Log Splitter Oil Change and Hydraulic Fluid Change

- February 26, 2024

- 0 comment

Taking personal responsibility for the upkeep of my tools and machinery, I find a particular sense of fulfillment and purpose in the routine task of changing the oil and hydraulic fluid in my log splitter. This practice transcends mere maintenance; it is both essential for the preservation and optimal performance of my equipment and serves as a form of personal engagement that connects me more intimately with the machinery that supports my firewood gathering efforts.

Throughout this review, I will delve into the nuances of this maintenance process, drawing from my direct encounters and practical knowledge. My aim is to provide a comprehensive evaluation of various products and approaches I have tested, sharing valuable insights and recommendations that stem from my firsthand experiences.

This detailed exploration will cover the critical aspects of oil and hydraulic fluid replacement in log splitters, aiming to equip readers with the information needed to make informed decisions about their own equipment maintenance practices.

Understanding the Importance

Before diving into the specifics, it’s crucial to understand why regular oil and hydraulic fluid changes are essential for your log splitter. These fluids play a pivotal role in the machine’s operation, lubricating moving parts, reducing friction, and facilitating smooth and efficient power transfer from the engine to the splitting mechanism. Over time, these fluids degrade and get contaminated with debris, which can lead to increased wear and tear, decreased efficiency, and even costly breakdowns.

5 Method Oil Change Process: A Step-By-Step Guide

Changing the oil in a log splitter is relatively straightforward, yet it requires attention to detail to ensure it’s done correctly. Firstly, I always make sure the engine is warm to help the oil flow more easily. After securing the splitter in a stable position, I remove the drain plug and let the old oil flow out into a pan.

While it drains, I take the opportunity to clean the area around the oil filter, preparing for a clean installation. Once the oil is fully drained, I replace the drain plug, install a new oil filter, and fill the engine with new oil, checking the level with the dipstick to ensure it’s just right.

In terms of oil type, I’ve found that a high-quality 10W-30 engine oil provides excellent protection across a wide range of temperatures, though the best choice can depend on your specific model and the climate you operate in:

1. Traditional Drain Method

- Preparation: Warm up the engine to thin the oil, allowing it to drain more easily.

- Draining: Turn off the engine and locate the oil drain plug beneath the engine. Place an oil catch pan under the plug, remove the plug, and allow the old oil to drain completely.

- Refilling: Once the oil has drained, replace the drain plug securely. Fill the engine with new oil of the recommended type and quantity, checking the level with the dipstick to ensure proper filling.

2. Vacuum Extraction Method

- Setup: Warm the engine as in the traditional method to thin the oil.

- Extraction: Instead of draining the oil from the bottom, use a vacuum oil extractor. Insert the extractor’s tube into the oil fill hole and vacuum out the old oil.

- Refilling Process: After extracting the old oil, refill with new oil as per the manufacturer’s recommendations, using the dipstick to check for the correct level.

3. Tilt Method

- Preparation Step: Warm up the engine.

- Tilting for Drainage: For log splitters without a convenient drain plug, you can tilt the machine to allow the oil to drain through the fill hole. Ensure you do this carefully and safely to avoid spillage.

- Refilling: Return the splitter to its upright position and refill with new oil, checking the level with the dipstick.

4. Pump Method

- Initial Steps: Warm the engine to make the oil more fluid.

- Using a Pump: Attach a manual or electric pump to the oil fill hole. The pump should be connected to a container where the old oil can be pumped out.

- Completion: Once all the oil has been removed, refill the engine with new oil according to the specifications, checking the oil level with the dipstick.

5. Siphon Method

- Warm-Up: Start by warming the engine.

- Siphoning Off: Use a siphon pump, placing one end in the oil fill hole and the other in a disposal container. Manually pump or allow the siphon to gravity-feed the oil out of the engine.

- Refill Procedure: After siphoning the old oil, carefully refill the engine with new oil, checking with the dipstick to ensure the oil level is correct.

