Best Wood Jointer Under $500

- November 20, 2023

- 0 comment

Are you on the hunt for a high-quality wood jointer without stretching your wallet? You’re not alone. Many woodworkers, whether seasoned experts or enthusiastic beginners face the challenge of balancing cost with quality. In this essential guide, we explore the realm of affordable woodworking tools, spotlighting the top wood jointers available for under $500.

List of Best Wood Jointers Under $500:

- Shop Fox Benchtop Jointer

- CRAFTSMAN Benchtop Jointer

- WEN JT630H Spiral Benchtop Jointer

- Delta Midi-Bench Jointer

- Porter-Cable Jointer

- RIKON Power Tools Benchtop Jointer with Helical Cutter head

- Grizzly Industrial Benchtop Jointer

We understand that precision in woodworking is non-negotiable, and a reliable jointer is key to achieving this. That’s why we’ve meticulously reviewed and compared the best budget-friendly jointers, focusing on their features, performance, and overall value. Our goal is to help you navigate through the myriad of options and find a jointer that not only fits your budget but also elevates your woodworking projects. Get ready to discover your next indispensable tool that promises to enhance your woodworking journey, all while keeping your finances in check

What is a Wood Jointer?

A wood jointer, essential in any woodworking shop, is a tool specifically designed for creating flat surfaces and straight edges on wood boards, distinguishing it from a planer. It features infeed and outfeed tables with a set of cutting blades located between them. The jointer’s primary role is to straighten and square the edges of boards, crucial for ensuring tight joints in woodworking projects. As a board passes over the jointer, the cutter head removes material from the bottom surface, correcting warps, twists, or bows. This process is particularly vital when working with rough lumber, as the jointer prepares the wood by making one face and one edge flat and square, setting the stage for further processing with a planer to achieve uniform thickness across the board.

Best Wood Jointer Under $500 Top Picks

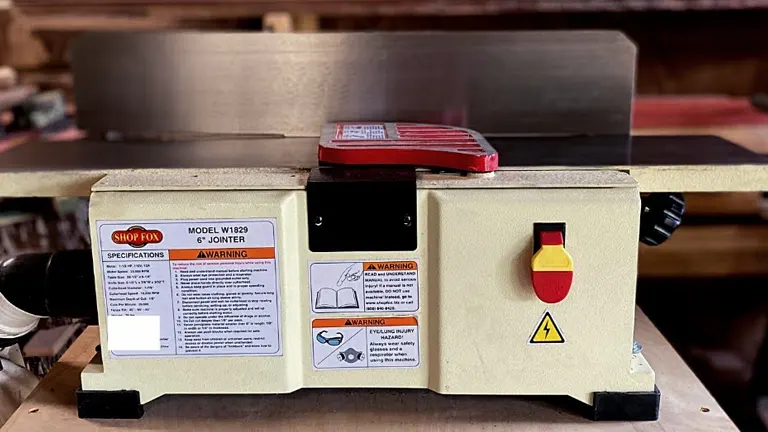

1. Shop Fox 6 in. 1-1/2 HP Benchtop Jointer

Quick Specifications

- Motor: 1-1/2 HP, 110V, single-phase

- Cutterhead Speed: 10,000 RPM, 20,000 cuts per minute

- Knife Size: 6 x 7/8 x 3/32 inch

- Table Size: 28-1/2″ length x 6-1/4″ width

- Fence Stops: 45 and 90 degrees

- Dust Port: 2-1/2 inch

- Weight: Approx. 80 pounds

The Shop Fox W1829 Benchtop Jointer emerges as a standout choice for woodworkers seeking precision and efficiency in a compact package. Powered by a robust 1-1/2 horsepower motor, it operates at a remarkable speed of 10,000 RPM, delivering 20,000 cuts per minute. This performance is particularly impressive considering its accessible price point under $500. The two-knife HSS cutter head is a highlight, ensuring clean and precise cuts every time. Its fine-adjust in-feed table knob is a thoughtful addition, allowing for meticulous control over cutting depth – a feature that both beginners and experienced woodworkers will appreciate for its contribution to precise, high-quality work.

The Shop Fox W1829 doesn’t just excel in performance; its design is equally commendable. This benchtop model, with its precision-ground cast iron table, combines durability with ease of use, making it suitable for a variety of woodworking tasks including surface planing, edge jointing, and bevel cutting. The aluminum fence is fully adjustable, with stops at key angles for convenience and precision. Moreover, its ability to perform bevel jointing up to 45 degrees adds to its versatility. The jointer’s compact design doesn’t compromise on power, making it a great fit for workshops where space is at a premium.

A standout feature of the Shop Fox W1829 is its integrated dust management system. The built-in mini impeller is ingeniously designed to suck chips away from the cutter head, channeling them efficiently through the 2-1/2-inch dust port. This feature not only maintains a cleaner work area but also enhances the machine’s longevity by preventing dust buildup. The inclusion of a dust connection filter chute compatible with standard galvanized trash cans is a thoughtful touch, showcasing Shop Fox’s commitment to convenience and cleanliness in workshop environments.

Pros

- Reliable 1-1/2 HP motor for consistent power.

- Compact design suitable for small workshops.

- Two-knife HSS cutter head for clean cuts.

- Adjustable aluminum fence with stops.

Cons

- Limited to lighter-duty tasks.

- Dust collection could be improved.

2. CRAFTSMAN 10-Amp Benchtop Jointer

Quick Specifications

- Motor: 10 Amp

- Speed Range: 6,000 to 11,000 RPM

- Cutterhead Speed: 12,000 to 22,000 cuts per minute

- Table Size: 30″ x 6-3/16″

- Fence: Center-mounted, 4-1/4″ height

- Weight: 40.2 pounds

The CRAFTSMAN 10-Amp Benchtop Jointer is a testament to versatility and power in a compact form, making it an appealing choice for woodworkers who need a reliable jointer under $500. One of its most impressive features is the variable speed range of 6,000 to 11,000 RPM, which, coupled with a cutter head speed of 12,000 to 22,000 cuts per minute, allows users to adapt the machine to various materials, both hard and soft. This flexibility is crucial for those who work with a diverse range of wood types and need a machine that can handle different sizes and hardness without compromising on quality or precision.

CRAFTSMAN has designed this jointer with user convenience in mind. The two-knife cutter head with a jackscrew knife leveling arrangement simplifies the often tedious process of knife replacement and adjustment. This feature not only saves time but also ensures that the knives are always at the optimal setting for precise cuts. Additionally, the center-mounted fence is a standout feature, providing ample support and ensuring accuracy during edge jointing. This jointer is particularly well-suited for tasks like edging, flattening, or face jointing, making it a versatile addition to any woodworker’s tool collection.

The jointer’s design strikes a balance between robust functionality and ease of handling. Weighing at around 40.2 pounds and with dimensions that make it a manageable benchtop tool, it is relatively portable for a woodworking machine. The extra-large 6-3/16″ x 30″ table offers ample workspace, and the two-knife, ball-bearing cutterhead promises durability and smooth operation. A built-in cutterhead lock is a thoughtful safety feature, ensuring secure operation. The machine’s heavy-duty 10 Amp motor is capable of handling both hard and soft woods, a testament to its power and durability.

Pros

- Variable speed range for different material types.

- Easy knife replacement and adjustment.

- Large table for ample work support.

- Heavy-duty motor suitable for various woods.

Cons

- Only a two-knife cutter head.

- Some users may prefer a longer table for larger projects.

3. WEN JT630H 10-Amp 6-Inch Spiral Benchtop Jointer

Quick Specifications

- Motor: 10 Amp

- Cutterhead Speed: 12,000 RPM

- Depth of Cut: 0 to 1/8 inch

- Table Size: 30″ x 6″

- Fence Size: 19-3/4″ x 4-1/4″, bevels up to 45°

- Dust Port: 2-1/2 inch

- Weight: 36.8 lb

The WEN JT630H 6-inch Spiral Benchtop Jointer represents a significant advancement in jointer technology, particularly in the under $500 category. The heart of its innovation lies in the spiral cutter head system, which uses 12 staggered HSS blades to deliver an exceptionally fine finish on both hard and softwoods. This design not only enhances the quality of the cuts but also contributes to a smoother operation with less noise and vibration compared to traditional straight knife systems. The powerful 10 Amp motor, with a speed of up to 12,000 RPM, ensures that the cutter head works efficiently, providing precision on every pass. The ability to adjust the infeed table for removing up to 1/8 inch of material per pass, combined with the onboard depth-of-cut scale, makes it easy to achieve consistent and accurate results.

WEN has thoughtfully designed the JT630H, focusing on both functionality and user safety. The jointer’s sizeable 30-inch by 6-inch table offers ample space for various workpieces, enhancing its versatility. The adjustable 19-3/4 inch by 4-1/4 inch fence, which bevels up to 45 degrees, is a valuable feature for creating angled cuts with precision. Safety is prioritized with the spring-loaded blade guard, which limits the exposure of the cutter head during operation, reducing the risk of accidental injury. Additionally, the inclusion of two push blocks further enhances safety during jointing tasks.

This benchtop jointer is designed with the user’s convenience in mind. Weighing approximately 36.8 pounds, it is relatively portable for a woodworking tool, making it a good fit for workshops where space is a premium or for those who need to move their tools frequently. The onboard dust port is a practical feature, allowing for easy cleanup and maintaining a tidy workspace. The 2-year warranty, backed by WEN’s reputation for customer service and availability of replacement parts, provides an extra layer of assurance for the buyer. The jointer’s 120V compatibility ensures it can be used in standard home workshops without the need for special electrical arrangements.

Pros

- Spiral cutterhead for a superior finish.

- Compact and lightweight, enhancing portability.

- Adjustable fence for versatile jointing.

- User-friendly design with safety features.

Cons

- Limited to smaller workpieces.

- Spiral cutterhead might require more maintenance.

4. Delta Midi-Bench Jointer

Quick Specifications

- Motor: 12 Amp, 120V

- Maximum Depth of Cut: 1/8″

- Cutterhead Speed: 10,000 RPM

- Table Size: 6-1/4″ x 28-1/2″

- Fence Size: 22-7/8″ L x 4-5/16″ H

- Fence Positive Stops: 90˚ and 45˚ In/Out

- Weight: 76 lbs

The Delta Midi-Bench Jointer stands out as a reliable and precise woodworking tool, ideal for those looking to invest under $500. It promises clean and accurate cuts every time, a claim supported by its heavy-duty cast iron fence and precision-machined table. The attention to detail in the machine’s construction ensures long-lasting accuracy, making it a dependable choice for both professional and amateur woodworkers. With a maximum cutting width of 6 inches and a depth of cut up to 1/8 inch, this jointer is well-suited for a variety of jointing tasks. The impressive 5-year warranty that accompanies the 37-071 model reflects the manufacturer’s confidence in its durability and performance.

Delta has focused on creating a jointer that not only performs well but also offers ease of use and longevity. The durable cast iron construction not only stabilizes the machine, reducing vibration during use but also contributes to its overall durability. The simple fence adjust system, with adjustable positive stops at 90˚ and 45˚ both in and out, is a standout feature for its ease of operation. Additionally, the aluminum cutterhead with two knives is designed for simplicity, featuring a jackscrew arrangement that facilitates easy adjustment and knife changes, which is particularly beneficial for those who prioritize minimal downtime and straightforward maintenance.

Efficiency in operation is another strong point of this jointer. The built-in dust blower, which effectively ejects chips and prevents clogging of dust chutes, is a practical feature that keeps the workspace clean and enhances the machine’s performance. Safety is also a key consideration in its design, as evidenced by the inclusion of push blocks, which allow for safe and easy material handling through the jointer. The specs of the machine, including a 12-amp motor, 120V voltage, and a cutter head speed of 10,000 RPM, strike an ideal balance between power and control, making it suitable for a wide range of jointing tasks.

Pros

- Durable cast iron construction for stability.

- Precision-machining ensures long-term accuracy.

- Adjustable fence with positive stops.

- Good for both soft and hard woods.

Cons

- Slightly heavier, affecting portability.

- Some users may find the motor less powerful for heavy-duty tasks.

5. Porter-Cable PC160JT Variable Speed 6-Inch Jointer

Quick Specifications

- Motor: 10 Amp

- Speed Range: 6,000 to 11,000 RPM

- Cutterhead Speed: 12,000 to 22,000 cuts per minute

- Table Size: 30″ x 6″

- Fence: Center-mounted

- Weight: 35 lb

The Porter-Cable PC160JT emerges as a standout option in the budget-friendly jointer market, offering remarkable versatility and adaptability. Its variable speed range from 6,000 to 11,000 RPM, combined with a cutter head speed of 12,000 to 22,000 cuts per minute, allows woodworkers to precisely tailor the jointer to the specific requirements of various materials, be it in size or hardness. This level of customization is a significant boon for those who frequently work with a diverse range of wood types. The jointer excels in various tasks such as edging, flattening, or face jointing, making it a highly versatile addition to any woodshop, whether for hobbyist or professional use.

Porter-Cable has carefully considered user efficiency in designing the PC160JT. The jointer features a two-knife cutter head with a jackscrew knife leveling arrangement, greatly simplifying the process of knife replacement and adjustment. This design element is particularly advantageous for maintaining a consistent workflow with minimal interruptions. The addition of a built-in cutter head lock further facilitates easy knife replacement and adjustments. Furthermore, the extra-large table enhances the jointer’s functionality, providing sufficient support for surfacing stock up to 6 inches wide and catering to a variety of project sizes.

In its design, the PC160JT strikes an impressive balance between practicality and compactness. The center-mounted fence ensures stable and accurate edge jointing, critical for quality woodworking. Its dimensions and weight of just 35 pounds make it a highly suitable option for small to medium-sized workshops, where space might be limited. The jointer’s portability also makes it an ideal choice for those who need to move their tools between different working locations. Powered by a robust 10-Amp motor, the PC160JT is built to handle a wide array of woodworking tasks efficiently. The build quality adheres to Porter-Cable’s known standards of durability and reliability, making it a durable investment for a wide range of woodworking applications.

Pros

- Variable speed for material-specific customization.

- User-friendly jackscrew knife adjustments.

- Center-mounted fence for accuracy.

- Lightweight and portable design.

Cons

- Limited maximum depth of cut.

- Some users report issues with infeed and outfeed table alignment.

6. RIKON Power Tools 20-600H 6″ Benchtop Jointer with Helical Cutter Head

Quick Specifications

- Motor: 10 AMP

- Cutterhead: Helical-style with 12 HSS, 2-edge insert cutters

- Table Size: 30″ x 6-3/16″

- Fence: Tilts from 90 degrees to 45 degrees

- Weight: 36 pounds

The RIKON Power Tools 20-600H 6″ Benchtop Jointer makes a strong impression in the sub-$500 jointer market, primarily due to its advanced cutting technology. The highlight is its 6-row helical-style cutter head, which comes equipped with 12 HSS, 2-edge insert cutters. This design not only ensures exceptional cutting action for flat, smooth surfacing results but also greatly simplifies the knife change process – a major plus for those prioritizing both performance and convenience. Powered by a robust 10 AMP motor, this benchtop jointer confidently handles a diverse array of wood types, making it a versatile tool for a wide range of woodworking projects.

RIKON’s focus on durability is evident in the all-steel construction of the 20-600H, combined with precision-machined aluminum tables. This solid build is key to its long-term stability and accuracy, essential for both professional woodworkers and demanding hobbyists. The large 30” x 6-3/16” table further enhances the jointer’s versatility, providing ample space for handling various wood sizes and contributing to the machine’s overall precision and utility in different projects.

The RIKON 20-600H is designed with user convenience and safety in mind. Its user-friendly features include a quick depth setting mechanism with an easy-to-read scale for hassle-free adjustments. The adjustable fence, which quickly and accurately tilts from 90 degrees to 45 degrees, allows for diverse cuts and angles, adding to the jointer’s functionality. Safety aspects such as the spring-loaded safety guard and the front-positioned on/off switch underscore RIKON’s commitment to safe operation. Additionally, the inclusion of two push blocks is a thoughtful touch, ensuring safer and more controlled material handling.

