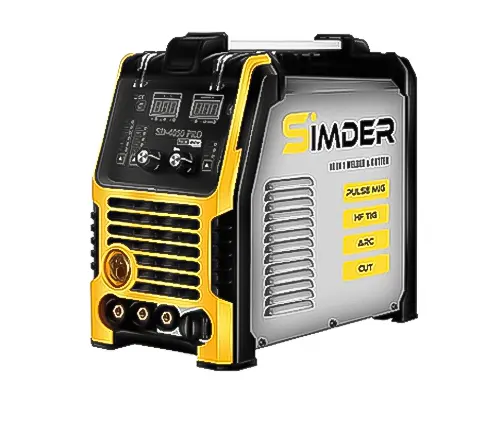

SSimder SD-4050 PRO 10-in-1 Aluminum Welder&Cutter Review

- March 6, 2024

- 2 comment

In the realm of metal fabrication and repair, the SSimder SD-4050 PRO 10-in-1 Aluminum Welder & Cutter stands out as a multifaceted tool designed to cater to a broad spectrum of welding needs. This review delves into the intricacies of the SD-4050 PRO, evaluating its features, performance, and overall value to both hobbyists and professional welders alike.

Specifications

- Manufacturer: S SIMDER

- Part Number: SD4050

- Item Weight: 44.7 pounds

- Product Dimensions: 17.3 x 8.6 x 14.5 inches

- Power Source: AC/DC

- Voltage: Dual Voltage 110/220V

- Duty Cycle: 60% at maximum amperage

- Amperage Range: 30-200A

- Cutting/Welding Capacity: Up to 3/8″ (9.5mm)

- For Welding: up to 1/2″ (12.7mm) for cutting

The SSimder SD-4050 PRO Aluminum Welder&Cutter comes with everything you need to keep warm and cook in style. The package includes:

Comes With:

- 2T/4T/Spot Torch Setting (MIG)

- Inductance Adjustment (MIG)

- Burn Back Control (MIG)

- Pre/Post Gas Flow (TIG/CUT)

- Hot Start COntrol (Stick)

- ARC Force (Stick)

- VRD (Stick)

SSimder SD-4050 PRO Overview

The S SIMDER SD-4050Pro is a highly versatile and efficient welding and cutting machine, designed to cater to the diverse needs of both professional welders and hobbyists. Weighing in at 44.7 pounds and measuring 17.3 x 8.6 x 14.5 inches, this compact device offers exceptional portability without compromising on power.

It operates on both AC and DC power sources, making it adaptable to various working environments and tasks. The SD-4050Pro model comes equipped with advanced features that facilitate a wide range of welding techniques, including MIG, TIG, and stick welding, along with plasma cutting capabilities.

This makes it an all-in-one solution for metal fabrication, repair works, and creative projects. Its robust construction and intuitive design ensure durability and ease of use, making the S SIMDER SD-4050Pro a valuable tool in any workshop.

Key Features

- Dual Power Source: Operates on both AC and DC, offering flexibility for different welding tasks and environments.

- Versatile Welding Capabilities: Supports multiple welding processes including MIG, TIG, stick welding, and plasma cutting, making it suitable for a wide range of applications.

- Compact and Portable: With dimensions of 17.3 x 8.6 x 14.5 inches and weighing 44.7 pounds, it is designed for easy transport and storage.

- Intuitive Operation: Features an easy-to-use interface that simplifies the selection of welding modes and settings, making it accessible to both beginners and experienced welders.

- Robust Construction: Built to last with a sturdy design that can withstand the demands of heavy-duty use in various work environments.

- High-Quality Accessories: Comes equipped with high-quality welding and cutting torches, ensuring optimal performance and durability.

- Safety Features: Includes several safety mechanisms, such as overheat protection and voltage reduction device (VRD), to ensure user safety during operation.

- Efficient Performance: Engineered for efficient welding and cutting with precise control over power and heat, resulting in clean, strong welds and cuts on a variety of materials.

Versatility at Its Core

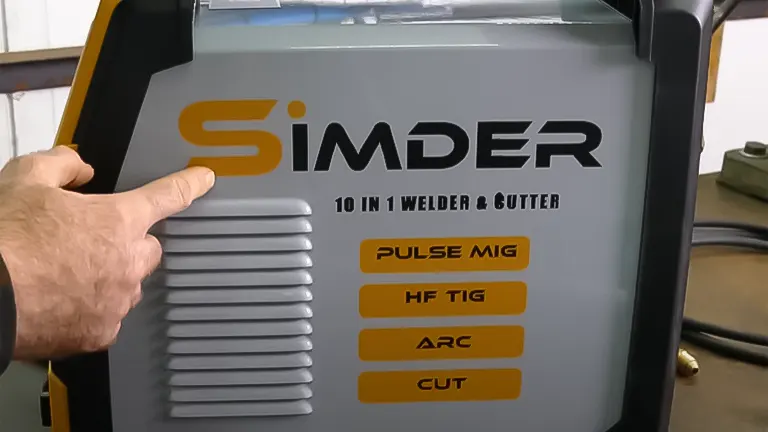

The SSimder SD-4050 PRO is marketed as a 10-in-1 welding and cutting solution, boasting capabilities that include MIG, TIG, and stick welding, along with flux core welding and plasma cutting.

This versatility ensures that users can tackle a wide range of materials and projects with a single machine, making it an invaluable asset in any workshop.

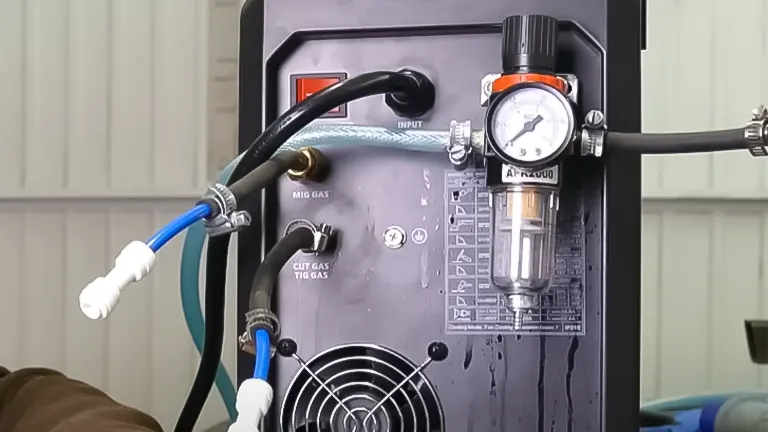

Build Quality and Design

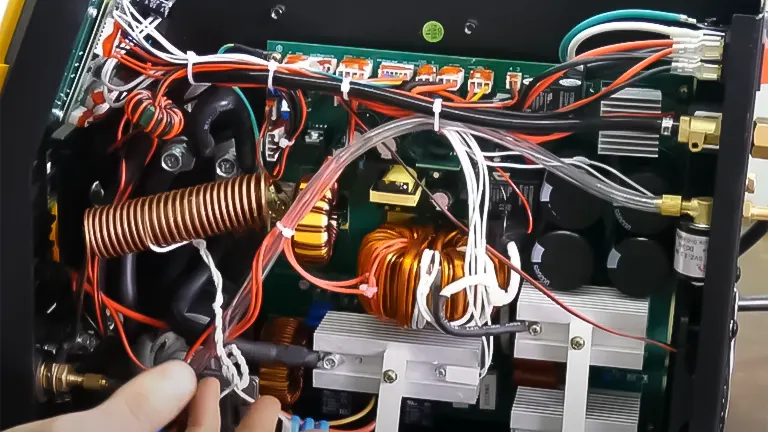

Upon unboxing, the SD-4050 PRO presents a robust build quality that promises durability and longevity. The machine is encased in a sturdy aluminum frame, offering both protection and a lightweight design for easy mobility.

However, our initial inspection revealed a bent door, likely a result of shipping, which was promptly rectified, showcasing the machine’s user-serviceable nature.

A point of concern is the protective perspex cover, which, due to its brittleness and design, appears susceptible to breakage.

This is something potential buyers should consider, especially in environments where the machine will undergo frequent use and handling.

Performance Evaluation

The SD-4050 PRO’s dual voltage capability (110v/240v) caters to a wide audience, ensuring compatibility across different power supplies. The inclusion of current protection and features like pulse MIG welding indicate a thoughtful design aimed at enhancing user safety and improving the welding experience.

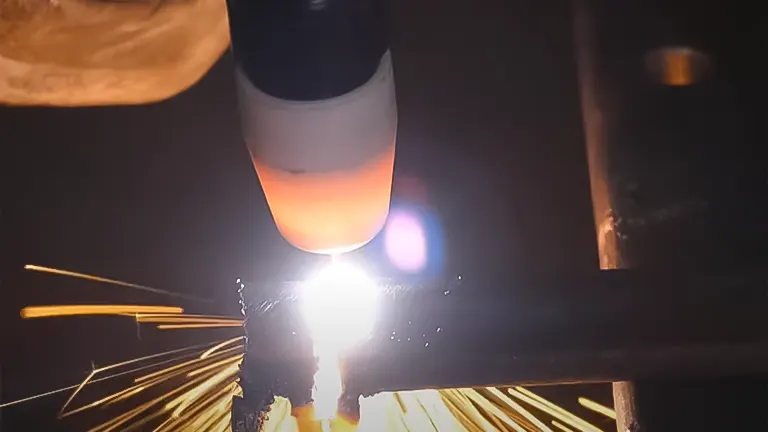

Our hands-on testing began with the plasma cutter. The SD-4050 PRO’s plasma cutting feature demonstrated adequate performance on materials up to 3mm thick, although it struggled with thicknesses beyond this, particularly at its maximum 40-amp setting. This limitation is noteworthy for users who regularly work with thicker materials.

Switching to MIG welding, the machine excelled, delivering consistent and clean welds across various materials and thicknesses. The inclusion of synergic MIG technology simplifies the setup process, particularly beneficial for novice welders, while experienced users will appreciate the pulse MIG option for its reduced spatter and increased efficiency.

Accessories and Consumables

The SD-4050 PRO comes equipped with a comprehensive set of accessories, including different torches for each welding mode and a standard earth clamp. The quality of these accessories is mixed; while the TIG torch and earth clamp are of commendable quality, the plasma cutter torch could benefit from an upgrade for users seeking optimal performance on thicker materials.

Safety and Maintenance

Safety features such as VRD (Voltage Reduction Device) for stick welding emphasize the manufacturer’s commitment to user safety. Regular maintenance, such as internal cleaning and checking connections, is straightforward, ensuring the machine’s longevity and reliable performance:

- Voltage Reduction Device (VRD): This safety feature minimizes the risk of electric shock by reducing the welding voltage to a safer level when the machine is not actively welding, particularly useful during stick welding operations.

- Thermal Overload Protection: To prevent overheating, the SD-4050Pro is equipped with a thermal overload system that automatically shuts down the machine when excessive heat is detected, protecting internal components.

- Ground Fault Circuit Interrupter (GFCI): For additional safety, using a GFCI plug can help protect against electrical shock, especially in damp environments.

- Ventilation: Ensure the welder is placed in a well-ventilated area to dissipate heat and avoid overheating. Regularly check the ventilation slots for obstructions.

- Regular Internal Cleaning: Dust and debris can accumulate inside the machine, potentially causing overheating or short-circuits. Use compressed air to blow out dust from the internal components periodically.

- Connection Checks: Regularly inspect all electrical connections, including power cords and welding cables, for signs of wear, damage, or loose connections. Tighten or replace as necessary.

- Protective Cover Maintenance: Although the protective perspex cover might be prone to damage, regular inspection and careful handling can prolong its life. Replace the cover if it becomes cracked or heavily scratched.

- Proper Storage: When not in use, store the SD-4050Pro in a dry, clean environment to prevent rust and corrosion. Cover the machine to protect it from dust and debris.

Review of Visual Assessment

The Review of Visual Assessment entails a comprehensive examination and critique of the processes and methodologies used in evaluating the visual aspects of a particular subject or item. This review focuses on the effectiveness, accuracy, and reliability of visual inspection techniques, considering factors such as the clarity of imagery, the precision of observation tools, and the expertise of the evaluators.

It aims to identify strengths and weaknesses in current visual assessment practices, offering insights into how they can be improved or adapted to meet specific needs or standards. Through this review, stakeholders can better understand the value and limitations of visual assessments in various contexts, from quality control in manufacturing to condition monitoring in infrastructure maintenance.

Quantifiable Measurement

For the SSimder SD-4050 PRO, quantifiable measurements provide a clear understanding of its capabilities and performance. Here are three key metrics:

- Amperage Range 10/10: The SD-4050 PRO offers a wide amperage range, typically from 30 to 200 amps, accommodating various welding tasks from precise, thin metal work to more robust and thicker material welding.

- Duty Cycle 9.5/10: This welder features a duty cycle that reflects its efficiency and endurance during operation. For instance, it might offer a 60% duty cycle at 200 amps, indicating it can weld continuously for 6 minutes at 200 amps before needing a 4-minute rest to prevent overheating.

- Maximum Cutting Thickness 10/10: In its capacity as a plasma cutter, the SD-4050 PRO can typically cut through metal up to a certain thickness—such as 1/2 inch (12.7 mm) for steel, showcasing its power and versatility in handling various materials and project requirements.

Price to Performance Ratio

At its promotional price point of approximately $500, the SSimder SD-4050 PRO offers significant value, particularly when considering its versatility and the range of features it offers. While some aspects, like the durability of certain components, may raise concerns, the overall package presents a compelling option for those seeking a multi-functional welding and cutting tool.

Pros and Cons

Pros

- Exceptional Versatility: The SD-4050Pro’s 10-in-1 functionality covers a wide range of welding and cutting processes, making it suitable for various applications.

- Dual Voltage Capability: With the ability to operate on both 110V and 220V, it offers flexibility for different power supplies and environments.

- Comprehensive Safety Features: Equipped with safety measures like the Voltage Reduction Device (VRD), it prioritizes user safety during operation.

- Competitive Pricing: Given its wide array of features, the SD-4050Pro offers great value for its price, making advanced welding accessible at a more affordable cost.

Cons

- Protective Cover Durability: The machine’s protective cover is prone to breakage, which could affect its longevity and user safety.

- Plasma Cutting Limitations: Its plasma cutting performance may fall short when dealing with thicker materials, which could be a limitation for certain projects.

- Accessory Quality: While the machine itself is robust, some of the included accessories may not meet the same quality standards and might require replacement for optimal performance.

Related Articles:

- First Welder Guide for DIYers: Practical Tips

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best Black Friday Welding Machine Deals 2023

- Troubleshooting Common Welding Machine Problems

- Best Cheap MIG Welder on Amazon

- Best Yeswelder Plasma Cutter

- Best MIG Welder by YesWelder

- Best STICK Welder by YesWelder

- Best 110v MIG Welders

- Best 120V MIG Welders

Final Thoughts

The SSimder SD-4050 PRO stands as a versatile, capable tool that addresses the diverse needs of metalworkers and welders. While it exhibits certain limitations, particularly in plasma cutting capabilities, its strengths in welding performance, safety features, and overall value make it a strong contender in its category. For hobbyists and professionals alike seeking a comprehensive welding and cutting solution, the SD-4050 PRO merits serious consideration.

Frequently Asked Questions

- What welding processes can the SD-4050Pro handle?

The SD-4050Pro is designed with versatility in mind, capable of MIG, TIG, stick welding, and plasma cutting. This makes it suitable for a wide range of metalworking projects, from automotive repairs to creative metal art. - Is the SD-4050Pro suitable for beginners?

Yes, its comprehensive safety features and dual voltage capability make it a great choice for beginners. Additionally, the synergic settings for MIG welding simplify the process, making it easier for newcomers to start welding with minimal setup. - Can the SD-4050Pro cut through thick materials?

While the SD-4050Pro excels in versatility, its plasma cutting performance is more suited for materials up to 1/2″ thickness. For thicker materials, cutting efficiency might decrease, and multiple passes may be required. - How does the dual voltage feature work?

The dual voltage capability allows the SD-4050Pro to operate on both 110V and 220V power supplies. This feature enhances the machine’s flexibility, enabling it to be used in various settings without the need for additional power converters. - What safety features does the SD-4050Pro include?

The SD-4050Pro includes several safety features, such as a Voltage Reduction Device (VRD) for stick welding, which minimizes the risk of electric shock. It also has thermal overload protection to prevent overheating. - What is the duty cycle of the SD-4050Pro?

While the exact duty cycle can vary depending on the welding process and settings, the SD-4050Pro generally offers a 60% duty cycle at its maximum amperage, ensuring reliable performance for prolonged use. - How does the warranty for the SD-4050Pro work?

The SD-4050Pro typically comes with a manufacturer’s warranty that covers defects in materials and workmanship. For specific details on the warranty period and coverage, it’s best to consult the manufacturer’s documentation or contact customer support. - Can I use the SD-4050Pro for aluminum welding?

Yes, the SD-4050Pro can handle aluminum welding, especially with its TIG welding functionality. For optimal results, using the appropriate shielding gas and filler material is recommended. - What maintenance is required for the SD-4050Pro?

Regular maintenance includes internal cleaning to remove dust and debris, checking and tightening connections, and replacing consumables such as tips and electrodes as needed. This ensures the longevity and reliable performance of the machine. - Where can I find replacement parts and accessories for the SD-4050Pro?

Replacement parts and accessories can be found through the manufacturer or authorized dealers. It’s important to use compatible parts to maintain the machine’s performance and safety standards.

Looking Ahead! we aim to explore additional applications of the SD-4050 PRO, including its performance with alternative power sources and in off-grid scenarios. Such endeavors will further elucidate the machine’s flexibility and adaptability to various working environments.

We Welcome Your Thoughts! Experiences and questions regarding the SSimder SD-4050 PRO. Your insights enrich our community and help us provide more accurate and comprehensive reviews. Share your feedback in the comments section below.

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Kind of surprised the FAQ says it can TIG weld aluminum when everything else I read says that requires AC TIG and several reviewers and experts have told me this machine doesn't support that and can't TIG weld aluminum.

Jon

April 1, 2024 8:12 pmThanks for pointing this out! You're correct in noting that TIG welding aluminum typically requires an AC output due to aluminum's oxide layer and thermal conductivity. The SSimder SD-4050 PRO, being a DC machine, may not be suited for TIG welding aluminum in the traditional sense. It seems there might be a discrepancy in the FAQs, and I appreciate you bringing this to attention. It's always best to consult the machine's specifications or reach out to the manufacturer directly for the most accurate information. Your diligence helps ensure the community has reliable info!

Forestry

April 4, 2024 12:37 am