Lincoln Electric POWER MIG 215 Welder Review

- January 18, 2024

- 0 comment

The Lincoln Electric K4877-1 POWER MIG 215 has truly distinguished itself as a standout choice for reliability and versatility. Join me as I delve into my journey with this welder, exploring its features, contrasting it with its counterparts, and weighing its advantages and disadvantages.

Technical Specifications

- Dimensions: 15.08 in x 10.88 in x 23.14 in (H x W x D) or 383 mm x 276 mm x 588 mm.

- Net Weight: 48 lbs (21.8 kg).

- Maximum Rating: 220A.

- User Interface (UI) Type: TFT – Graphic.

- Wire Feeding Processes: MIG and Flux Cored.

- Maximum Wire Thickness: 0.045 in (1.1 mm).

- Minimum Wire Thickness: 0.025 in (0.6 mm).

- Sample MIG Wire Included: Yes.

- Input Voltage: 120/230V.

- Input Hertz: 60.

Key Features

- Multi-Process Capability: Offers versatility with the ability to perform MIG, Flux-Cored, DC TIG, and Stick welding.

- Amperage Range: Provides a broad range of up to 215 amps, accommodating various materials and thicknesses.

- Dual Voltage Input: Supports both 120V and 230V input, making it adaptable to different power supplies.

- Digital Controls and Color Display: Features an intuitive digital interface with a color display for easy setup and adjustments.

- Robust and Compact Design: The welder is built sturdy yet is compact in size, ideal for different workshop environments.

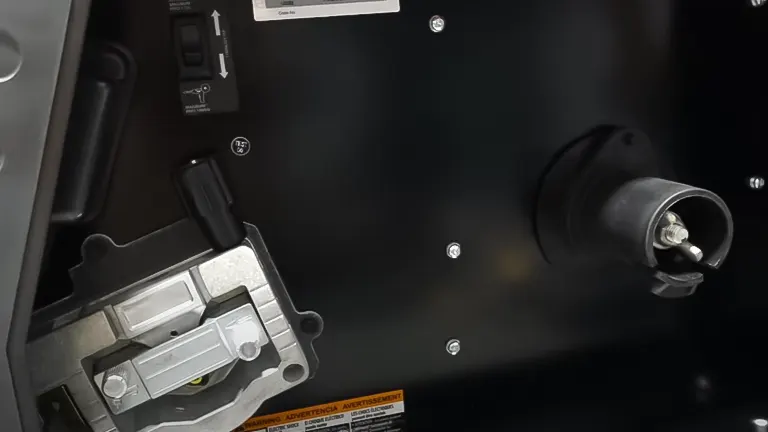

- Advanced Wire Feed System: Equipped with a reliable wire feed system that ensures consistent weld quality.

- Stable Arc Performance: Delivers a stable and smooth arc across all processes, ensuring high-quality welding results.

- High Duty Cycle: Offers a 60% duty cycle at 170 amps, providing a balance between continuous welding and cooling periods.

- Comprehensive Safety Features: Includes thermal overload protection and other safety features to ensure safe operation.

- Ready-Pak Option: Comes with a Ready-Pak option, which includes essential accessories and gear to get started right away.

Performance and Features

The Lincoln Electric K4877-1 POWER MIG 215 demonstrates outstanding versatility as a multi-process welder, a feature that I’ve found to be incredibly advantageous. This machine adeptly handles MIG, Flux-Cored, DC TIG, and Stick welding processes, eliminating the need for multiple separate welders.

This adaptability is particularly beneficial for those of us who frequently work across various welding environments and tackle projects that require different welding techniques. For instance, the capability to switch seamlessly between MIG welding for general fabrication and TIG for precision work on thinner materials is not just convenient but also cost-effective.

This welder is a true all-rounder, accommodating a wide array of welding tasks without compromising on performance. Its utility extends from automotive repairs and customization to general shop work and even art projects, making it an ideal choice for both professional and hobbyist welders.

From a technical perspective, the POWER MIG 215’s amperage range is noteworthy, extending up to 215 amps. This robust power output allows me to confidently work on a diverse range of materials, including both delicate thin sheet metals and robust, thicker structural components.

The welder’s capacity to handle such a spectrum of materials is not only impressive but also crucial for ensuring high-quality welds across different projects. Furthermore, the machine’s duty cycle of 60% at 170 amps deserves a special mention. This specification indicates that the welder can operate at 170 amps for 6 minutes in a 10-minute cycle without overheating, striking a fine balance between sustained power output and operational efficiency.

This aspect of the welder is particularly appreciated during longer welding sessions, where consistent performance and reduced downtime are key. Overall, the POWER MIG 215 excels in delivering a harmonious blend of power, versatility, and efficiency, making it a standout choice in its class.

User Experience

The user experience with the Lincoln Electric K4877-1 POWER MIG 215 is notably user-friendly, catering to both novices and seasoned welders alike. One of the standout features that facilitate this ease of use is the advanced digital control interface, complete with a vibrant color display. This intuitive control panel significantly simplifies the setup process, allowing users to fine-tune their welding parameters with precision and ease.

Even those who are relatively new to welding find this interface approachable, with clear, easy-to-understand settings and prompts. In terms of physical design, the welder’s construction strikes a perfect balance between durability and compactness. Its robust build instills confidence in its longevity and ability to withstand the rigors of a busy workshop environment.

Yet, its compact size is a boon for space-constrained areas, making it an ideal fit for smaller workshops or for those who need to frequently move the unit around different work sites. This combination of user-friendly controls and thoughtful design makes the POWER MIG 215 a practical and versatile tool in any welding setting.

When it comes to the actual welding experience, the POWER MIG 215 shines with its exceptional performance across various welding processes. The machine consistently delivers a stable and smooth arc, a critical factor that contributes to high-quality welds. This steadiness is especially noticeable when engaging in TIG welding, where the welder produces crisp, clean welds, making it suitable for applications requiring a higher level of precision and finish.

Similarly, in stick welding mode, the machine demonstrates impressive penetration capabilities. This deep penetration ensures strong, reliable welds even on thicker materials, an essential aspect for structural welding or heavy-duty repair work. Another noteworthy feature is the welder’s reliable wire feed system.

It maintains a consistent feed rate, which is crucial for achieving uniform weld quality—a key consideration for professional projects where consistency and accuracy are paramount. Overall, the welding experience with the POWER MIG 215 is gratifying, blending ease of use with exceptional welding performance, making it a valuable asset for any welder seeking quality and reliability in their work.

Review of Visual Characteristics

The Lincoln Electric K4877-1 POWER MIG 215 Welder boasts a sleek and modern design, characterized by its compact and robust build. Its visual appeal lies in the harmonious blend of industrial functionality and modern aesthetics. The welder features a distinctive red and black color scheme, typical of Lincoln Electric’s signature style, which not only adds to its professional appearance but also makes it easily recognizable in a workshop setting.

The front panel is well-organized, showcasing a user-friendly digital interface with a clear, vibrant color display that enhances its contemporary look. This interface is not just visually pleasing but also intuitive to use, adding to the machine’s overall ergonomic design. The compact dimensions ensure that it doesn’t occupy excessive space, making it a practical addition even in workshops where space is at a premium. Overall, the POWER MIG 215’s visual characteristics reflect a thoughtful design that merges practicality with a modern, professional appearance.

Safety Features

- Thermal Overload Protection: Automatically shuts off the welder to prevent overheating, enhancing both the safety of the operator and the longevity of the machine.

- Voltage Reduction Device: Reduces the open-circuit voltage when not welding, minimizing the risk of electric shock.

- Gas Solenoid Valve: Prevents gas leaks when the welder is not in use, ensuring safe operation.

- Built-in Contactors: Keeps the welding wire electrically “cold” until the gun trigger is pressed, for added safety.

- Circuit Breaker Protection: Shields the welder from power surges and electrical faults.

- Overcurrent Protection: Guards against excessive current draw, which can cause overheating and potential damage.

- Fan-As-Needed (F.A.N.) Cooling System: Operates the cooling fan only when needed, reducing the intake of dust and debris and preventing overheating.

- Ground Fault Interruption: Ensures the welder is automatically shut off in the event of a ground fault, enhancing operator safety.

- Robust Metal Casing: Protects internal components from damage and reduces the risk of accidents due to external impacts.

- Safety Compliance: Meets relevant safety standards and certifications, ensuring that the welder adheres to established safety norms and regulations.

Table of Comparison vs. Competitors

Here’s a comparison table for the Miller Multimatic 215, ESAB Rebel EMP 215ic, and Lincoln POWER MIG 215, covering key features and specifications:

| Feature/Specification | Miller Multimatic 215 | ESAB Rebel EMP 215ic | Lincoln POWER MIG 215 |

|---|---|---|---|

| Process Types | MIG, Flux-Cored, DC TIG, Stick | MIG, Flux-Cored, DC TIG, Stick | MIG, Flux-Cored, DC TIG, Stick |

| Amperage Range | 30-230A | 5-240A | Up to 215A |

| Voltage Input | 120V/240V | 120V/230V | 120V/230V |

| Max Wire Speed | 600 ipm | 595 ipm | 580 ipm |

| User Interface | LCD Display | TFT Multilingual Display | Digital Controls, Color Display |

| Weight | 38 lbs (17.2 kg) | 40 lbs (18 kg) | 48 lbs (21.8 kg) |

| Dimensions (H x W x D) | 12.5″ x 11.25″ x 20.5″ | 16″ x 9″ x 23″ | 15.08″ x 10.88″ x 23.14″ |

| Duty Cycle | 60% @ 150A (240V) | 40% @ 205A, 25% @ 240A | 60% @ 170A |

| Wire Feed Speed Range | 1.3-17.8 m/min | 1.5-12.1 m/min | Not specified |

| Portable | Yes | Yes | Yes |

| Additional Features | Auto-Set Elite, Fan-On-Demand | Smart MIG, sMIG Technology | Diamond Core Technology, Ready-Pak |

Comparisons and Suitability

When compared to other welders in its class, such as the Miller Multimatic 215 or the ESAB Rebel EMP 215ic, the Lincoln POWER MIG 215 holds its ground well. While Miller and ESAB offer similar multi-process capabilities, I found Lincoln’s user interface to be more intuitive. However, if you are looking for more advanced TIG features, the Miller might edge out slightly.

The Lincoln POWER MIG 215 is ideal for medium to heavy-duty home projects, automotive repairs, and light industrial work. Its versatility makes it a great all-rounder, suitable for both hobbyists and professional welders who need a reliable, multi-purpose machine.

Pros and Cons

| Pros | Cons |

|---|---|

| Versatility: Handles multiple welding processes efficiently. | Price: Higher priced than some entry-level models. |

| User-Friendly: Easy setup with clear digital controls. | TIG Accessories: Lacks some advanced TIG features; separate purchase required. |

| Performance: Stable arc and excellent weld quality. | |

| Build Quality: Sturdy yet not overly bulky. |

This table succinctly presents the pros and cons of the Lincoln Electric K4877-1 POWER MIG 215 Welder, providing a clear and concise comparison of its advantages and limitations.

Prescription for Best Uses

The Lincoln Electric K4877-1 POWER MIG 215 Welder is best suited for a wide range of applications, making it an ideal choice for both professional workshops and serious hobbyists. Its multi-process capability efficiently handles MIG, Flux-Cored, DC TIG, and Stick welding, perfect for diverse projects ranging from auto-body repair and fabrication to general metalworking and home DIY projects.

Its robust design, combined with user-friendly features, makes it suitable for both experienced welders and beginners looking for a reliable, high-performance tool. Whether it’s for constructing metal art, repairing machinery, or working on custom automotive modifications, the POWER MIG 215 offers the flexibility and power needed for high-quality, efficient welding in various settings.

Concluding Reflections

In conclude, the Lincoln Electric K4877-1 POWER MIG 215 emerges as a formidable choice in the realm of welding equipment. This machine impressively harmonizes key attributes such as versatility, high-level performance, and ease of use, making it a valuable asset in any workshop setting. Its ability to adeptly handle a variety of welding processes makes it a particularly attractive option for those who require a multifaceted tool capable of adapting to different project needs. While the price point of the POWER MIG 215 may be on the higher side compared to some entry-level alternatives, the investment is well justified when considering the comprehensive range of features and dependable performance it offers. The welder’s robust construction, coupled with its reliable operation, ensures that it stands as a solid investment for long-term use.

This welder is ideally suited not only for professionals who demand consistency and precision in their work but also for hobbyists who seek a high-quality tool to elevate their craft. Its user-friendly interface ensures that even those with less experience can navigate its features with relative ease, making it a welcoming tool for a wide range of users.

Frequently Asked Questions

- What types of welding can the Lincoln POWER MIG 215 perform?

The POWER MIG 215 is a multi-process welder capable of MIG, Flux-Cored, DC TIG, and Stick welding. - What is the maximum amperage output of the POWER MIG 215?

This welder has a maximum amperage output of up to 215 amps. - Can the POWER MIG 215 operate on both 120V and 230V inputs?

Yes, it is designed to operate with dual voltage input, supporting both 120V and 230V. - Is the POWER MIG 215 suitable for beginners?

Yes, its user-friendly digital controls and intuitive color display make it suitable for beginners. - What is the duty cycle of this welder?

The POWER MIG 215 has a duty cycle of 60% at 170 amps. - How portable is the POWER MIG 215?

It is relatively portable with a robust yet compact design, weighing 48 lbs. - Does the POWER MIG 215 come with a wire feeder?

Yes, it includes a reliable wire feed system. - What is the price range of the POWER MIG 215?

While prices may vary, the POWER MIG 215 is generally considered a higher investment compared to entry-level models. - Are TIG welding accessories included with the POWER MIG 215?

No, TIG accessories for the POWER MIG 215 need to be purchased separately. - Can the POWER MIG 215 be used for professional welding projects?

Absolutely, it is suitable for both professional and hobbyist applications due to its versatility and high-quality weld performance.

We’re eager to hear from you! Feel free to share your own experiences and opinions regarding the Lincoln Electric K4877-1 POWER MIG 215 Welder in the comments section below. Your personal insights and feedback are invaluable, helping fellow welders and enthusiasts make well-informed decisions. Let’s build a community of knowledge around this versatile welding machine!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment