Norwood LumberMan MN27 Sawmill Review

- July 25, 2023

- 0 comment

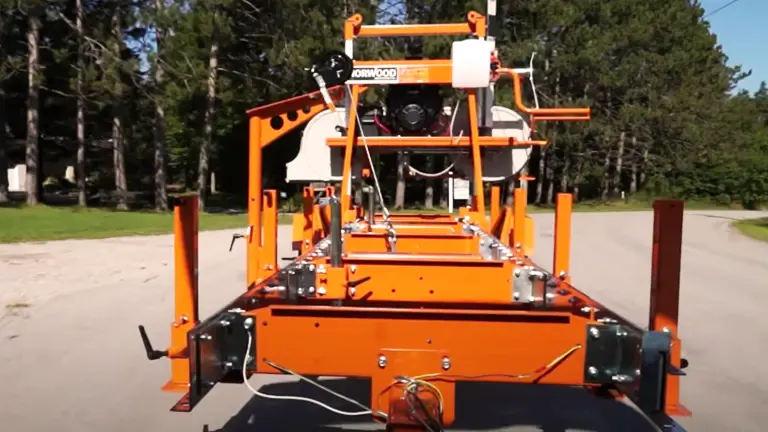

One of the most transformative developments in the field of forestry and lumber processing has been the introduction of the LumberMan MN27. This unique and powerful machine has revolutionized the way we process timber, impacting the industry in ways that are both practical and economical. This article takes an in-depth look into this fascinating machine, highlighting its features, benefits, and the transformative effects it has had on the industry.

Specifications

- Maximum log diameter: 27 inches

- Maximum board width: 23 inches

- Maximum board length: 12 feet 9 inches

- Weight: 275 pounds

- Frame material: Steel

- Sawmill type: Chainsaw

- Chainsaw requirements: 66cc or greater chainsaw with ripping chain

- Price: $5,460.00

Additional Features

- Adjustable blade depth

- Quick-release chainsaw mount

- Log rests and adjustable log dogs

- Track system (optional)

- Oiler (optional)

- Carrying case

- Sawyer-Assist Technology

- A rigid 4″ tubular port directs sawdust down toward the ground. Or use it to connect a chip-extractor and exhaust the sawdust outside your sawing shed.

- Dual fixed 1¼” blade guides are precision-machined, hardened, zinc-dichromate plated, and include sealed double ball bearings.

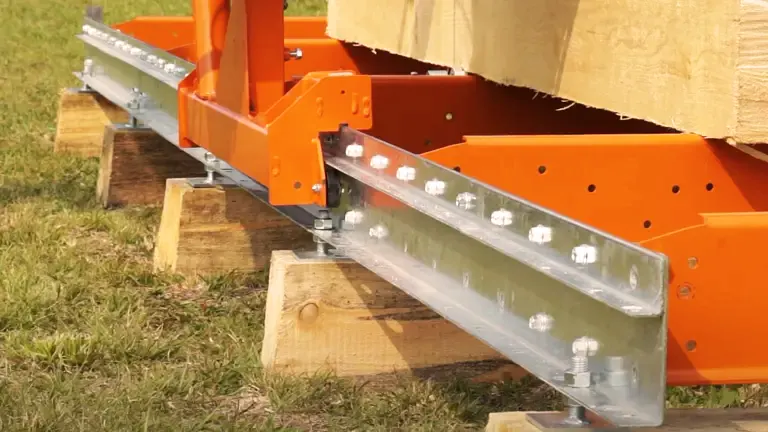

- Ten micro-adjust leveling feet for ground-level stationary sawing help ensure the mill stays stable for safe, accurate cuts.

The LumberMan MN27: What’s in a Name?

When you first encounter the name LumberMan MN27, you might be inclined to think it’s a character from a futuristic comic book. But in reality, it’s a powerful machine designed to disrupt traditional lumber processing. The name seems fitting for a device that has been designed to embody both strength and efficiency, two key attributes of a lumberjack. The ‘MN27’ part of the name represents its model number, reflecting its advanced features and improvements over previous models.

Features and Design

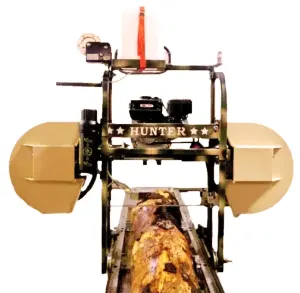

In terms of design, the LumberMan MN27 is a standout. Its durable steel frame, efficient hydraulic system, and advanced automated controls make it a reliable choice for modern timber operations. Key features include the 27-ton log splitter, which can efficiently break down logs of varying sizes, and the bandsaw mill, capable of producing precision cuts for a variety of woodworking projects.

The LumberMan MN27 is also characterized by its user-friendly interface, allowing operators with varying levels of experience to run the machine effectively. The inclusion of safety mechanisms, such as emergency stop buttons and protective barriers, underlines the machine’s commitment to worker safety.

The machine’s design caters to the needs of different operators, with adjustable seat and control heights, making it more inclusive for people of varying physical attributes. Additionally, its compact design allows it to fit in spaces where other machines cannot, increasing its utility in various logging environments.

Pros

- Efficiency: The LumberMan MN27’s 27-ton log splitter and bandsaw mill can process logs swiftly and precisely, increasing productivity and reducing labor costs.

- User-friendly Interface: The machine’s intuitive control panel and digital display make it easy to operate, even for individuals with limited experience with such machinery.

- Safety Measures: The LumberMan MN27 comes equipped with safety mechanisms, such as emergency stop buttons and protective barriers, enhancing operator safety.

- Durability: With its robust steel frame, this machine is built to last, reducing the need for frequent repairs and replacements.

- Reduced Waste: By optimizing the use of raw materials, the LumberMan MN27 minimizes waste, contributing to more sustainable lumber processing practices.

- Compact Design: Its compact design allows it to fit into spaces where other machines cannot, making it suitable for a wide range of work environments.

Cons

- Initial Cost: The LumberMan MN27, given its advanced features and sturdy design, comes with a relatively high upfront cost, which may be a barrier for small-scale operations or individual craftspeople.

- Maintenance: While the machine is designed to be low-maintenance, the upkeep of its hydraulic system and other complex components may require specialized knowledge and could be time-consuming.

- Power Consumption: Despite its efficiency in lumber processing, the LumberMan MN27 uses a considerable amount of power. This could lead to high electricity costs, especially for businesses operating on a large scale.

- Training: Although the machine has a user-friendly interface, operators still need some level of training to ensure safe and efficient use. This could add to the initial cost and time required to integrate the machine into the operations.

- Size: Despite its compact design, the LumberMan MN27 is still a sizeable machine that may not be suitable for operations with limited workspace.

Transforming the Lumber Industry

One of the most remarkable impacts of the LumberMan MN27 is its transformative effect on the lumber industry. Traditional lumber processing methods have often been labor-intensive and time-consuming. The LumberMan MN27, however, brings unprecedented efficiency, helping businesses to increase their productivity significantly.

It minimizes manual labor and optimizes the use of raw materials. This reduction in waste not only makes the process more efficient but also contributes to sustainability efforts in the industry. Moreover, its durability and low-maintenance needs reduce operating costs, making it a cost-effective solution for businesses of all sizes.

The Future of Lumber Processing

As we look toward the future, it’s clear that machines like the LumberMan MN27 are paving the way for a new era in lumber processing. The continued development and refinement of this technology hold great promise for further improving efficiency and sustainability within the industry.

We might envision future models of the LumberMan series incorporating features like AI-driven optimization for log splitting and cutting, ensuring the maximum yield from each log. Integration with Internet of Things (IoT) technologies could enable real-time monitoring and predictive maintenance, minimizing downtime and further enhancing productivity.

Moreover, sustainable innovation could take the form of solar-powered models, reducing reliance on fossil fuels and making lumber processing greener.

Conclusion

The LumberMan MN27 is more than just a machine; it’s a product of human ingenuity and innovation. A testament to our relentless pursuit of efficiency and progress. Despite its few drawbacks, the potential and benefits it offers far outweigh its limitations. It stands as a beacon, highlighting the power of technology to revolutionize industries and make our lives easier. It’s not just about processing timber; it’s about creating value, reducing waste, and driving sustainable growth in the lumber industry.

As we navigate through the age of automation, machines like the LumberMan MN27 are not just tools; they are partners in our quest for a better, more efficient future. As we stand at this junction, the path ahead is exciting. We can look forward to further enhancements, improvements, and, most importantly, the human creativity that will continue to drive these advancements. As much as the LumberMan MN27 is the product of our past efforts, it’s also the key to our future, promising a journey that’s as rewarding as the destination itself.

Frequently Asked Questions about the LumberMan MN27

- What kind of logs can the LumberMan MN27 process?

The LumberMan MN27 can process a variety of log types and sizes, thanks to its powerful 27-ton log splitter and precise bandsaw mill. It can handle both softwood and hardwood species. - How user-friendly is the LumberMan MN27?

The LumberMan MN27 is designed with a user-friendly interface that includes an intuitive control panel and a digital display. However, proper training is recommended for safe and efficient operation. - What safety features does the LumberMan MN27 offer?

The LumberMan MN27 includes several safety features such as emergency stop buttons, protective barriers, and safety interlocks to enhance operator safety during usage. - What is the maintenance requirement of the LumberMan MN27?

While the LumberMan MN27 is designed to be durable and low-maintenance, regular checks and maintenance are necessary for its hydraulic system and other components. Periodic cleaning, lubrication, and inspection of parts for wear and tear are recommended. - What power source does the LumberMan MN27 require?

The LumberMan MN27 typically runs on electric power. However, depending on the model and the setup, some versions may operate using other power sources. - How much space do I need to accommodate the LumberMan MN27?

Despite its compact design relative to its capabilities, the LumberMan MN27 is a sizeable machine. You should ensure that you have adequate space for both the machine and safe operation, including room for handling and maneuvering logs. - How does the LumberMan MN27 contribute to sustainability?

The LumberMan MN27 contributes to sustainability by optimizing the use of raw materials and reducing waste during lumber processing. Future models may also incorporate features such as solar power operation or energy-efficient designs. - Is the LumberMan MN27 suitable for small-scale operations or individual craftspersons?

While the LumberMan MN27 is designed for efficiency and precision, its relatively high upfront cost may be a consideration for small-scale operations or individual craftspeople. However, the long-term benefits in terms of increased productivity and reduced labor may justify the investment.

We’d love to get your feedback! Share your personal experiences and opinions about the Norwood LumberMan MN27 Sawmill in the comments section below. Your insights could assist fellow woodworkers in making informed choices!

Leave your comment