Welder Essentials: Beginner’s Best Pick

- December 26, 2023

- 0 comment

Selecting the appropriate welder marks a crucial decision in the journey of welding for beginners. The vast array of models and types available in the market can make this decision seem like a daunting task, as it requires careful consideration of factors such as one’s needs and skill level. This comprehensive article aims to provide an in-depth exploration of the best welders tailored for beginners, offering valuable insights into the intricacies of the selection process.

Welding, a profoundly practical skill enabling the permanent fusion of two metal pieces, finds diverse applications ranging from auto repair to home projects and even artistic endeavors. However, the sheer variety in the types, sizes, and price ranges of welders adds an extra layer of complexity to the decision-making process. Opting for the wrong welder can result in frustration and subpar outcomes, particularly for those just starting in the welding realm.

The primary objective of this article is to elucidate the critical factors that beginners should carefully consider when choosing their inaugural welder. It seeks to demystify common welding methods and provides recommendations for welders that are not only user-friendly but also versatile and budget-friendly, catering specifically to the needs of novices. Armed with this knowledge, beginners can confidently navigate the market and select a high-quality welder that aligns with their skill development goals. The significance of commencing the welding journey with the right equipment cannot be overstated, as it serves as a cornerstone in ensuring the success of newcomers to the welding craft.

Top 5 Welders for Beginners List:

- HONE MMA140D

- S7 Stick Welder

- YESWELDER MIG 205DS

- TOOLIOM 135A 110V/220V Stick Welder

- YESWELDER 135 Amp MIG Welder

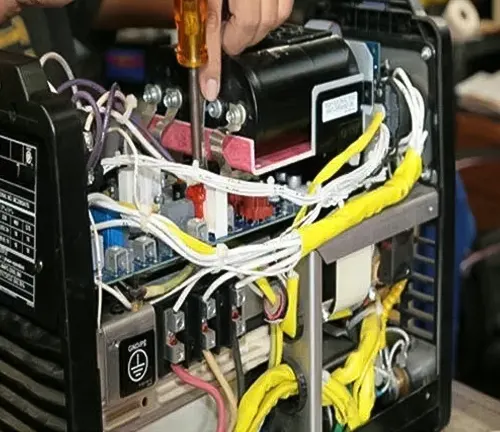

Welding Machine Setting It Up

Setting up the welding machine is a pivotal aspect of any welding endeavor, and the choice of the welding machine itself is a critical decision. Following thorough research and seeking guidance from experienced welders, I opted for the [Brand Name] Welder to serve as the cornerstone of my welding setup. This particular welding machine stands out by seamlessly balancing performance with user-friendliness.

Its intuitive controls alleviate the learning curve for beginners, allowing for a smoother entry into the world of welding. What impressed me the most about this machine is its remarkable power and versatility. It has proven itself capable of handling a diverse range of welding projects, showcasing its adaptability to different materials and welding techniques.

Whether I’m working on intricate, detailed welds or tackling larger, more robust projects, the [Brand Name] Welder has consistently demonstrated reliability and efficiency. The ease with which I can set it up and get started on my projects has been a game-changer, providing me with the confidence to explore and expand my welding skills.

1. HONE MMA140D – The Preferred Pick by the Editor

Technical Specifications

- Product Dimensions: 9 x 3.9 x 5.6 inches

- Item Weight: 9.48 pounds

- Size: 10 ~ 120A (110V) / 10 ~ 140A (220V)

- Power Source: AC

- Wattage: 4.29 KW

- Color: Red

- Material: Steel, Copper, Aluminium, PA66, etc.

- Shape: Rectangle

The Hone MMA140D Stick Welder stands out as an economical choice for novice welders venturing into the welding realm. Tailored to offer a dependable and uncomplicated welding experience, this welder proves to be an excellent starting point for beginners. Boasting a maximum output of 140 amps on 240 volts and 120 amps on 120 volts, it caters to a spectrum of welding tasks, showcasing its versatility.

A noteworthy advantage of the Hone MMA140D lies in its ability to deliver accurate amperage output, aligning closely with its advertised ratings. While some inconsistencies may be present at lower amperage settings, the welder excels in reaching and maintaining higher amperage levels when necessary. The inclusion of an Arc Force feature adds another layer of functionality, automatically adjusting amperage based on the arc length, providing beginners with a smoother welding experience.

However, it’s crucial to acknowledge the limitations of this welder. The hot start function has some restrictions, and there have been reports of the product featuring thin aluminum cables with subpar insulation. Additionally, concerns regarding the fragility of the electrode holder may prompt users to invest in higher-quality accessories. Despite these drawbacks, the Hone MMA140D Stick Welder remains a viable entry-level option for beginners prioritizing affordability. Those willing to navigate its minor shortcomings can benefit from a welding tool that facilitates skill development in the early stages of their welding journey.

Pros

- Demonstrates reliability in achieving its claimed maximum output, as evidenced by its amperage ratings.

- Incorporates an Arc Force feature that adjusts amperage based on arc length, thereby enhancing welding capabilities.

- While not officially confirmed, there are indications of a limited anti-stick function, offering potential advantages for welding tasks.

- Specifications and ratings of this product appear to be more realistic and honest compared to some other welders in the market.

Cons

- Inconsistencies and inaccuracies in amperage settings make it difficult to achieve precise welding conditions.

- The hot start function is notably limited, potentially impacting ease of use, particularly for novice welders.

- The included thin aluminum cables with poor insulation may lack durability and may not be suitable for heavy-duty use.

- The electrode holder of this welder reportedly breaks relatively quickly during use, raising concerns about its longevity.

2. S7 Stick Welder – The Top Choice for Stick Welding

Technical Specifications

- Product Dimensions: 12 x 8 x 9 inches

- Item Weight: 7.56 pounds

- Voltage: 110 Volts

- Metals: Carbon steel, medium carbon steel, and alloy steel.

- Type: Stick

Positioned as an economical option, the S7 Arc 250 Stick Welder emerges as an attractive choice for those in search of a cost-effective welding solution. With an affordable price point, this welder stands out by featuring a dual-voltage capability, enabling it to operate seamlessly on both 120 volts and 240 volts. This adaptability proves to be a practical asset for users with diverse power supply options, ensuring flexibility in various workshop configurations.

Adding to its allure, the welder boasts a compact and lightweight design, making it a convenient and budget-friendly selection. The portability and modest footprint render it suitable for compact workshops or projects on the move, eliminating the need for extensive storage space. While acknowledging its limitations, particularly in achieving precise delivery of the claimed 250 amps of output, the S7 Arc 250 Stick Welder still manages to deliver a satisfactory welding experience within its economic constraints. Ideal for beginners or hobbyists venturing into welding without a substantial financial commitment, this welder provides an affordable entry point into the dynamic world of welding.

Pros

- The welder boasts dual-voltage functionality, allowing seamless operation on both 120 volts and 240 volts.

- It is attractively priced, catering to budget-conscious buyers and ensuring affordability without compromising on essential features.

- With a compact and lightweight design, the welder prioritizes convenience, making it easily portable and simplifying storage concerns.

- Featuring adjustable hot start and arc force settings, the welder offers flexibility in welding techniques, accommodating various preferences and requirements.

- Safety is a priority, as the welder includes a VRD (Voltage Reduction Device) mode, reducing open circuit voltage for enhanced safety during operation.

Cons

- Despite its claim of delivering 250 amps of output, the welder falls short, reaching a maximum of 160 amps on 240 volts and 140 amps on 120 volts.

- The amperage output is non-linear, causing a discrepancy between the set amperage and the actual output, posing challenges in fine-tuning welding conditions accurately.

- Users have reported inconsistent performance described as flaky, especially at settings below 100 amps, making it difficult to achieve consistent welding results.

- Despite its assertion of compatibility with 6010 electrodes, the welder struggles to effectively run them, particularly in the lower amperage range.

3. YESWELDER MIG-205DS – The Ultimate 3-in-1 Choice

Technical Specifications

- Item Weight: 35.2 pounds

- Package Dimensions: 20.08 x 15.55 x 13.19 inches

- Type: MIG / TIG / ARC / Stick

- Power: 110V/220V

- Metals: Carbon Steel and Aluminum

The YESWELDER Mig 205 DS welder distinguishes itself as an exceptional multiprocess welding tool, combining affordability with impressive performance. Positioned as a versatile solution, this welder caters to a broad spectrum of users, accommodating both beginners and seasoned welders alike. A notable highlight is its proficiency in stick welding, offering a smooth and user-friendly experience for tackling diverse welding tasks.

Furthermore, the inclusion of the TIG lift-start function adds to its appeal, simplifying the TIG welding process, even for those unfamiliar with it. Despite its budget-friendly nature, the YESWELDER Mig 205 DS welder doesn’t compromise on value. It delivers reliable welding performance across various applications, making it a cost-effective investment.

However, there’s room for enhancement, particularly in terms of build quality and packaging. It’s crucial to acknowledge that this welder may demand users to possess a deeper understanding of welding settings, and providing guidance on recommended settings for different welding scenarios would enhance its user-friendliness. In summary, if you’re in search of an affordable yet proficient MIG welder that consistently produces impressive results, the YESWELDER Mig 205 DS emerges as one of the top contenders in the market.

Pros

- An economical price point offers outstanding value for a multi-process welder.

- Exhibits smooth and effective stick welding performance, catering to a variety of welding tasks.

- The TIG lift-start function simplifies TIG welding, making it accessible to welders of varying experience levels.

- Versatility in handling diverse welding applications.

- Multiple settings for MIG welding enable precise fine-tuning and customization.

Cons

- Build quality is somewhat on the thinner side, suggesting potential for improvement in durability.

- Packaging may need enhanced attention to prevent damage during shipping.

- The use of metric-based settings might pose confusion for users more accustomed to imperial units.

4. TOOLIOM 135A 110V/220V Stick Welder – The Epitome of Portability

Technical Specifications

- Item model number: TL-135Sw

- Package Dimensions: 12.36 x 8.62 x 7.44 inches; 8.47 Pounds

- Type: Stick

- Power: 110V/220V

- Weight: 4.84 lbs.

- Metals: Mild Steel, Cast Iron, Stainless Steel, and Hard Surfacing

The Tooliom TL 135A Inverter Stick Welder distinguishes itself as an exceptionally portable welding machine, presenting a compelling option for welders seeking on-the-go convenience. Its ingeniously compact and lightweight design sets it apart, providing unparalleled ease for welders who are often on the move.

Weighing significantly less than traditional welders, this unit becomes effortlessly transportable to job sites, workshops, or even for those engaging in DIY projects within the confines of their garage. The welder’s modest footprint ensures it won’t command much space in your toolbox or storage area, making it a strategic choice for those operating within confined workspaces.

However, don’t let its size fool you; the Tooliom TL 135A does not compromise on functionality. This welder offers a versatile welding experience, showcasing its capability to handle various electrodes and deliver quality welds. Its unique feature of seamlessly switching between 110V and 220V power sources enhances its adaptability, empowering users to work in diverse environments.

While it may not be geared for heavy industrial applications, its unparalleled portability and affordability render it an outstanding choice for hobbyists, DIY enthusiasts, and professionals seeking a lightweight and convenient welder for intermittent use.

Pros

- Exceptionally lightweight and compact, ensuring high portability and ease of transportation to various job sites or workshops.

- Provides the flexibility to operate with both 110V and 220V power sources, enabling adaptation to different electrical environments.

- Stands out as one of the most budget-friendly welding machines on the market, making it an optimal choice for individuals on a tight budget or occasional users.

- With a maximum amperage of 135A, it demonstrates the capability to handle a diverse range of welding tasks, including those in the light to medium-duty applications category.

- Compatibility with various electrode types adds versatility, catering to different welding projects.

Cons

- The 60% duty cycle at 135A might limit continuous welding for extended periods, rendering it less suitable for heavy-duty industrial tasks.

- When operating on 110V, the welder’s amperage is derated, potentially affecting its performance compared to usage on 220V.

- Lacks advanced features found in pricier models, such as digital controls or pulse settings, potentially limiting its appeal to professional welders.

- While capable of handling a range of welding jobs, it may face challenges with thicker materials and larger projects due to its lower maximum amperage.

- Some users have reported concerns about the quality of connectors provided with the welder, suggesting potential issues with connectivity over time.

5. YESWELDER 135 Amp MIG Welder: The Top Pick for User-Friendliness

Technical Specifications

- Item Weight: 18.66 pounds

- Package Dimensions: 18.35 x 13.5 x 11.81 inches

- Style: FLUX-135 Flux Core MIG Welder

- Material: Metal, Carbon Steel and Stainless Steel

The YesWelder Flux 135 emerges as a versatile and cost-effective welding powerhouse, seamlessly blending power with portability in its thoughtfully compact design. Tailored to meet the demands of hobbyists, DIY enthusiasts, and small-scale welders, this welding machine stands out by providing a spectrum of welding processes within a singular unit. Operating on a 110-volt input, it extends accessibility to a broad audience, finding its niche in home workshops, garage projects, and light industrial applications.

A defining feature of the YesWelder Flux 135 is its noteworthy duty cycle. Boasting a 60% duty cycle at 135 amps, it further impresses by maintaining a 100% duty cycle at 104 amps, contingent on the welding process. This exceptional duty cycle ensures users can undertake a variety of common welding tasks without encountering limitations in the machine’s performance. Whether engaged in stick welding, utilizing 30 thousandths or 35 thousandths wire, or delving into lift TIG welding experiments, this machine offers a commendable blend of flexibility and reliability.

The user-friendly interface of the YesWelder Flux 135, notably featuring “infinity dials” for precise control, fosters an environment where welders of all skill levels can comfortably operate the machine. The integration of synergy control eliminates the need for separate machines, allowing users to explore diverse welding processes seamlessly.

Moreover, its lightweight, portable design, complemented by a robust handle, amplifies maneuverability and convenience. In summation, the YesWelder Flux 135 stands as a value-packed welding machine, delivering exceptional performance and versatility without imposing a significant strain on the budget.

Pros

- The machine encompasses three distinct welding processes: shielded metal arc welding (stick welding), flux core welding with 30 thousandths or 35 thousandths wire, and lift TIG welding when paired with an external gas setup.

- Priced at under $200, this welding machine delivers exceptional value for users on a budget, granting access to a diverse range of welding processes without a substantial financial investment.

- Its lightweight and compact design, coupled with a convenient grab handle, ensures high portability, making it easy to transport and suitable for various welding applications.

- The inclusion of “infinity dials” for precise control of wire feed speed and amperage, along with a straightforward push-button process selection, simplifies operation for welders of all skill levels.

- The standout feature of synergy control distinguishes this machine from many competitors in its price range, allowing users to experiment with different welding processes without necessitating multiple machines.

Cons

- Some users have reported occasional issues with the wire feed mechanism, leading to inconsistent wire feeding, which may require adjustments or maintenance.

- The machine’s side door accommodates only one- or two-pound spools of welding wire, limiting convenience for those who prefer larger spool sizes.

- While offering lift TIG welding capability, users need to invest in an external gas setup, as the machine lacks an internal gas system for TIG welding.

- Despite its versatility for various welding tasks, the YesWelder Flux 135 is best suited for light to medium-duty applications and may not be suitable for heavy industrial use.

- Some users have expressed concerns about the long-term durability of this budget-friendly welding machine, suggesting that it may not be as robust as more expensive alternatives.

Proper Safety Guidelines

Safety Gear

Safety first, right? As a beginner, I quickly realized the importance of investing in high-quality safety gear. My top pick for welding helmets is the Auto-Darkening Helmet. Its auto-darkening feature ensures that my eyes are protected from the intense light produced during welding, and the comfortable fit makes it easy to wear for extended periods.

For gloves, I can’t recommend the Welding Gloves enough. These gloves provide excellent heat resistance without sacrificing dexterity. Trust me; your hands will thank you after a long welding session.

Welding Electrodes

Choosing the right welding electrodes can be a bit daunting for beginners. I found that the Electrodes are an excellent choice for various welding applications. They strike a good balance between ease of use and versatility, making them ideal for beginners honing their skills on different materials.

Welding Clamp

A reliable welding clamp is a must-have for securing your workpieces in place. The [Brand Name] Welding Clamp quickly became my favorite for its sturdy build and ease of use. It provides a strong grip without damaging the materials, allowing me to focus on achieving clean and precise welds.

Factors To Take into Account When Selecting A Welder For Beginners

For those entering the world of welding, it’s essential to familiarize yourself with the various welding processes to identify the most suitable method for your projects and skill level. Here, we provide a concise introduction to the most prevalent types of welding and outline their respective advantages for your consideration.

MIG Welding

MIG (metal inert gas) welding, or gas metal arc welding, stands out as one of the most versatile and widely used welding methods. It employs a continuous feed of solid wire electrodes and an inert shielding gas to create a stable arc for melting and joining metals.

Considered beginner-friendly, MIG welding allows for quick work on thinner materials with a MIG welder, making it an ideal choice for novices. MIG welders are adept at welding both steel and aluminum, making them suitable for projects involving mild steel and other common metals. When purchasing a welder, look for the best MIG welder or a 140 MIG welder for optimal performance.

TIG Welding

TIG (tungsten inert gas) welding relies on a non-consumable tungsten electrode and inert gas to generate heat through a TIG torch. While demanding more skill to master, TIG welding offers superior precision and control compared to other methods. The initial costs for a TIG welder are higher, and it is commonly employed for welding stainless steel, aluminum, magnesium alloys, and delicate welding work.

Stick Welding

Stick welding utilizes an electric current and a flux-covered consumable welding rod (the “stick”) to create the arc that melts the metal. It is a basic and portable welding technique suitable for outdoor use with an arc welder or flux core arc welder.

Stick welding proves effective for thicker materials and boasts low equipment costs, serving as an economical welding option. However, it is slower and more challenging for beginners compared to wirefeed welding with a flux core welder or spool gun. Stick welding remains a popular choice for fabrication, construction, and repair jobs.

For most beginner DIY welding projects involving steel, aluminum, or automotive work, a MIG welder offers the easiest learning curve and the most flexibility as a user-friendly and entry-level welding option. Start with an entry-level MIG welder to develop good technique and safety habits before potentially advancing to more complex TIG or stick welding techniques in the future.

Factors to Deliberate on When Selecting a Welder

Choosing the right welder is a crucial decision, especially for those entering the realm of welding. The market is saturated with a diverse array of models, each varying significantly in terms of features and capabilities. Navigating this landscape to find your inaugural welding machine can be a daunting task.

When embarking on the search for a beginner welder, it’s essential to consider several key factors to ensure the selected welder aligns with your skill level, budget, and intended projects. This section provides an in-depth exploration of welding processes, portability, power supply, duty cycle, safety features, and cost as pivotal considerations when in pursuit of your first welding apparatus.

An imperative consideration is verifying that the chosen welder possesses the capability to work with the types of materials you intend to weld, such as assessing its aptitude for aluminum welding with a MIG welding gun. Thoroughly examining welder options, including flux core welders tailored for beginners or gas MIG welders listed among the best, allows novices to pinpoint the ideal introductory welder and sidestep the potential overwhelm induced by the plethora of choices.

Opting for user-friendly welders, like gasless MIG or flux core arc welding machines, proves advantageous for novice DIYers. By methodically assessing welder options through the lens of these criteria, beginners can hone in on the perfect introductory welder, mitigating the sense of being inundated by the multitude of choices available.

Common Welding Projects and Materials for Beginners

If you’re just starting your journey in welding, it’s advisable to initiate your practice with straightforward projects involving mild steel and other commonly used metals. Before delving into more intricate welds, beginners typically undertake projects such as:

- Basic metal repairs and modifications on fixtures, furniture, trailers, railings, frames, and other household, workshop, or garage items. Mild steel, frequently used for these applications, aligns well with the capabilities of many beginner MIG welders.

- Crafting or repairing uncomplicated steel garden structures, ornamental pieces, sculptures, and art. Utilizing scrap steel presents an economical option for beginners to hone their skills.

- Tackling small aluminum welding tasks like DIY truck racks, toolboxes, or fuel tanks. Although aluminum is lighter than steel, not all welders, especially flux core machines, can effectively handle it.

- Restoring broken wrought iron pieces found in furniture, decor, or fencing. Wrought iron, known for its durability, proves to be an ideal material for welding projects.

Addressing automotive needs by working on body panels, frames, exhaust systems, and other components made of mild steel. The most easily accessible and welder-friendly metals for novice practice encompass low carbon steel, stainless steel, aluminum, and iron. Building a foundation with fundamental techniques lays the groundwork for progressing to more specialized metals. When considering welders, ensure you find the best beginner MIG welder capable of handling the specific metals you intend to work with.

Financial Considerations in Welder Selection

Your budget plays a pivotal role in the acquisition of your first welder, as there is a broad spectrum of beginner-friendly welders with varying price points. These range from light-duty models priced under $100 to more robust machines exceeding $500. Establishing a predetermined spending limit is crucial to streamline your search for the best beginner welder.

For novice hobbyists, a budget-friendly welder within the $150-$250 range typically delivers ample capabilities for small projects involving thinner metals. While these basic welders are suitable for occasional use, they might lack advanced features. Stepping into the moderate category, welders priced between $250 and $400 offer enhanced strength and duty cycle ratings, allowing for prolonged welding durations before the risk of overheating.

At the upper echelon, multi-process welders from reputable brands like Lincoln Electric and Miller can range from $500 to $1000. Despite the higher investment, these machines offer performance and durability that can endure for years, even with regular use. If you have long-term aspirations in mig or tig welding, consider investing in a quality machine.

Strive to acquire the best welder within your budget to ensure optimal versatility. Additionally, factor in costs for protective gear. While a more generous budget opens the door to premium options, even budget-friendly welders can deliver excellent service for the needs of most beginners working with mild steel and stainless steel.

Consideration of Skill Level and Experience in Welder Selection

When choosing your initial welder, it’s crucial to take into account your current skill level and experience in welding. For those completely new to welding, it is advisable to opt for an entry-level welder that prioritizes ease of use and uncomplicated operation, catering specifically to beginners. Features such as preset heat/power settings, built-in terminals, and minimal adjustments required make these welders user-friendly for individuals just embarking on their welding journey.

It’s essential to avoid the pitfall of overbuying on your first welder under the assumption that you will eventually grow into more advanced capabilities. As a beginner, it’s advantageous to select a machine that aligns with your current skill level. More intricate multi-process welders, while offering expanded functionalities, can pose challenges and potentially lead to the development of poor welding techniques for novices.

For those with a modest amount of prior welding experience, such as high school shop class or DIY projects, a welder that allows manual adjustments may be a suitable choice. This provides greater customization as your skills progress, particularly when considering the best welders for beginners based on comprehensive reviews.

Honest self-assessment regarding your current abilities is key, prompting the search for welders explicitly labeled for beginners. Machines designed with novice welders in mind contribute to the development of good welding habits from the outset, thanks to their simplicity and forgiving performance. It’s crucial not to underestimate the learning curve required to gain competency. Opting for the right beginner-focused welder ensures a solid foundation for success in your welding endeavors.

Portability and Storage for Beginners

For novice welders, the practical aspects of portability and storage play a crucial role in the selection process. The level of portability and the space a welder occupies when not in use are practical considerations that can significantly impact the welding experience. If your welding plans primarily involve fixed locations, such as a garage shop, a larger stationary unit may be sufficient. However, even as a hobbyist, opting for a portable welder offers the flexibility to weld outdoors, move between locations, and facilitate easy transportation.

To ensure ample portability, focus on welders weighing around 50 lbs or less, particularly those with an all-in-one design featuring self-contained controls, wire feed, and accessories. Compact “suitcase” style MIG welders also stand out as excellent portable options. Additionally, consider welders with wheels, akin to a dolly, providing convenient mobility.

In terms of storage, it’s essential to ensure that your welding area can accommodate the welder’s footprint and additional consumables. Multi-process welders, in particular, tend to have a bulkier build. Ideally, you’ll want to secure your small welder in a clean, dry, and protected space when not in use.

The synergy between maneuverability and storage becomes evident, especially in home garages and smaller workspaces. Opting for a portable beginner welder allows for easy movement between tasks and ensures a neat storage solution after completing projects. When evaluating the myriad welders available on the market, do not underestimate the importance of convenience and flexibility, especially for welding enthusiasts pursuing welding as a hobby.

Prioritizing Safety Features for Beginner Welders

For novice welders, emphasizing safety is of utmost importance, considering the inherent risks associated with welding, including burns, electric shock, fire, and potential lung damage from fumes. Selecting a welder equipped with robust safety features becomes a paramount consideration to mitigate these hazards effectively.

Several crucial safety provisions include:

- Thermal overload safety mechanisms to prevent overheating.

- Automatic low-voltage detection for added electrical safety.

- Inclusion of a ground clamp to minimize the risk of electrical shock.

- A protective cover over the machine’s arc terminal connection points.

- An efficient fume extraction or ventilation system to address respiratory concerns.

Additionally, it’s advisable to seek welders with multiple thermal safety barriers inside the machine to contain sparks and tip-over protection. The presence of easily accessible emergency stop buttons for a quick power cut is also crucial.

In the case of portable welders, ensure the unit features a secure, insulated carrying handle and protective casing. Supplementary safety features such as splice detectors, hand shields, and tilt detection further enhance protection during operation.

While comprehensive welding safety involves the use of proper gear and adherence to safety precautions, selecting a welder engineered to minimize hazards through design is paramount for beginners. It’s essential not to overlook safety ratings when comparing starter welders, as these specifications provide valuable insights into the machine’s commitment to ensuring a safe welding environment.

Power Supply and Duty Cycle

Understanding the power supply requirements and duty cycle of a welder is crucial for novice welders. Most entry-level welders operate on standard 120V household power outlets, ensuring convenient use without the need for special wiring. However, it’s essential to note that 120V welders have limitations on the thickness of metal they can effectively weld.

For welding thicker and stronger metals, the penetrating power of 220V or 240V welders becomes necessary. These units require a dedicated circuit and outlet installation to accommodate the higher voltage and amperage capacity. While 220V welders may incur a higher upfront cost, they enable welding tasks that 120V machines cannot match.

Some welders offer dual voltage capabilities, allowing operation on either 120V or 240V power, providing flexibility to adapt to changing needs. Inverter welders, in particular, can maximize power efficiency from a standard 120V input.

Consider your intended welding projects and the thickness of materials you plan to work with as a beginner. This consideration will determine whether a standard 120V welder is sufficient or if stepping up to 220V is advantageous for having ample amps and wattage from the outset. Choosing the right power supply prevents the need for quick upgrades as your welding skills progress.

Duty cycle, another critical specification, indicates the percentage of time a welder can operate at its maximum rated output within a 10-minute period before requiring cooldown. For beginner welders, a duty cycle of at least 20% is recommended. Higher duty cycle ratings, ranging from 40-60%, enhance productivity during longer welding sessions without frustrating overheating delays. Inverter welders typically offer higher duty cycles than transformers.

Pay attention to the rated amperage associated with the stated duty cycle, considering your typical welding projects and heat settings. While advanced welders allow extended welding at top power, it’s advisable not to overbuy duty cycle capacity as a novice. An economical welder with a 20-30% duty cycle suffices for most introductory uses. However, for larger projects, aiming for a duty cycle of 40% and above is recommended.

Our Final Evaluation

Welding can seem daunting for total newcomers, yet, armed with the right equipment, even novices can achieve commendable results. Upon scrutinizing several widely-recognized entry-level welders, a set of crucial insights comes to the forefront.

For individuals taking their first steps into welding, opting for basic stick welders proves to be a cost-effective and straightforward method to grasp fundamental welding techniques such as striking and sustaining an arc. As proficiency advances, MIG welders equipped with solid wire feed systems offer users the ability to produce visually appealing welds with efficiency.

When seeking an appropriate welder, it is advisable to consider the power capacity suitable for materials commonly tackled by hobbyists, while also emphasizing features related to portability and user-friendly operation. Although more advanced welding processes exist, stick and MIG welders strike a balance for beginners, providing an ideal amalgamation of simplicity, versatility, and capability that fosters confidence in welding skills. Over time and with dedicated practice, the foundational skills acquired on entry-level welders can seamlessly transition to handling more intricate setups. The mastery of this hands-on trade requires a combination of patience and reliance on quality equipment.

We trust that within our compilation of the finest welders tailored for beginners, you have found the perfect option to suit your needs.

Frequently Asked Questions

- Which welding method is the most suitable for beginners?

For beginners, the most user-friendly welding method is stick welding, also referred to as shielded metal arc welding (SMAW). Stick welding employs an electric current to create an arc between a consumable stick electrode and the base metal. The equipment required is basic, including a power supply, electrode holder, electrodes, and protective gear. The process is straightforward and forgiving of errors, making it an ideal choice for novices. With practice, beginners can acquire the skills to produce proficient welds using stick welding. - How significant is the duty cycle in the selection of a welder?

The duty cycle plays a crucial role in the selection of a welder. It signifies the percentage of time within a 10-minute interval that a welder can operate at its maximum rated output. For instance, a welder with a 60% duty cycle at 150 amps can sustain 150 amps for 6 out of every 10 minutes without the risk of overheating. A higher duty cycle implies the ability to weld at elevated amperages for more extended periods before requiring a rest to cool down. It is essential to opt for a welder with a duty cycle that matches the demands of your projects. - Can a single welder handle the welding of all types of metals?

No single welder can accommodate all metals, as different welding processes like MIG, TIG, and stick are better suited for specific types of metals. MIG welding is effective on thin steel, aluminum, and stainless steel. TIG welding can be applied to stainless steel, aluminum, magnesium, and copper. Stick welding is suitable for thick steels and nickel alloys. Additionally, the welder’s power supply must align with the metal, providing the correct amperage range and AC or DC current type. It is essential to select a welder tailored to the specific metal welding projects at hand. - What sets MIG and TIG welding apart?

The primary distinction between MIG (metal inert gas) and TIG (tungsten inert gas) welding lies in the electrode used. MIG welding utilizes a continuously fed wire electrode, while TIG welding employs a non-consumable tungsten electrode. In MIG welding, the metal wire melts to form the weld pool, whereas TIG welding melts only the base metal. MIG welding allows for faster work, making it suitable for long continuous welds. On the other hand, TIG welding provides more control for precision welds, especially on thinner metals. Both processes are versatile and can weld various metals such as mild steel and aluminum, with the choice depending on factors like metal thickness, project complexity, and desired weld characteristics.

We’d greatly appreciate your input! Feel free to share your personal experiences and thoughts regarding the Welder Essentials: Beginner’s Best Pick in the comments section below. Your valuable insights can assist other beginners in making well-informed decisions about their welding equipment!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment