Miller Bobcat 250 Generator Welder Review

- January 9, 2024

- 0 comment

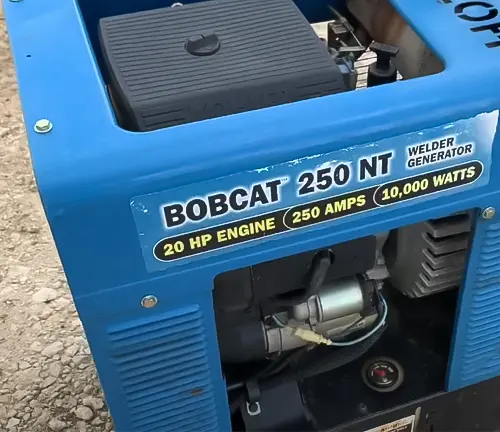

Unleash Welding Power with Miller Bobcat 250 – Your Ultimate Solution! AC DC CC CV, 9,500 Watts, Stick, TIG, MIG, & More! Get Compact Power Now. This review delves into my extensive firsthand encounters with this robust machine, offering a user-centric evaluation that draws on practical experience and insights gained from real-world applications.

Technical Specifications

- Generator Power: 11,000 Watts Peak, 9,500 Watts Continuous

- Engine: Kohler CH730

- Horsepower (HP): 23.5 hp at 3,600 rpm

- Material Type: Twin-cylinder, four-cycle overhead valve, industrial air-cooled, gasoline

- Weld Speed: 3,600 rpm

- Idle Speed: 2,300 rpm

- Fuel Capacity: 12 gal. (45 L)

- Weight: 501 lb (227 kg)

- Dimensions: H: 28″ (711 mm) W: 20″ (508 mm) L: 40.5″ (1029 mm)

- Height To Top of Exhaust: 32.75″ (832 mm)

My Personal Experience About Miller Bobcat 250

In my personal experience with the Miller Bobcat 250 Generator Welder, the first aspect that left a lasting impression was its unparalleled welding power. As a welder who frequently tackles diverse projects, I found the 11,000 watts peak and 9,500 watts continuous power output to be a game-changer.

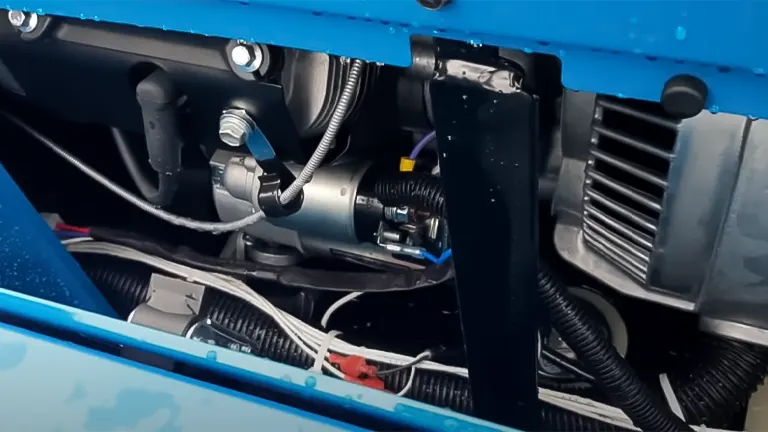

This robust performance allowed me to effortlessly handle various welding tasks, from intricate detailing to heavy-duty structural work, showcasing the machine’s versatility and reliability in every application. The Kohler CH730 engine, with its 23.5 horsepower at 3,600 rpm, consistently delivered a seamless welding experience, providing ample power for my welding needs.

Furthermore, the machine’s portability surprised me, considering its weight of 501 pounds. The integrated wheels and compact design facilitated easy maneuverability around job sites, even in tight spaces. The welder’s sturdy construction and durability were evident in its ability to withstand the rigors of demanding work environments.

From construction sites to remote locations, the Miller Bobcat 250 proved its mettle, and its fuel efficiency ensured prolonged operation without frequent refueling. Overall, my personal experience with the Miller Bobcat 250 has solidified my trust in its performance, making it an indispensable tool in my welding arsenal for both its power and durability.

Performance and Precision

Performance and precision are the cornerstones of the Miller Bobcat 250, defining its capabilities as a welding and power-generating workhorse. At the heart of its prowess lies a robust 23-horsepower engine, a true powerhouse that significantly elevates the welding experience. This formidable engine ensures a seamless and smooth welding process, effortlessly accommodating a diverse range of electrodes.

The versatility it offers is particularly noteworthy, enabling welders to tackle various applications with ease, from intricate detailing to heavy-duty structural projects. The Miller Bobcat 250’s ability to adapt to different welding requirements speaks volumes about its precision and reliability, traits that resonate with professionals seeking a tool that can meet the demands of any job site.

The generator capabilities of the Miller Bobcat 250 further underscore its performance excellence. Providing an impressive 11,000 watts of peak power and a continuous power output of 9,500 watts, this machine stands as a beacon of reliability in power generation.

This substantial power output not only ensures the efficient operation of the welder itself but also allows users to run multiple tools concurrently, eliminating the need for constant tool swapping and optimizing productivity. The Miller Bobcat 250’s commitment to unwavering performance and precision makes it a standout choice for welders who demand nothing short of excellence in their welding and power generation endeavors.

Portability and Visual Appeal

Portability and visual appeal converge seamlessly in the design of the Miller Bobcat 250, offering welders a robust yet surprisingly mobile solution. Despite weighing 501 pounds, this welder distinguishes itself through a thoughtful design that prioritizes ease of movement.

The integration of durable wheels and a well-balanced structure ensures that transporting the Miller Bobcat 250 across the job site becomes a manageable task. This feature is particularly advantageous for welders who need to navigate diverse terrain or transport the machine to different locations throughout the day.

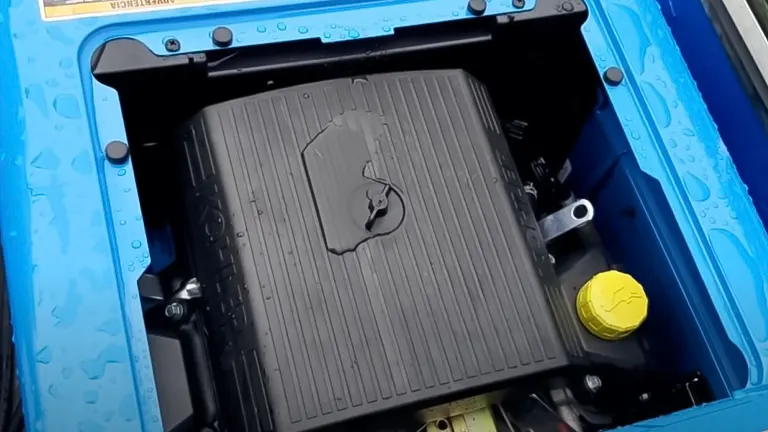

In addition to its practicality, the Miller Bobcat 250 boasts a visually appealing rugged design that underscores its durability. The welder’s exterior not only exudes a sense of reliability but also signifies its ability to withstand the demanding conditions of a job site. The compact dimensions further contribute to its visual appeal, allowing it to seamlessly fit into tight spaces.

For welders working in confined areas where maneuverability is key, the Miller Bobcat 250’s design becomes a valuable asset, ensuring that the tool not only performs exceptionally but also looks the part with its robust and aesthetically pleasing construction.

Duty Cycle and Usability

The Miller Bobcat 250 impressively combines a high-duty cycle with user-friendly features, solidifying its reputation as a dependable workhorse in the welding industry. The duty cycle of this welder is a standout feature, reflecting its ability to sustain continuous operation without overheating.

With a robust design and efficient cooling mechanisms, the Miller Bobcat 250 boasts an impressive duty cycle that ensures extended periods of welding without compromising performance. This feature is particularly advantageous for professionals engaged in large-scale projects, providing them with the confidence that the welder can handle the demands of prolonged use.

In terms of usability, the Miller Bobcat 250 excels with its intuitive controls and ergonomic design. The user-friendly interface allows both seasoned welders and novices to operate the machine with ease. Clear labeling, accessible knobs, and a straightforward setup process contribute to a seamless user experience.

The welder’s versatility, accommodating various welding applications, further enhances its usability. Whether you’re engaged in intricate detail work or tackling heavy-duty projects, the Miller Bobcat 250 adapts effortlessly to different welding needs, making it an ideal choice for welders seeking a combination of high performance and user-friendly design.

Visual Aspects Review

The visual aspect of the Miller Bobcat 250 Generator Welder is as impressive as its performance. Its rugged and robust design not only conveys durability but also translates to a visual appeal that instills confidence in its ability to withstand the harshest job site conditions. The welder’s well-engineered exterior is marked by a thoughtful layout, incorporating accessible controls and a clear interface that enhances its overall usability.

The integrated wheels, a practical addition to its design, not only contribute to its mobility but also add a layer of functionality to its visual appeal. The compact dimensions of the Miller Bobcat 250 make it visually striking, ensuring it can fit into tight spaces on the job site, a crucial factor for professionals working in confined environments. Overall, the visual aspect of the Miller Bobcat 250 complements its rugged performance, making it not just a reliable tool but also a visually appealing addition to any welding setup.

