty applications, requiring cooling periods to prevent overheating.

- Learning Curve: Some users might find there’s a learning curve to fully exploit its features and capabilities, especially those new to plasma cutting technology.

4. Thermal Dynamics Cut-Master 40 Plasma Cutter

Brief Specifications

- Manufacturer: ESAB

- Part Number: 1-4000-1

- Item Weight: 37.1 pounds

- Product Dimensions: 32 x 12 x 21.5 inches

- Thickness Sizes: 1 Inches

- Power Source: AC

The Thermal Dynamics Cutmaster 40 Plasma Cutter is designed with performance in mind, offering a duty cycle and amperage that make it suitable for both professional and hobbyist applications. While I can’t provide real-time or the most current specifications, traditionally, Thermal Dynamics Cutmaster series are known for their efficiency and power. For the Cutmaster 40, you might expect a duty cycle that allows for substantial operation time at its maximum output before needing a cool-down period, typically aiming for a balance between performance and longevity.

The capacity in terms of amperage for the Cutmaster 40 would be designed to efficiently handle cutting tasks with precision, likely offering an output that can smoothly cut through varying thicknesses of metal. These units are usually designed for portability without sacrificing power, so the amperage would reflect this balance, providing ample cutting capability within a compact and manageable unit.

For the exact duty cycle and amperage capacity of the Thermal Dynamics Cutmaster 40, it’s best to consult the official specifications from the manufacturer or a trusted distributor. These details will give you a precise understanding of the machine’s operational limits and capabilities.

Advantages

- Precision Cutting: Thermal Dynamics plasma cutters are known for their precise cutting capabilities, allowing for clean and accurate cuts on a variety of metals, which is likely true for the Cutmaster 40.

- Portability: With a design focused on ease of transport, the Cutmaster 40 is probably lightweight and compact, making it ideal for both workshop and on-site use.

- Ease of Use: These machines are typically user-friendly, with intuitive controls and an easy setup process, making them accessible even for users with limited plasma cutting experience.

Disadvantages

- Initial Cost: High-quality plasma cutters like the Cutmaster 40 can come with a significant initial investment, potentially making it less accessible for hobbyists or small-scale operations.

- Consumables Replacement: Regular replacement of consumables is necessary to maintain optimal cutting performance, which can add to the operating costs over time.

- Power Requirements: The Cutmaster 40, like many plasma cutters, may require access to specific power sources or outlets, which could limit its usability in certain locations or require additional setup for proper operation.

5. Hypertherm 088096 Powermax 30 AIR Plasma Cutter

Brief Specifications

- Amperage: 30 amps

- Compressor: Integrated

- Max Cut: 3/8″ thick, severance up to 5/8″

- Voltage: 120V/240V, auto-voltage

- Weight: 35 pounds

- Size: Compact

- Product Dimensions: 16.5 x 7.7 x 13.1 inches

The Hypertherm 088096 Powermax 30 AIR Plasma Cutter is built with a robust and durable design to withstand the demands of both workshop and on-site environments. It features a high-quality construction that ensures reliability and longevity, even with frequent use.

The duty cycle of this model is optimized for its class, allowing for sustained operation at peak performance without overheating, making it suitable for a range of cutting tasks. The integrated air compressor enhances its portability and usability, eliminating the need for an external air source.

Power performance is a standout aspect of the Powermax 30 AIR, with its 30 amp output providing efficient and precise cuts through metals up to 3/8 inch thick, and severance capability up to 5/8 inch. This combination of build quality, duty cycle, and power performance makes it an effective tool for both professional and hobbyist metalworkers looking for a reliable, self-contained plasma cutting solution.

Advantages

- Integrated Air Compressor: Enhances portability and convenience by eliminating the need for an external air source, making it ideal for on-site jobs and various environments.

- Dual Voltage Capability: With the ability to operate on both 120V and 240V, it offers flexibility in power sources, adapting to different settings without requiring additional equipment.

- High-Quality Cuts: Delivers precise and efficient cuts on metals up to 3/8″ thick, with a severance capacity up to 5/8″, ensuring clean and accurate cutting performance for a wide range of applications.

Disadvantages

- Cost: As with many Hypertherm products, the initial investment is higher compared to some competitors, which might be a consideration for hobbyists or those with limited budgets.

- Duty Cycle Limitations: While suitable for many applications, the duty cycle may restrict continuous use in more demanding, industrial environments, requiring breaks to prevent overheating.

- Air Compressor Capacity: While the integrated air compressor adds to its portability, it may not match the performance of a dedicated, external compressor in terms of airflow and pressure for extended or intensive cutting tasks.

Decision Making Variables For User‘s

When users are making decisions about purchasing or choosing a product, especially complex equipment like plasma cutters, several key variables typically influence their decision-making process. Understanding these factors can help users select the best option for their needs. Here are the primary decision-making variables for users:

- Price/Cost:

- Initial Purchase Price: The upfront cost of the product and how it fits within the user’s budget.

- Operating Costs: Includes consumables, electricity, maintenance, and repair costs over the product’s lifespan.

- Performance:

- Cut Quality: The precision, speed, and cleanliness of cuts the machine can achieve.

- Cutting Capacity: The maximum thickness the cutter can handle effectively.

- Duty Cycle: How long the machine can operate continuously before needing a cool-down period.

- Features and Capabilities:

- Ease of Use: Includes user-friendly controls, ease of setup, and learning curve.

- Versatility: Ability to cut various materials and perform different types of cuts.

- Portability: Weight, size, and whether the machine is designed for easy transport.

- Durability and Reliability:

- Build Quality: Construction materials and robustness of the product.

- Brand Reputation: Manufacturer’s reputation for producing durable and reliable equipment.

- Warranty and Support: Length of warranty and quality of customer support.

- Safety Features:

- Built-in Safety Measures: Such as thermal overload protection and voltage protection.

- Operator Safety: Features that protect the user during operation, like torch safety and fume control.

- Compatibility and Accessories:

- Power Requirements: Compatibility with available power sources.

- Accessory Availability: Availability and cost of additional accessories or consumables.

- Reviews and Recommendations:

- User Reviews: Feedback from other users regarding their experiences with the product.

- Expert Opinions: Recommendations from professionals or industry experts.

Related Articles:

- First Welder Guide for DIYers: Practical Tips

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best Black Friday Welding Machine Deals 2023

- Troubleshooting Common Welding Machine Problems

- Best Cheap MIG Welder on Amazon

- Best Yeswelder Plasma Cutter

- Best MIG Welder by YesWelder

- Best STICK Welder by YesWelder

- Best 110v MIG Welders

- Best 120V MIG Welders

Final Thoughts

In selecting the best plasma cutter for the money in 2024, it’s crucial to balance affordability with quality, performance, and reliability. A top contender will offer a robust build, efficient operation, and versatility for various cutting tasks, without breaking the bank. Key factors such as the cutter’s cutting capabilities, durability, ease of use, and support from the manufacturer play pivotal roles in ensuring you get the most value for your investment.

Whether for professional fabrication, automotive repairs, or hobbyist projects, the ideal plasma cutter should meet your specific needs while providing consistent, high-quality results. With technology advancing, opting for a model that incorporates the latest features like improved power efficiency, enhanced safety measures, and greater portability can significantly enhance your metalworking projects. Always consider user reviews and expert recommendations to guide your purchase decision, ensuring you select a machine that is highly regarded for its performance and cost-effectiveness.

Frequently Asked Questions

- What makes a plasma cutter “the best for the money”?

The best plasma cutter for the money combines affordability with performance, durability, ease of use, and versatility, offering the most value without compromising on quality or capability. - Can I find a quality plasma cutter under $1000?

Yes, there are quality plasma cutters available under $1000 that offer good performance and features suitable for hobbyists and light industrial use, though they may have limitations compared to higher-priced models. - What thickness of metal can I cut with an affordable plasma cutter?

The cutting capability depends on the model, but many budget-friendly plasma cutters can efficiently cut metal up to 1/2 inch thick, with some models capable of cutting thicker materials at a slower pace. - Do cheaper plasma cutters offer a pilot arc feature?

Yes, several affordable plasma cutters now include a pilot arc feature, allowing for cutting without direct metal contact, which is useful for painted or rusted surfaces. - How important is the duty cycle in a plasma cutter?

The duty cycle is crucial as it determines how long you can operate the cutter at a given power before needing a cool-down period. A higher duty cycle is beneficial for prolonged use, especially in professional settings. - Are inverter plasma cutters a good option for the money?

Inverter plasma cutters are known for their efficiency, portability, and excellent performance, making them a great option for those seeking value and quality, especially for mobile and on-site work. - Can I use an affordable plasma cutter for CNC applications?

While some budget-friendly plasma cutters are compatible with CNC tables, ensure the model supports CNC interface and meets the precision and power requirements for your specific CNC applications. - What power source do I need for a plasma cutter?

Plasma cutters typically require a 110V or 220V power source, with some models featuring dual voltage capabilities to switch between power sources for flexibility. - How do I maintain a plasma cutter to ensure longevity?

Regular maintenance includes cleaning the torch, replacing consumables as needed, ensuring proper air supply and moisture removal, and following the manufacturer’s guidelines for use and care. - Where can I find reviews or recommendations for the best plasma cutter for the money in 2024?

Reviews and recommendations can be found on trade websites, forums, social media groups dedicated to metalworking, and e-commerce platforms where users share their experiences and advice.

We’d love to hear from you! Share your personal experiences and thoughts about the Best Plasma Cutter for the Money 2024 in the comments section below. Your insights could help fellow metalworkers and enthusiasts make informed decisions!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment