Best Small Skid Steer Attachments: Boost Your Productivity

- October 20, 2023

- 0 comment

In the dynamic realm of construction and landscaping, where efficiency is paramount, the role of small skid steer attachments emerges as a game-changer. These compact and versatile tools have become the unsung heroes of productivity, ingeniously transforming skid steer loaders into multifunctional workhorses. Whether you’re excavating, lifting, drilling, or navigating tight urban spaces, small skid steer attachments are the secret weapon for streamlining tasks and saving valuable time. This article delves into the world of these indispensable attachments, exploring their diverse applications, cost-effectiveness, and the technological advancements propelling them into the forefront of industries beyond construction. Join us on a journey to discover how these attachments are revolutionizing productivity, one task at a time.

Purpose of the Article

This article will explore the different types of small skid steer attachments and their impact on productivity. We will also discuss the benefits of using attachments, as well as considerations to keep in mind when choosing the right attachments for your needs.

What are Small Skid Steer Attachments?

Small skid steer attachments are specialized tools designed to enhance the functionality of skid steer loaders, which are compact and versatile construction machines. These attachments can be easily mounted onto the front of the skid steer, transforming it into a multifunctional powerhouse capable of performing various tasks. Examples of attachments include buckets for digging, forks for lifting, augers for drilling, and brushes for sweeping. Small skid steer loaders equipped with these attachments are particularly valuable for navigating tight spaces and confined job sites, making them essential in urban construction and landscaping projects. The adaptability of these attachments extends across industries, including agriculture, forestry, and snow removal, offering a cost-effective solution for diverse applications. In essence, small skid steer attachments play a crucial role in boosting efficiency, versatility, and overall productivity in a wide range of work environments.

The Foundation: Understanding Skid Steers

Before we delve into the transformative power of attachments, let’s first establish the foundation of skid steers. These compact machines, known for their agility and maneuverability, serve as the backbone for a myriad of tasks in construction, landscaping, agriculture, and beyond. Their ability to navigate tight spaces and adapt to different terrains makes them an invaluable asset on any job site.

The Role of Attachments in Skid Steer Performance

Attachments are the secret sauce that elevates skid steers from basic utility to exceptional versatility. They come in various categories, each designed for specific tasks. Whether it’s moving earth, lifting pallets, or drilling holes, there’s an attachment tailored for the job.

Understanding the Need for Attachments

Skid steer loaders are versatile, but their default functions have limitations. This is where attachments come into play, extending the capabilities of these compact machines. Imagine a skid steer not just as a loader, but as a multi-functional powerhouse tailored to specific tasks.

Attachments open up a world of possibilities. Whether it’s digging, lifting, carrying, or grappling, there’s an attachment designed for the job. They enhance precision, efficiency, and versatility, making your small skid steer a dynamic tool for a variety of applications.

Small Skid Steer Attachments: A Deep Dive

Bucket Attachments

Buckets are the workhorses of skid steer attachments. From grapple buckets for handling debris to rock buckets for sifting through soil, these attachments make quick work of material handling and excavation tasks.

1. Titan Attachments 72 inch Skeleton Rock Bucket

Key Features

- Skeleton frame

- Replaceable teeth

- Reinforced side cutters

- Universal skid steer connection

The Titan Attachments 72 inch Skeleton Rock Bucket is a durable and versatile attachment that is ideal for a variety of tasks. The bucket has a skeleton frame design that allows dirt to fall through the bottom, making it easier to quickly sift out rocks and debris. The front cutting edge includes bolt-on bucket teeth, which are excellent for digging hard dirt, gravel, and sand. The deep-well rock dam features thick tines spaced 4-inches apart, allowing dirt to fall through while keeping rocks in place. The sides feature a welded-on reinforced cutting edge providing optimum strength when lifting heavier loads.

| Overall Height | 20-in. |

| Inside Height | 14-in. |

| Spacing Between Tines | 4-in. |

| Tooth Count | 6 |

| Overall Width | 74.5-in. |

| Inside Width | 72.5-in. |

| Tine Thickness | 0.5-in. |

| Finish | Powder-Coated Black |

| Overall Depth | 49.5-in. |

| Inside Depth | 38.5-in. |

| Cutting Edge | 0.75-in. |

| Product Weight | 670 lb. |

Here are some tips on how to install a Titan Attachments 72 inch Skeleton Rock Bucket:

- Park your skid steer or tractor on a level surface.

- Engage the parking brake.

- Lower the lift arms and bucket to the ground.

- If necessary, use a block of wood or other object to support the bucket so that it is level.

- Clean the mounting plate on your skid steer or tractor and the quick-tach mounting plate on the bucket with a wire brush or solvent.

- Align the quick-tach mounting plate on the bucket with the mounting plate on your skid steer or tractor.

- Secure the quick-tach mounting plate to the mounting plate on your skid steer or tractor using the four bolts provided.

- Raise the lift arms and bucket slightly to make sure that the bucket is properly attached.

- Lower the lift arms and bucket to the ground.

Additional tips:

- Make sure that the quick-tach mounting plate is properly aligned with the mounting plate on your skid steer or tractor before securing it with bolts.

- Tighten all bolts to the specified torque.

- Inspect the bucket and mounting plate regularly for signs of wear or damage.

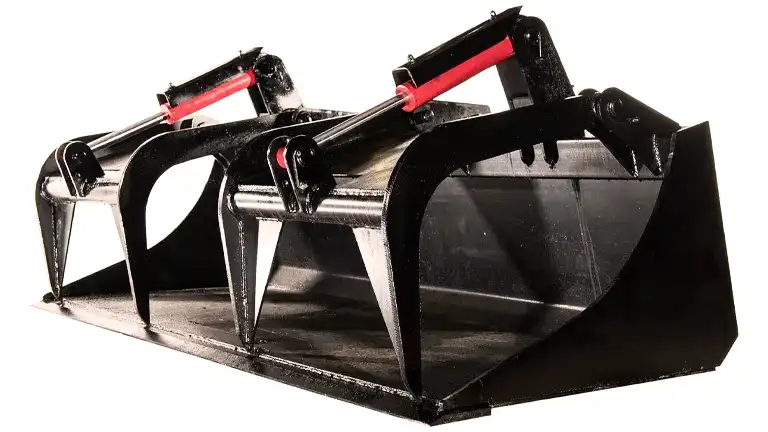

2. McLaren Industries 84 Inches Grapple Buckets

Key Features

- Universal skid steer style hookup

- Heavy-duty twin (2×8) inch hydraulic cylinders

- OEM quality HOLMBURY brand flat face couplers

- Heavy-duty replaceable cast bucket teeth

- All pins and bushings are greaseable to reduce wear and tear

The McLaren Industries 84 Inches Grapple Buckets are versatile and durable attachments for skid steers and other heavy machinery. They are used to pick up and move a variety of materials, including rocks, logs, brush, debris, and other odd-shaped or hard-to-lift objects. The grapple buckets feature two hydraulically operated tines that close around the load to grip it securely. The McLaren Industries 84 Inches Grapple Buckets are ideal for a variety of applications, including demolition and recycling, land clearing, logging, construction, and agriculture. They are made from heavy-duty materials and are designed to withstand the rigors of commercial use.

| Weight | 1031 lbs. |

| Width | 84 inches |

| Opening Height | 44″ from the tip of the tong to the edge of the bucket |

| Side Thickness | 3/8 inches |

| Bucket Thickness | 3/16 inches |

| Teeth Length | 35.5 inches |

| Teeth Thickness | 5/8 inches |

| Couplers | OEM Quality HOLMBURY Brand Flat Face Couplers |

Here are some tips on how to install McLaren Industries 84 Inch Grapple Buckets:

- Park your skid steer on a level surface.

- Engage the parking brake.

- Lower the boom to the ground.

- Turn off the engine.

- Remove the existing bucket attachment, if necessary.

- Clean the mounting plate on the skid steer and the mounting brackets on the grapple bucket.

- Align the mounting brackets on the grapple bucket with the mounting plate on the skid steer.

- Secure the grapple bucket to the skid steer using the provided hardware.

- Tighten the hardware to the manufacturer’s specifications.

- Raise the boom and test the grapple bucket.

Here are some additional tips:

- Make sure that the grapple bucket is compatible with your skid steer.

- Use the correct size and type of hardware to secure the grapple bucket to the skid steer.

- Tighten the hardware to the manufacturer’s specifications.

- Test the grapple bucket to make sure that it is operating properly before using it.

Fork Attachments

Fork attachments bring a new dimension to skid steer capabilities, excelling in tasks such as pallet handling, material transportation, and storage. Their advantage becomes apparent in confined spaces where larger equipment might struggle.

