Bandsaw Blade Guide 2024

- July 12, 2023

- 0 comment

A bandsaw, the unsung hero of any workshop, can help you carve your way through an array of materials, from the softest woods to hardened steel. At the heart of this machine is the bandsaw blade – an incredible fusion of technology, metallurgy, and precision. Understanding its subtleties can help you make the most of this workshop workhorse. This comprehensive guide will help you understand the various facets of a bandsaw blade, ensuring you choose the perfect blade for your next project.

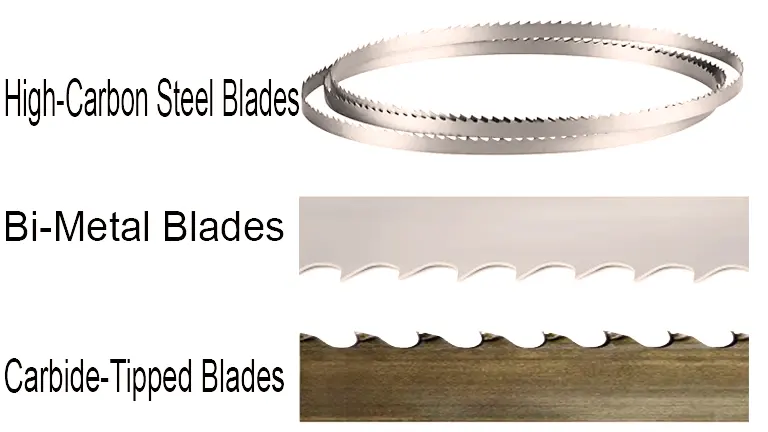

1. Material

Material composition is a key determinant of a bandsaw blade’s characteristics, determining its overall durability and the types of materials it can effectively cut.

- High Carbon Steel Blades: These blades are made from high-carbon steel, an alloy that combines iron and carbon. This material provides the blade with impressive toughness, making it suitable for cutting a variety of materials like wood, plastic, and non-ferrous metals. These blades are typically more affordable than their high-speed or carbide-tipped counterparts, making them a popular choice among hobbyists or those who don’t use their bandsaws regularly.

- Bi-Metal Blades: Bi-metal blades offer enhanced strength and flexibility compared to their high-carbon steel counterparts. These blades are created by combining high-speed steel (HSS) teeth with a flexible alloy back. The HSS teeth offer excellent heat and wear resistance, allowing the blade to maintain its edge even when cutting harder woods and non-ferrous metals. Meanwhile, the flexible alloy back helps to prevent the blade from breaking under stress. This combination of features makes bi-metal blades a favorite among serious woodworkers and professionals.

- Carbide-Tipped Blades: Carbide-tipped blades are designed to handle the toughest cutting tasks. The carbide tips provide superior hardness and heat resistance compared to other materials, enabling these blades to cut through hardened steel, abrasive wooden materials, and non-ferrous metals with ease. Given their capabilities, carbide-tipped blades are often the go-to choice for heavy-duty tasks and commercial applications.

2. Width

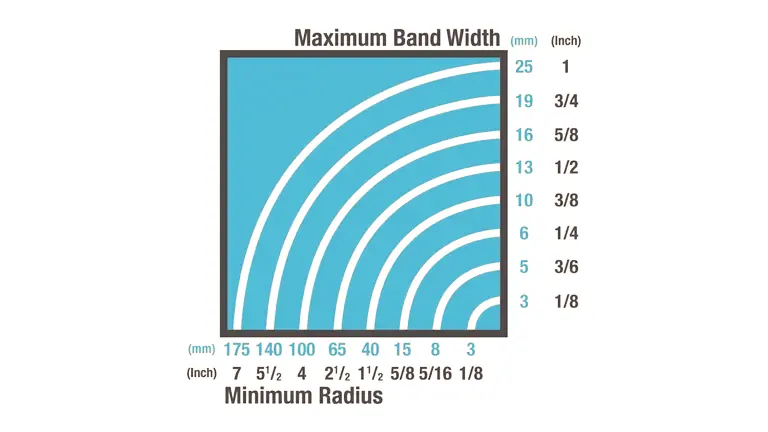

The width of your bandsaw blade affects its performance in several ways, most notably its minimum cut radius and its resistance to deflection under pressure.

- Wider Blades: Wider blades offer more resistance to bending, making them ideal for tasks that require a straight cut, such as resawing or ripping. The increased width provides more rigidity, allowing the blade to resist lateral pressure without deviating from its path. As a result, wider blades can help maintain a straight, accurate cut, even when cutting through thicker materials.

- Narrower Blades: Narrower blades, on the other hand, are designed for more intricate work. They can handle tight radius cuts, making them an invaluable tool for cutting curves or complex patterns. Their smaller width allows them to flex more, enabling the blade to navigate tight turns without breaking or binding.

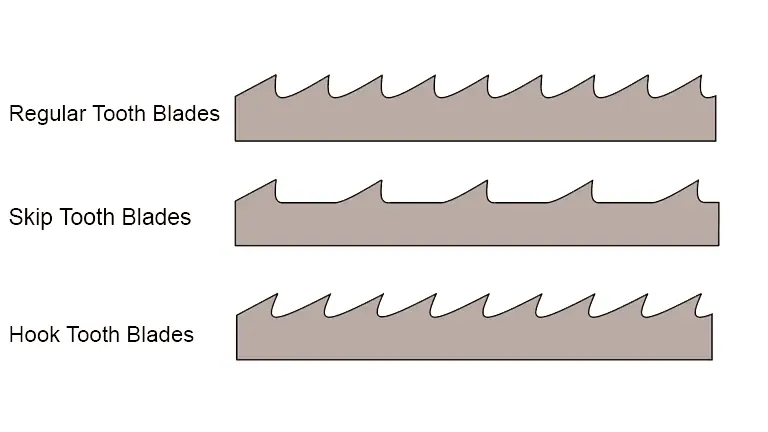

3. Tooth Design

The design of a bandsaw blade’s teeth plays a vital role in its cutting abilities.

- Regular Tooth Blades: These blades feature evenly spaced teeth, making them ideal for general-purpose cutting. They typically provide a smooth, fine finish, particularly when used with thinner materials. The consistent spacing between the teeth helps to ensure an even cut, making these blades a versatile choice for a wide range of projects.

- Skip Tooth Blades: Skip tooth blades have widely spaced teeth, which helps to prevent the blade from clogging when cutting softer, non-ferrous metals or plastics. The increased space between the teeth allows these materials to clear out more effectively, reducing the likelihood of the blade becoming jammed.

- Hook Tooth Blades: Hook tooth blades are characterized by their larger teeth and deeper gullets (spaces between the teeth). These features enable the blade to clear out chips more effectively, which helps to prevent the blade from getting bogged down when cutting thicker or harder materials. The larger teeth and deeper gullets also allow the blade to cut at higher speeds, making hook tooth blades an excellent choice for more demanding tasks.

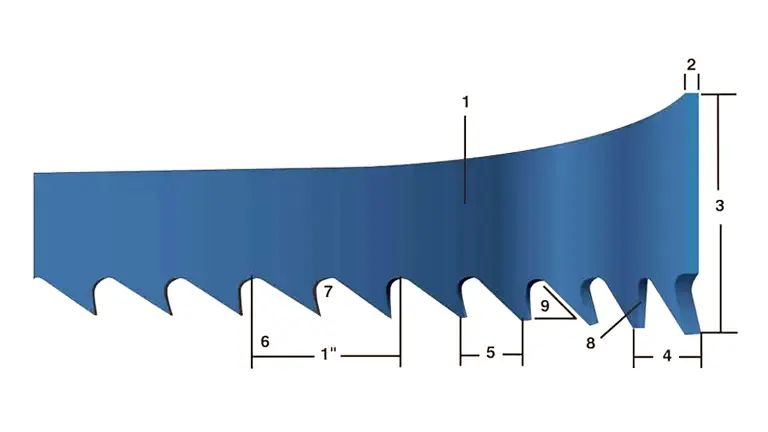

4. Anatomy

- Blade Back: This refers to the main body of the blade, excluding the area where the teeth are located.

- Thickness: This refers to the measure of the blade from one side to the other.

- Width: This is the designated measurement of a saw blade taken from the topmost point of the tooth to the rear of the band, also referred to as the height.

- Set: This is the deviation of the tooth from the central line, shifting to both the right and left, which makes room for the blade back to progress through the cut or kerf.

- Tooth Pitch: This is the distance measured from the apex of one tooth to the apex of the succeeding tooth.

- Teeth per Inch (TPI): This denotes the number of teeth in every inch of the blade, calculated from one gullet (the valley between teeth) to the next.

- Gullet: This is the curved space located at the base of the tooth. The depth of the gullet is measured as the distance from the tooth’s peak to the bottommost part of the gullet.

- Tooth Face: This is the tooth’s surface where the material being cut forms a chip.

- Tooth Rake Angle: This is the angle of the tooth’s face, gauged relative to a line that is perpendicular to the blade’s cutting direction.

Mastering the Bandsaw Blade Sets

The set of a bandsaw blade refers to how far the teeth are offset from the centerline of the blade. This offset can significantly impact the performance of the blade.

- Standard Set: In a standard set, the teeth are arranged in a left-right-straight pattern. This pattern provides a versatile cutting edge that’s suitable for general-purpose cutting. The alternating left-right teeth help to clear out material from the cut, while the straight tooth helps to maintain the blade’s stability.

- Alternate or High Set: In an alternate or high set, the teeth follow a left-right-left-right pattern, with each tooth offset further from the centerline than in a standard set. This arrangement provides a more aggressive cut, making it ideal for tasks like resawing. The higher set allows the blade to clear out more material, which can help balance speed and finish.

- Variable Set: As the name implies, a variable set varies the sequence and degree of tooth offset. This variability can help reduce noise and vibration, providing a smoother cut. It’s particularly effective when cutting thin materials, where stability and precision are key.

The Nuance of TPI (Teeth Per Inch)

TPI, or teeth per inch, is a critical factor in determining the performance of your bandsaw blade. It affects the speed of the cut, the smoothness of the finish, and the type of material the blade can effectively cut.

| TPI | Minimum Material Thickness |

|---|---|

| 32 | 3/32″ |

| 24 | 1/8″ |

| 18 | 5/32″ |

| 14 | 1/4″ |

| 10 | 5/16″ |

| 8 | 3/8″ |

| 6 | 1/2″ |

| 4 | 3/4″ |

| 3 | 1″ |

| 2 | 1-1/2″ |

- Lower TPI: Blades with a low TPI (2-6) have larger, more aggressive teeth and deeper gullets. This design allows the blade to remove more material with each pass, enabling faster but rougher cuts. These blades are typically used for resawing, ripping, or making quick cuts in thicker materials.

- Higher TPI: Blades with a high TPI (14-24) feature smaller, closely spaced teeth. These blades remove less material with each pass, which results in slower, smoother, and more precise cuts. They’re a great choice for detailed work, cutting thin materials, or when a high-quality finish is paramount.

- Mid-range TPI: Blades with a mid-range TPI (6-14) strike a balance between speed and finish. These blades are versatile and suitable for general-purpose cutting, making them a solid choice for a wide variety of tasks.

Understanding the different components and features of bandsaw blades will help you choose the right blade for your needs, ensuring efficient and high-quality cuts every time.

Bandsaw Blade Maintenance: Ensuring Longevity and Performance

Like any tool, your bandsaw blade requires regular maintenance to ensure optimal performance and longevity.

- Cleaning: Regular cleaning helps prevent the build-up of sap, dust, and other materials, which can cause your blade to dull quickly. Use a blade and a bit cleaner to keep the blade in optimal condition.

- Sharpening: Sharp teeth are crucial for quality cuts. A dull blade can overheat, warp, and even break, making sharpening an essential part of maintenance. You can sharpen your blades using a file, diamond stone, or a specialized sharpening tool, but remember to follow the original angle of the blade teeth.

- De-tensioning: After use, especially after prolonged or heavy-duty use, it’s beneficial to de-tension the blade. Continuous high tension can cause the blade to distort and decrease its lifespan.

- Lubrication: Lubrication can reduce heat build-up, minimize wear, and prolong the life of your blade. Use a lubricant recommended by the blade manufacturer.

- Storage: Store your blades properly when not in use. Hang them on a wall-mounted rack or coil them correctly for storage. Avoid leaving them in damp or corrosive environments to prevent rust.

In conclusion, the bandsaw, a quintessential tool for any woodworking enthusiast or professional, owes much of its versatility and efficiency to its blade. The range of bandsaw blades available, each designed for a specific type of cut and material, offers immense flexibility in how we approach our projects.

Understanding the different aspects of a bandsaw blade – the material it’s made from, the width, tooth design, and TPI – allows us to make informed decisions, ensuring we pick the perfect blade for each task. Equally important is the maintenance and safety of these blades, which ensures longevity, optimal performance, and well-being.

Bandsaw blades are more than just pieces of metal. They are an embodiment of the fine balance between science and art, between utility and creativity. With this guide, we hope to have shed some light on their nuances, helping you understand, appreciate, and ultimately, master this invaluable tool.

So the next time you step into your workshop, look at your bandsaw with newfound respect. Think about the blade that’s mounted on it, its strengths, its limitations, and its suitability for the task at hand. Choose wisely, work safely, and most importantly, enjoy the process. After all, every masterpiece starts with a single cut.

Here’s to many happy hours of creating and crafting with your bandsaw – may each project you undertake be a symphony of precision and perfection. Happy woodworking!

Frequently Asked Questions

- What is the right TPI for my bandsaw blade?

The ideal TPI (Teeth Per Inch) depends on the material you’re cutting and the kind of cut you desire. Lower TPI is suitable for quicker, coarser cuts in thicker materials, while higher TPI is used for slow, smooth, and precise cuts, typically in thinner materials. - How do I determine the correct blade length for my bandsaw?

The best way to find the appropriate blade length is to check the user manual of your bandsaw. If this isn’t available, you can measure the distance between the two pulleys. - When should I replace my bandsaw blade?

If you notice decreased performance, increased feed resistance, or deteriorated cut quality, it might be time to replace your blade. Visible signs of wear, such as missing or worn teeth, can also indicate a need for replacement. - Can I use the same bandsaw blade for different materials?

While some blades can handle different materials, using a blade designed specifically for the material you’re cutting will result in better performance and longevity. For instance, blades designed for wood might not perform well or last long when used to cut metal. - What causes a bandsaw blade to break?

Blade breakage can result from various factors, such as excessive tension, improper blade tracking, inadequate lubrication, or a dull blade forced to cut. - How do I prevent my bandsaw blade from rusting?

Store your blade in a dry, clean environment to prevent rust. Some users also recommend applying a light coat of oil or WD-40 to the blade before storage. - What is the purpose of the tooth set in a bandsaw blade?

The tooth set allows the blade to cut a kerf (groove) slightly wider than the blade body, reducing friction and heat build-up, and allowing waste material to clear more efficiently. - Why does my bandsaw blade keep drifting?

Blade drift can be due to several reasons, such as incorrect blade tension, dull blade, misaligned wheels, or an improperly adjusted guide assembly. - Can a bandsaw blade be sharpened?

Yes, certain types of bandsaw blades can be sharpened. It’s worth noting, however, that the process can be labor-intensive and requires precision. Many woodworkers prefer to replace dull blades, especially if they’re inexpensive or have smaller teeth that are difficult to sharpen accurately.

Your expertise is essential! If you’re familiar with the latest trends and insights in bandsaw blade technology for 2024, we encourage you to share your knowledge in the comments section below. Help fellow woodworking enthusiasts stay up-to-date by discussing factors like blade materials, tooth configurations, and specialized applications. Your insights could make a significant difference in guiding others towards the right bandsaw blade choices for their projects. Join the conversation and contribute to the collective understanding of bandsaw blades in 2024!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment