Woodland Mills Woodlander Sawmill Review (HM130MAX)

- July 18, 2023

- 2 comment

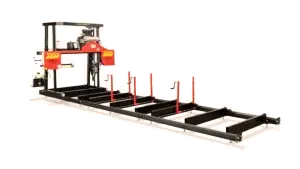

Delve into the world of portable sawmills and you will inevitably come across a standout model that’s setting new benchmarks in performance, reliability, and ease of use: the Woodland Mills HM130MAX. This portable sawmill, also known as the HM130MAX Woodlander, delivers a harmonious balance of industry-grade design, advanced features, and unbeatable efficiency. For those interested in a comprehensive Woodland Mills HM130MAX review, it’s clear that this model from Woodland Mills is setting new standards in the portable sawmill market.

Product Specifications

- Maximum log diameter: 30″ (76cm)

- Maximum board width: 28″ (71cm)

- Maximum board length: 10′ 5″ (3.1m) with standard track & trailer; 16′ 11″ (5.1m) with Woodlander XL

- Minimum board thickness: 1/16″ (2mm)

- Saw head travel: 16″ (40cm)

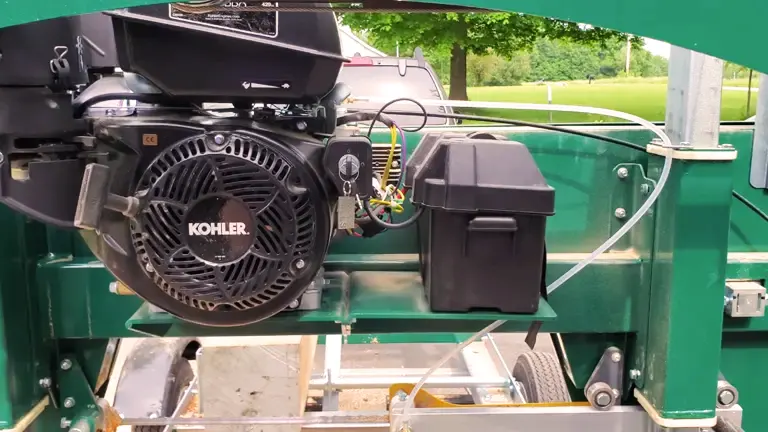

- Engine: 14HP Kohler gas/petrol engine

- Weight: 900 lbs (410kg)

- Price: $6,618.00 – $7,611.00

Additional Features

- 4-post saw head design with the reinforced back beam for ultimate rigidity

- Easy-to-turn hand crank system for raising and lowering saw head

- Galvanized steel posts and track

- Reversible blade for smooth, clean cuts

- Automatic blade lubrication system

- RapidChange™ blade system for quick and tool-less blade changes

- Operation hour meter

- Woodlander™ trailer for multi-terrain transportation, comfortable operation height and easy storage

Personal Experience

The moment the HM130MAX Woodlander arrived, the assembly process began. Though initially intimidating due to the machine’s size and complexity, the detailed instruction manual and supporting video tutorials provided by Woodland Mills guided me through each step, making the process manageable and educational.

Firing up the HM130MAX Woodlander, the power of the Kohler engine was palpable. It effortlessly cut through a medium-sized log of pine on the first run, delivering a smooth, precise cut. The auto-locking sawhead system was a boon, eliminating the need for constant manual adjustments and improving overall productivity.

With time, I tested the HM130MAX Woodlander on various types of wood. Its performance remained consistent and efficient, handling both softwood and hardwood with equal finesse. The portability feature added to the overall convenience, making the movement of this heavy-duty machine relatively easy.

Regular maintenance, including blade tensioning and cleaning, was vital for optimal performance. Fortunately, the blade lubrication system made this task less arduous, maintaining the blade in good condition and extending its lifespan.

In the few instances when I had to contact Woodland Mills’ customer support, they were responsive and knowledgeable, ready to assist and guide, which added significantly to the overall experience.

Investing in the HM130MAX Woodlander meant investing in a blend of power, portability, and precision, a combination that I found invaluable in my woodworking pursuits.

Mighty Design, Resilient Construction

The HM130MAX Woodlander is powered by a hard-hitting 14HP Kohler engine, expertly calibrated to deliver potent and consistent power for sawmilling tasks. The engine is designed to accommodate the rigors of cutting through diverse types of wood. From the soft grain of pine to the denser structures of oak and walnut, the HM130MAX can tackle them all, a testament to its formidable engine and precision engineering.

In terms of construction, the HM130MAX features a tubular steel frame. This type of frame ensures maximum strength and resilience, resulting in a robust and durable sawmill capable of withstanding the stresses of continuous use. The tubular steel also provides protection against harsh environmental conditions, including exposure to severe weather. With such a robust design, your investment in the HM130MAX Woodlander is assured to be a long-lasting one.

User-friendly Operations

One of the most remarkable features of the HM130MAX Woodlander is its auto-locking sawhead system. This innovative system eliminates the need for manual adjustments, thus enhancing productivity. By automating the lock of the sawhead, each cut delivered is consistent and precise. The user no longer needs to engage in repetitive manual locking and unlocking, which can slow down the sawmilling process.

Additionally, the HM130MAX features an integrated blade lubrication system, which is another significant advantage. This system automatically lubricates the blade, reducing friction during operation, extending the blade’s lifespan, and contributing to the overall efficiency of the sawmill.

The sawmill’s dimensions also add to its appeal. Designed to handle logs with a diameter of up to 30″ (76cm) and capable of delivering a width of cut of 22″ (56cm), the HM130MAX Woodlander is equipped to manage a variety of woodworking projects. It can even create a full-width slab cut up to 22″ wide in a single pass, underscoring the machine’s exceptional performance capabilities.

Benefits and Drawbacks

Benefits:

- Powerful Performance: The HM130MAX Woodlander’s 14HP Kohler engine delivers impressive power, providing the necessary strength to handle diverse woodworking tasks effortlessly.

- Durable Construction: The sawmill’s tubular steel frame ensures durability and resilience, promising longevity even with intensive usage.

- Versatility: The HM130MAX Woodlander can handle a broad range of log sizes and types, allowing it to adapt to various woodworking projects.

- Portability: The inclusion of a trailer system enhances the sawmill’s mobility, enabling easy transportation to different worksites.

- User-Friendly Features: With its auto-locking sawhead system and integrated blade lubrication system, the HM130MAX Woodlander simplifies the sawmilling process and improves efficiency.

Drawbacks:

- Assembly Requirement: The HM130MAX Woodlander needs to be assembled upon delivery. Although the company provides detailed instructions and video tutorials, the process can still be time-consuming and complex.

- Noise Production: Like most heavy-duty machinery, the HM130MAX Woodlander generates considerable noise during operation, which might require you to use ear protection.

- Maintenance Needs: Regular maintenance, including blade tensioning and cleaning, is necessary to keep the sawmill performing optimally. While the built-in lubrication system simplifies this task, it still requires time and effort.

- Investment Cost: The HM130MAX Woodlander comes with a substantial price tag. However, the sawmill’s robust performance, durability, and advanced features justify this investment in the long run.

Mobility with Strength

While the HM130MAX Woodlander is a robust machine, Woodland Mills has brilliantly balanced its hefty construction with thoughtful design for portability. The sawmill features a trailer system with DOT-approved components, including lights for visibility, reflectors for safety, and tires capable of handling different terrains. The ability to transport this powerhouse of a machine to different sites or remote woodlands makes it an excellent choice for jobs that require flexibility and mobility without compromising on power and performance.

Unwavering Support

Woodland Mills is known for its exceptional customer service and stands firmly behind its products. This is demonstrated in the two-year warranty assurance provided for the HM130MAX Woodlander, which offers users peace of mind about their investment. Furthermore, the company provides comprehensive guides and tutorial videos that simplify the assembly and operation processes. This wealth of resources facilitates a user-friendly experience, even for those new to operating such machinery.

Exemplary Performance

The HM130MAX Woodlander excels in delivering speed, precision, and productivity. Key to its performance is the large 19″ cast-iron bandwheel, which ensures the smooth running of the Lenox Woodmaster hardened steel blades. The synergy between these components allows the HM130MAX Woodlander to deliver smooth, precise, and accurate cuts consistently. Whether you’re processing softwoods or hardwoods, the HM130MAX is a reliable companion that guarantees quick, precise, and efficient results every time.

Conclusion

The HM130MAX Woodlander from Woodland Mills offers a compelling mix of power, durability, versatility, and mobility, making it a standout choice in the realm of portable sawmills. It is engineered to meet the needs of diverse woodworking projects, promising consistent, high-quality performance. While the assembly process and regular maintenance require some effort, the sawmill’s user-friendly features and efficient operation make these tasks more manageable. Despite the initial investment, the HM130MAX Woodlander proves to be a valuable asset, providing reliable, professional-grade sawmilling capabilities whether you’re a hobbyist woodworker or running a small-scale commercial operation. Investing in the HM130MAX Woodlander means investing in a machine that’s ready to tackle your most challenging sawmilling tasks with remarkable ease and precision.

Frequently Asked Questions (FAQs) about the HM130MAX Woodlander:

- What kind of engine does the HM130MAX Woodlander use?

The HM130MAX Woodlander uses a robust 14HP Kohler engine, providing sufficient power for various sawmilling tasks. - What are the dimensions of logs that the HM130MAX Woodlander can handle?

The HM130MAX Woodlander is designed to handle logs with a diameter of up to 30″ (76cm) and can deliver a width of cut of 22″ (56cm). - Does the HM130MAX Woodlander have any features to simplify operation?

Yes, the HM130MAX Woodlander features an auto-locking sawhead system that eliminates the need for manual adjustments, ensuring consistent and precise cuts. It also comes with an integrated blade lubrication system that reduces friction during operation and extends the blade’s lifespan. - Is the HM130MAX Woodlander portable?

Yes, despite its robust structure, the HM130MAX Woodlander is designed with a trailer system equipped with DOT-approved lights, reflectors, and tires for easy transportation. - What kind of support does Woodland Mills offer for the HM130MAX Woodlander?

Woodland Mills offers a two-year warranty for the HM130MAX Woodlander. They also provide comprehensive guides and tutorial videos to assist with assembly and operation. - What materials make up the HM130MAX Woodlander?

The HM130MAX Woodlander is constructed with a tubular steel frame, and a large 19″ cast-iron bandwheel, and uses Lenox Woodmaster hardened steel blades. - Does the HM130MAX Woodlander create a lot of noise?

Like most heavy-duty machinery, the HM130MAX Woodlander does generate considerable noise during operation. It’s recommended to use ear protection during operation. - Does the HM130MAX Woodlander require assembly?

Yes, the HM130MAX Woodlander needs to be assembled upon delivery. However, Woodland Mills provides detailed instructions and video tutorials to help guide users through the process. - How often does the blade need to be replaced?

The lifespan of the blade on the HM130MAX Woodlander can vary depending on usage and the type of wood being cut. Regular maintenance, such as using the integrated blade lubrication system, will help extend the blade’s lifespan. - What types of wood can the HM130MAX Woodlander handle?

The HM130MAX Woodlander is versatile enough to handle a variety of wood types, ranging from softwoods like pine to harder woods such as oak and walnut.

Your perspective matters to us! We invite you to share your personal experiences and thoughts about the Woodland Mills Woodlander Sawmill (HM130MAX) in the comments section below. Your insights could greatly assist fellow readers in making well-informed decisions regarding the HM130MAX sawmill’s capabilities and performance.

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

2 comments

Thank you for this, I just ordered a chipper from these folks and depending on how that works i am considering one of their sawmills.

I have the 126 bandmill great was never had a problem but if you ever do they have the best tect. support I have ever seen. Just got the RS8 blade sharpener like the mill works great great set up instructions I may not have to buy blades for years. Great company

Larry Carter

November 22, 2023 6:37 pm