With dimensions of 30 x 17.5 x 13 inches and weighing just 36 pounds, the RIKON 20-600H is notably compact and lightweight for a jointer. This makes it an ideal choice for workshops where space is at a premium or for woodworkers who require a portable jointer. Despite its smaller size, it does not compromise functionality, offering the power and precision necessary for both small-scale hobbyists and professional woodworkers.

Pros

- Helical-style cutter head for smooth finishes.

- All-steel construction ensures durability.

- Quick depth setting mechanism for ease of use.

- Compact and relatively lightweight.

Cons

- Limited cutting width may not suit larger projects.

- Helical cutter requires careful handling during changes.

7. Grizzly Industrial G0725-6″ x 28″ Benchtop Jointer

Quick Specifications

- Motor: 1-1/2 HP, 110V, single-phase, 12A

- Cutterhead Speed: 10,000 RPM

- Maximum Depth of Cut: 1/8″

- Table Size: 6-1/4″ x 28-1/2″

- Fence Size: 22-7/8″ L x 4-5/16″ H

- Dust Port: 2-1/2 inch

- Weight: Approx. 59 pounds

The Grizzly Industrial G0725 is a compact yet powerful benchtop jointer, highly regarded for its robust build and efficient performance. Featuring a cast-iron body, it significantly reduces vibration, offering stability and precision in each pass. The heart of its operation lies in the 1-1/2 HP motor, which drives a 2-knife cutter head at 10,000 RPM, adeptly handling a variety of wood types. The use of high-speed steel (HSS) for the knives ensures longevity and consistent sharpness, contributing to smooth, tear-free finishes. This combination of power and precision makes the G0725 a standout choice, especially in workshops where space is limited.

Grizzly has thoughtfully designed the G0725 with user convenience in mind. The jointer features a center-mounted aluminum fence, adjustable at 45°, 90°, and 135°, providing flexibility for different jointing tasks. Despite its small footprint, it doesn’t skimp on functionality, capable of mounting and dismounting quickly for easy storage or transport. Weighing 59 pounds, it’s both portable and durable enough to handle substantial workloads. The inclusion of a built-in dust collection system, complete with a blower, chute, and bag, further enhances its appeal by keeping the work area clean and reducing cleanup time.

The G0725 is backed by Grizzly’s 1-year warranty, reflecting confidence in its build quality and performance. The comprehensive manual, crafted by Grizzly’s U.S.-based team, simplifies assembly and maintenance, making it accessible even for less experienced users. Additionally, Grizzly’s reliable U.S.-based technical support and the easy availability of parts and accessories online ensure that users receive long-term value from their investment. This combination of reliable performance, ease of use, and dependable support makes the Grizzly G0725 an excellent investment for both hobbyists and professional woodworkers seeking a quality jointer within a moderate budget.

Pros

- Cast-iron body reduces vibration for stable operation.

- Compact size suitable for small shops.

- Effective dust collection system.

- Includes a 1-year warranty for reliability.

Cons

- Some users may find the motor power insufficient for very hard woods.

- The fence system could be more robust for heavy use.

What to Consider When Choosing the Best Jointer

When choosing the best jointer for your woodworking needs, there are several key factors to consider to ensure you get the right tool for your projects. Here’s a comprehensive guide to help you make an informed decision:

- Type of Jointer

- Benchtop Jointers: Ideal for home woodworkers with limited space. They are smaller, and lighter, and offer portability and easy storage. While they lack the power of larger models, they are suitable for less intensive tasks.

- Cabinet-Style Jointers: These are larger, stationary units designed for more demanding work. They are better suited for handling longer pieces of wood and typically come with more substantial fences for precision cutting.

- Power: The power of a jointer is crucial as it determines the ease of cutting through wood and the smoothness of the finish. Higher-powered models are more efficient with hardwoods and broader cuts.Jointers typically range from 1-horsepower motors in 6-inch models to 2-horsepower motors in 8-inch models, and up to 3 horsepower in high-end commercial-grade jointers.

- Material and Build Quality: The durability and longevity of a jointer depend on its build quality. Look for jointers with sturdy cast-iron feeder tables and guide fences for sustained performance.

