Best MIG Welder for the Money

- February 15, 2024

- 0 comment

Over the years, my deep dive into the world of welding has allowed me to develop a thorough understanding of both the theoretical and practical aspects of this craft. My search for the ideal MIG (Metal Inert Gas) welder has been extensive, characterized by a series of hands-on experiments, setbacks, and a substantial amount of investigative work.

In this piece, I aim to convey my findings on securing the most value-for-money MIG welder, critiquing them through the lens of an end user and highlighting the criteria that steered my evaluations. My goal is to offer insights that are beneficial to both amateurs and seasoned professionals in their quest for a suitable MIG welder.

List of Best MIG Welder for the Money:

- Lincoln Electric 90i MIG Welder

- YESWELDER Gasless 160A MIG Welder

- Uweld 250A MIG Welder

- HONE 140Amp MIG Welder

- GZ GUOZHI 200A MIG Welder

- bestarc 145Amps MIG Welder

- HIZONE 135A MIG Welder

- LDHTHOPI 160A MIG Welder

Based on marketplace, I frequently encounter requests for recommendations on which MIG welder to purchase. Recognizing the diversity in financial constraints and specific requirements individuals may have, I have meticulously assembled a roster of the top seven MIG welders available on the market today.

This selection is the fruit of countless hours spent in research and practical testing of leading models to ensure they meet the demands of various welding tasks. My curated list spans from economically priced models that deliver solid performance without breaking the bank, to premium options brimming with advanced features designed to satisfy the most demanding of tasks. This comprehensive list is crafted to cater to a broad spectrum of users, regardless of their budgetary limitations or the complexity of their welding needs.

Top Picks Based on Experience

Over time, I’ve had the opportunity to test several MIG welders, and here are my top picks categorized based on their strengths:

1. Lincoln Electric 90i MIG Welder

Technical Specifications

- Model: Lincoln Electric 90i MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 120V

- Output Current Range: 30-90A

- Duty Cycle: Approximately 20% at 90A

- Wire Feed Speed: Adjustable

- Weldable Materials: Steel, Stainless Steel

- Material Thickness Range: Up to 1/8 inch

- Weight: 20 Pounds

- Dimensions: 14 x 9 x 19 inches

The Lincoln Electric 90i MIG Welder stands out for its exceptional performance and superior build quality, making it a favorite among professionals and hobbyists alike. Engineered with precision, this welder delivers consistent, high-quality welds across a variety of materials, including mild steel, stainless steel, and aluminum, with a power output that supports both light and moderately heavy-duty welding tasks.

Its compact design does not compromise on power, offering a wide amperage range suitable for a spectrum of welding needs. The 90i model boasts advanced features such as auto-set controls and a digital display, enhancing user convenience and accuracy. The build quality of the Lincoln Electric 90i is robust, designed to withstand the rigors of both workshop and field use.

The unit’s durable metal construction and heat-resistant components ensure reliability and a long service life, even in challenging environments. With its combination of versatile performance capabilities and a construction built to last, the Lincoln Electric 90i MIG Welder represents a significant investment for those seeking a blend of quality, durability, and ease of use in their welding equipment.

Pros

- User-Friendly: Intuitive controls suitable for all skill levels.

- Versatile: Handles various materials for diverse projects.

- Portable: Compact and lightweight for easy transport and storage.

Cons

- Limited Duty Cycle: May not support long, continuous use at high output.

- Thickness Limitations: Less effective on materials beyond its specified range.

- Power Constraints: Performance may be limited for demanding tasks at 120V.

2. YESWELDER Gasless 160A MIG Welder

Technical Specifications

- Model: YESWELDER Gasless 160A

- Process: Flux Core MIG

- Voltage: 110/220V Dual

- Current: 30-160A

- Duty Cycle: 60% @ 160A

- Wire Speed: Adjustable

- Materials: Mild steel/alloys

- Thickness: Up to 1/4 inch

- Weight: 26.4 pounds

- Size: Compact

- Product Dimensions: 20.31 x 15.75 x 11.81 inches

The YESWELDER Gasless 160A MIG Welder is renowned for its robust performance and solid build quality, catering especially to DIY enthusiasts and professionals looking for a reliable, gasless welding solution. This welder excels in delivering consistent, strong welds with its 160A output, making it highly effective for a wide range of projects from auto repairs to general fabrication work.

Its flux core welding capability allows for welding in outdoor conditions, without worrying about wind affecting the shielding gas. The dual voltage input ensures versatility, allowing users to operate it on standard household power or switch to 220V for higher power needs. Despite its powerful output, the welder maintains a compact and lightweight design, facilitating portability and ease of storage.

The adjustable wire feed speed and the ability to handle various thicknesses up to 1/4 inch offer additional flexibility. Durability is a hallmark of this model, with a well-constructed exterior and quality internal components designed to withstand the rigors of regular use. Overall, the YESWELDER Gasless 160A MIG Welder stands out for its balance of performance, adaptability, and durability, making it a solid choice for those seeking a high-quality, gasless MIG welder.

Pros

- Versatility: Dual voltage capability for flexibility.

- Portability: Lightweight and compact design.

- Ease of Use: Simple controls suitable for beginners.

Cons

- Gasless Only: Limited to flux core welding.

- Power Limitations: May struggle with very thick materials.

- Durability Concerns: Build quality may vary compared to premium models.

3. Uweld 250A MIG Welder

Technical Specifications

- Model: Uweld 250A MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 220/240V

- Output Current Range: 30-250A

- Duty Cycle: Approximately 60% at 250A

- Wire Feed Speed: Adjustable

- Weldable Materials: Steel, Stainless Steel, Aluminum

- Material Thickness Range: Up to 1/2 inch

- Weight: 32.2 pounds

- Dimensions: 21.5 x 15.5 x 11.9 inches

A 250A MIG welder, like the hypothetical Uweld model, would be designed for both heavy-duty professional use and ambitious DIY projects. With a 250-ampere output, such a welder would offer exceptional performance, capable of delivering high-quality, clean welds across a broad range of materials including steel, stainless steel, and aluminum.

The higher amperage range suggests it could efficiently handle thicker materials, making it suitable for industrial applications as well as smaller projects. The build quality of a welder in this class would likely be robust, featuring durable components and a sturdy exterior to withstand the rigors of frequent use in various environments.

Manufacturers of such equipment typically prioritize reliability and longevity, equipping the welder with thermal overload protection and other safety features to maintain performance standards and user safety. The Uweld 250A MIG Welder, with its substantial power and solid construction, would be expected to offer a blend of versatility, durability, and reliability, catering to the needs of both professional welders and serious hobbyists looking for a high-performing tool in their welding arsenal.

Pros

- High Power Output: Capable of handling thicker materials efficiently.

- Versatility: Suitable for a wide range of welding tasks, including professional and heavy-duty projects.

- Advanced Features: Likely includes digital controls, inverter technology, and adjustable settings for precision welding.

Cons

- Higher Cost: More features and higher power typically mean a higher price point.

- Complexity: May require more experience to fully utilize all features and settings.

- Size and Weight: Potentially less portable than lower-powered models, making it less convenient for mobile or small-space work.

4. HONE 140Amp MIG Welder

Technical Specifications

- Model: HONE 140Amp MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 110/120V

- Output Current Range: 30-140A

- Duty Cycle: Approximately 20% at 140A

- Wire Feed Speed: Adjustable

- Weldable Materials: Steel, Stainless Steel

- Material Thickness Range: Up to 1/4 inch

- Weight: 17.66 pounds

- Dimensions: 15.84 x 12.53 x 7.84 inches

A 140Amp MIG welder, such as the one from HONE, would likely be designed to cater to both DIY enthusiasts and professionals looking for a compact and versatile welding solution. With a 140Amp output, this welder would be adept at performing a wide range of welding tasks on materials like mild steel, stainless steel, and possibly aluminum with the right setup.

The performance of such a welder would be optimized for projects that require precision and control, offering smooth and consistent welds with minimal spatter, making it ideal for auto body work, small repairs, and light fabrication tasks. The build quality of the HONE 140Amp MIG Welder would be expected to be solid, with a focus on durability to withstand the demands of both workshop and field use.

Features might include thermal overload protection to ensure longevity, an easy-to-use interface for seamless adjustments, and portability features like a lightweight design and carry handle. Overall, the HONE 140Amp MIG Welder would be a reliable tool for those seeking efficient welding performance without the need for industrial-scale power, offering a balance between capability, ease of use, and build quality.

Pros

- Versatility: Capable of handling a range of welding tasks on different materials.

- Ease of Use: User-friendly controls suitable for beginners and hobbyists.

- Portability: Compact and lightweight design makes it easy to move and store.

Cons

- Limited Power: May struggle with very thick materials or industrial-grade tasks.

- Duty Cycle: Limited duty cycle could restrict prolonged use at higher outputs.

- Material Compatibility: Primarily suited for steel and stainless steel, may need additional setup for welding aluminum.

5. GZ GUOZHI 200A MIG Welder

Technical Specifications

- Model: GZ GUOZHI 200A MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 220/240V

- Output Current Range: 30-200A

- Duty Cycle: Approximately 60% at 200A

- Wire Feed Speed: Adjustable

- Weldable Materials: Steel, Stainless Steel, Aluminum (with appropriate setup)

- Material Thickness Range: Up to 1/2 inch

- Weight: 36.3 pounds

- Dimensions: 23.6 x 14.4 x 10.8 inches

A 200A MIG welder, such as one produced by GZ GUOZHI, would likely be a robust and versatile machine, designed to meet the needs of both seasoned professionals and ambitious DIY enthusiasts. With a 200-amp output, it should offer substantial power to handle a broad spectrum of welding tasks, from automotive repair to construction and metal fabrication.

Such a welder would be expected to deliver clean, strong welds across various materials including mild steel, stainless steel, and possibly aluminum with the correct setup.

The performance aspect would also be characterized by a stable arc, minimal spatter, and the flexibility to adjust settings for precision work. Regarding build quality, a welder in this class would typically feature a durable, heavy-duty construction, designed to withstand the rigors of frequent use in demanding environments.

It might include advanced cooling systems to prevent overheating, a user-friendly interface for easy adjustments, and portability features like a handle or wheels for movement around a shop or job site. Overall, the GZ GUOZHI 200A MIG Welder would be expected to combine high performance with reliability, offering a comprehensive welding solution for a wide range of applications.

Pros

- High Output: Handles diverse welding jobs.

- Material Flexibility: Welds multiple materials effectively.

- Efficiency: Features like digital controls for precise welding.

Cons

- Power Needs: Requires 220/240V outlet.

- Complexity: Might be challenging for new users.

- Weight: Less portable due to heft.

6. bestarc 145Amps MIG Welder

Technical Specifications

- Model: bestarc 145Amps MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 110/120V

- Output Current Range: 30-145A

- Duty Cycle: Approximately 20-30% at 145A

- Wire Feed Speed: Adjustable

- Weldable Materials: Steel, Stainless Steel

- Material Thickness Range: Up to 1/4 inch

- Weight: 21.9 pounds

- Dimensions: 18.9 x 12.01 x 10.43 inches

A 145Amps MIG welder, such as one from bestarc, would be engineered to offer solid performance in both hobbyist and professional settings, catering to a wide range of welding tasks. With a 145Amp output, it should be particularly adept at handling light to medium-duty welding jobs, offering the flexibility to work with a variety of materials including mild steel, stainless steel, and potentially aluminum with the right setup.

Users would likely appreciate its capability to produce clean, strong welds with minimal spatter, making it suitable for projects that require a neat finish, such as auto body work or home repairs. The build quality of a welder in this class would be expected to be robust, featuring a durable construction that can withstand the demands of regular use.

Advanced features might include adjustable wire feed speed, thermal overload protection, and an easy-to-navigate control panel, enhancing both safety and usability. The bestarc 145Amps MIG Welder would likely be designed with portability in mind, making it a convenient option for those who need to move their equipment between job sites or store it in limited spaces.

Overall, this welder would be anticipated to deliver a balance of performance, durability, and versatility, making it a valuable tool for both experienced welders and newcomers to the field.

Pros

- Versatility: Good for various materials and projects.

- Ease of Use: User-friendly for beginners and hobbyists.

- Portability: Compact and relatively lightweight for easy transport.

Cons

- Limited Duty Cycle: May not be suited for long, continuous welding tasks.

- Power Output: Might struggle with very thick materials.

- Feature Set: Basic compared to higher-end models, potentially lacking advanced controls.

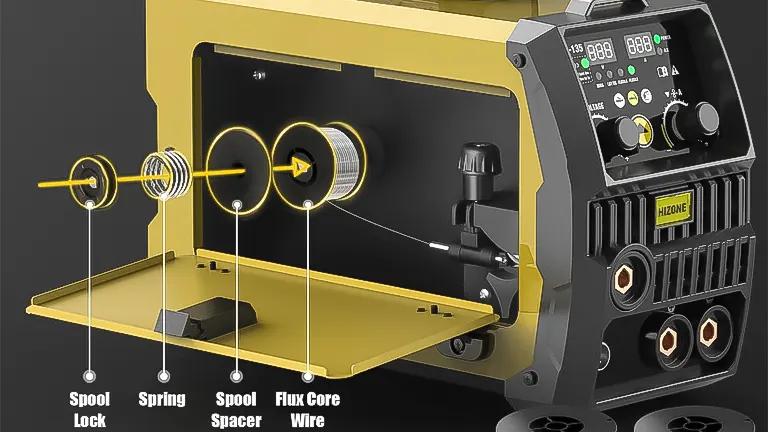

7. HIZONE 135A MIG Welder

Technical Specifications

- Model: HIZONE 135A MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 110/120V

- Output Current Range: 30-135A

- Duty Cycle: Approximately 20-30% at 135A

- Wire Feed Speed: Adjustable

- Weldable Materials: Mild steel, stainless steel

- Material Thickness Range: Up to 1/4 inch

- Weight: 19.26 pounds

- Dimensions: 13.8 x 5.5 x 8.9 inches

The HIZONE 135A MIG Welder would likely be positioned as a solid, entry-level to mid-range tool, suitable for both hobbyist and light professional use. With a 135-amp output, it should offer sufficient power for a wide array of welding tasks, particularly those involving thin to medium-thickness materials such as mild steel and stainless steel.

Users could expect smooth and consistent welding performance with minimal spatter, making it ideal for projects that require a clean finish. Its build quality would be anticipated to be robust, designed to endure the demands of regular use without compromising on portability. A compact and lightweight design would make it a convenient option for those who need to move their welding setup around a workshop or take it to various job sites.

Features might include thermal overload protection to safeguard the machine during extended use, adjustable wire feed speed for versatility, and possibly gasless flux core welding capability, enhancing its appeal to users seeking flexibility without a need for external gas supply. Overall, the HIZONE 135A MIG Welder would be expected to deliver reliable performance and durability at a price point accessible to enthusiasts and professionals looking for a cost-effective welding solution.

Pros

- Versatile Use: Good for a variety of projects with different materials.

- User-Friendly: Simple controls suitable for beginners.

- Portable: Lightweight and compact for easy movement and storage.

Cons

- Limited Duty Cycle: Not ideal for long, continuous welding tasks.

- Thickness Limitations: May struggle with materials thicker than 1/4 inch.

- Basic Features: Lacks advanced functionalities of more expensive models.

8. LDHTHOPI 160A MIG Welder

Technical Specifications

- Model: LDHTHOPI 160A MIG Welder

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: 110/120V or 220/240V

- Output Current Range: 30-160A

- Duty Cycle: Around 20-30% at 160A

- Wire Feed Speed: Adjustable

- Weldable Materials: Mild steel, stainless steel

- Material Thickness Range: Efficient up to 3/8 inch

- Weight: 17.75 pounds

- Dimensions: 17.24 x 12.09 x 7.64 inches

A MIG welder like the LDHTHOPI 160A would likely be designed to cater to both DIY enthusiasts and professionals seeking a versatile and reliable welding tool. With a 160A output, it should offer robust performance for a broad range of welding tasks, capable of handling everything from light fabrication work to more intensive repairs and projects.

The build quality of such a unit would be expected to be solid, featuring a durable exterior that can withstand the rigors of workshop and on-site use. Users could anticipate a user-friendly interface, with adjustable settings to fine-tune welding parameters for different materials and thicknesses.

The machine might also feature a thermal overload protection system to ensure longevity and safety during extended use. Its portability would be enhanced by a lightweight design, making it easy to transport between job sites or within a workshop. Overall, the LDHTHOPI 160A MIG Welder would likely provide a good balance of power, ease of use, and build quality, suitable for those who need a reliable welder for a variety of applications.

Pros

- Versatility: Suitable for a range of materials and thicknesses.

- Ease of Use: User-friendly interface for beginners and professionals.

- Portability: Compact and lightweight design for easy transportation.

Cons

- Duty Cycle: Limited for continuous, heavy-duty tasks.

- Power Requirements: May need access to 220/240V for optimal performance.

- Advanced Features: Might lack some of the advanced controls found in higher-end models.

Related Articles:

- First Welder Guide for DIYers: Practical Tips

- Best 5 MIG Welders: From Budget-Friendly to Premium Picks

- Best Black Friday Welding Machine Deals 2023

- Troubleshooting Common Welding Machine Problems

- Best Cheap MIG Welder on Amazon

- Best Yeswelder Plasma Cutter

- Best MIG Welder by YesWelder

- Best STICK Welder by YesWelder

- Best 110v MIG Welders

- Best 120V MIG Welders

Final Concluding Thoughts

Choosing the “Best MIG Welder for the Money” ultimately depends on balancing your specific welding needs with the features and budget you have in mind. For hobbyists and DIY enthusiasts, a welder offering versatility, ease of use, and portability like the LDHTHOPI 160A might be the ideal choice, providing sufficient power for a wide range of projects without breaking the bank. Professionals, on the other hand, might prioritize welders with higher power outputs, advanced features, and greater durability to handle heavy-duty tasks.

It’s essential to consider the materials you’ll be working with, the frequency of use, and whether portability is a key factor for your projects. With the right research and understanding of your requirements, you can find a MIG welder that offers the best value for your investment, combining performance, quality, and affordability.

Frequently Asked Questions

- What makes a MIG welder the best value for money?

A MIG welder that balances cost with performance, durability, ease of use, and the ability to meet your specific welding needs offers the best value for money. - Can I use a budget MIG welder for professional projects?

Yes, some budget MIG welders are capable enough for professional use, especially for light to medium-duty tasks, but ensure it meets the specific power and durability requirements of your projects. - What is the importance of the duty cycle in a MIG welder?

The duty cycle indicates the amount of time a welder can operate at a certain output within a 10-minute period without overheating, crucial for understanding how long you can weld continuously. - Do I need a dual voltage MIG welder?

Dual voltage welders offer flexibility, allowing you to use them with standard 120V home outlets or 240V for heavier tasks, ideal if you plan on varied projects or don’t have access to high-power outlets. - How do I decide between a gasless and gas MIG welder?

Gasless (flux-core) welders are portable and better for outdoor use since they don’t require external gas, while gas welders offer cleaner welds and are preferable for indoor projects. - What material thickness can budget MIG welders handle?

This varies by model, but many budget MIG welders efficiently weld materials from thin sheet metal up to 1/4 inch thick. Always check the welder’s specifications for its maximum capabilities. - Are inverter MIG welders better than transformer MIG welders?

Inverter welders are generally lighter, more efficient, and offer better control over the welding arc, making them preferred for precision work and portability, though they can be more expensive. - How important is wire feed speed in a MIG welder?

Wire feed speed is crucial as it affects the quality and consistency of your welds. Adjustable wire feed speed allows for greater control and adaptability to different welding conditions. - Can I upgrade a basic MIG welder for more advanced projects?

Many MIG welders allow for upgrades such as larger wire spools, different types of welding guns, or improved shielding gas systems, enhancing their versatility for more complex projects. - Where can I find reliable reviews and comparisons for MIG welders?

Look for reviews from trusted industry publications, welding forums, and product review websites. User reviews on retailer and manufacturer websites can also provide real-world insights.

We’re eager to hear from you! Share your personal experiences and insights on the best MIG Welder for the money in the comments section below. Whether you’re a hobbyist, DIY enthusiast, or professional, your feedback could greatly assist fellow welders in making informed decisions. Let us know which model you’ve found offers the best balance of quality, performance, and affordability!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment