How to Adjust a Miter Saw for Accurate Cuts

- December 4, 2023

- 1 comment

Achieving precise and accurate cuts with a miter saw is essential for any woodworking or DIY enthusiast. The miter saw, a versatile power tool designed for making crosscuts and angled cuts, can deliver exceptional results when properly adjusted. Whether you’re embarking on a home improvement project or crafting intricate woodwork, understanding how to fine-tune your miter saw is paramount. In this guide, we’ll explore step-by-step instructions on how to adjust a miter saw for accurate cuts, ensuring that your projects are not only visually appealing but also meet the highest standards of craftsmanship. Mastering the art of calibration and alignment will empower you to unlock the full potential of your miter saw and elevate your woodworking skills to new heights.

What You Need To Know About Miter Saw?

A miter saw is a handy power tool extensively used in woodworking and carpentry to create accurate and clean cuts in diverse materials such as wood, metal, and plastics. Featuring a circular saw blade mounted on a pivoting arm, this tool allows users to smoothly bring down the blade onto the material. What sets the miter saw apart is its ability to make precise angled cuts effortlessly. By pivoting the saw head horizontally, it excels at miter cuts, and by tilting it vertically, it achieves bevel cuts. There are various types available, including compound miter saws that enable both miter and bevel adjustments, and sliding compound miter saws, which incorporate a sliding mechanism for enhanced cutting capacity. Renowned for their efficiency, precision, and user-friendly nature, miter saws have become indispensable for professionals and hobbyists engaged in a wide range of woodworking and construction projects.

Different Types of Miter Saw

Compound Miter Saw

A compound miter saw is a versatile woodworking tool designed to perform a range of precision cuts, making it an indispensable asset for carpenters and DIY enthusiasts. This type of saw excels at executing crosscuts, miter cuts, bevel cuts, and compound cuts. Its versatility stems from the ability to tilt the blade both horizontally (miter) and vertically (bevel). There are two main types of compound miter saws: single compound and dual compound. A single compound miter saw allows bevel cuts in one direction, while a dual compound miter saw offers the flexibility to make bevel cuts in both directions. This distinction is crucial for users seeking enhanced flexibility in handling various cutting requirements. Compound miter saws play a pivotal role in tasks such as framing, trim work, and furniture making, owing to their capacity for intricate and accurate cuts. Additionally, they come in both sliding and non-sliding varieties, with the sliding compound miter saw allowing for wider cuts due to its sliding mechanism.

Sliding Miter Saw

The sliding miter saw is a dynamic and advanced woodworking tool that elevates the capabilities of traditional miter saws. It shares the fundamental features of its non-sliding counterpart, excelling in crosscuts, miter cuts, bevel cuts, and compound cuts. What sets the sliding miter saw apart is its innovative design, incorporating sliding rails that enable the saw blade to move forward and backward. This sliding mechanism significantly increases the saw’s cutting capacity, allowing it to easily handle wider boards. There are two main types of sliding miter saws: single-bevel sliding compound miter saws and dual-bevel sliding compound miter saws. The single bevel version tilts in one direction for bevel cuts, while the dual bevel sliding miter saw offers the flexibility to tilt in both directions, eliminating the need to flip the workpiece. This adaptability makes the sliding miter saw an ideal choice for professionals and hobbyists tackling diverse woodworking projects that demand precision and efficiency.

Tips on How to Adjust Your Miter Saw for Accurate Cutting

1. Selecting The Right Blade

Choosing the right blade for your miter saw is crucial and depends on the material you’re working with. Crosscutting blades are ideal for clean and precise cuts across the wood grain, while rip blades excel at efficient cutting along the grain. For versatility in handling both crosscutting and ripping tasks, consider using combination blades that seamlessly adapt to various woodworking projects.

Keep in mind the tooth count – opt for a higher count for thin materials and a lower count for thicker ones. Always follow manufacturer guidelines meticulously and prioritize safety precautions when changing blades for a smooth and secure transition.

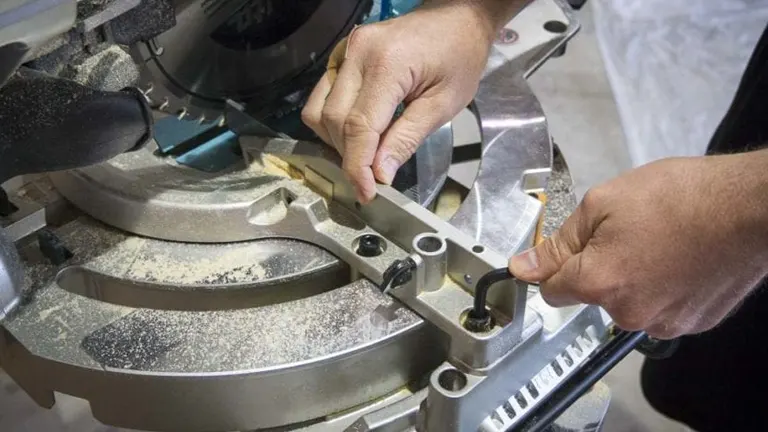

2. Calibrating The Miter Saw

Accurate cuts rely on essential calibration procedures, which entail adjustments to both bevel and miter angles. Begin by utilizing a bevel square to set the bevel angle precisely at 0 degrees, ensuring proper alignment. Simultaneously, for the miter angle, employ a square against the fence and blade, setting the angle to 0 degrees and meticulously confirming precision. To uphold accuracy, it is crucial to routinely inspect and tighten adjustment knobs, thereby maintaining the optimal calibration of your miter saw.

3. Measuring And Marking

Utilize essential measuring tools like a tape measure, combination square, and speed square. For precise angles, a digital angle finder can be beneficial. Ensure clear and visible markings with sharp pencils or marking knives. Double-check measurements before cutting, incorporating a dry-fit method to guarantee accuracy.

4. Proper Technique And Safety

Establish a secure working environment by adhering to appropriate body position and posture guidelines. Safeguard the stability of the workpiece by firmly securing it with clamps or a vise, preventing any unwanted movement during the cutting process. Ensure the constant presence of the blade guard and make use of suitable safety gear to guarantee a protected working environment. Uphold the optimal functioning and safety of the miter saw by consistently performing maintenance services. Regular servicing is essential to sustain the efficiency and safety features of the equipment.

5. Maintaining The Miter Saw

Sustain the operational efficiency of your miter saw by engaging in routine cleaning practices, preventing the accumulation of dust and debris. Apply a high-quality lubricant to the moving components, following the manufacturer’s recommended guidelines for optimal performance. Maintain a sharp blade to steer clear of imprecise cuts and potential harm to the motor. Consistent adherence to regular maintenance routines contributes to the enduring longevity and sustained accuracy of your miter saw.

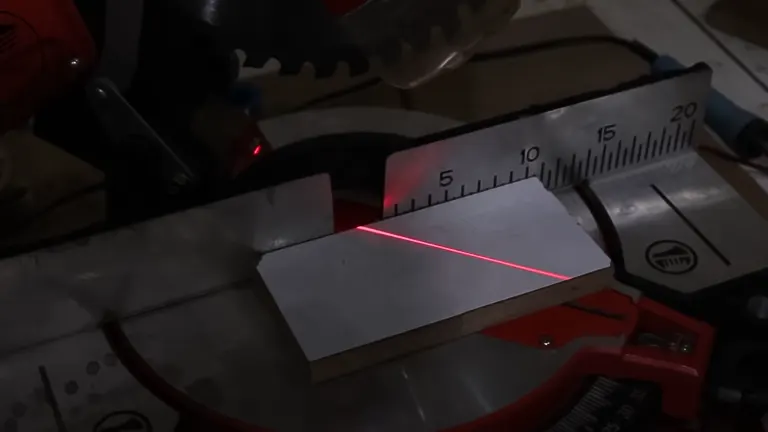

6. Check and Adjust the Laser Guide

Verify the precise alignment of the laser guide on your miter saw with the cutting path. Align the laser guide meticulously in accordance with the manufacturer’s instructions, ensuring it accurately corresponds with your designated cut line. This meticulous adjustment enhances the overall cutting accuracy of your miter saw.

7. Utilize a Zero-Clearance Throat Plate

Enhance the performance of your miter saw by exchanging the standard throat plate with a zero-clearance throat plate. This adjustment effectively minimizes tear-out and splintering, ensuring cleaner and more precise cuts, especially beneficial when handling delicate materials.

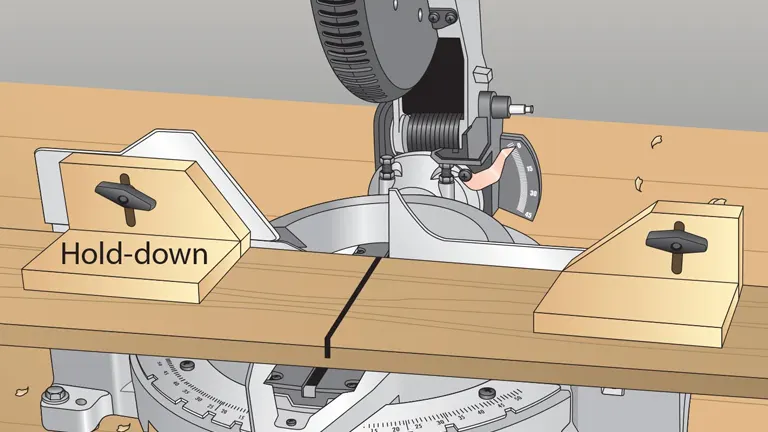

8. Employ a Backer Board for Mitigating Tear-Out

When faced with the challenge of cutting materials susceptible to tear-out, like plywood or veneered surfaces, employ a strategic approach by introducing a sacrificial backer board. Position this supplemental board strategically behind the intended workpiece to effectively reduce the occurrence of tear-out, resulting in a heightened level of precision and cleanliness in your cuts. This method showcases a proactive stance, demonstrating a commitment to achieving optimal results while mitigating potential challenges associated with materials prone to tear-out.

9. Consider a Fine-Toothed Blade for Finishing

When aiming for finishing cuts that demand a polished and smooth outcome, transition to a fine-toothed blade. These blades are specifically designed to generate minimal tear-out, making them the optimal choice for attaining a professional and refined finish in your woodworking endeavors.

10. Prioritize Safety First

Before you embark on any adjustments to your miter saw, it’s imperative to take a moment for safety precautions. The first and foremost step is to make sure that your miter saw is unplugged. This simple act eliminates any risk of accidental starts and ensures that you have complete control over the adjustment process. Safety should be a non-negotiable priority in any woodworking task, and unplugging the saw is a fundamental practice to guarantee a secure workspace.

In addition to unplugging the miter saw, it’s essential to don appropriate safety gear. This includes safety glasses to shield your eyes from potential debris and hearing protection to safeguard your ears from the noise generated during operation. These safety measures extend beyond mere compliance; they actively contribute to creating a focused and secure work environment. By taking these initial steps, you not only shield yourself from potential hazards but also cultivate a mindset of precision and attentiveness as you adjust your miter saw.

Importance of Accurate Cuts With Miter Saw

- Quality Craftsmanship: Accurate cuts contribute to the overall quality of woodworking projects, reflecting a high level of craftsmanship and attention to detail.

- Seamless Project Assembly: Precise cuts ensure that components fit together seamlessly, leading to a polished and professional-looking finished product.

- Safety: Accurate cuts reduce the risk of wood pieces shifting during the cutting process, minimizing the chances of kickback or binding, thus enhancing overall workshop safety.

- Efficiency: Avoiding mistakes associated with inaccurate cuts saves time and materials, improving the efficiency of project execution.

- Aesthetics: Accurate cuts enhance the aesthetics of the final project, creating a visually appealing and well-crafted result.

- Project Accuracy: Achieving precise angles and measurements ensures that the project aligns with design specifications and meets the intended requirements.

- Material Conservation: Accurate cuts help minimize material wastage, optimizing the use of wood and reducing overall project costs.

- Versatility: Accurate miter saw cuts enable woodworkers to tackle a wide range of projects, from intricate fine woodworking to larger construction tasks.

- Professional Results: Whether for professional woodworking or personal projects, accurate cuts contribute to achieving professional-level results.

- Enhanced Project Durability: Accurate cuts promote the proper assembly of components, leading to a more durable and long-lasting final product.

In summary, the importance of accurate cuts with miter saws spans various aspects of woodworking, including craftsmanship, safety, efficiency, aesthetics, and the overall success of the project. Woodworkers are encouraged to prioritize precision in their cuts to reap these numerous benefits.

Things to Consider When Adjusting a Miter Saw for Accurate Cuts?

- Blade Selection: Choose the right blade for your specific task and material. Crosscutting, rip, or combination blades offer different advantages, and considering the tooth count is crucial for the material thickness.

- Calibration: Ensure the miter saw is accurately calibrated. This involves adjusting the bevel and miter angles to guarantee they are aligned, especially when dealing with angles other than 90 degrees.

- Measurement and Marking: Utilize precise measuring tools such as a tape measure, combination square, or digital angle finder. Clear and accurate marking on the workpiece is essential for achieving the intended cut.

- Safety Measures: Prioritize safety by adopting proper body position and posture. Always hold the workpiece securely with clamps, never compromise on using the blade guard, and wear appropriate safety gear.

- Maintenance: Regularly clean the miter saw to prevent dust and debris buildup, lubricate moving parts following manufacturer guidelines, and keep the blade sharp to avoid inaccuracies and potential motor damage.

- Additional Techniques: Implement techniques like using a sacrificial backer board for materials prone to tear-out or switching to a fine-toothed blade for finishing cuts to enhance precision.

- Double-Checking Measurements: Before making the final cut, double-check measurements to avoid costly mistakes. Employ a dry-fit method to ensure the workpiece aligns accurately with the saw blade.

By considering these factors and taking a comprehensive approach, you can fine-tune your miter saw for accurate and precise cuts in various woodworking projects.

Miter Saw Hacks | Tricks of the Trade

Related Articles and Guides

- Miter Saw Guide: Single VS Dual Bevel

- How To Build A Miter Saw Station

- 7 DIY Miter Saw Station Plans For Your Workshop

- 5 Miter Saw Tips to Make Accurate Cuts

Final Verdict

Final Verdict

In summary, achieving precise cuts with a miter saw necessitates a meticulous approach. It commences with selecting the appropriate blade for the material, followed by crucial calibration to ensure accurate angles. Utilizing proper measuring tools, clear marking techniques, and meticulous double-checking contribute to the overall precision. Safety measures, regular maintenance, and additional techniques like using a sacrificial backer board or a fine-toothed blade further enhance the woodworking process. In essence, the path to accurate miter saw cuts involves a comprehensive strategy, covering blade selection, calibration, measurement accuracy, safety adherence, and ongoing maintenance practices for a truly professional outcome.

FAQs

- Why is blade selection crucial when using a miter saw for accurate cuts?

Blade selection is critical as it determines the quality of the cut. Different blades, such as crosscutting, rip, or combination blades, cater to specific materials and cutting requirements, influencing the precision of your woodworking projects. - How often should I calibrate my miter saw for optimal performance?

Regular calibration is essential. Aim for calibration whenever you notice discrepancies in bevel or miter angles, ensuring that your miter saw maintains accuracy and produces precise cuts. - Can using a fine-toothed blade make a difference in the quality of my cuts?

Absolutely. Fine-toothed blades are designed for finishing cuts, minimizing tear-out, and contributing to a polished, professional finish. They are particularly effective when precision and smoothness are paramount. - What safety measures should I prioritize when using a miter saw?

Always wear appropriate safety gear, including safety glasses and ear protection. Maintain proper body positioning, secure workpieces with clamps, and never compromise on the use of the blade guard to ensure a safe cutting environment. - How do I know if my miter saw needs maintenance, and what should I check?

Regularly inspect for sawdust and debris accumulation, clean the saw’s surface, blade guard, and blade after each use. Lubricate moving parts following manufacturer guidelines and ensure the blade remains sharp to prevent inaccurate cuts and motor damage. - Can a misaligned laser guide affect the accuracy of my cuts?

Absolutely. A misaligned laser guide can lead to inaccurate cuts. It’s crucial to adjust the laser guide according to the manufacturer’s instructions, ensuring it precisely aligns with your marked cut line for improved cutting accuracy. - Why is a sacrificial backer board recommended for certain materials?

Materials prone to tear-out, like plywood or veneered surfaces, benefit from a sacrificial backer board. Placing it behind the workpiece minimizes tear-out, ensuring cleaner and more precise cuts. - Is double-checking measurements really necessary before cutting?

Yes, it’s a crucial step. Double-checking measurements helps avoid costly mistakes. Additionally, employing a dry-fit method by aligning the workpiece with the saw blade before the final cut ensures accuracy and prevents errors.

As we wrap up this exploration into the nuances of adjusting a miter saw for accurate cuts, it becomes evident that precision in woodworking is an art form, and the miter saw is a versatile tool that, when fine-tuned, can elevate your craftsmanship. From the careful selection of blades tailored to different materials to the intricacies of calibration and the implementation of safety measures, each facet plays a pivotal role in achieving those immaculate cuts. Remember, it’s not merely a technical process but a holistic journey, encompassing blade choices, calibration finesse, meticulous measurement, and ongoing maintenance. Whether you’re a seasoned woodworker or just embarking on this creative path, may the insights gathered here contribute to the refinement of your skills and the pursuit of excellence in every precise cut you make with your miter saw. Happy crafting!

Benjamin Brooks

Forestry AuthorGreetings! I'm Benjamin Brooks, and my journey over the past 15 years has revolved around the fascinating realms of content creation, expertise in snow clearing, and the intricate world of lumberjacking and landscaping. What began as a simple curiosity about the natural world and heavy machinery has evolved into a passionate profession where my love for crafting words intertwines seamlessly with my lumberjacking and garden skills.

I need a half a dozen of those

Allison

December 18, 2023 7:58 pm