- Blades and Cutting Depth: The width of the cutting blade and the maximum cutting depth are important. Wider blades allow for handling larger wood stock, and greater cutting depth reduces the number of passes needed to flatten a board.The number of blades also plays a role, with more blades typically resulting in smoother cuts.

- Portability: Consider the weight and size of the jointer, especially if you need to move it around. Benchtop models offer more portability but can still be quite heavy.

- Knife Options: Jointers come with either straight blades or helical/spiral cutter heads. Straight blades are common in benchtop models but may require more frequent maintenance. Helical or spiral cutter heads provide a smoother finish and are often found in higher-end models.

- Dust Collection: A good dust collection system is essential for maintaining a clean and safe workshop. Look for jointers with effective dust collection ports suitable for the size of the machine.

- Additional Features

- Safety features like push handles and easily accessible off switches enhance the safety of the jointer.

- Additional conveniences like adjustable fences and easy-to-use controls for table height and fence angle can significantly improve the user experience.

Overall Conclusion and Recommendation for the Best Wood Jointer Under $500

In the realm of wood jointers under $500, each model brings its own set of strengths to the table, catering to various needs and preferences in woodworking. After considering the balance of power, precision, versatility, and user-friendly features, the WEN JT630H 6-Inch Spiral Benchtop Jointer emerges as the top recommendation. This jointer strikes an impressive balance between advanced technology and affordability. Its spiral cutterhead system with 12 HSS blades is particularly noteworthy, offering exceptional cutting action and a superior finish on both hard and soft woods. This feature, combined with its powerful 10 Amp motor, ensures both smooth operation and remarkable durability.

Furthermore, the WEN JT630H is designed with user convenience in mind, featuring a spacious 30″ x 6″ table and an adjustable fence that bevels up to 45 degrees. This makes it versatile enough to handle various jointing tasks with ease. The jointer’s compact and lightweight design, weighing just 36.8 pounds, is an added advantage for workshops where space is at a premium or for woodworkers who value portability. Additionally, the jointer’s safety features, such as the spring-loaded blade guard and the inclusion of push blocks, demonstrate a thoughtful consideration for the user’s safety and comfort.

Overall, the WEN JT630H stands out for its perfect blend of functionality, durability, and ease of use, making it an excellent choice for both amateur and experienced woodworkers looking for a high-quality jointer within a moderate budget.

FAQs

- What is the difference between a jointer and a planer, and do I need both in my workshop?

This question addresses the common confusion between the functions of jointers and planers, and whether both are necessary for a woodworking shop. - Can a wood jointer be used to create rabbets and chamfers, or is it solely for flattening and squaring?

This explores the versatility of a jointer in performing tasks beyond its primary function. - How do I safely change the knives on my wood jointer, and how often should they be replaced or sharpened?

Safety and maintenance are crucial for the longevity and effectiveness of a jointer. This question guides users on proper maintenance routines. - What are the advantages of a helical cutterhead in a jointer compared to traditional straight knife cutterheads?

This question delves into the technological advancements in jointer cutterheads and how they impact the machine’s performance. - How does the size of the jointer affect the types of projects it can handle?

This addresses the importance of jointer size and how it correlates with project scale and type. - Can a benchtop jointer effectively handle hardwoods, or is it primarily for softer woods?

Users often wonder about the capability of smaller, more affordable jointers in handling various wood types. - What are some essential safety tips to follow while using a wood jointer?

Safety is paramount. This question emphasizes the best practices for safely operating a jointer. - How does the fence angle impact the jointing process, and what are some tips for accurate adjustments?

This question focuses on the technical aspect of using a jointer and how to achieve precise results. - Is there a significant difference in dust collection efficiency among different jointers?

This is important for maintaining a clean and safe working environment, especially in smaller workshops. - How can I minimize snipe on a wood jointer?

Snipe can be a common issue with jointers. This question offers insights into reducing or eliminating this problem.

Join the discussion below by sharing your experiences, tips, or reviews. Your contributions help others make informed decisions and navigate their chainsaw choices with confidence. Let’s build a community of shared knowledge for all wood-cutting enthusiasts!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment