Miller 200-MIG Electric Wire Feed Welder Review

- January 23, 2024

- 0 comment

Experience versatile welding with the Miller 200-MIG Electric Wire Feed Welders, a multi-process unit offering MIG, Stick, and DC TIG capabilities. Ideal for a range of applications, this welder features MVP (Multi-Voltage Plug) for 120V/230V input, ensuring adaptability in various environments. With a compact design of 25.6 x 13.3 x 17 inches and weighing 46.25 pounds, it’s perfect for both shop and field use. Boasting an output range of 200A and a duty cycle of 20% for MIG and 30% for Stick/TIG, it delivers reliable performance for your welding needs.

Technical Specifications

- Welding Process: MIG (Metal Inert Gas)

- Input Voltage: Dual voltage capability (120V/240V)

- Amperage Range: Up to 200 amps

- Wire Feed Speed Range: Variable

- Weldable Materials: Steel, Stainless Steel, Aluminum

- Weight: Approximately 40 lbs

- Dimensions: 25.6 x 13.3 x 17 inches; 46.25 Pounds

- Weight: 29 lbs

User Experience and Performance

The user experience of the Miller 200-MIG (907518) Electric Wire Feed Welder is notably superior, distinguishing it in its category for several compelling reasons. From the initial operation, the machine’s intuitive design and user-friendly interface immediately stand out. This ease of use is no coincidence; it’s evident that Miller has meticulously crafted this welder with the end-user’s convenience and ease in mind.

The layout of controls is logical and accessible, enabling quick adjustments without the need for constant reference to a manual. Such design choices not only streamline the welding process but also significantly reduce the learning curve for beginners. For the experienced welder, this translates to a smoother, more efficient workflow, allowing for quick mode transitions and settings adjustments.

In terms of performance, the Miller 200-MIG excels with its straightforward and responsive controls. Whether it’s fine-tuning the voltage for a specific material or adjusting the wire feed speed for different thicknesses, the welder responds accurately and reliably. This level of control is particularly advantageous when working on a variety of projects, offering a degree of precision that can be hard to find in other models in its class.

Moreover, the consistent performance across different materials and thicknesses highlights the welder’s versatility, making it a valuable tool for a wide range of applications. This consistent reliability not only boosts the welder’s appeal to professionals who demand high performance but also to hobbyists seeking quality results without the complexity often associated with professional-grade equipment.

Power and Versatility

The Miller 200-MIG (907518) Electric Wire Feed Welder is endowed with remarkable power and versatility, traits that are essential for a wide range of welding tasks. One of the most notable features of this welder is its multi-voltage plug, which allows it to operate seamlessly on both 120V and 240V power supplies.

This dual voltage capability is a significant advantage, particularly for users who need a welder that can adapt to different working environments and power sources. Whether it’s in a home garage with a standard 120V outlet or in a professional setting where 240V is available, the Miller 200-MIG adjusts effortlessly, providing the same high level of performance.

This flexibility not only broadens the scope of projects one can undertake but also eliminates the need for additional equipment or voltage converters, making it a practical choice for both hobbyists and professionals.

In terms of material versatility, my experience with the Miller 200-MIG was nothing short of impressive. The machine’s robust power output and superior arc performance were consistently evident when welding various materials, including steel, stainless steel, and aluminum. It handled different thicknesses with remarkable ease, delivering high-quality, reliable welds each time.

This consistency in performance is crucial for projects that demand precision and strength, especially when dealing with diverse materials. For instance, welding thin sheets of aluminum requires a delicate balance of power and control, which the Miller 200-MIG managed with precision, producing clean, strong welds with minimal spatter.

Similarly, when working with thicker steel sections, the welder provided sufficient penetration and a stable arc, key factors in achieving structurally sound and aesthetically pleasing welds. This ability to adapt to various materials and thicknesses without compromising on quality or reliability is a testament to the welder’s superior design and engineering, positioning it as a top choice for those seeking a versatile, powerful welding solution.

Precision and Control

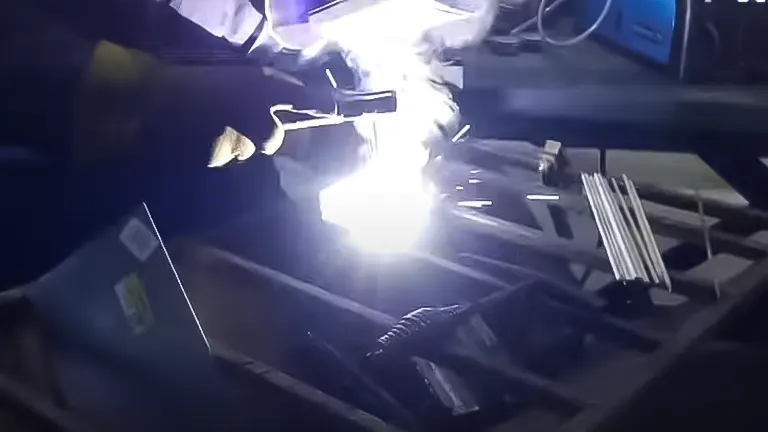

The Miller 200-MIG welder stands out for its exceptional precision and control, features that are vital for achieving high-quality welding results. During my time using this welder, I was particularly impressed by the stability of the arc it produced. This stability is a cornerstone of precision welding, as it directly affects the consistency and quality of the weld.

Furthermore, the welder’s fine-tune voltage control is a standout feature. It allows for nuanced adjustments in small increments, granting the user an extraordinary level of control over the welding process. This capability is especially beneficial when working with thinner materials where precision is paramount. Thin materials are often more susceptible to heat distortion and can be easily marred by excessive spatter.

The Miller 200-MIG’s ability to finely adjust the voltage means that the welder can precisely control the heat input and arc characteristics, resulting in clean, spatter-free welds. Such control not only enhances the aesthetic quality of the welds but also ensures their structural integrity, making the Miller 200-MIG an invaluable tool for projects requiring meticulous attention to detail.

Review of Visual Design Concepts

A Review of Visual Design Concepts entails a comprehensive examination of the aesthetic and functional aspects of design elements within a specific context. This process involves critically assessing the effectiveness of visual design strategies, such as color schemes, typography, imagery, and overall layout, in conveying the intended message or achieving the desired effect.

Key considerations include how well the design aligns with the project’s objectives, its appeal to the target audience, and its usability or readability. Such a review is crucial in determining the visual impact and practical efficacy of the design, ensuring it not only captures attention but also facilitates clear communication and enhances user experience. This approach is fundamental in crafting designs that are not only visually striking but also effectively serve their intended purpose.

Good Build Quality

The Miller 200-MIG (907518) Electric Wire Feed Welder boasts an exceptional build quality, reflecting a commitment to durability and reliability. Constructed with high-grade materials, this welder is designed to withstand the rigors of frequent use in various environments, from professional workshops to home garages.

Attention to detail is evident in its robust casing, secure fittings, and well-engineered internal components, which together ensure a long service life with minimal maintenance. The machine’s sturdy construction not only enhances its longevity but also contributes to consistent performance under different welding conditions. This solid build quality is a hallmark of the Miller brand, reassuring users of a reliable and enduring welding solution that can handle a wide array of welding tasks with ease.

Duty Cycle and Included Features

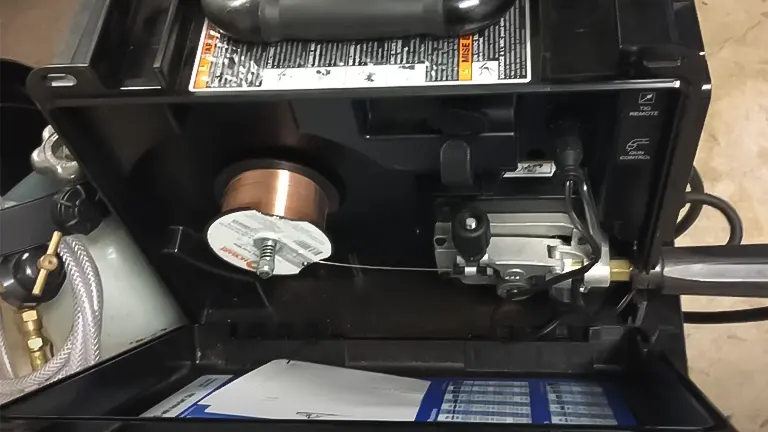

The Miller 200-MIG (907518) Electric Wire Feed Welder stands out with its impressive duty cycle and array of included features, designed to meet the demands of both professional and hobbyist welders. The duty cycle of this welder, indicative of its ability to perform under continuous use, is robust and suited for prolonged welding sessions, reducing downtime and increasing productivity. In terms of features, it comes equipped with a multi-voltage plug for versatile power access, fine-tune voltage control for precision welding, and an intuitive interface that simplifies the adjustment of settings.

The inclusion of advanced wire feeding technology enhances its performance, particularly in creating consistent, high-quality welds. Additionally, the welder’s portability is a notable feature, facilitated by its compact design, making it an ideal tool for varied work environments. These features, combined with the reliable duty cycle, make the Miller 200-MIG not just a powerful welding tool but also a practical and efficient choice for a wide range of welding applications.

Table of Comparison vs. Competitors

Here’s a comparison table for the ARCCAPTAIN 200A ARC/Lift TIG + Stick Welder and the Miller 200-MIG (907518) Electric Wire Feed Welder:

here’s a detailed comparison table between the Miller 200-MIG (907518) Electric Wire Feed Welder and the ARCCAPTAIN 200A ARC/Lift TIG + Stick Welder:

| Feature/Specification | Miller 200-MIG (907518) Electric Wire Feed Welder | ARCCAPTAIN 200A ARC/Lift TIG + Stick Welder |

|---|---|---|

| Welding Processes | MIG (Metal Inert Gas) | ARC, Lift TIG, Stick |

| Input Voltage | Dual voltage (120V/240V) | Commonly 110/220V |

| Amperage Range | Up to 200A | Up to 200A |

| Duty Cycle | Robust, suitable for prolonged use | Typically high, varies with mode |

| Weight | Approximately 40 lbs | Generally lighter, varies by model |

| Material Compatibility | Steel, Stainless Steel, Aluminum | Depends on the mode; versatile for metals |

| User Interface | User-friendly, suitable for all skill levels | Functional, may require more expertise |

| Precision and Control | High, especially for MIG welding | High, especially in TIG and Stick modes |

| Portability | Portable, but slightly heavier | Generally more portable |

| Target User | Both professionals and hobbyists | Skilled users, especially for TIG/Stick |

| Additional Features | Multi-voltage plug, fine-tune voltage control | Lift TIG capability, ARC/Stick flexibility |

Comparative Analysis with Other Models

When comparing the Miller 200-MIG (907518) Electric Wire Feed Welder to the ARCCAPTAIN 200A ARC/Lift TIG + Stick Welder, a few key differences stand out. The Miller 200-MIG excels in MIG welding with its dual voltage capability, making it highly versatile for various environments. It’s particularly user-friendly, catering to both novices and professionals, and is renowned for producing clean, consistent welds across different materials and thicknesses.

On the other hand, the ARCCAPTAIN 200A is a more specialized tool, offering ARC, Lift TIG, and Stick welding capabilities, which might appeal more to users who require these specific welding processes. It’s generally more lightweight and portable compared to the Miller 200-MIG, and often comes at a more affordable price point.

However, it may demand a higher skill level, especially for TIG and Stick welding. In summary, while the Miller 200-MIG shines in its MIG welding prowess and ease of use, the ARCCAPTAIN offers greater flexibility for those needing TIG and Stick welding functionalities.

Pros and Cons

| Pros | Cons |

|---|---|

| Multi-Voltage Flexibility: | Price: |

| Great for various environments and | Higher cost compared to basic models, which |

| power outlets. | might deter hobbyists. |

| User-Friendly Interface: | Weight: |

| Easy to navigate for beginners, yet | Slightly heavier than some competitors, |

| sophisticated enough for professionals. | impacting portability. |

| Superb Arc Quality: | |

| Produces clean, consistent welds with | |

| minimal spatter. | |

| Durability: | |

| Built to last, it’s a reliable machine | |

| for frequent use. |

Key Decision Potential Factors For User’s

When selecting a wire feed welder, the crucial aspects that guide my decision are the quality of the arc, the machine’s versatility, and its user-friendliness. The Miller 200-MIG excels in these domains, making it a standout choice. It consistently delivers high-quality welds across a diverse range of materials and thicknesses, showcasing its adaptability for various welding tasks. Additionally, its user-oriented design ensures ease of operation, which is beneficial for both professionals and hobbyists. This combination of superior arc quality, versatility in handling different welding scenarios, and straightforward usability positions the Miller 200-MIG as an optimal tool for a wide array of welding needs.

Best Overall Consideration

In evaluating the best overall option among electric wire feed welders, the Miller 200-MIG (907518) stands out as a top contender. This recommendation stems from its remarkable combination of power, accuracy, and ease of use. The welder excels in producing neat and uniform welds, a key factor in assessing welding performance. Its adaptability is another strong point, as it efficiently handles a variety of welding projects, making it a versatile tool for different welding requirements.

While the upfront cost of the Miller 200-MIG may be on the higher side compared to some other models, the investment is well justified by its superior quality and durability. This welder is particularly suitable for individuals who are serious about their welding, as it offers long-term reliability and consistent performance. Its ability to blend high-grade welding capabilities with user-friendly features makes the Miller 200-MIG an excellent choice for a broad spectrum of users, from professionals to enthusiastic hobbyists.

Final Verdict

In conclusion, the Miller 200-MIG (907518) Electric Wire Feed Welder stands as a top-tier choice in its category. Its exemplary blend of power, precision, and user-friendliness makes it an ideal tool for a wide range of welding tasks. While its price point is higher than some entry-level models, the investment is justified by its exceptional performance, versatility in handling various materials and thicknesses, and its robust build quality, ensuring longevity. This welder is not just an asset for professional welders but also a valuable investment for hobbyists seeking a reliable, high-quality welding experience. Its ability to consistently deliver clean and uniform welds, combined with its ease of use, firmly establishes the Miller 200-MIG as a leading choice in the electric wire feed welder market.

Frequently Asked Questions

- What materials can the Miller 200-MIG weld?

The Miller 200-MIG is versatile in its capacity, efficiently welding materials like steel, stainless steel, and aluminum. It can handle a range of thicknesses, making it suitable for various projects from auto repair to crafting. - Is the Miller 200-MIG suitable for beginners?

Yes, this welder is designed with a user-friendly interface, making it accessible for beginners. Its straightforward controls and intuitive design provide an easier learning curve for those new to welding. - Can the Miller 200-MIG operate on both 120V and 240V?

Absolutely. The welder comes with a multi-voltage plug, enabling it to operate on both 120V and 240V. This feature enhances its versatility and adaptability to different working environments. - How does the Miller 200-MIG ensure precision in welding?

The welder offers fine-tune voltage control, allowing for small incremental adjustments. This facilitates precise control over the welding process, crucial for achieving clean, spatter-free welds, especially on thinner materials. - What is the weight and size of the Miller 200-MIG?

The Miller 200-MIG is relatively compact and portable, weighing around 40 lbs. Its size and weight make it manageable for movement around a workshop or transport to different job sites. - How durable is the Miller 200-MIG?

Built with high-quality materials and designed for frequent use, this welder is known for its durability. It’s a reliable machine that can withstand rigorous use in various environments. - Does the Miller 200-MIG come with a warranty?

Yes, Miller typically offers a warranty with their welders. It’s advisable to check the specific warranty details at the time of purchase for the exact terms and coverage. - Can the Miller 200-MIG handle heavy-duty welding tasks?

While it is exceptionally versatile and capable, the Miller 200-MIG is best suited for medium to heavy-duty tasks. Its power and precision make it ideal for both professional projects and serious hobbyist applications. - Is there any special maintenance required for the Miller 200-MIG?

Regular maintenance like cleaning the machine, checking wire feed and connections, and ensuring proper care of the gun and cable is recommended. However, it doesn’t require any special or unusual maintenance beyond what is typical for welders. - What accessories are needed to start welding with the Miller 200-MIG?

To start welding, you’ll need appropriate safety gear (helmet, gloves, protective clothing), welding wire suitable for your project, gas cylinders for MIG welding (if using gas), and basic welding tools. The welder comes with most of what you need to get started, but specific consumables and accessories will depend on your project requirements.

We’re eager to hear your feedback! Please share your personal experiences and opinions regarding the Miller 200-MIG (907518) Electric Wire Feed Welder in the comments section below. Your firsthand insights and reviews could greatly assist fellow welders and enthusiasts in making informed decisions about this tool. Your contribution is invaluable in helping others understand the real-world performance and benefits of the Miller 200-MIG. Let’s build a community of informed users together!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment