Why Does My Chainsaw Cut Crooked? Understanding and Fixing the Issue

- January 25, 2024

- 1 comment

A chainsaw is an indispensable tool for many, adept at handling everything from routine yard maintenance to professional logging tasks. However, it can quickly become a source of frustration when it begins to cut crookedly, compromising not just efficiency but also safety. This article aims to dissect the reasons behind this common issue and offers practical solutions to ensure your chainsaw is functioning at its best.

Understanding the Problem

When a chainsaw doesn’t cut straight, it can make even the simplest task laborious and time-consuming. A crooked cut is often an indicator of underlying problems with the chainsaw’s components or the cutting technique used. Identifying and addressing these issues is crucial not just for the longevity of your tool but also to ensure your safety during its operation.

Common Causes of a Crooked Chainsaw Cut

1. Dull or Damaged Chain

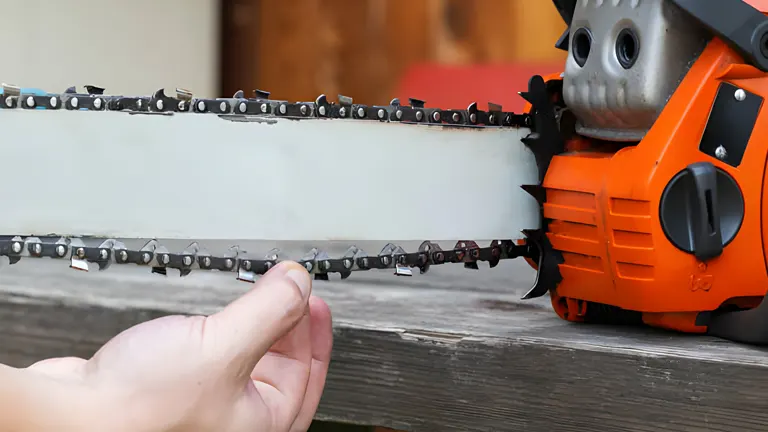

The condition of the chain is paramount in ensuring a straight cut with a chainsaw. A chain that has become dull due to regular use, or has teeth that are damaged or unevenly worn, will struggle to cut cleanly through wood. This often results in a cut that veers off the intended path, making the task at hand more time-consuming and challenging. Moreover, operating with a dull or damaged chain requires more force, potentially leading to dangerous scenarios like kickback. To prevent this, it’s crucial to regularly sharpen the chain, ensuring that each tooth is consistently shaped and sharp. Regular inspections for damage and appropriate corrective measures are also essential in maintaining the chain’s condition.

2. Improper Chain Tension

The tension of a chainsaw chain significantly influences the tool’s performance. A chain that’s too tight can strain the motor and increase the risk of the chain snapping mid-operation. Conversely, a chain that’s too loose might sag or derail from the bar, causing uneven cuts or even posing a safety hazard. Therefore, maintaining the correct tension is critical. Before starting work, and periodically during use, check the chain’s tension and adjust it according to the manufacturer’s specifications. A properly tensioned chain should allow for smooth operation, ensuring a straight cut and prolonging the lifespan of the bar and chain.

3. Worn or Bent Bar

The guide bar plays a critical role in directing the chain and ensuring a precise cut. Over time, the bar can suffer from wear, or it might get bent due to improper use or accidents. When the bar is not perfectly straight or if it has uneven wear, it fails to guide the chain accurately, leading to crooked cuts. Regularly inspect the bar for signs of wear, bending, or any irregularities. If the bar is bent or worn unevenly, it’s essential to replace it to ensure the chainsaw operates safely and efficiently. A well-maintained bar is crucial for achieving straight cuts and extending the life of the chainsaw.

4. Incorrect Cutting Techniques

The technique used while operating a chainsaw greatly impacts the quality of the cut. Applying uneven pressure, using the chainsaw at an incorrect angle, or twisting the saw during a cut can all lead to deviations from a straight path. Additionally, improper technique can lead to dangerous situations, including kickback. To ensure straight cuts and safe operation, it’s important to use the chainsaw correctly. Maintain a firm grip, stand in a stable position, and apply consistent pressure throughout the cut. Avoid using the tip of the bar for cutting, and always cut with the chain rotating at full speed. Proper technique not only ensures cleaner cuts but also contributes to the overall safety and effectiveness of your work.

5. Mechanical Issues

The chainsaw’s mechanical condition, including the sprockets, engine, and alignment of the guide bar, plays a crucial role in its cutting performance. Worn sprockets can lead to uneven chain movement, while a misaligned bar can direct the chain off course. Similarly, an engine that’s not running optimally can affect the chain’s speed and stability. It’s important to conduct regular inspections and maintenance of these components. Replace any worn parts promptly, ensure the engine is in good condition, and check that the bar is correctly aligned as per the manufacturer’s guidelines. Addressing these mechanical issues is essential not only for achieving straight cuts but also for maintaining the overall health and longevity of the chainsaw.

Diagnosing the Problem

Start by inspecting the chain for dullness or damage. Then, check the tension and adjust if necessary. Examine the bar for any signs of wear or bending. Also, review your cutting technique and make sure you’re following the manufacturer’s guidelines. Lastly, check for any mechanical issues that might need a professional’s touch.

Solutions and Maintenance Tips

Sharpening the Chain

Properly sharpening your chainsaw chain is crucial for efficient and safe operation. A dull chain makes your work harder and more dangerous. Use a file designed for your chain’s pitch or a professional sharpener to maintain the sharpness of each tooth. When sharpening, ensure that each tooth is filed to the same angle and length to promote an even cutting action. Regular sharpening not only enhances the cutting performance but also extends the lifespan of the chain. Make it a routine to check the sharpness of your chain before starting any cutting job, and sharpen it as needed to maintain peak performance.

Adjusting the Chain Tension

Correct chain tension is vital for effective cutting and the safety of the chainsaw operator. A chain that is too loose can come off the bar, while a chain that is too tight can wear the bar and chain rapidly and even cause the saw to work harder than necessary. Follow the manufacturer’s guidelines to adjust the chain tension, ensuring it’s neither too tight nor too loose. A general rule of thumb is that the chain should snugly fit against the bar but still be able to rotate freely without too much resistance. Checking and adjusting chain tension should be a part of your regular maintenance routine, especially before starting any cutting task.

Bar Maintenance and Replacement

The condition of the guide bar is essential for straight cuts and the overall health of your chainsaw. Regularly clean the bar to remove any debris, sap, or dirt that can affect the chain’s movement. Inspect the bar for signs of wear, bending, or uneven wear patterns. If the bar is bent or the wear is uneven, it’s crucial to replace it to ensure the chainsaw’s safe and efficient operation. A well-maintained bar helps in guiding the chain accurately and prolongs the life of both the bar and chain.

Regular Maintenance Checks

Consistent and thorough maintenance checks are the backbone of a well-functioning chainsaw. Regularly inspect all components of your chainsaw, including the chain, bar, sprockets, air filter, and spark plug. Consult the chainsaw’s manual for specific maintenance routines and adhere to the recommended service schedules. Keeping a close eye on these components and addressing issues promptly can prevent minor problems from escalating into major ones and helps ensure that your chainsaw is always ready for optimal performance.

When to Seek Professional Help

If you’ve gone through all these steps and your chainsaw still cuts crookedly, or if you encounter a complex mechanical issue, it’s time to consult a professional. Sometimes, an expert’s touch is needed to get your tool back in top shape.

Conclusion

A chainsaw that cuts crookedly can turn an otherwise straightforward task into a challenge. By understanding the common causes, regularly maintaining your tool, and applying the right techniques, you can ensure that your chainsaw cuts straight and true. Remember, a well-maintained chainsaw isn’t just more efficient; it’s also safer to use.

Encounter any peculiar chainsaw issues or have tips of your own? Share your experiences in the comments below, and help fellow readers cut through their problems with ease!

FAQs

- Can temperature changes affect my chainsaw’s cutting performance?

Yes, temperature changes can affect your chainsaw, particularly the chain tension. In colder weather, the chain can contract, making it tighter on the bar. Conversely, in warmer temperatures, the chain might expand, leading to a looser fit. It’s important to check and adjust the chain tension accordingly in different weather conditions to ensure optimal performance. - How can I tell if my chainsaw chain is sharpened evenly?

An evenly sharpened chain is crucial for straight cuts. One way to check is by measuring the length of the cutting edge on each tooth; they should all be the same length. Also, visually inspect the angles; inconsistencies can lead to a crooked cut. If you’re unsure, consider seeking professional sharpening services. - Is it necessary to replace the chainsaw bar and chain together?

While not always necessary, it’s often recommended to replace both the bar and chain at the same time. This ensures that they wear evenly and maintain optimal performance. Using a new chain on a worn bar (or vice versa) can lead to quicker wear and affect cutting precision. - What’s the best way to clean sap or resin off my chainsaw?

Sap and resin can impede your chainsaw’s performance. To clean it, first, ensure the chainsaw is off and cool. Use a commercial resin solvent or a mixture of household detergent and water to gently clean the affected areas. For stubborn resin, you might need to carefully use a putty knife or similar tool. Always wear gloves and follow the manufacturer’s cleaning recommendations. - How often should I perform a thorough maintenance check on my chainsaw?

The frequency of thorough maintenance checks can vary based on how often you use the chainsaw and the conditions it’s used in. As a general rule, a complete maintenance check (including the air filter, spark plug, chain, bar, and sprockets) should be performed after every 10 hours of operation, or at least once at the beginning and end of the cutting season. - Can using the wrong type of oil affect my chainsaw’s cutting performance?

Yes, using the wrong type of oil can lead to poor lubrication, increased wear on the bar and chain, and can even affect the engine’s performance. Always use the type of oil recommended by the manufacturer, and ensure it’s suitable for the climate you’re working in (some oils are formulated for specific temperature ranges). - How do I know if my chainsaw’s bar is bent or just worn out?

To check if the bar is bent, remove the chain and lay the bar on a flat surface. Look for gaps between the bar and the surface, which indicate bending. Wear is often indicated by a narrower or uneven edge on the guide rails or visible signs of scarring. In either case, a compromised bar should be replaced to ensure safe and efficient operation.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

I've used all types of bar oil over the years, but my fav. Is clean new 30 weight. But it's getting harder to find nowdays.

Jim Rowell

February 2, 2024 6:45 pm