1. Titan Attachments Pin-On Pallet Fork Frame Skid Steer Attachment

Key Features

- Universal skid steer quick tach mounting system

- Pin-on pallet fork blades

- Hefty pallet fork blades

- Shank hole in fork ends

- Chain buckle retainer

- See-through headache rack

- 2,600-pound load capacity

The Titan Attachments Pin-On Pallet Fork Frame Skid Steer Attachment is a durable and versatile attachment that makes moving and transporting hefty items easier. It easily and securely attaches to any skid steer or tractor equipped with the SSQA or Universal Skid Steer Style Quick Tach System. The frame is rated at a 2,600 LB loading capacity and is crafted with a see-through headache rack to increase its durability and capacity. It features pin-on mounts for the included hefty pallet fork blades and a chain buckle with loop and chain retainer to tie-down loads using 0.5″ thick chains or ropes. The thick fork blades include shank holes at the fork ends for 2″ ball points, allowing you to tow or lift with a 2″ trailer hitch ball (sold separate). This attachment is ideal for a variety of tasks, including hauling large logs, stumps, lumber, timber, pallets, and other heavy materials. It is perfect for use on farms, in landscaping projects, and in agricultural settings.

| Frame Height | 35.5-in. |

| Fork Length | 46-in. |

| Shank Hole | 0.75-in. |

| Weight Capacity | 2,600 lb. |

| Frame Width | 48.75-in. |

| Fork Width | 4-in. |

| Fork Pair Weight | 98 lb. |

| Frame Depth | 9-in. |

| Frame Weight | 116 lb. |

| Fork Thickness | 2-in. |

Here are some tips on how to install a Titan Attachments Pin-On Pallet Fork Frame Skid Steer Attachment:

- Park your skid steer on a level surface. This will help ensure that the pallet forks are installed correctly and safely.

- Lower the boom and lift arms of the skid steer to their lowest position. This will give you plenty of room to maneuver the pallet forks into place.

- Position the pallet forks behind the skid steer, with the quick-tach mounting plate facing the skid steer.

- Align the mounting pins on the pallet forks with the quick-tach mounting plate on the skid steer.

- Use a grease gun to apply a thin coat of grease to the mounting pins. This will help prevent wear and tear and make it easier to install and remove the pallet forks in the future.

- Raise the boom of the skid steer and guide the mounting pins into place.

- Once the mounting pins are in place, secure them with the lock pins.

- Lower the boom of the skid steer and test the pallet forks by raising and lowering them a few times.

Here are some additional tips:

- Be careful not to overtighten the lock pins. Overtightening can damage the mounting pins and make it difficult to remove the pallet forks in the future.

- Test the pallet forks by raising and lowering them a few times before using them. This will help ensure that the pallet forks are properly installed and functioning correctly.

2. Mophorn Pallet Forks Skid Steer Attachment for Loader Bucket 58.7″

Key Features

- 4000 Lbs Loading Capacity

- High Compatibility

- Easy to Assemble & Use

- 23.6″-45″ Adjustable Width

- Security & Durable Structure

The Mophorn Pallet Forks Skid Steer Attachment for Loader Bucket 58.7″ is a heavy-duty attachment that allows you to use your skid steer to move pallets, logs, lumber, firewood, hay bales, brush, and other materials. It has a load capacity of 4,000 lbs and is compatible with almost all loader bucket skid steer tractors. The forks are made of heavy-duty steel and are 42.9 inches long, 3.9 inches wide, and 1.97 inches high. They are attached to the loader bucket using a screw rod and clamp system, which is easy to use and secure. The Mophorn Pallet Forks Skid Steer Attachment is a versatile and durable attachment that can be used for a variety of tasks. It is a great choice for farmers, landscapers, contractors, and other professionals who need to move heavy materials.

| Weight | 96.8 pounds |

| Package Dimensions | 60 x 12 x 4 inches |

| Material | Heavy Duty Steel |

| Loading Capacity | 4000 lbs. |

| Overall Length | 58.7″ |

| Fork Length | 42.9″ |

| Fork Width | 3.9″ |

| Fork Height | 1.97″ |

Here are some tips on how to install Mophorn Pallet Forks Skid Steer Attachment for Loader Bucket:

- Park your skid steer on a level surface. This will help to ensure that the pallet forks are installed correctly.

- Engage the parking brake. This will help to prevent the skid steer from moving while you are installing the pallet forks.

- Lower the skid steer’s loader bucket to the ground. This will make it easier to attach the pallet forks.

- Position the pallet forks in front of the loader bucket. Make sure that the pallet forks are centered and that the forks are parallel to the loader bucket.

- Attach the pallet forks to the loader bucket. The pallet forks should come with a set of mounting hardware. Use this hardware to attach the pallet forks to the loader bucket.

- Tighten all of the mounting bolts. Make sure that the pallet forks are securely attached to the loader bucket.

- Raise the skid steer’s loader bucket slightly. This will help to test the installation of the pallet forks.

- Try moving the pallet forks forward and backward. If the pallet forks move freely, then the installation is complete.

Here are some additional tips:

- Make sure that the pallet forks are compatible with your skid steer.

- Check the weight capacity of the pallet forks and make sure that it is greater than the weight of the loads that you will be lifting.

- Inspect the pallet forks for any damage before installing them.

- Use a level to make sure that the pallet forks are installed correctly.

- Tighten all of the mounting bolts regularly.

Augers and Drilling Attachments

Augers and drilling attachments take center stage in projects requiring holes and precise drilling. Ideal for construction and landscaping, these attachments save time and effort, providing a level of precision that manual methods can’t match.

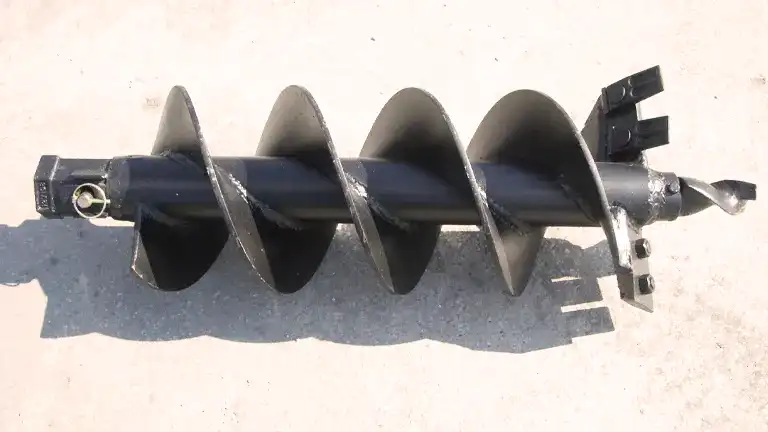

1. Titan Attachments Auger Bit 24″ x 48″ Steel 6″ Boring Head 2″ Hex Connectivity

Key Features

- 2″ Hex Connectivity

- Built in 6″ boring head tooth with hardware

- Designed for moderate ground conditions

- All steel construction for durability

The Titan Attachments Auger Bit 24″ x 48″ Steel 6″ Boring Head 2″ Hex Connectivity is a heavy-duty auger bit designed for use with skid steers and other construction equipment. It has a 24-inch diameter and is 48 inches long. The bit is made of steel and has a 6-inch boring head with eight cutting teeth. The 2-inch hex connectivity allows it to be easily attached to skid steers and other equipment.

This auger bit is designed for use in moderate ground conditions. It is not intended for use in hard or rocky soil. The bit is ideal for digging holes for fence posts, foundations, and other construction projects.

| Bit diameter | 24 inches |

| Boring head diameter | 6 inches |

| Bit length | 48 inches |

| Overall Length | 48 in. |

| Cutting Teeth | 8 |

| Material | Steel |

| Weight | 139 lb. |

| Shank type | Round |

Here are some tips on how to install a Titan Attachments Auger Bit:

- Make sure your auger attachment is compatible with your power equipment. The Titan Attachments Auger Bit 24″ x 48″ Steel 6″ Boring Head 2″ Hex Connectivity has a 2″ hex connectivity, so you will need a power equipment that has a 2″ hex shaft.

- Inspect the auger bit for any damage. If there is any damage, do not use the auger bit.

- Clear the area where you will be using the auger bit. Remove any rocks, debris, or other obstacles.

- Attach the auger bit to your power equipment. Follow the instructions that came with your power equipment.

- Start the auger bit slowly. Gradually increase the speed as the auger bit begins to dig into the ground.

- Apply even pressure to the auger bit. Do not force the auger bit into the ground.

- Be careful of underground obstacles. If you hit an underground obstacle, stop the auger bit immediately.

- Once you have finished digging the hole, remove the auger bit from your power equipment.

Here are some additional tips:

- Wear safety glasses and gloves when using an auger bit.

- Be aware of your surroundings and watch out for other people and animals in the area.

- Take breaks often, especially if you are digging in hard or rocky soil.

- If you are digging a deep hole, use a ladder or scaffolding to get in and out of the hole safely.

2. Lowe SQ-36H Skid Steer Auger Bit Attachment

Key Features

- Heavy-duty construction

- Large cutting diameter

- Replaceable teeth

- Versatile use

- Easy to use and maintain

The Lowe SQ-36H Skid Steer Auger Bit Attachment is a heavy-duty attachment that is used with skid steer loaders to drill large holes for fence posts, trees, and other applications. It is made of high-quality steel and features a durable powder coat finish. The auger bit is also equipped with a pilot point to help it stay centered in the ground while drilling. The SQ-36H is compatible with a variety of skid steer loaders, and it can be easily attached and removed using a quick attach system. It is backed by a one-year warranty from Lowe Manufacturing.

In short, the Lowe SQ-36H Skid Steer Auger Bit Attachment is a durable and easy-to-use attachment that is ideal for contractors and landscapers who need to drill large holes.

| Diameter | 36 inches |

| Shaft collar | 2-inch hex |

| Material | High-quality steel |

| Finish | Durable powder coat |

| Teeth | 4 replaceable |

| Gearbox | Heavy-duty |

| Overall length | 48 inches |

| Mounting plate | Compatible with most skid steer loaders |

Tips on how to install Lowe SQ-36H Skid Steer Auger Bit Attachment:

- Park the skid steer on a level surface.

- Turn off the engine and set the parking brake.

- Lower the boom and bucket to the ground.

- Get out of the skid steer and inspect the auger bit attachment. Make sure that it is clean and free of debris.

- Align the mounting plate of the auger bit attachment with the quick attach plate on the skid steer.

- Use the skid steer’s control levers to raise the auger bit attachment until the mounting pins align with the holes on the quick attach plate.

- Use a locking pin to secure each mounting pin in place.

- Connect the hydraulic hoses from the auger bit attachment to the hydraulic ports on the skid steer.

- Get back in the skid steer and start the engine.

- Use the skid steer’s control levers to test the auger bit attachment. Make sure that it rotates freely and that the hydraulic hoses are not leaking.

Here are some additional tips:

- Make sure that the skid steer is rated for the weight and size of the auger bit attachment.

- Use a skid steer with a quick attach plate to make it easier to install and remove the auger bit attachment.

- Be careful not to overtighten the mounting pins.

- Check the hydraulic hoses for leaks before each use.

- Be aware of your surroundings when operating the auger bit attachment. Avoid digging near underground utilities or other hazards.

Brush Cutters and Mulchers

When it comes to land clearing and site preparation, brush cutters and mulchers are the tools of choice. These attachments efficiently manage vegetation, ensuring a clean and organized work environment.

1. FAE Group Skid Steers Mulchers UML/SSL/VT

Key Features

- Automatic variable displacement hydraulic motor

- Fixed tooth rotor

- Fully enclosed body

- Diverter valve kit

- Sonic system

FAE Group Skid Steers Mulchers UML/SSL/VT are a series of forestry mulchers designed for skid steers with 75-120 hp. They are known for their robust construction, ergonomic design, and excellent performance.

The UML/SSL/VT mulchers have a fixed tooth rotor that can handle woody material up to 20 cm in diameter. They are also equipped with a variable displacement hydraulic motor that automatically adjusts its speed to match the load, resulting in increased productivity and reduced fuel consumption.

| Recommended tractor power | 75-120 hp |

| Recommended working pressure | 200-350 bar |

| Recommended flow volume | 130-150 l/min |

| Working widths | 1340 mm |

| Maximum cutting diameter | 20 cm |

| Rotor | Fixed tooth |

| Hydraulic motor | 110/60cc variable torque hydraulic piston motor |

Tips on how to install FAE Group Skid Steers Mulchers UML/SSL/VT:

- Before installation, make sure the skid steer is in a level position and the parking brake is engaged.

- Remove the skid steer’s bucket attachment.

- Attach the mulcher to the skid steer’s quick attach plate.

- Connect the mulcher’s hydraulic hoses to the skid steer’s hydraulic system.

- Engage the skid steer’s hydraulic system and check for any leaks.

- Raise the mulcher off the ground and adjust the height so that the rotor is parallel to the ground.

- Tighten all bolts and nuts.

Additional tips:

- Always use a qualified mechanic or FAE dealer to install your mulcher.

- Read the mulcher’s owner’s manual carefully before installation and operation.

- Make sure the skid steer is powerful enough to handle the mulcher.

- Inspect the mulcher regularly for wear and tear.

- Replace any damaged parts immediately.

Trenchers

Trenchers play a crucial role in digging trenches for utilities. Whether laying cables or pipes, these attachments streamline the process, offering efficiency and precision in every dig.

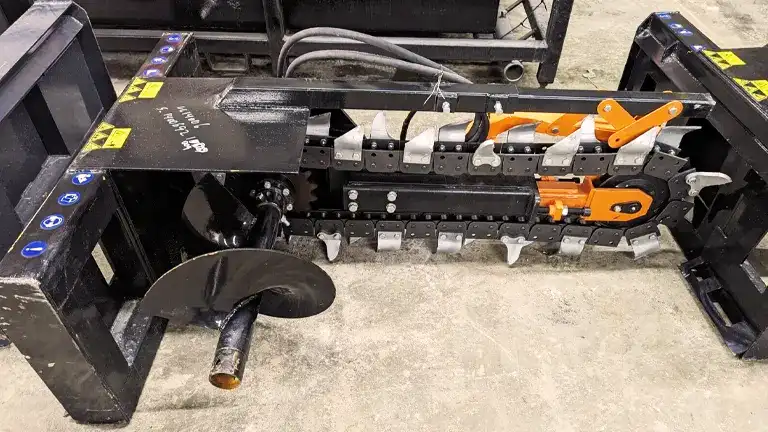

1. Agrotk Skid Steer Trenchers Attachment 48″

Key Features

- 48-inch wide chain

- Hydraulic depth control system

- Combo chain

- Heavy-duty construction

The Agrotk Skid Steer Trencher Attachment 48″ is a heavy-duty trencher that can be used with skid steers to dig irrigation trenches, lay cable, and install drainage pipes. It has a 48-inch wide chain that can cut through a variety of soil types, including hard clay and rocky soil. It also has a hydraulic depth control system that allows you to easily adjust the depth of the trench. The Agrotk Skid Steer Trencher Attachment 48″ is a powerful, versatile, and durable piece of equipment that is built to last.

| Width | 48″ |

| Trenching depth | 48″ (122 cm) |

| Trenching width | 6″, 8″, 10″, or 12″ (15, 20, 25, or 30 cm) |

| Chain | Combo chain |

| Weight | 1,120 lbs |

| Hydraulics | Requires 30-45 gpm at 2,500-3,000 psi |

| Compatibility | Most skid steers with a universal mounting plate |

Tips on how to install Agrotk Skid Steer Trenchers Attachment 48″:

- Park your skid steer on a level surface.

- Turn off the engine and engage the parking brake.

- Raise the loader arms to their highest position.

- Attach the quick coupler to the skid steer’s loader arms.

- Lower the loader arms and align the trencher attachment with the quick coupler.

- Engage the quick coupler to lock the trencher attachment in place.

- Connect the hydraulic hoses from the trencher attachment to the skid steer’s hydraulic ports.

- Check the hydraulic connections for leaks.

- Lower the trencher attachment to the ground.

- Adjust the trencher attachment’s depth and angle.

- Start the skid steer engine and engage the hydraulic flow.

- You are now ready to start trenching.

Additional tips:

- Make sure that the quick coupler is compatible with both the skid steer and the trencher attachment.

- Use the correct hydraulic hoses and fittings.

- Tighten all hydraulic connections securely.

- Check the hydraulic connections for leaks before starting to trench.

- Adjust the trencher attachment’s depth and angle to suit the specific needs of your project.

- Be careful not to overload the skid steer’s hydraulic system.

- If you are trenching in hard or rocky soil, you may need to use a rock hammer to break up the ground before trenching.

Advantages of Using Small Skid Steer Attachments

- Versatility: Small skid steer attachments not only significantly expand the range of tasks your equipment can handle, but from digging and lifting to grading and sweeping, there’s an attachment tailored for nearly every job.

- Cost-Effectiveness: Opting for versatile attachments over multiple specialized machines presents a cost-effective alternative, as a single compact skid steer equipped with a range of attachments can effectively fulfill the roles of numerous dedicated vehicles.

- Time-Saving: Attachments play a pivotal role in streamlining tasks, significantly reducing the time needed to execute projects. The heightened efficiency and precision afforded by these attachments not only expedite project completion but also contribute to an overall boost in productivity.

- Adaptability to Various Environments: Small skid steer loaders, when fitted with the appropriate attachments, prove highly adept at efficiently navigating and operating within tight and confined spaces. This adaptability is particularly advantageous in urban construction sites and landscaping projects where the availability of space is limited, allowing for enhanced maneuverability and productivity in constrained environments.

- Enhanced Precision: Attachments are meticulously designed for specific tasks, providing a level of precision that could be challenging to attain using a standard skid steer bucket. This heightened precision becomes particularly crucial in tasks such as grading, where accuracy is paramount for successful and effective project execution.

- Increased Efficiency in Material Handling: Attachments such as pallet forks and grapples play a crucial role in optimizing material handling processes by facilitating easier lifting, carrying, and positioning of materials. These tools contribute significantly to the efficiency and smooth logistics on job sites, streamlining the overall workflow and enhancing productivity.

- Diverse Applications: Small skid steer attachments are versatile tools with applications spanning across diverse industries such as construction, landscaping, agriculture, and forestry. Their adaptability is a key feature, making them well-suited for a wide range of projects and industries, thereby enhancing their utility and effectiveness in different work environments.

- Reduced Environmental Impact: Utilizing a single small skid steer with various attachments not only streamlines operations but also diminishes the requirement for multiple machines, thereby curbing the overall environmental footprint. This integrated approach promotes efficiency in tasks and concurrently lowers fuel consumption, making significant strides towards environmental sustainability.

- Increased Job Site Safety: Specialized attachments not only facilitate the handling of tasks that could pose hazards to workers but also contribute to an overall improvement in job site safety. The incorporation of remote operation capabilities in certain attachments adds an extra layer of safety, enabling operators to control the equipment from a secure distance, thereby minimizing potential risks associated with on-site operations.

- Flexibility for Changing Project Requirements: As project requirements evolve, the versatility of attachments allows for quick adaptation without the need for significant equipment changes. This flexibility is particularly valuable in dynamic construction and landscaping environments.

- Compact Size and Maneuverability: Small skid steer loaders are inherently compact and maneuverable, making them well-suited for various job sites. Attachments complement these qualities, ensuring that the equipment remains agile and effective in confined spaces.

- Improved Return on Investment (ROI): The combination of cost-effectiveness, increased efficiency, and adaptability contributes to a higher return on investment for small skid steer loaders equipped with attachments. The versatility ensures that the equipment remains valuable across a range of projects and tasks.

Benefits of Small Skid Steer Attachments

The integration of small skid steer attachments brings a myriad of benefits to the table. Not only do they boost efficiency and productivity, but they also offer a cost-effective solution compared to investing in standalone machinery for each task. Their adaptability to diverse applications makes them an indispensable asset for any project.

Tips for Choosing the Right Attachments

- Compatibility is Key: Ensure seamless integration by selecting attachments that are compatible with your specific skid steer model. Check hydraulic connections, weight limits, and mounting mechanisms to guarantee a perfect match.

- Define Your Purpose: Clearly outline the primary tasks your small skid steer will undertake. Different attachments excel in distinct applications—whether it’s excavation, grading, or material handling—choose attachments aligned with your project objectives.

- Versatility Matters: Seek attachments with a range of functionalities to maximize utility. A versatile attachment, like a 4-in-1 bucket, can handle various tasks, offering a cost-effective and flexible solution.

- Scale with Project Scope: Tailor your attachment choices to the scale and scope of your projects. Residential landscaping may demand lighter attachments, while heavy-duty construction requires robust, industrial-grade tools.

- Invest in Quality: Prioritize quality over initial costs when selecting attachments. High-quality attachments are more durable, demand less maintenance, and provide a longer lifespan, ensuring a wise investment.

- Explore Reputable Brands: Navigate the market by researching reputable attachment manufacturers and brands. Leverage insights from industry reviews and recommendations to make informed decisions.

- Hydraulic Harmony: Confirm that your skid steer’s hydraulic system aligns with the hydraulic requirements of the chosen attachments. Understanding flow and pressure specifications is crucial for seamless operation.

- Swift Attachment Change: Opt for attachments with user-friendly attachment change systems. Quick couplers and universal mounting plates facilitate efficient and swift changes, enhancing overall job site efficiency.

- Ease of Maintenance: Consider the maintenance and serviceability aspects of your chosen attachments. Attachments with accessible components and readily available replacement parts can minimize downtime and maintenance costs.

- Secure Warranty and Support: Prioritize attachments backed by robust warranties and responsive after-sales support. A reliable support system ensures peace of mind and assistance in the event of any challenges.

- Weight Distribution Wisdom: Safeguard stability by ensuring that your skid steer can handle the weight of chosen attachments. Maintaining proper weight distribution is paramount for safe and effective operation.

- Future-Proof Your Investment: Envision the growth of your projects and the potential expansion of tasks. Select attachments that not only meet current needs but also allow for future scalability, ensuring a lasting and adaptable investment.

- Operator Proficiency: Invest in thorough training for skid steer operators to optimize attachment usage. A skilled operator can unlock the full potential of your attachments, enhancing overall efficiency and safety.

Future Trends in Small Skid Steer Attachments

As technology advances, so do skid steer attachments. Explore the future trends shaping this dynamic market, from innovative designs to emerging technologies that promise to further enhance the capabilities of these compact machines.

Conclusion

In conclusion, small skid steer attachments are the unsung heroes on job sites, elevating the performance of these already impressive machines. From buckets to augers, each attachment plays a unique role in expanding the scope of what skid steers can achieve. As you embark on your projects, consider the transformative power that these attachments bring to the table, and witness firsthand how they can boost your productivity to new heights.

FAQs

- Can I use small skid steer attachments on any skid steer model, or do they have to be model-specific?

While there’s some compatibility, it’s crucial to check specifications. Attachments may require specific hydraulic flow rates or other features that vary between models. Always refer to the manufacturer’s guidelines to ensure a proper fit. - Are there attachments designed for environmentally sensitive projects, like wetland restoration or conservation efforts?

Absolutely! There are specialized attachments like low-impact trenchers and mulchers designed with features to minimize soil disturbance. These are perfect for projects where environmental preservation is a priority. - How do small skid steer attachments save time and costs on construction sites?

Small skid steer attachments offer a versatile alternative to standalone machinery, reducing the need for multiple pieces of equipment. This consolidation not only saves on equipment costs but also streamlines project timelines. Operators can switch between tasks quickly, minimizing downtime and maximizing efficiency. - Can operators easily switch attachments on-site, or is professional assistance required?

The ease of attachment swapping depends on the attachment’s design. Many modern skid steers are designed for quick changes, allowing operators to switch between various tools without extensive technical knowledge. Safety guidelines and manufacturer recommendations should always be followed. - Are there any smart technologies integrated into small skid steer attachments?

Absolutely! There are ongoing advancements in automation and smart technology for skid steer attachments. Some attachments feature automation for precise digging or cutting, while others have sensors and telematics that provide real-time data on performance and maintenance needs. These innovations contribute to improved accuracy and operational efficiency.

In the realm of construction and heavy equipment, the marriage of small skid steer attachments to these versatile machines has unleashed a world of potential. With each turn of the wrench and every quick swap of an attachment, the landscape of productivity in various industries is forever altered. As we conclude this exploration into the synergy between skid steers and their attachments, it becomes abundantly clear that these tools are the unsung heroes of the job site, the driving force behind efficiency, versatility, and cost-effectiveness. As your trusted publisher, we hope this journey through the world of small skid steer attachments has left you inspired and informed, ready to embrace the boundless opportunities that these attachments offer. We look forward to sharing more groundbreaking insights and discoveries with you in the future, as innovation continues to shape the landscape of heavy equipment and productivity.

Benjamin Brooks

Forestry AuthorGreetings! I'm Benjamin Brooks, and my journey over the past 15 years has revolved around the fascinating realms of content creation, expertise in snow clearing, and the intricate world of lumberjacking and landscaping. What began as a simple curiosity about the natural world and heavy machinery has evolved into a passionate profession where my love for crafting words intertwines seamlessly with my lumberjacking and garden skills.

Leave your comment