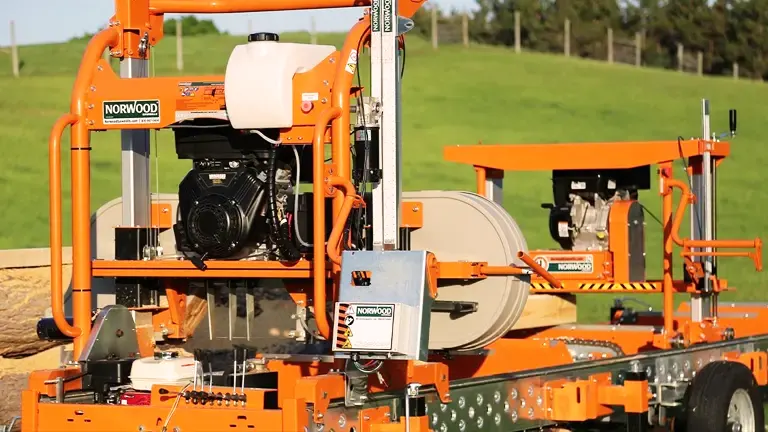

Norwood Log Moulder LX26 Review

- July 26, 2023

- 1 comment

The Norwood Log Moulder LX26 is an impressive amalgamation of innovation and efficiency, setting a new benchmark in the forestry and woodworking industry. In this comprehensive review, we delve deeper into the machine’s intricacies, and its ability to contribute to sustainability in woodworking and explore areas where improvements can be made to foster more inclusivity within the industry.

Specifications

- Maximum log diameter: 26 inches

- Maximum board width: 12 inches

- Maximum board length: 10 feet (with optional track system)

- Weight: 175 pounds

- Frame material: Steel

- Sawmill type: Chainsaw

- Chainsaw requirements: 66cc or greater chainsaw with ripping chain

- Price: $5,980.00

Additional Features

- Adjustable blade depth

- Quick-release chainsaw mount

- Log rests and adjustable log dogs

- Track system (optional)

- Oiler (optional)

- Carrying case

- Sawyer-Assist Technology

- Rigid 4″ tubular port directs sawdust down toward the ground. Or use it to connect a chip extractor and exhaust the sawdust outside your sawing shed.

- Dual fixed 1¼” blade guides are precision-machined, hardened, zinc-dichromate plated, and include sealed double ball bearings.

- Ten micro-adjust leveling feet for ground-level stationary sawing help ensure the mill stays stable for safe, accurate cuts.

- Adjustable bed angles allow you to mill live-edge slabs, and bevel edges, and create other custom shapes.

- The built-in fence system allows you to mill boards to a precise width.

- Norwood’s exclusive Sawyer-Assist Technology automatically adjusts the blade height for different sawing tasks, ensuring accurate and consistent cuts.

Personal Experience

Upon first encounter, the Norwood Log Moulder LX26 impresses with its robust, compact design and promises of efficiency and versatility. Handling logs up to 26 inches in diameter and 13 feet in length, it’s clear that the LX26 is built for heavy-duty work.

Upon setup, the machine feels durable, and the quality of its components shines through. It’s compact, considering its capabilities, making it easy to accommodate in different workspaces. The machine’s ability to automatically feed logs reduces manual input, and it’s remarkable to witness how smoothly the LX26 can handle different sizes of logs.

The process of molding logs into usable lumber is impressively efficient. The dual cutter heads deliver precision that’s unmatched by other tools I’ve used in the past. The power of the motor can be adjusted to meet the demands of different tasks, providing flexibility in the woodworking process.

The sustainability aspects of the LX26 also stand out. By enabling the efficient use of locally sourced wood and reducing waste, it feels like I’m making a contribution to a more sustainable woodworking industry.

However, operating the LX26 isn’t without its challenges. The machine’s advanced features present a steep learning curve, and it takes time and practice to get fully accustomed to the machine’s capabilities. The lack of comprehensive training materials adds to this challenge.

Also, the high price point of the LX26, though justified by its impressive capabilities, could be a barrier for smaller operations or hobbyists. Despite this, the overall performance and potential long-term benefits make the initial investment seem worthwhile.

A Deeper Look at the LX26

Norwood, a well-established name in the woodworking realm, has introduced the Log Moulder LX26 as a formidable machine designed to convert raw logs into usable, high-quality lumber. Its advanced design and functionalities, surpassing traditional woodworking tools, mark it as a potential disruptor in the sector.

The LX26 is essentially a heavy-duty machine capable of handling logs of up to 26 inches in diameter and up to 13 feet in length. Such broad size capacity opens the door to a range of possibilities, allowing woodworkers to process all types of wood, from small to large-sized logs. This allows for a significant level of versatility, accommodating various projects and needs.

Equipped with two cutter heads, the LX26 ensures precise and efficient moulding. The power of the motor can be adjusted to meet the demands of different woodworking tasks, allowing operators to fine-tune their process for optimal results. This, combined with an automatic feed system, reduces the need for manual input and increases overall productivity.

The compact design of the Log Moulder LX26 further emphasizes its utility, facilitating portability and easy setup in different workspaces. Its durable and corrosion-resistant parts ensure not only longevity but also reliable performance over time, a critical aspect in such a significant investment.

Unique Idea: A Sustainability Enabler

An interesting perspective to consider when examining the Norwood Log Moulder LX26 is its potential role in enhancing sustainability within the woodworking industry. By efficiently utilizing raw logs and reducing waste, the LX26 fosters responsible forestry practices. This efficiency, coupled with the transformation of fallen or cleared trees into usable lumber instead of letting them decay or burn, underpins the machine’s environmentally-friendly profile.

By optimizing the use of locally sourced wood, the LX26 also contributes to the reduction of the carbon footprint linked with long-distance transportation of lumber. This aligns well with contemporary shifts towards local sourcing and environmentally friendly business practices.

Benefits of the Norwood Log Moulder LX26:

- Versatility: The LX26 can handle logs of up to 26 inches in diameter and up to 13 feet in length, catering to a broad range of woodworking needs.

- Efficiency: With the integration of two cutter heads and an automatic feed system, the LX26 can deliver precise and efficient moulding, boosting productivity significantly.

- Durable and Portable: Its compact design coupled with corrosion-resistant parts ensures longevity and allows for easy setup in various workspaces, enhancing its convenience.

- Promotes Sustainability: The LX26 enables efficient use of raw logs and locally sourced wood, thus reducing waste and potentially reducing the carbon footprint associated with long-distance transportation of lumber.

Drawbacks of the Norwood Log Moulder LX26:

- High Cost: The price point of the LX26 may be a significant hurdle, especially for small-scale woodworkers or hobbyists, making it less accessible for those operating on a tighter budget.

- Steep Learning Curve: The advanced features and capabilities of the LX26 could be challenging for beginners or those unfamiliar with log moulding machines, leading to potential operational difficulties.

- Lack of Smart Features: As of my knowledge cutoff in September 2021, the LX26 does not integrate digital technology or automation for real-time monitoring or remote adjustments. This could be seen as a missed opportunity given the ongoing trends toward digital transformation in industries.

- Limited Support Resources: While the LX26 is a highly advanced piece of machinery, there could be better support in terms of training materials or online tutorials, especially for those new to log moulding machines.

Suggestion: Integration of Digital Technology

An area that Norwood could explore is the integration of digital technology into their machinery, like the LX26. The incorporation of smart technology and automation could provide users with more precise control over their woodworking processes, including real-time monitoring and the ability to adjust parameters remotely. This could make the LX26 an even more powerful tool, allowing woodworkers to maximize their output while maintaining high-quality results.

Critiques and Room for Improvement

Despite its strengths, the Norwood Log Moulder LX26 is not without its challenges. The most significant hurdle is the high price point, which might make it inaccessible to small-scale woodworkers or hobbyists. For larger operations, this investment is worthwhile, but for smaller businesses, it’s necessary to consider if the initial cost can be recouped within a reasonable timeframe.

Another critique is the steep learning curve. While the automatic feed system and other advanced features enhance productivity, they can be challenging for beginners or those unfamiliar with log moulding machines. Norwood could address this by offering comprehensive training materials or even online tutorials to make the transition smoother for new users.

Conclusion

In summary, the Norwood Log Moulder LX26 is a remarkable piece of machinery that brings multiple benefits to the woodworking and forestry industry. Its advanced features and capacity for heavy-duty work make it a solid investment for large-scale operations. The machine’s potential to contribute to sustainability and the possibility of incorporating digital technology adds unique dimensions to its value.

However, its high cost and learning curve cannot be overlooked. These issues should be addressed by Norwood by perhaps offering more affordable models or providing more accessible and comprehensive training resources.

While the LX26 stands as a powerful tool that is revolutionizing the woodworking industry, there remains room for Norwood to enhance its success and make log moulding more accessible to a diverse range of woodworkers.

Frequently Asked Questions

- What is the maximum size of log the LX26 can handle?

The Norwood Log Moulder LX26 can handle logs up to 26 inches in diameter and 13 feet in length. - Does the LX26 come with an automatic feed system?

Yes, the LX26 has an automatic feed system which helps reduce manual input and increase overall productivity. - Is the LX26 suitable for small-scale woodworkers or hobbyists?

While the LX26 is an excellent machine in terms of performance, its high cost may make it less accessible for small-scale woodworkers or hobbyists. - What is the learning curve like for the LX26?

The LX26’s advanced features can present a steep learning curve, especially for those unfamiliar with log molding machines. Norwood could provide more comprehensive training materials to help users get up to speed faster. - How does the LX26 contribute to sustainability?

The LX26 is efficient in its use of raw logs, which reduces waste. Additionally, it allows for the use of locally sourced wood, which can help reduce the carbon footprint associated with the long-distance transportation of lumber. - What maintenance does the LX26 require?

Like any other machinery, the LX26 requires regular maintenance to ensure longevity and optimum performance. This includes regular cleaning, lubrication, and periodic checks of its parts for wear and tear. - Can the LX26 be used for commercial lumber production?

Yes, with its heavy-duty capabilities and high efficiency, the LX26 can be used for commercial lumber production. However, the feasibility also depends on the scale of operation and financial aspects, given its high initial cost.

We invite you to share your thoughts and experiences with the Norwood Log Moulder LX26 in the comments below! Whether it’s about its performance, efficiency, or versatility, we’re eager to hear from those who have used this powerful tool. Have you found the LX26 to be the best log moulder in your woodworking journey? Let us know!

What are the blades made of? Are they carbide? Can they be sharpened? How long do they last? How many logs can you sculpt approximately before the blades become dull?

Paul

March 19, 2024 2:27 am