Hobart Handler 140 MIG Welder Review

- January 2, 2024

- 2 comment

Enter the Hobart Handler 140, a potential solution that strikes a balance between power and portability, making it a suitable choice for many hobbyists and DIY enthusiasts. Despite its reputation for reliability, it’s crucial to acknowledge that the Hobart Handler 140 is gradually falling behind in the ever-evolving landscape of welding technology.

Just like its predecessors that aimed to set new standards, the Handler 140 is facing stiff competition from contemporary brands that provide lighter and more potent MIG machines at a more budget-friendly price point. In the subsequent sections of this article, we will meticulously explore the pros and cons of the Hobart Handler 140, shedding light on its strengths and weaknesses. Additionally, we will delve into alternative options in the market that may offer superior value for your hard-earned money, considering the evolving landscape of MIG welding machines.

Hobart Handler 140 Product Overview

The Hobart 500559 Handler 140 MIG Welder is a versatile and reliable welding machine designed to meet the needs of both beginners and seasoned welders. Boasting a welding range of 25 to 140 amps, this MIG welder provides the flexibility to handle a diverse array of welding tasks, from light-duty projects to more demanding applications.

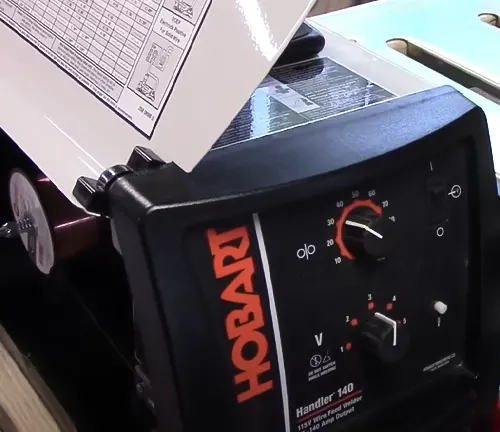

With a user-friendly interface featuring a 5-position voltage control selector, users can make precise adjustments based on the thickness of the material, ensuring optimal performance. The durable all-metal construction and heavy-duty components contribute to the machine’s longevity, making it a robust investment for any workshop.

Despite its compact and portable design, the Hobart Handler 140 doesn’t compromise on power, delivering a smooth arc and consistent wire feed for clean and professional welds. With straightforward setup and operation, this MIG welder has become a popular choice for those seeking a reliable and efficient welding solution.

Key Features

- Wide Welding Range: The Hobart 500559 Handler 140 MIG Welder provides versatility with a 25 to 140 amp welding range.

- Precision Controls: Featuring a user-friendly 5-position voltage control selector for precise adjustments, catering to both beginners and seasoned welders.

- Durable Build: Crafted with a robust, all-metal construction, including steel, stainless steel, and aluminum components, ensuring longevity.

- Portability: Compact dimensions (19 x 11 x 13 inches) and a weight of 57 pounds make it easy to transport for various work environments.

- 5-Year Warranty: Backed by a 5-year limited warranty, offering long-term reliability and peace of mind for the investment.

Technical Specifications

- Manufacturer: Hobart

- Part Number: 500559

- Product Style: Welder

- Material: Stainless Steel, and Aluminum

- Power Source: Corded-electric

- Installation Method: MIG-welding

- Item Weight: 57 pounds

- Product Dimensions: 19 x 11 x 13 inches

- Warranty Description: 5-year limited warranty

Hobart Handler 140 Performance Accuracy

In the realm of MIG welders, achieving precision and accuracy in performance is crucial for ensuring optimal results in a variety of welding applications. The Hobart Handler 140 stands out prominently in this regard, demonstrating its prowess from the outset.

What immediately caught my attention was its remarkable capability to seamlessly navigate through a spectrum of welding tasks, effortlessly transitioning between light-duty assignments and more demanding projects.

With a broad welding range spanning from 25 to 140 amps, this machine exemplifies versatility, accommodating materials of varying thickness with ease. This expansive range allows welders to tailor their output to the specific demands of the task at hand, enhancing the precision of the welding process.

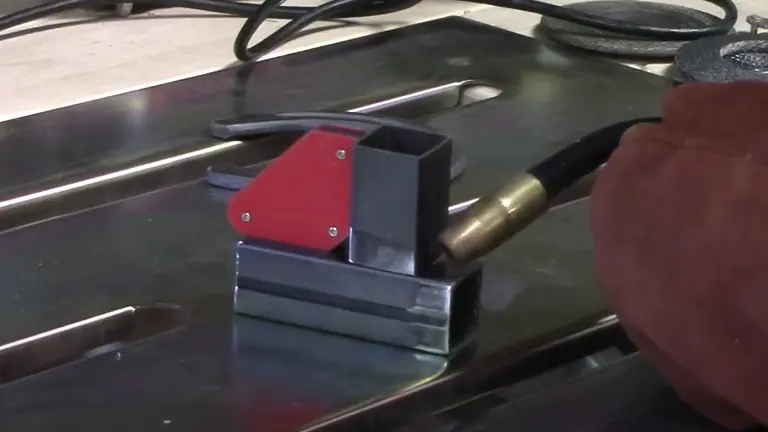

My personal experiences with the Handler 140 underscore its reliability in delivering accurate and consistent performance. Whether tasked with delicate auto body repairs or engaging in the intricacies of substantial fabrication projects, this MIG welder has proven itself to be a reliable companion, consistently meeting the demands of diverse welding challenges.

The nuanced control offered by the machine, coupled with its ability to maintain accuracy across different thicknesses of metal, establishes the Handler 140 as a commendable choice for those who prioritize precision in their welding endeavors.

One standout feature is the 5-position voltage control selector, allowing for precise adjustments based on the thickness of the material. The smooth arc and consistent wire feed ensure clean and professional welds, even for beginners. The duty cycle of 20% at 90 amps is commendable for a machine of this size and is a testament to its reliability during prolonged use.

Build Quality and Durability

The Hobart 500559 Handler 140 MIG Welder shines brightly in the realm of build quality and durability, presenting a robust and meticulously crafted design that speaks volumes about its commitment to lasting performance.

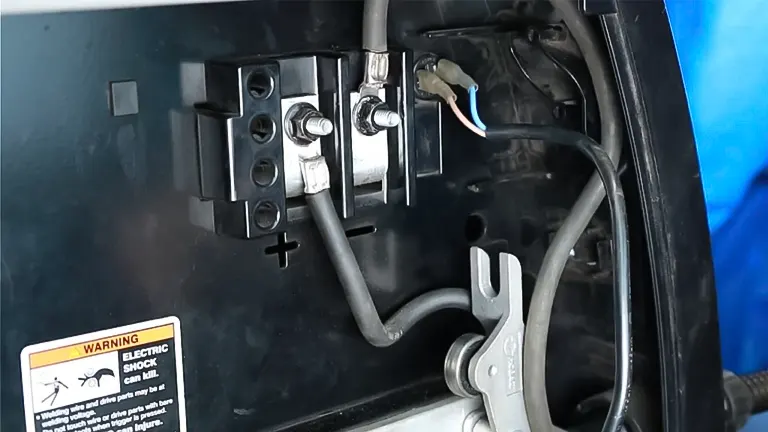

The all-metal wire drive is a testament to the machine’s durability, providing a sturdy and reliable mechanism for seamless wire feeding during the welding process. This robust construction not only enhances the welder’s longevity but also contributes to consistent and precise welding outcomes, crucial factors for those engaged in various welding applications.

In a bustling workshop environment, where tools endure constant wear and tear, the Handler 140 stands resilient. Its heavy-duty work clamp and durable ground cable further fortify its structural integrity, ensuring stable and secure connections during welding tasks. The welder’s ability to withstand the rigors of regular use positions it as a dependable, long-term investment for welding enthusiasts and professionals alike.

The focus on durability not only safeguards the machine against premature wear but also instills confidence in users, assuring them that the Handler 140 is a reliable companion ready to tackle the challenges of a busy workshop for years to come.

Powerful and Ease of Use

The Hobart 500559 Handler 140 MIG Welder seamlessly blends power with user-friendly design, making it an ideal choice for both seasoned welders and beginners taking their first steps into the world of welding. Setting up the Handler 140 is a breeze, thanks to its straightforward assembly process, and users are guided with clarity through the entire operation by the comprehensive user manual provided.

This thoughtful approach to user guidance ensures that individuals, regardless of their expertise level, can quickly grasp the nuances of assembly and operation, minimizing the learning curve associated with welding.

The welder’s intuitive interface stands as a testament to its commitment to ease of use. The incorporation of easy-to-adjust settings empowers users to fine-tune the machine according to the specific demands of their welding projects, providing a level of control that caters to diverse skill levels.

This user-centric design not only facilitates a hassle-free welding experience but also promotes confidence and efficiency in achieving precise and clean welds. Furthermore, the built-in thermal overload protection acts as a safety net during extended use, preventing overheating and safeguarding both the welder and the user, enhancing the overall user experience and contributing to the Handler 140’s reputation as a powerful yet accessible welding tool.

Review of Visual Aspects

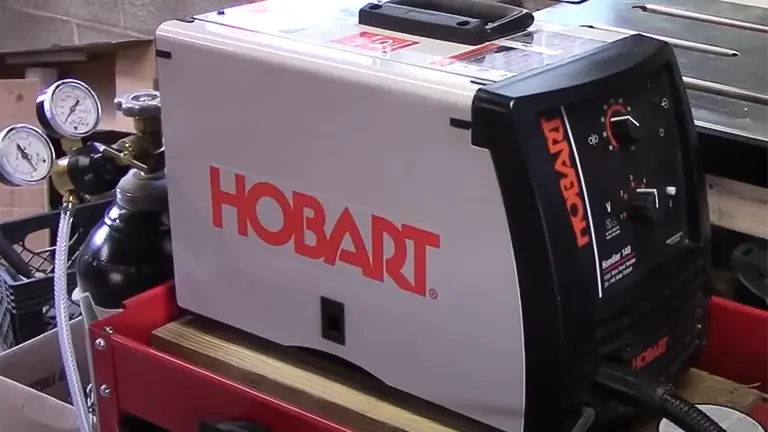

The visual aspects of the Hobart 500559 Handler 140 MIG Welder are a testament to its sturdy and professional design. The welder features a compact yet robust exterior, adorned with the iconic Hobart branding that immediately instills confidence in its quality.

The predominantly metallic construction exudes durability, presenting a machine that means business in any workshop setting. The control panel is laid out intuitively, contributing to the overall user-friendly design. The sleek, matte finish not only adds a touch of sophistication but also serves a practical purpose by reducing glare during operation.

The attention to detail is evident in the thoughtful placement of components, such as the well-positioned wire feed system and the neatly integrated handle for easy portability. Overall, the visual presentation of the Handler 140 aligns seamlessly with its reputation for reliability and performance, making it an aesthetically pleasing addition to any welding workspace.

Key Considerations Before Purchasing the Hobart 140

Duty Cycle

Understanding the duty cycle is paramount when evaluating the Hobart 500559 Handler 140 MIG Welder. With a duty cycle of 20% at 90A output, it’s important to note that this figure is relatively low compared to various competing models. While the Handler 140 is adept at completing hobbyist-level welding tasks, its limited duty cycle becomes apparent during prolonged use.

For instance, an alternative pick in the market boasts a remarkable 100% duty cycle at 100A, enabling users to weld continuously at that amperage without interruptions. In contrast, the Handler 140’s 20% duty cycle at 90A confines the welding activity to a mere 2 minutes before necessitating an 8-minute cooldown period. This limitation should be carefully considered, especially when compared to alternative brands that offer more extended and uninterrupted welding capabilities.

Heavy Transformer Core

While transformer welders boast longevity, their drawback lies in their weight and difficulty in mobility. Hobart positions the Handler 140 as a “portable” MIG welder, and technically, its 57 lbs body is movable. However, the crucial question arises: should you move it?

Given the advancements in IGBT inverters, opting for a transformer welder for the sake of portability might be a questionable choice. Inverter technology has evolved to the point where it can significantly reduce the weight of welding equipment by over 50%. Moreover, reputable brands now offer durable inverters supported by extensive warranties, making them not only lightweight but also reliable—rendering inverters as a compelling alternative to traditional transformers, especially for those who prioritize ease of movement and portability.

- Stock Thickness: You can weld 24 ga. to ¼ inch mild and stainless steel. Not shabby given the affordable price. But if you need to handle thicker material, you will need a bigger, more expensive MIG welder.

- Fixed-Voltage System: The Hobart Handler 140 uses an outdated, 5-points fixed-voltage range. While this is good, nothing beats infinite voltage adjustability. What if you thinned out the metal too much while grinding the rust off? What if the metal thickness doesn’t match the recommended settings chart? There are many reasons why you would like to fine-tune the voltage output. Hobart recognized this. That’s why their Ironman 240 (upgrade of Ironman 230) now provides an infinitely adjustable voltage. However, their Handler 140 never got such an update yet. This wouldn’t be an issue if Handler 140 were cheaper. But, at this price, today, I expect better.

- No Advanced Functions: Since Hobart 140 uses an older transformer technology, it can’t support advanced functions possible with inverter welders. There are no 2T/4T functions for easier welding in tight corners or long welds. Likewise, it doesn’t support inductance control or tack welds. This is something to consider because many modern welders have these useful functions at no increase in price.

Consumables

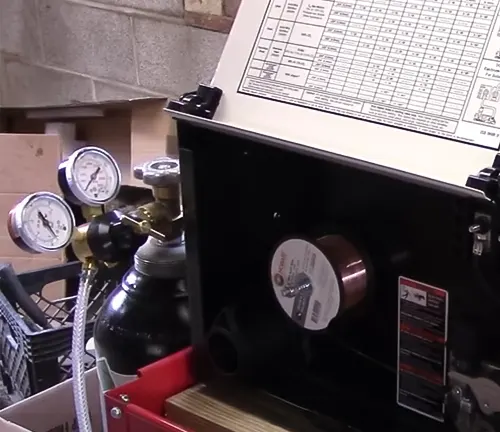

Included in the package are some consumables, although it’s crucial to note that if your welding plans involve MIG welding, additional purchases will be necessary. Specifically, you’ll need to acquire solid wire, as none is provided in the initial package.

Additionally, before embarking on any MIG welding projects, a separate purchase of a gas bottle is required. Furthermore, it’s advisable to invest in extra tips of various sizes, as the initial package only includes (2) 0.030 contact tips.

Aluminum

The Hobart 500559 Handler 140 allows for MIG welding of aluminum within the 20 to 16-gauge range. However, it’s important to highlight that the welder is not spool gun ready for aluminum welding. This limitation makes the Handler 140 less suitable for those who frequently work with aluminum across different thicknesses.

Examining the fine print of the Hobart Handler 140 spec sheet reveals a requirement to maintain the MIG lead as straight as possible. Additionally, the wire feed-ability may not be as optimal when welding steel, a consequence of the machine lacking support for a spool gun.

CO2/Miller Regulator

The inclusion of a Miller regulator in the package is a positive aspect, given Miller’s longstanding reputation in the welding industry. However, users should be aware that if they plan to run pure CO2, Hobart advises against it with this regulator. The frosting of CO2 can potentially impact the regulator’s performance.

Therefore, if utilizing C100, a swap of the regulator may be necessary to ensure optimal functionality. This detail underscores the importance of understanding and adhering to the recommended gases for seamless operation with the Hobart 500559 Handler 140.

Absence of DINSE Connectors for Polarity and Ground Clamp

Inexpensive welders commonly feature an integrated ground clamp and lack standard plugs on the front of the unit. However, as of 2022, the Hobart Handler 140 can no longer be categorized as an inexpensive model, given the elevated standards set by competing brands. The integrated ground clamp, while a common characteristic in its price range, poses challenges for users who may need to replace the lead due to damage or dissatisfaction with its length.

Furthermore, this design choice complicates the process of switching polarity, requiring users to open the welder and rewire the lead connectors for DCEN or DCEP. Some brands in this price range utilize standard DINSE plugs, streamlining this procedure, and a review of one such model will be explored later in this article.

- Work Clamp: While the MIG gun and cable leads are adequately lengthy at 10 feet, the 6-gauge ground cable, although featuring quality sheathings, is on the smaller side. The Hobart work clamp, lacking a braided bonding wire to connect the clamp jaws, is comparatively smaller than some alternatives. Users have the option to swap the clamp on the Hobart unit, albeit at an additional cost. The convenience of managing the cables is commendable, but users should factor in the potential expense of upgrading the work clamp for optimal performance.

- Price/Quality Ratio: Undoubtedly, the Hobart Handler 140 remains a reliable welder. However, in the current landscape of welding equipment, its price point is debatable in terms of value. While the Handler 140 offers solid performance, competing models provide more features at a lower price, impacting its overall price-to-quality ratio. In the present market, a reevaluation of the unit’s pricing could potentially position it as a more competitive choice, given the increasing standards set by other models in its category.

Comparisons and Considerations

In comparing the Hobart 500559 Handler 140 MIG Welder with other models on the market, several factors come into play that potential buyers should consider. One notable aspect is its power source – running on a 120V (20A circuit) makes it more accessible for home users or workshops without access to higher voltage setups. The excellent build quality and flawless arc quality are consistent strengths, highlighting the reliability associated with the Hobart brand.

However, its limitations become apparent when examining its welding capabilities with aluminum. While it can weld aluminum using a regular MIG gun, this method is more prone to wire nesting, potentially affecting the quality of welds. Comparatively, some competing models offer dedicated spool gun compatibility, providing a more efficient solution for aluminum welding.

The duty cycle of the Handler 140 is another critical consideration. Although it delivers reliable performance, its duty cycle is significantly lower than some competitors. For users engaging in prolonged welding sessions, this may pose a limitation. Additionally, the weldable thickness range and amperage output fall below some alternative brands, impacting its suitability for heavy-duty industrial applications.

Another noteworthy aspect is its weight; while still portable, it is heavier than newer competing models, potentially affecting the ease of transportation between job sites. Despite these considerations, the Handler 140 remains an attractive option due to its solid build, user-friendly design, and the reassurance of a 5/3/1 warranty, covering key components for an extended period. Ultimately, potential buyers should weigh the specific requirements of their welding projects against these factors to determine if the Handler 140 aligns with their needs and budget constraints.

Alternatives To Consider

As we noted a few times, some alternatives provide more value for the money, in our opinion. The Hobart 500559 Handler 140 and Eastwood MIG 140 make the best models for comparison.

They offer a similar build quality and warranty, while providing better specs. Plus, Eastwood is a USA brand with a long history, just like Hobart.

Table of Comparison vs. Competitors

Here’s a comparison table between the Hobart 500559 Handler 140 MIG Welder and the Eastwood 140 Amp 120V MIG Welder:

| Feature | Hobart 500559 Handler 140 MIG Welder | Eastwood 140 Amp 120V MIG Welder |

|---|---|---|

| Power Source | 120V | 120V |

| Amperage Output | 25 – 140 amps | 30 – 140 amps |

| Duty Cycle | 20% at 90A | 30% at 90A |

| Weldable Thickness Range | 24 ga. – 1/4 in. | 24 ga. – 3/16 in. |

| Wire Feed Speed Control | Yes | Yes |

| Wire Diameter Capability | 0.023″ – 0.035″ | 0.023″ – 0.035″ |

| Weight | 57 pounds | 62 pounds |

| Spool Gun Ready | No | No |

| Warranty | 5/3/1 Limited Warranty | 3-year Limited Warranty |

| Additional Features | Infinite wire speed control, 3-groove drive roller | 4 voltage settings, 2 drive roll, grooves, thermal overload protection |

| Price | $797.17 USD | $399.99 USD |

Please note that specific features and specifications may vary, and it’s recommended to refer to the respective product manuals and official specifications for the most accurate and up-to-date information.

Hobart Handler 140 Pros and Cons

| Pros | Cons |

|---|---|

| – Runs on 120V (20A circuit) | – Not spool gun ready |

| – Excellent build quality | – Welds aluminum using a regular MIG gun prone to wire nesting |

| – Flawless Hobart’s arc quality | – Significantly lower duty cycle than competing models |

| – Reliable wire feed system up to 700 inches/minute | – Lower amperage output and weldable thickness range compared to other brands |

| – Infinite wire speed control between min. and max. | – 110v input only |

| – User-friendly 3-groove drive roller (“Quick Select”) | – Heavier than new competing models |

| – Strong 5/3/1 Warranty (e.g. transformer covered for 5 years) | – Requires rewiring the connection inside the spool wire compartment for MIG to flux-cored welding, an outdated method |

| – Made in the USA | – No support for advanced settings like inductance control, 2T/4T, and others |

| – Doesn’t support infinite adjustability for voltage output | |

| – No digital display | |

| – Integrated ground clamp, making it difficult to change | |

| – Regulator not C100 compatible | |

| – Work clamp is light and undersized | |

| – Aluminum thickness range is small (only 16 to 20 gauge) |

Is This Hobart 140 Handler Welder Worth Buying?

The decision to invest in the Hobart 500559 Handler 140 MIG Welder hinges on the nature of your welding requirements. If you are a hobbyist, DIY enthusiast, or engaged in light fabrication, the Handler 140 offers versatility with its welding range of 25 to 140 amps, making it suitable for various tasks.

The user-friendly interface, durable construction, and reliable wire feed system contribute to its appeal. However, potential buyers should carefully consider certain limitations, such as the lower duty cycle, particularly if involved in prolonged welding sessions.

Additionally, the absence of spool gun readiness for aluminum welding may affect its suitability for those frequently working with aluminum. While it provides solid performance, individuals seeking a balance between portability and power might explore newer models with advanced inverter technology, considering the Handler 140’s weight and transformer design.

Overall, for those prioritizing durability, simplicity, and solid welding capabilities for light to moderate tasks, the Hobart Handler 140 remains a dependable choice, but it’s crucial to weigh its features against specific project requirements.

Decision Making

One pivotal decision-making variable for users considering the Hobart 500559 Handler 140 MIG Welder is the intended scope and nature of their welding projects. The Handler 140 is exceptionally well-suited for hobbyists, DIY enthusiasts, and small-scale fabricators due to its versatile performance and user-friendly design. If the primary focus is on tasks such as auto body repairs, light fabrication, or general household welding projects, the Handler 140’s welding range of 25 to 140 amps, coupled with its intuitive controls and compact size, makes it an attractive choice.

However, for users engaged in heavy-duty industrial applications that demand higher amperage output and a broader weldable thickness range, alternative models with more robust capabilities might be more suitable. Ultimately, aligning the features of the Handler 140 with the specific requirements of the intended projects is a crucial variable in the decision-making process for potential users.

Conclusion

After thorough evaluation, the Hobart 500559 Handler 140 MIG Welder stands out as a top-tier choice for both beginners and experienced welders alike. Its impressive performance, durability, and user-friendly design make it a reliable companion in any welding workshop. While it may have some limitations, its overall value and versatility make it the best choice for hobbyists, DIYers, and small-scale fabricators. I wholeheartedly recommend the Handler 140 for anyone in search of a dependable MIG welder that delivers on its promises.

The Hobart Handler 140 was one of the best entry-level welders for a long time. It’s still a good machine, but the newer technology available on inexpensive welders today has a significant edge over the Hobart 140. The Eastwood company is a well-established brand, and their MIG welders offer quality on par with Hobart. Considering that they are backed by a 3-year warranty, and deliver better specs at a lower price, the Eastwood 180 and 140 make a better value for the money.

Frequently Asked Questions

- What power source does the Hobart 500559 Handler 140 require?

The Handler 140 runs on a 120V power source, drawing 20A from a circuit. - Is the Hobart Handler 140 suitable for welding aluminum?

Yes, the Handler 140 can weld aluminum using a regular MIG gun. However, users should be aware that this method may be more prone to wire nesting. - Does the Hobart Handler 140 have spool gun compatibility?

No, the Handler 140 is not spool gun ready, and users need to use a regular MIG gun for welding aluminum. - What is the duty cycle of the Hobart Handler 140?

The Handler 140 has a duty cycle of 20% at 90 amps. Users should be mindful of this limitation during extended welding sessions. - Can the Hobart Handler 140 be used for industrial applications?

While the Handler 140 is a reliable choice for various tasks, its lower amperage output and weldable thickness range may limit its suitability for heavy-duty industrial applications. - Is the Handler 140 portable?Yes, the Hobart Handler 140 has a compact design and weighs 57 pounds, making it relatively portable and suitable for different work environments.

- What warranty does the Hobart Handler 140 come with?

The Handler 140 is backed by a strong 5/3/1 warranty, with the transformer covered for 5 years, providing users with confidence in its durability. - Can the Hobart Handler 140 switch between MIG and flux-cored welding?

Yes, the Handler 140 can switch between MIG and flux-cored welding, but users need to rewire the connection inside the spool wire compartment, which may be considered an outdated method. - Does the Hobart Handler 140 support advanced settings like inductance control and 2T/4T?

No, the Handler 140 lacks support for advanced settings such as inductance control, 2T/4T, and others. - Is there a digital display on the Hobart Handler 140?

No, the Handler 140 does not feature a digital display. Users need to rely on the intuitive interface and manual adjustments for welding settings.

We’re eager to learn from your firsthand experiences with the Hobart 500559 Handler 140 MIG Welder! Feel free to drop your comments below, sharing your thoughts and insights. Your personal encounters with this welding machine could be invaluable for others considering their next equipment investment. Your input may just be the guidance someone needs to make an informed decision. Join the conversation and let’s build a community of informed welders helping each other out!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

I’ve been using the 140 for years. My small business needs makes it a great choice. We use two 140’s almost everyday and have two more as backups. We don’t weld anything other than steel. Not any real issues at all. I’d recommend this machine to anyone looking to get into welding.

Walt

March 9, 2024 12:30 pmThe Hobart Handler 140 MIG Welder, with its reliability and suitability for steel welding, comes highly recommended for both beginners and those running a small business. Its consistent performance in a commercial setting underscores its quality and efficiency.

Edward Smith

March 11, 2024 7:07 am