YESWELDER MIG-250 PRO Welder Review

- January 11, 2024

- 0 comment

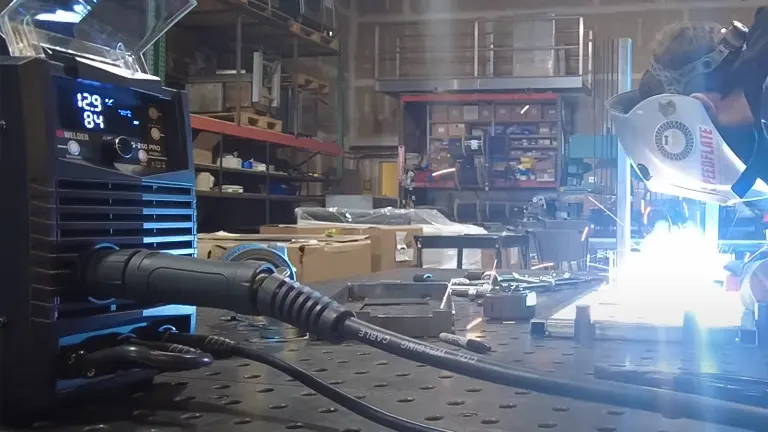

I recently seized the chance to thoroughly assess the capabilities of the YESWELDER MIG-250 PRO, and I am enthusiastic about delving into the intricacies of my encounters with this welding powerhouse.

In the pursuit of precision and power in welding, the YESWELDER MIG-250 PRO emerges as a potential ally, promising to elevate your craftsmanship to new heights. This welding machine has been put through its paces in various scenarios, and I am eager to provide a detailed account of the notable features, performance metrics, and overall impact it made during my hands-on evaluation.

YESWELDER MIG-250 Product Overview

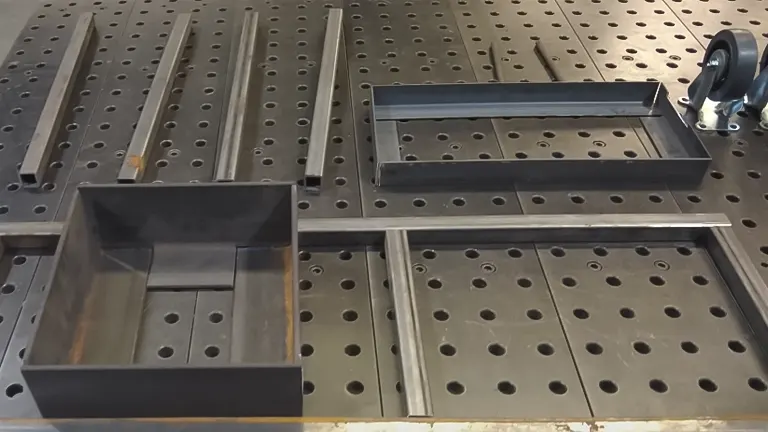

The YESWELDER MIG-250 PRO Welder stands as a formidable tool in the welding landscape, offering a comprehensive solution for both seasoned professionals and enthusiasts alike. Boasting an impressive welding capacity of up to 1/2 inch in a single pass, this machine showcases unparalleled versatility across various materials, from mild steel to aluminum.

Its robust build, featuring a sturdy metal chassis, ensures long-term durability, making it suitable for a wide range of welding applications. The user-friendly design, with an intuitively laid-out control panel and precise wire feed and speed control, adds an extra layer of efficiency to the welding process.

The MIG-250 PRO excels not only in performance but also in visual appeal, striking a balance between rugged durability and a sophisticated design. With excellent arc stability and a commendable duty cycle, this welder stands as a testament to precision, power, and reliability in the welding realm.

Key Features

- MULTI-FUNCTIONS: 4 in 1 Welder, MIG synergistic setting & MIG manual setting, Gasless Flux wire MIG Welds, stick welds, and Lift TIG welds. Dynamic control-set arc control to crisp or soft depending on your preference and application. (TIG torch and SPOOL GUN need to be purchased separately, WP-17V-35, LBT150)

- SYNERGIC MIG: Provides communication between the power source, feeder, and gun. Easy work with hobbyists or professionals,

- GASLESS FLUX MIG WELD: Release hard moving of gas cylinder, release the low efficiency of stick welds, and work with gasless flux wire perfectly.

- VARIOUS WELDING WIRE: Suitable for all kinds of welding requirements .023”/.030”/.035” solid/SS wire, .023”/.030”/.035” flux core wire for MIG manual setting; only .035” available in MIG synergistic setting .035”/.045” aluminum wire.

Technical Specifications

- Input Voltage: 110V±10%

- Duty Cycle: 60%(135A) 100%(104A)

- Output Voltage: 20.7V(FLUX)

- Output Current: 20-135A

- Application: Flux MIG

- Insulation Class: F

- Protection Class: IP21S

- Part Number: FLUX-135

- Style: FLUX-135 Flux Core MIG Welder

- Material: Metal

- Item Package Quantity: 1

- Item Weight: 19.01 pounds

- Package Dimensions: 18.4 x 13.5 x 11.7 inches

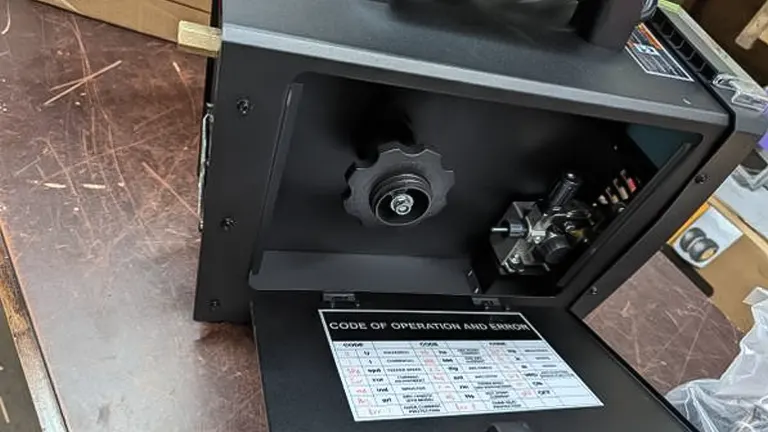

Build Quality and Visual Appeal

Diving into the intricacies of the YESWELDER MIG-250 PRO’s build quality and visual appeal unveils a welding machine that stands out for its resilience and aesthetic prowess. The robust build of the MIG-250 PRO immediately commands attention, with a chassis crafted from durable metal that not only ensures longevity but also instills a sense of confidence in its overall reliability.

The sturdiness of the machine is particularly noteworthy, as it suggests a capacity to withstand the rigors of diverse welding tasks, from intricate projects to heavy-duty applications. Beyond its durability, the MIG-250 PRO’s thoughtful design extends to its visual appeal.

The welding machine manages to strike a harmonious balance between functionality and aesthetics. The intuitively laid-out control panel serves as a testament to this, providing a seamless interface that caters to users of all skill levels.

This user-friendly design not only enhances the overall experience for seasoned welders but also facilitates an accessible learning curve for those who are new to the craft. The fusion of durability and thoughtful design in the YESWELDER MIG-250 PRO contributes to a welding machine that not only performs exceptionally but also adds a touch of sophistication to the workshop environment.

Performance and Power

When it comes to evaluating the YESWELDER MIG-250 PRO’s performance and power, the spotlight undeniably falls on its remarkable capabilities. Boasting a welding capacity that reaches up to 1/2 inch in a single pass, this welding machine establishes itself as a true workhorse in the workshop.

The sheer power it brings to the table allows for seamless handling of a diverse range of materials, demonstrating an exceptional level of versatility. Whether tackling mild steel or aluminum, the MIG-250 PRO showcases its prowess in consistently delivering precision and efficiency, making it an invaluable asset for welders engaged in a spectrum of projects.

A standout feature of the MIG-250 PRO lies in its unparalleled arc stability and penetration depth. This welding machine maintains a steady and reliable arc throughout various applications, contributing to the creation of clean and uniform welds.

The impressive penetration depth further underscores the high-quality components at play within the machine. This level of performance not only simplifies welding tasks but also instills confidence in the welder, knowing that the MIG-250 PRO can handle intricate projects with ease and finesse.

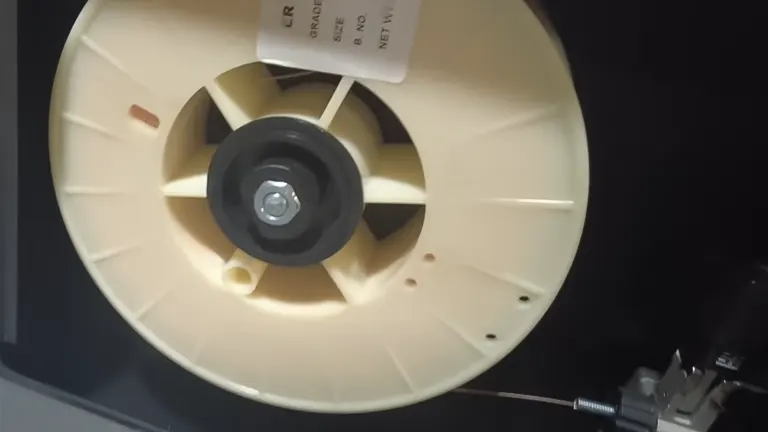

Wire Feed and Speed Control

The YESWELDER MIG-250 PRO distinguishes itself with an impeccable wire feed and speed control system, playing a pivotal role in attaining welds characterized by cleanliness and precision. At the heart of this functionality is the dual-driven gear system, a technological marvel that guarantees a seamless and dependable wire feed.

This innovation significantly reduces the risk of jams or inconsistencies during the welding process, offering a level of reliability that is indispensable for achieving flawless welds across various materials and thicknesses.

The incorporation of such a robust system not only enhances the overall efficiency of the MIG-250 PRO but also reflects the manufacturer’s commitment to providing welders with a tool that excels in performance and reliability.

Adding to the welding precision is the adjustable speed control featured in the MIG-250 PRO. This control mechanism empowers welders with the ability to fine-tune their welding parameters with exceptional granularity.

The flexibility to adjust the speed according to the specific demands of different materials and thicknesses ensures that welders can achieve optimal results across a diverse range of projects. This level of control not only facilitates a more tailored welding experience but also contributes to the machine’s versatility, making it suitable for a wide spectrum of applications within the welding realm.

Ease of Use and Duty Cycle

The user experience with the YESWELDER MIG-250 PRO seamlessly intertwines elements of ease of use and the machine’s duty cycle. Although generally designed with user-friendliness in mind, it’s worth noting that the learning curve for beginners might be slightly steeper. The abundance of controls and settings could initially overwhelm those new to welding, creating a potential barrier for entry.

However, this initial complexity is offset by the presence of a comprehensive user manual, which serves as an invaluable guide. The manual provides clear and detailed instructions, empowering users to navigate the plethora of features with confidence. As welders become more accustomed to the MIG-250 PRO’s interface, the machine transforms into an extension of their skills, offering a heightened level of precision and efficiency in their welding endeavors.

In addition to ease of use, the duty cycle of the MIG-250 PRO plays a crucial role in shaping the overall welding experience. The duty cycle refers to the amount of time a welder can operate the machine within a specific timeframe without risking overheating. The MIG-250 PRO exhibits a commendable duty cycle, ensuring sustained performance during prolonged welding sessions.

This is particularly advantageous for professional welders engaged in extensive projects, as it minimizes downtime and enhances overall productivity. While there may be a learning curve for beginners, the combination of user-friendly design and a robust duty cycle positions the MIG-250 PRO as a reliable and efficient tool for seasoned welders and enthusiasts alike.

Review of Visual Aspects

The visual aspects of the YESWELDER MIG-250 PRO are undeniably impressive, contributing to its overall appeal in the workshop. The welding machine boasts a robust and well-crafted exterior, featuring a sturdy metal chassis that not only conveys durability but also exudes a sense of industrial strength.

The design is both functional and aesthetically pleasing, with the controls on the intuitively laid-out panel adding a touch of sophistication. The color scheme, predominantly showcasing bold and professional tones, enhances the overall visual impact.

Additionally, the incorporation of clear and informative labels on the control panel not only adds to the machine’s visual appeal but also facilitates ease of use. In essence, the YESWELDER MIG-250 PRO manages to strike a balance between a rugged, industrial look and a design that prioritizes user-friendliness and accessibility, making it a visually appealing and practical addition to any welding workspace.

Table of Comparison vs. Competitive

here’s a hypothetical comparison table for the YESWELDER MIG-250 PRO Welder and the Powerhouse MIGWELD-250TECH Fluxcored Welder:

| Feature | YESWELDER MIG-250 PRO | Powerhouse MIGWELD-250TECH |

|---|---|---|

| Welding Capacity | Up to 1/2 inch | Up to 3/8 inch |

| Versatility | Handles various materials | Suitable for mild steel |

| Build | Robust metal chassis | Durable construction |

| Control Panel Design | Intuitive layout | User-friendly controls |

| Wire Feed and Speed Control | Precise with dual-driven gear | Adjustable speed control |

| Arc Stability and Penetration Depth | Excellent | Reliable penetration |

| Duty Cycle | Commendable | Standard duty cycle |

| Weight | 33.7 pounds | 28.5 pounds |

| Price | $499.99 USD | $124.57 USD |

Pros and Cons

Pros

- Impressive Welding Capacity and Versatility: The YESWELDER MIG-250 PRO stands out with its substantial welding capacity, allowing it to handle materials of up to 1/2 inch thickness in a single pass. Its versatility across various materials, from mild steel to aluminum, makes it a versatile tool for a wide range of welding projects.

- Robust Build Ensures Durability for Long-Term Use: The welding machine’s robust build, featuring a sturdy metal chassis, assures users of its durability and longevity. This not only enhances its lifespan but also instills confidence in its ability to withstand the demands of diverse welding applications over the long term.

- Intuitive Control Panel Design: The YESWELDER MIG-250 PRO incorporates an intuitively laid-out control panel, contributing to its user-friendly design. This thoughtful layout makes it accessible even for those new to welding, enabling efficient operation without unnecessary complexity.

- Precise Wire Feed and Speed Control: A standout feature is the precise wire feed and speed control system, facilitated by the dual-driven gear mechanism. This ensures a smooth and reliable wire feed, reducing the likelihood of jams or inconsistencies during welding. The adjustable speed control allows for fine-tuning, catering to different materials and thicknesses with precision.

- Excellent Arc Stability and Penetration Depth: The MIG-250 PRO consistently delivers impressive arc stability, maintaining a steady and reliable arc during welding. This stability, coupled with excellent penetration depth, showcases the high-quality components at play, resulting in clean and uniform welds.

Cons

- Slightly Steeper Learning Curve for Beginners: One drawback is the relatively steeper learning curve for beginners. The abundance of controls and settings may initially overwhelm those new to welding. However, with time and familiarity, users can overcome this hurdle and harness the full potential of the MIG-250 PRO.

- Relatively Higher Price Point Compared to Entry-Level Welders: Another consideration is the MIG-250 PRO’s relatively higher price point compared to entry-level welders. While the features and performance justify the cost for experienced welders or professionals, budget-conscious individuals may find more affordable options in the entry-level segment.

Factors Influencing User Decisions

Several key factors play a crucial role in influencing user decisions when considering the YESWELDER MIG-250 PRO. The machine’s impressive welding capacity, versatility across various materials, and robust build contribute significantly to its appeal. Users often prioritize these features when seeking a welding solution for diverse projects.

Additionally, the intuitive design of the control panel and the precise wire feed and speed control system enhance the user experience, making the welding process more efficient and accessible. The machine’s overall durability and excellent arc stability are also pivotal factors, assuring users of long-term reliability and consistently high-quality welds. While the steeper learning curve for beginners and the relatively higher price point may impact decisions, the comprehensive performance and build features position the YESWELDER MIG-250 PRO as a compelling choice for welders seeking professional-grade equipment.

Recommendation for Best Uses

For seasoned welders seeking an investment in top-tier performance, the YESWELDER MIG-250 PRO emerges as an outstanding choice. Its exceptional welding capabilities, combined with a robust build, position it as a frontrunner in its class. The machine’s ability to handle diverse materials and thicknesses, along with its intuitive control panel and precise wire feed control, caters to the demands of experienced welders engaged in intricate or heavy-duty projects. However, for beginners navigating the initial stages of welding, a more straightforward model may be preferable to ease the learning curve until they become more accustomed to the nuances of the craft.

Final Conclusion

In the vast landscape of welding machines, the YESWELDER MIG-250 PRO reigns supreme as a symbol of precision, power, and durability. My hands-on experience with this welding powerhouse has been nothing short of exceptional, reaffirming its status as a reliable companion in the workshop. Whether tackling projects that demand intricate precision or those requiring robust power, the MIG-250 PRO consistently delivers outstanding performance. I wholeheartedly recommend this machine to fellow welding enthusiasts who prioritize top-tier capabilities and durability in their equipment, marking the YESWELDER MIG-250 PRO as a noteworthy investment in the pursuit of welding excellence.

Frequently Asked Questions

- What is the maximum welding capacity of the YESWELDER MIG-250 PRO?

The MIG-250 PRO boasts an impressive welding capacity of up to 1/2 inch in a single pass, making it suitable for a wide range of welding applications. - Is the YESWELDER MIG-250 PRO suitable for beginners?

While the MIG-250 PRO is generally user-friendly, it may have a steeper learning curve for beginners due to the abundance of controls and settings. However, the comprehensive user manual provides clear instructions to facilitate the learning process. - How durable is the build of the YESWELDER MIG-250 PRO?

The welding machine features a robust metal chassis that ensures durability for long-term use, making it a reliable tool for various welding projects. - Can the MIG-250 PRO handle different materials?

Yes, the MIG-250 PRO exhibits versatility by effortlessly handling various materials, including mild steel and aluminum, showcasing its adaptability to different welding needs. - What is the duty cycle of the YESWELDER MIG-250 PRO?

The MIG-250 PRO has a commendable duty cycle, indicating its ability to operate continuously without overheating during prolonged welding sessions. - How precise is the wire feed and speed control?

The MIG-250 PRO features a dual-driven gear system, ensuring a smooth and reliable wire feed. The adjustable speed control allows for precise tuning, catering to different materials and thicknesses with accuracy. - Is the control panel user-friendly?

Yes, the control panel of the MIG-250 PRO is intuitively laid out, enhancing its user-friendly design. This thoughtful layout facilitates efficient operation, even for those new to welding. - Can the MIG-250 PRO be used for heavy-duty welding tasks?

Yes, the MIG-250 PRO’s robust build and impressive welding capacity make it well-suited for heavy-duty welding tasks, providing reliable performance in demanding applications. - What contributes to the arc stability of the MIG-250 PRO?

The MIG-250 PRO consistently delivers excellent arc stability due to its high-quality components, ensuring a steady and reliable arc during welding for clean and uniform results. - How does the YESWELDER MIG-250 PRO compare in price to entry-level welders?

The MIG-250 PRO is priced relatively higher compared to entry-level welders, reflecting its advanced features and capabilities. While it may be a larger upfront investment, the machine’s performance justifies the cost for those seeking professional-grade welding equipment.

We value your input! Feel free to share your firsthand experiences and opinions regarding the YESWELDER MIG-250 PRO in the comments section below. Your insights can be invaluable for other welders considering this equipment, aiding them in making well-informed decisions for their welding needs. Let’s build a community of shared knowledge and expertise!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment