Ironton 125 Flux Cored Welder Review

- April 8, 2024

- 0 comment

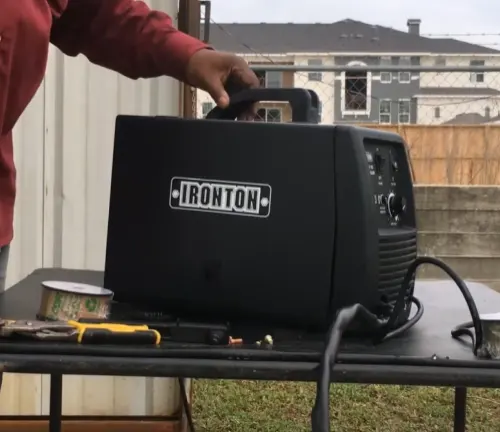

The Ironton 125 Flux Cored Welder is a compact and versatile welding unit designed for those looking to undertake both DIY projects and light industrial tasks. This review aims to give you a detailed first impression, examining everything from unboxing to initial performance assessments.

We’ve got your welding covered! Find comfy, Best welding gloves, Best welding carts, Best welding jackets, plus top picks for Best TIG Welder, Best MIG Welder & Best ARC Welders – all without breaking the bank!

Specifications

- Welding Process: Flux-Cored

- Input Voltage: 115V AC

- Output Range: Up to 125 amps

- Max Welding Thickness: 3/16 inch (mild steel)

- Wire Feed Speed Control: Adjustable

- Portability: Compact and lightweight design

- Operation: Gasless

- Material Compatibility: Primarily mild steel

- Power Source: Electric, standard household outlet

Unboxing Experience

The packaging of the Ironton 125 Flux-Cored Welder is straightforward yet sturdy, ensuring that the unit arrives without any damage.

Inside the box, users will find the welder itself, a flux-cored welding wire, a welding gun, a ground clamp, and a user manual. The presentation is clean and organized, which makes for an easy start right out of the gate.

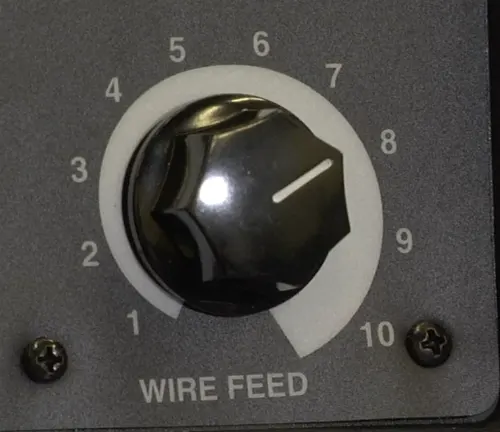

Adjustable Controls

It comes with adjustable wire feed speed and welding current, allowing users to fine-tune the welder according to the specific requirements of the job. This flexibility is essential for achieving the best possible results across a range of materials and thicknesses.

Plug-and-Play Setup

The welder is designed for quick and easy setup right out of the box. This plug-and-play approach reduces downtime and allows users to start welding shortly after unboxing the unit.

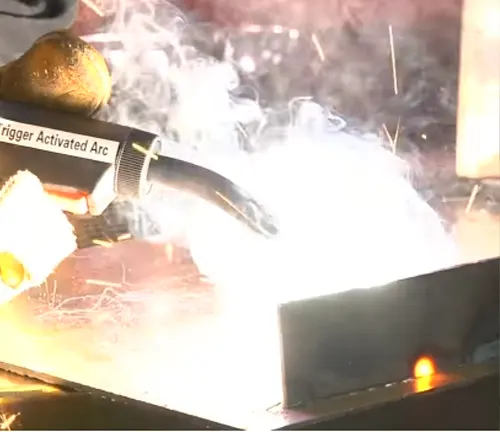

Flux-Cored Welding

This welder utilizes flux-cored welding technology, which doesn’t require an external shielding gas. This makes it more versatile for outdoor use or in windy conditions, as well as more cost-effective since there’s no need to purchase gas.

Compact and Portable Design

With a weight of just under 38 pounds and a compact frame, this welder is designed for easy transport and storage. It’s an ideal choice for those who need a mobile welding solution or have limited workspace.

Design and Build Quality

The first thing you’ll notice is its compact design. Weighing in at just under 38 pounds, this welder is relatively lightweight and portable, making it a good choice for those who need to move their welding setup around frequently.

The build quality feels solid, with a metal housing that can withstand the rigors of a workshop environment. The welding gun and ground clamp also feel durable and well-made.

Performance

Upon initial use, the Ironton 125 Flux-Cored Welder impresses with its capability. It offers adjustable wire feed speed and welding current, allowing users to fine-tune the welder to the specific task at hand. The welder operates on a standard 115V household outlet, delivering a maximum output of 125 amps. This is sufficient for welding mild steel up to 3/16 inch thick, covering a wide range of applications.

The flux-cored welding process it uses is well-suited for outdoor work, as it doesn’t require an external shielding gas. This not only makes the setup simpler and more cost-effective but also allows for welding in conditions that might be challenging for gas-shielded processes.

Setup and Ease of Use

Setting up the Ironton 125 Flux-Cored Welder is remarkably straightforward, thanks in part to the clear and concise instructions provided in the user manual. It’s a plug-and-play setup; after installing the flux-cored wire and connecting the welding gun and ground clamp, you’re essentially ready to begin welding. The simplicity of the setup makes this welder an excellent choice for beginners or those who appreciate efficiency in their tools.

Pros and Cons

Pros

- High power for thick materials.

- Durable, reliable build.

- Efficient, long-lasting operation.

- Easy, comfortable use.

Cons

- Pricier than some rivals.

- Loud on intensive tasks.

Safety and Maintenance

Safety Tips

- Wear Proper Gear Always use a welding helmet with appropriate shade, flame-resistant clothing, gloves, and safety glasses to protect against sparks, heat, and UV radiation.

- Ventilation Ensure your welding area is well-ventilated to avoid inhaling harmful fumes. Use exhaust systems or weld outdoors if possible.

- Electrical Safety Check that the welder is properly grounded. Avoid using the welder in wet conditions to prevent electric shock.

- Fire Safety Keep a fire extinguisher nearby. Remove flammable materials from the welding area to prevent fire hazards.

- Be Aware of Surroundings Make sure there are no tripping hazards and that other people in the area are protected from sparks and bright light.

Maintenance Tips

- Regular Inspection Before each use, inspect the welder for any damage to cables, the welding gun, and the unit itself. Look for signs of wear or damage that could affect operation or safety.

- Clean After Use After each welding session, clean the welder, focusing on the gun and wire feeder to prevent blockages. Remove any accumulated slag or spatter.

- Wire Feeder Maintenance Check the wire feeder regularly for smooth operation. Clean and lubricate it according to the manufacturer’s instructions to ensure consistent wire feed speed.

- Check Connections Periodically check all electrical connections, including the ground clamp, for tightness and wear. Loose connections can lead to poor weld quality and increased electrical hazards.

- Storage Store the welder in a dry, clean place when not in use. This prevents rust and damage from environmental factors.

Assessment of Visual Concepts

The visual design of the Ironton 125 Flux-Cored Welder effectively communicates its functionality and reliability through a series of thoughtful design choices. Its industrial aesthetic, characterized by a robust, matte black casing, suggests durability and the ability to withstand the rigors of heavy use in varied environments, from the home workshop to more demanding industrial settings. The compactness of the device does not only contribute to its portability but also reflects a design philosophy that values efficiency and utility, making it clear that this tool is built for work rather than show.

The layout and presentation of the control panel on the welder are designed with the user in mind. Controls are straightforward and minimalistic, avoiding unnecessary complexity which can be intimidating to novices. This simplicity in design extends to the labeling of controls, which are clear and readable, ensuring ease of use and reducing the learning curve for inexperienced welders.

About This Item

- Flux-Cored Welding Technology Utilizes advanced flux-cored welding technology for efficient welding without external shielding gas, ideal for indoor and outdoor projects.

- Compact and Portable Design Features a lightweight, compact design for easy transport and storage, allowing for effortless movement and neat storage when not in use.

- Adjustable Welding Settings Comes equipped with adjustable wire feed speed and welding current settings, offering the flexibility to fine-tune for different materials and thicknesses, ensuring optimal welding results.

- Durable Construction Built with a robust metal housing and high-quality components to withstand the demands of DIY and light industrial environments, ensuring reliability and performance longevity.

Comparison Table

| Feature | Ironton 125 Flux-Cored Welder | Lincoln Electric K2185-1 Handy MIG Welder |

|---|---|---|

| Welding Process | Flux-Cored | MIG/Flux-Cored |

| Input Voltage | 115V | 115V |

| Output Range | Up to 125 amps | 35-88 amps |

| Max. Welding Thickness | 3/16 inch (mild steel) | Up to 1/8 inch (mild steel) |

| Wire Feed Speed Control | Adjustable | Adjustable |

| Portability | Compact and lightweight for easy transport | Compact and lightweight for easy transport |

| Gasless Operation | Yes | Yes, when using flux-cored wire |

| Additional Features | Durable metal construction, simple setup | Comes with welding gun and cable assembly, work clamp and cable, gas nozzle, gas regulator and hose, making it versatile for both MIG and flux-cored welding |

| Price Point | Generally lower than Lincoln Electric | Higher compared to Ironton due to added MIG capability |

Lincoln Electric K2185-1 Handy MIG Welder Specifications

- Type: MIG/Flux-core

- Input Voltage: 120V

- Output Amperage: Up to 88 amps

- Material Thickness: Up to 1/8 inch (MIG), 1/4 inch (Flux-core)

- Weight: 46 pounds

- Wire Feed Speed Control: Adjustable

- Voltage Control: Fixed

- Portability: Heavier, less portable than lighter models

- Welding Capability: Versatile, capable of both MIG and Flux-core welding

- Price Range: Slightly higher, reflecting dual welding capability

Final Thoughts

While long-term durability and the performance over varied and extended use cases are beyond the scope of a first impression review, the Ironton 125 Flux-Cored Welder shows promising potential. Its combination of portability, ease of setup, and capable welding performance makes it a strong contender in its price range and category. Whether you’re tackling repairs, creative projects, or light fabrication work, this welder merits consideration.

In conclusion, the Ironton 125 Flux-Cored Welder makes a solid first impression, striking a good balance between functionality and user-friendliness. For anyone looking to dive into the world of welding without a hefty investment or complication, this unit offers an appealing starting point.

Frequently Asked Questions

- What type of welding is the Ironton 125 Flux-Cored Welder designed for?

It’s specifically designed for flux-cored welding, which doesn’t require external shielding gas. - Can I use the Ironton 125 Welder for MIG welding?

No, the Ironton 125 is exclusively a flux-cored welder and does not support MIG welding. - What is the maximum welding thickness for the Ironton 125 Welder?

It can weld mild steel up to 3/16 inch thick. - Do I need a separate power supply to use the welder?

No, the welder operates on a standard 115V household electrical outlet. - Is the wire feed speed adjustable?

Yes, the welder features adjustable wire feed speed to accommodate different welding needs. - Can the Ironton 125 Welder be used outdoors?

Absolutely, its flux-cored welding capability is particularly suitable for outdoor use. - How heavy is the welder, and is it portable?

The welder is lightweight and compact, making it easily portable for various job sites. - What materials can I weld with the Ironton 125 Welder?

It’s most effective on mild steel, suitable for a range of DIY and light industrial projects. - Does the welder come with a warranty?

You should check with the retailer or manufacturer for specific warranty details, as these can vary. - What accessories are included with the Ironton 125 Welder?

Typically, it comes with a welding gun, ground clamp, and possibly other accessories, but it’s best to verify the included items at the time of purchase for any changes or updates.

We’re eager to hear from you! If you’ve had the opportunity to use the Ironton 125 Flux-Cored Welder, please share your experiences and insights in the comments section below. Your personal perspective could greatly assist others in understanding the welder’s performance and capabilities, helping them make well-informed decisions. Whether it’s about your projects, the welder’s features, or any tips you’ve discovered, your input is invaluable!

Jack Williams

Forestry AuthorI'm Jack Williams, Jack Williams, my expertise in welding and generator technologies extends beyond traditional boundaries. With over 13 years of experience, I have honed my skills in a range of heavy-duty equipment, focusing particularly on welding and power generation. My passion for nature and commitment to ecological sustainability inform my approach to work. I emphasize safety, efficiency, and staying current with technological advancements. Beyond my technical skills, I am dedicated to sharing knowledge and fostering environmental awareness, aiming to contribute positively to both the welding and generator operation industries.

Leave your comment