Proper Safety Features of the Miller Bobcat 250 Generator Welder

- Thermal Overload Protection: The Miller Bobcat 250 is equipped with thermal overload protection mechanisms, preventing the welder from overheating during extended use. This feature ensures the safety of both the equipment and the operator by automatically shutting down the machine if it exceeds safe temperature limits, preventing potential damage and reducing the risk of accidents.

- Electric Shock Prevention: Integrated safety features in the Miller Bobcat 250 include measures to prevent electric shocks. The design incorporates insulated components and effective grounding to minimize the risk of electric shock hazards, safeguarding the operator and those working close to the welding site.

- Emergency Shutdown Switch: The welder is designed with an emergency shutdown switch, allowing operators to quickly and efficiently cut power in case of any unforeseen issues or emergencies. This immediate power cutoff enhances overall job site safety, providing a swift response in critical situations.

- Low Oil Shutdown: To protect the engine from damage, the Miller Bobcat 250 includes a low oil shutdown feature. If the oil level drops to a critical point, the welder automatically shuts down, preventing engine damage due to insufficient lubrication. This proactive safety measure ensures the longevity of the equipment.

- Spark Arrestor: The inclusion of a spark arrestor in the Miller Bobcat 250’s design is crucial for fire prevention. This safety feature traps and reduces the risk of sparks or hot particles from escaping the exhaust, minimizing the chance of fire hazards in potentially flammable environments. The spark arrestor adds an extra layer of safety, making the welder suitable for various job site conditions.

What Sets Apart

What sets apart the Miller Bobcat 250 Generator Welder is its harmonious combination of power, durability, and versatility. The welder’s impressive power output, boasting 11,000 watts of peak power and 9,500 watts of continuous power, places it at the forefront of its class.

This robust performance ensures that it can handle a diverse range of welding applications, from intricate detailing to heavy-duty structural work, providing unparalleled versatility for professionals. The Miller Bobcat 250 distinguishes itself in terms of durability with its rugged design, standing as a testament to its ability to endure challenging job site conditions.

This durability not only contributes to the longevity of the machine but also instills confidence in its reliability, making it a standout choice for those seeking a welding solution that can withstand the rigors of demanding environments.

Additionally, what sets the Miller Bobcat 250 apart is its attention to user-friendly design elements. The integration of wheels into its construction addresses concerns about its weight, facilitating easy mobility around job sites.

The intuitive controls and clear interface make it accessible to both seasoned welders and beginners, emphasizing a user-centric approach. The balanced design, which combines stability during operation with compact dimensions, sets the Miller Bobcat 250 apart in terms of practicality and ease of use. These features collectively make it a tool that not only excels in performance but also stands out for its thoughtful design, addressing the needs of professionals across various welding applications.

Pros and Cons

Pros

- Powerful and Versatile Welding Capabilities: The Miller Bobcat 250 excels in delivering a robust welding performance, catering to a wide range of applications. Its powerful engine ensures seamless welding experiences, making it a versatile tool for both intricate detailing and heavy-duty structural projects.

- High Peak and Continuous Power Output: With an impressive 11,000 watts of peak power and 9,500 watts of continuous power, the Miller Bobcat 250 stands out for its ability to run multiple tools simultaneously. This feature optimizes productivity on the job site, eliminating the need for constant tool swapping.

- Rugged Design for Durability: The welder’s rugged design is a testament to its durability, showcasing the Miller Bobcat 250’s ability to withstand the rigors of demanding job site conditions. Its sturdy construction ensures longevity and reliability, providing peace of mind for professionals working in challenging environments.

- Integrated Wheels for Easy Mobility: Despite its weight of 501 pounds, the Miller Bobcat 250 maintains portability through the inclusion of integrated wheels. This feature facilitates easy maneuverability around the job site, enhancing the welder’s practicality, especially in settings with varying terrain.

- Excellent Fuel Efficiency: The Miller Bobcat 250 demonstrates commendable fuel efficiency, allowing for extended operation without frequent refueling. This feature is crucial for welders who require sustained performance without interruptions on the job.

Cons

- Relatively Heavy Compared to Some Competitors: Weighing 501 pounds, the Miller Bobcat 250 is comparatively heavier than some competitors in the market. While the integrated wheels mitigate this concern, the weight may still be a consideration for those prioritizing lightweight options for enhanced portability.

- Initial Investment May Be Higher Than Entry-Level Models: The Miller Bobcat 250’s quality and performance come at a price, and the initial investment may be higher than entry-level models. However, the long-term benefits in terms of durability, power, and versatility often outweigh the higher upfront cost for professionals seeking a reliable and high-performing welding solution.

Decision-Making Factors

In the decision-making process for choosing a generator welder, I prioritize key factors such as power output, durability, and portability. The Miller Bobcat 250 stands out as an exemplary choice, excelling in both power and durability, making it the preferred option for professionals requiring a reliable and robust machine. Despite its weight of 501 pounds, the integrated wheels alleviate portability concerns, and the resulting stability during operation proves to be a worthwhile trade-off. Overall, the Miller Bobcat 250 strikes a well-balanced equation, offering a dependable welding solution that harmonizes power, durability, and practicality for a variety of job site demands.

Final Thoughts

In conclusion, the Miller Bobcat 250 Generator Welder stands as a formidable companion for welding professionals seeking a blend of power, durability, and practicality. Its impressive welding capabilities, coupled with its rugged design, make it a versatile powerhouse capable of tackling a diverse range of applications with ease. The generator’s outstanding peak and continuous power output ensure efficiency and productivity on the job site, allowing for the simultaneous operation of multiple tools.

The integrated wheels contribute to its mobility, mitigating concerns about its weight and adding stability during welding. While the initial investment may be higher than some entry-level models, the Miller Bobcat 250 proves to be a worthy and long-lasting investment for those prioritizing reliable performance in demanding work environments. Overall, this welder encapsulates a harmonious balance of features, making it a top choice for professionals who demand excellence in their welding equipment.

Frequently Asked Questions

- What is the duty cycle of the Miller Bobcat 250, and how does it impact its performance?

The duty cycle of the Miller Bobcat 250 is a measure of its sustained operation without overheating. With an impressive duty cycle, this welder ensures extended periods of use without compromising performance, making it suitable for large-scale projects. - Can the Miller Bobcat 250 run multiple tools simultaneously with its generator capabilities?

Yes, the Miller Bobcat 250’s generator offers both high peak (11,000 watts) and continuous (9,500 watts) power output, enabling it to run multiple tools concurrently, optimizing productivity on the job site. - How does the rugged design of the Miller Bobcat 250 contribute to its durability in challenging job site conditions?

The rugged design of the Miller Bobcat 250 enhances its durability, allowing it to withstand the rigors of demanding job site conditions. This durability ensures a reliable and long-lasting performance, even in tough environments. - Is the Miller Bobcat 250 user-friendly for individuals with varying levels of welding experience?

Yes, the Miller Bobcat 250 features an intuitive user interface with clear labeling and accessible controls, making it user-friendly for both seasoned welders and beginners. - What is the fuel capacity of the Miller Bobcat 250, and how does it contribute to its operational efficiency?

The Miller Bobcat 250 has a fuel capacity of 12 gallons (45 liters). This, coupled with its excellent fuel efficiency, ensures extended operation without frequent refueling, making it a reliable choice for prolonged welding tasks. - How does the integrated wheel system contribute to the portability of the Miller Bobcat 250?

Despite its weight of 501 pounds, the integrated wheels make the Miller Bobcat 250 surprisingly easy to move around the job site, providing enhanced portability and maneuverability. - What kind of engine powers the Miller Bobcat 250, and what is its horsepower?

The Miller Bobcat 250 is equipped with a Kohler CH730 engine, boasting a robust 23.5 horsepower at 3,600 rpm, ensuring a powerful and efficient welding experience. - Can the Miller Bobcat 250 fit into tight spaces on the job site?

Yes, the compact dimensions of the Miller Bobcat 250 (H: 28″, W: 20″, L: 40.5″) allow it to fit into tight spaces, catering to professionals working in confined or restricted environments. - What are the notable advantages of the Miller Bobcat 250’s visual appeal and rugged construction?

The visually appealing rugged design of the Miller Bobcat 250 not only signifies its durability but also adds to its overall stability during operation, making it a robust and aesthetically pleasing welding solution. - How does the Miller Bobcat 250 balance its weight with integrated wheels, and why is stability during operation crucial?

While weighing 501 pounds, the integrated wheels of the Miller Bobcat 250 ensure ease of mobility, and the added weight contributes to stability during welding, providing control and security during operation, which is crucial for a smooth welding process.

We welcome your input! Feel free to share your firsthand encounters and opinions regarding the Miller Bobcat 250 Generator Welder in the comments section. Your unique insights may prove invaluable in assisting other professionals in making well-informed decisions when selecting welding equipment. Let’s build a community of shared knowledge and experiences to enhance the understanding of this powerful tool!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment