Logosol F2 Chainsaw Mill Review

- April 12, 2024

- 0 comment

Explore the Logosol F2 Chainsaw Mill, a portable milling revolution perfect for woodworkers seeking precision and flexibility.

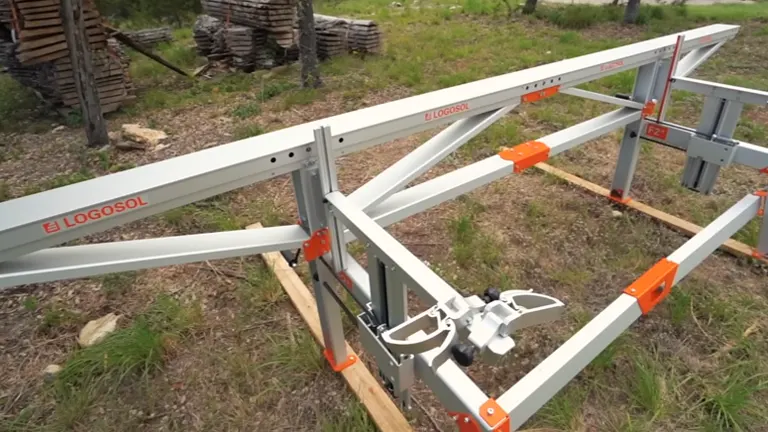

The Logosol F2 Chainsaw Mill is a game-changer in portable milling technology, and I’m excited to share how it could revolutionize your woodworking projects. As someone who appreciates both traditional craftsmanship and modern innovation, I found the Logosol F2 not just efficient but remarkably flexible for various milling tasks. Originating from Sweden—a leader in woodworking innovation—this mill combines the best of durability and portability. In this review, I’ll dive into its standout features and solid design, showing why it’s an essential tool for anyone from hobbyists to seasoned lumberjacks, especially if you value precision without sacrificing the convenience of mobility.

Specifications of Logosol F2 Chainsaw Mill

- Weight: 60.4 kg

- Height: 1.0 m

- Length: 4 m

- Width: 0.7 m

- Log size: Up to 50 cm in diameter, 3.7 m long

- Distance between log lifters: 1 or 2 meters

- Sawing capacity: 3-4 logs per hour

- Motor options: Chainsaws with 3.3 kW (4.5 hp) or Logosol’s electric saws

- Petrol engine: Stihl MS391

- Log-loading height: 0.6 m

- Min. board thickness: 50 mm (2 inches)

- Max. cant width: 40 cm

Construction and Portability

Constructed from lightweight yet durable anodized aluminum, the F2 Chainsaw Mill is designed to handle logs up to 50 cm in diameter with the standard setup.

What sets this mill apart is its ultra-portable design; the entire unit can be easily disassembled and fits into the trunk of a standard car, making it ideal for remote milling sites. Weighing just 65.65 kg and measuring 4 meters in length with a width of 0.7 m, it’s impressively manageable. This mill’s frame consists of 1-meter sections, ensuring quick assembly and disassembly, whether in your backyard or deep in the woods.

Operational Flexibility and Efficiency

The F2 offers incredible operational flexibility, thanks to its modular design which allows for extensions up to 6 meters, catering to longer logs. It features a smart set-up that includes adjustable log lifters, giving you the option to position logs at 1 or 2 meters apart, based on log size.

The mill is designed for a high output of 3-4 logs per hour, making it exceptionally productive for its class. Each cut is precise thanks to an auto-locking system with clear scales and fixed sawing measurements, ensuring each board is cut to accurate dimensions.

Motor Options and Wood Management

This chainsaw mill can be used with various motor options to suit your needs. The recommended Stihl MS391, with a 3.3 kW engine, offers reliable power, or you can opt for the more robust Stihl MS661 for faster processing.

For stationary setups, Logosol’s high-efficiency electric saws with an automatic feed unit can further enhance milling capacity. Whether dealing with hard oak or knotty pine, the F2 handles different wood types with ease, delivering a smooth finish and clean boards, free from residual sawdust.

Advanced Customization Options for the Logosol F2 Chainsaw Mill

One of the most compelling features of the Logosol F2 Chainsaw Mill is its adaptability, offering advanced customization options that cater to varying milling needs and project scales. This flexibility is crucial for woodworkers and professionals who anticipate evolving requirements as their milling experience or business grows.

The F2 mill is designed with a smart modular system that allows for significant adjustability in its setup. Users can choose from several length options starting at 4 meters (about 13 feet), which is ideal for smaller projects or limited spaces. For larger projects, the mill can extend up to 6 meters (nearly 20 feet), accommodating longer logs and more ambitious milling tasks. This modular approach doesn’t just end with length adjustments; additional extensions can be added, extending the mill by up to 2 meters at a time. This feature proves invaluable when tackling exceptionally long logs or when a project demands the milling of varied log sizes.

Moreover, the F2’s design incorporates adjustable log lifters that can be set at 1 or 2-meter intervals, providing further versatility. Whether dealing with thick forest logs or smaller fruit tree trunks, the mill adapts seamlessly to the log dimensions, ensuring precise cuts regardless of the wood type or size. This adjustability ensures that as users’ skills and needs grow, their equipment can grow right alongside them without the need for costly upgrades or replacements.

Additionally, the mill supports various motor options, from more robust petrol-driven chainsaws for fieldwork to high-efficiency electric saws for stationary setups, emphasizing its utility in diverse working environments. This range of motor options ensures that users can find the perfect balance between power and efficiency for their specific milling conditions.

These customization features underscore the F2 Chainsaw Mill’s commitment to providing a scalable milling solution that not only meets the user’s current needs but also adapts to their future requirements. This level of customization facilitates a more personalized milling experience, enhancing both the quality of the work produced and the satisfaction of the user.

Ease of Use and Maintenance

Remarkably, the F2 Chainsaw Mill is not only easy to operate but also virtually maintenance-free. Its aluminum construction doesn’t rust and is dirt-repellent, which means it can stand outdoors indefinitely without degradation, simplifying long-term storage and upkeep.

Adjusting the mill to different slab thicknesses is straightforward; simply turn the handles on each leg to lift the log incrementally, with each click indicating a quarter-inch rise. This feature, combined with its stability and precision, makes the F2 a joy to use.

Comparison with Competitors: Logosol F2 vs. Granberg MK-IV Alaskan Chainsaw Mill

|  | |

|---|---|---|

| Portability | Highly portable, easy assembly/disassembly | Portable but requires more setup |

| Maximum Log Diameter | Up to 50 cm | Up to 76 cm (depends on model) |

| Length Options | 4 to 6 meters (extendable with modules) | Standard size up to 8 feet, extendable |

| Material | Anodized aluminum (rust-free) | Aircraft aluminum and steel |

| Ease of Use | Built-in lift system, ratcheting height adjustment | Manual log adjustment, requires experience |

| Performance | Suitable for hardwood and softwood | Ideal for large logs and heavy-duty use |

| Versatility | Modular extensions available | Various size rails available |

| Maintenance | Maintenance-free, dirt repellent | Minimal maintenance required |

| Cost | €2,600.00 | More budget-friendly options available |

| Recommended Saw Type | Compatible with chainsaws of min 3.3 kW (4.5 hp) | Requires powerful chainsaws, often 70cc or higher |

The Logosol F2 and Granberg MK-IV Alaskan Chainsaw Mills cater to different needs within the portable milling market. The Logosol F2 excels in user-friendliness with features like a built-in lift system, rust-free anodized aluminum construction, and a modular design that allows for easy transport and assembly. It is ideal for both hardwood and softwood and supports a log diameter of up to 50 cm, making it versatile for various milling tasks.

In contrast, the Granberg MK-IV is more suited for heavy-duty milling with its capacity to handle logs up to 76 cm in diameter. It requires a more powerful chainsaw and is built from robust aircraft aluminum and steel, designed for larger projects and extensive use. While it may need more setup and is less portable than the Logosol, it offers more budget-friendly options and is adaptable with extendable rails for different log sizes.

Overall, the choice between these two mills would depend on the specific requirements of the user, such as the typical log size they work with and their need for portability and ease of use. The Logosol F2 offers advanced, maintenance-free features for regular millers who value convenience, while the Granberg provides a sturdy and economical solution for those dealing with larger logs and more frequent milling.

Practical Tips and Tricks for Using the Logosol F2 Chainsaw Mill

When it comes to maximizing the performance and lifespan of the Logosol F2 Chainsaw Mill, there are several practical tips and tricks that can make a big difference. Here’s a guide to help you get the best results from this versatile tool, whether you’re milling softwood in your backyard or hardwood in the forest.

Choosing the Right Saw Chain

- Chain Type: Opt for a ripping chain specifically designed for chainsaw mills. Ripping chains cut along the grain efficiently and produce smoother surfaces.

- Chain Size: Ensure the chain size matches the guide bar and the sprocket. Using the correct size and type reduces wear and enhances the cutting precision.

Maintenance Tips

- Regular Cleaning: After each use, clean the chainsaw mill to remove sawdust and debris, which can accumulate and affect performance.

- Check for Wear: Regularly inspect the rails and the chain for signs of wear or damage. Replace any worn parts promptly to maintain accuracy and safety.

- Lubrication: Keep the chainsaw well-lubricated according to the manufacturer’s recommendations. Proper lubrication reduces friction, which can cause premature wear and tear.

Milling Techniques

- Log Preparation: Ensure logs are clean and free from dirt and stones, which can dull the chain quickly.

- Cutting Depth: Adjust the cutting depth according to the log size and the desired slab thickness. Using the built-in ruler and ratcheting system, you can precisely control the depth for consistent results.

- Milling Speed: Adjust your milling speed based on the hardness of the wood and the sharpness of the chain. Harder woods or a dull chain require a slower feed rate to prevent stalling the saw.

Handling Different Types of Wood

- Softwood: When milling softwood, you can increase the feed rate slightly, as softwoods are easier to cut through.

- Hardwood: For hardwoods, a slower feed rate helps ensure smooth cuts and reduces the strain on the chainsaw.

- Weathered Wood: Be cautious with weathered or aged wood, as it can be harder and more abrasive than freshly cut logs.

Conclusion

In conclusion, the Logosol F2 Chainsaw Mill is more than just a tool; it’s a versatile companion for any woodworking enthusiast or professional looking to maximize efficiency and precision in their milling operations. Its blend of portability, robust design, and ease of use make it an outstanding choice for anyone looking to venture into milling their own lumber, whether in a fixed location or in the field. If you’re serious about milling, the F2 offers the reliability, flexibility, and performance needed to transform raw logs into valuable planks and boards. If you’re ever near the Woodshed, my commercial building, feel free to stop by for a personal walkthrough of this fantastic milling machine.

FAQs

- Is investing in a chainsaw mill worth it?

Yes, a chainsaw mill is an invaluable tool for transforming logs into lumber, which can be used for various purposes like construction or as firewood, making it a versatile addition to your tool collection. - What minimum engine size is recommended for a chainsaw mill?

For effective and efficient milling, a chainsaw with a minimum of 70cc engine power is recommended. Chainsaws with lesser power may wear out quicker and use more fuel. - How do I select the right chainsaw mill?

When choosing a chainsaw mill, consider the size and type of logs you plan to mill. Stationary mills are suitable for larger logs, offering more power, while portable mills are ideal for smaller logs. - What are the primary uses of a chainsaw mill?

Chainsaw mills are primarily used to cut logs into planks, converting unwanted logs into usable material, which is a cost-effective solution compared to other milling options. - Which chainsaw chain is best for milling?

For milling, chains with .063″ gauge or .404″ pitch are recommended, especially for larger saws. Skip-tooth versions are ideal for wider cuts, enhancing cutting efficiency. - What is the thinnest cut possible with a chainsaw mill?

With the right attachment like the Alaskan Mill Mark III, a chainsaw mill can cut boards as thin as 1/2″ and as thick as 13″, allowing for precise dimensional lumber production. - Which Stihl chainsaw model is best suited for milling?

Models like the Stihl MS 661 C-M, MS 462 C-M, and MS 391 are favored for milling due to their robust engines and ease of use, suitable for various milling needs. - What type of chainsaw chain provides the fastest cut?

Full chisel chains are the fastest, especially in clean softwood, due to their sharp corners that easily split wood fibers. Semi-chisel chains offer a balance between speed and durability. - How accurate are chainsaw mills?

Chainsaw mills can achieve impressive accuracy, capable of cutting planks up to 32” wide and depths from 1/2″ to 13″, producing consistently straight and even cuts. - How do I handle large logs with a chainsaw mill?

For larger logs, ensure your chainsaw mill is equipped with the appropriate extensions and log lifters to handle logs up to 50 cm in diameter, with options for even larger logs if necessary.

We’d love to hear from you! If you have any thoughts or experiences with chainsaw mills, or if you have any questions about the Logosol F2 Chainsaw Mill, please share them in the comments below. Your insights could help others who are considering this tool for their projects. Let’s keep the conversation going!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment