Understanding the Significance of 4/4 in Lumber

- April 20, 2023

- 1 comment

What does 4/4, 5/4, 6/4, 8/4, 10/4, 12/4 mean?

The fraction indicates an approximate thickness of the lumber and is more of an identifier than an accurate measurement, as there are additional factors to consider.

What’s the reason behind using these unusual fractions?

While standard sizes like 1×6 or 2×8 are common in softwood lumberyards for materials such as fir, pine, and cedar, the hardwood industry follows a different approach. This is because hardwoods like red oak, cherry, and maple are primarily used for custom or made-to-fit products such as furniture and cabinetry, where uniform sizes in raw materials are unnecessary and more problematic. For instance, since kitchen tables do not have a standard size, sawmills cut hardwood logs to obtain the best yield, resulting in boards with varying widths instead of uniform ones. Sawmills avoid cutting logs to specific sizes or uniform widths as that would produce more waste and require more labor, leading to increased board costs.

On the other hand, softwoods are sold in “standard” sizes like 1×6 and 2×8, as they are cut for particular applications that require those sizes. In building construction, standard and uniform sizes are typically utilized from one building to another, such as door jambs and wall studs.

Thus, the hardwood industry’s standard for indicating lumber size starts with its thickness, expressed as a fraction: 4/4, 5/4, 6/4, 8/4, and so on. This system of naming lumber thickness by quarters was established by the National Hardwood Lumber Association, an organization founded in 1898 to develop a uniform system of grading rules for the inspection and measurement of hardwood lumber.

Now, let’s talk about the most prevalent fraction, which is 4/4.

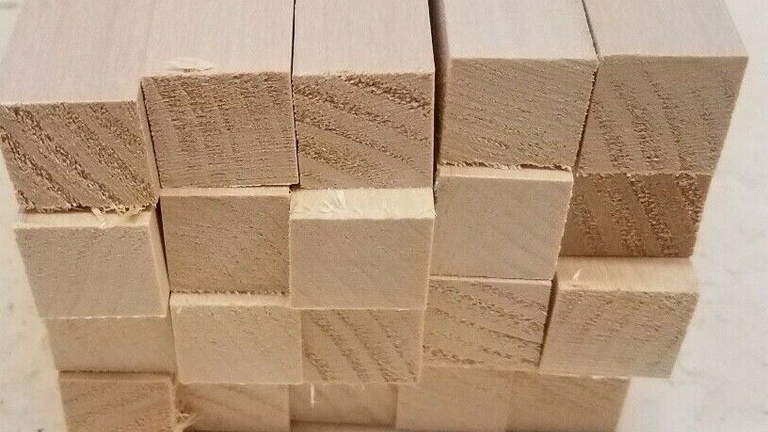

When speaking, I usually refer to 4/4 as ‘four quarters,’ which stands for four quarters of an inch. If you’re good with numbers, you might have already figured out that 4/4 roughly equals one inch in thickness. Similarly, 5/4 means around 1-1/4″ thick, 6/4 means approximately 1-1/2″ thick, how thick is 8/4 lumber roughly 2″ thick, and 12/4 means about 3″ thick. However, to determine the actual measured thickness of the lumber, you need to look for another identifier, such as S2S or RGH. S2S indicates that the lumber has been planed smooth and flat on two sides, while RGH means that it’s still rough sawn and inconsistent. Lumber usually starts as rough sawn, but it needs to be planed smooth and flat before sizing it for the project.

S2S lumber was once rough but has now been planed smooth and flat, which removes some of its thickness. This process answers the question of why 4/4 lumber isn’t exactly one inch thick. The actual measured thickness of S2S 4/4 lumber is 13/16″, which is the standard acceptable thickness of surfaced 4/4 lumber according to NHLA rules.

A lumber dealer like Woodworkers Source faces a dilemma when it comes to rough lumber. Should they surface it smooth and clean, or sell it rough? Both options have their advantages, but stocking both is not practical.

Rough Vs. Surfaced

Pros of Rough Sawn Lumber (RGH):

- Typically less expensive compared to surfaced lumber.

- Can yield more thickness than the standard surfaced thickness.

Cons of Rough Sawn Lumber (RGH):

- Difficult to inspect grain, figure, and color.

- Often cupped or distorted from the drying process.

- Requires time and labor to plane and flatten before moving on to final sizing.

- Heavier and costs more per board foot to ship.

Pros of Surfaced Lumber (S2S):

- Easier for less-equipped woodworkers to use

- Grain, figure, and color are easier to inspect

- Uniform in thickness

- Lighter and less expensive to ship

Cons of Surfaced Lumber (S2S):

- Less control over final thickness

- Surfacing adds to the cost

- Less margin for dealing with cupping and warping

The weight of rough versus surfaced lumber is not always an obvious difference, and while many people assume rough lumber is cheaper due to not having the added cost of surfacing, this is not the whole story. The weight of the lumber also plays a significant role in transportation costs for truckloads or container loads from suppliers. For instance, a flatbed truck can carry up to 45,000 lbs, and the cost of moving that load remains constant, regardless of whether the lumber is rough or surfaced. However, the amount of lumber that will fit on the truck varies, with roughly 11,000 board feet of rough lumber and 14,000 board feet of surfaced lumber. Therefore, it is more practical to pay the slight fee for surfacing (which is around $0.10 per board foot) to the wholesaler to fit more lumber on the truck or container.

Good description

JOE THOMAS

April 21, 2023 11:39 pm