5 Methods of Hydraulic Fluid Change

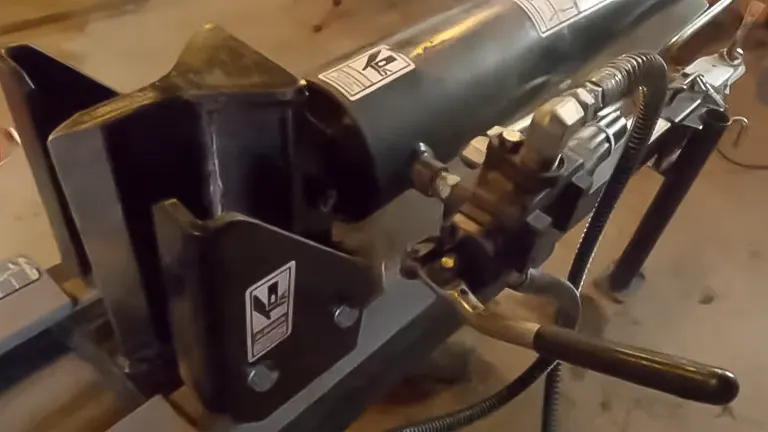

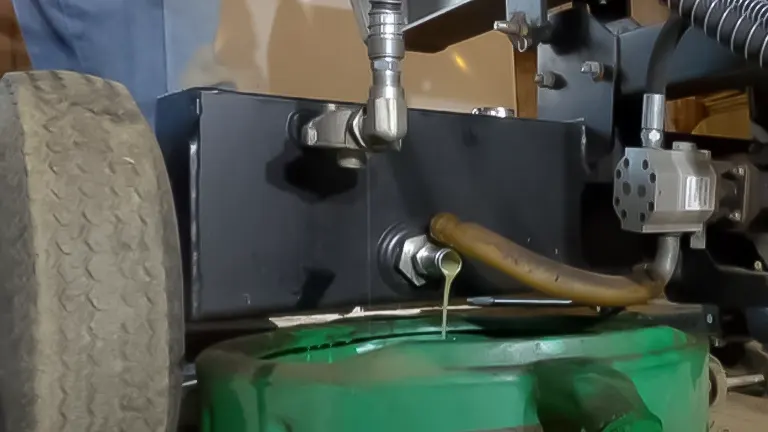

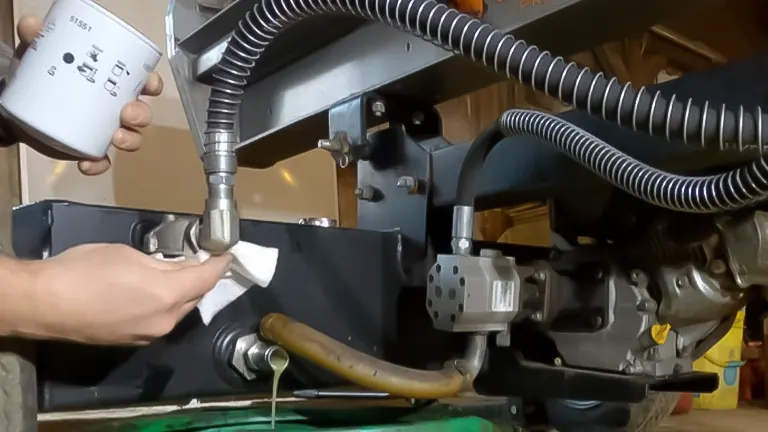

The hydraulic fluid change is a bit more involved but equally critical. The process begins by draining the old fluid, which involves locating the drain plug on the hydraulic tank, removing it, and letting the fluid drain completely. It’s a good opportunity to inspect the hydraulic filter and replace it if necessary, ensuring the system remains free from contaminants.

After draining, I fill the system with new hydraulic fluid, paying close attention to the manufacturer’s specifications regarding type and capacity. I’ve experimented with different brands and found that a premium-grade, high-viscosity hydraulic fluid significantly enhances the splitter’s performance, especially in colder weather.

Changing the hydraulic fluid in a log splitter is essential for maintaining its hydraulic system’s efficiency and longevity. Here are five methods to perform a hydraulic fluid change effectively:

1. Drain Plug Method

- Preparation: Ensure the hydraulic system is not pressurized by operating the control lever to release any built-up pressure.

- Draining: Locate the hydraulic fluid tank’s drain plug at the bottom or lowest point of the system. Place a catch basin underneath, remove the plug, and allow the old fluid to drain completely.

- Refilling: After draining, replace the drain plug securely. Refill the tank with the recommended type of hydraulic fluid to the appropriate level as indicated by the tank’s sight glass or dipstick.

2. Siphon Method

- Set Up: Relieve any hydraulic system pressure as described above.

- Siphoning Out Fluid: Insert a siphon pump hose into the hydraulic fluid reservoir and the other end into a disposal container. Use the pump to siphon out the old hydraulic fluid.

- Refill Process: Once the old fluid is removed, refill the reservoir with new hydraulic fluid, ensuring the fluid level meets the system’s requirements.

3. Pump-Out and Change Filter Method

- Preparation Phase: Release the pressure in the hydraulic system to prevent any accidents.

- Using a Pump to Extract Fluid: Connect a manual or electric pump to the hydraulic fluid reservoir. Pump the old fluid out into a suitable container for disposal.

- Refilling Step: After extracting the old fluid, carefully refill the reservoir with the recommended hydraulic fluid, checking the level to ensure proper filling.

4. Tilt and Drain Method

- Initial Steps: Safely depressurize the hydraulic system.

- Tilting for Complete Drainage: If your log splitter allows, carefully tilt the machine to help guide the hydraulic fluid towards the reservoir’s drain plug or opening, facilitating complete drainage.

- Refill Procedure: Return the machine to its original position and proceed to refill the hydraulic system with new fluid, monitoring the level to avoid overfilling.

5. Hydraulic System Flush and Fluid Refilling

- System Preparation: Start with pressure release as previously mentioned.

- Partial Drain and Refill: Drain a portion of the old hydraulic fluid and refill it with new fluid. Operate the splitter briefly to circulate the new fluid.

- Complete Fluid Change: Repeat the draining process to remove the mixed fluid, ensuring a more thorough removal of old fluid and contaminants. Finally, refill with fresh hydraulic fluid to the correct level.

Each method has its own set of advantages, depending on the specific design of your log splitter and the tools you have at your disposal. Some methods, like the pump-out or siphon methods, are particularly useful if direct access to a drain plug is difficult or if you want to avoid tilting the machine.

The hydraulic system flush is an advanced method that ensures a more comprehensive replacement of the old fluid, which can be beneficial for systems that have not been serviced for a long time or have been heavily used. Always refer to your log splitter’s manual for specific recommendations on hydraulic fluid types and change intervals, and ensure to dispose of the old fluid in an environmentally responsible manner.

Pros of Maintenance

- Extended Equipment Lifespan: Regular maintenance significantly prolongs the life of your equipment, ensuring it remains operational for years to come without major issues.

- Improved Performance and Efficiency: Maintenance tasks such as oil and hydraulic fluid changes enhance the machine’s performance, making it work more smoothly and efficiently, which can lead to faster and more reliable operations.

- Prevention of Costly Repairs: By catching and addressing small issues early through routine maintenance, you can avoid more significant and expensive problems down the line, saving money and downtime.

Cons of Maintenance

- Time and Effort Required: Regular maintenance demands a commitment of time and physical effort, which might be challenging to fit into a busy schedule or for those who prefer not to engage in mechanical tasks.

- Cost of High-Quality Fluids and Filters: Using high-quality oils, hydraulic fluids, and filters is recommended for the best maintenance outcomes, but these can come at a higher cost compared to standard options, impacting your maintenance budget.

Final Thoughts and Recommendations

Based on my experience, the importance of regular oil and hydraulic fluid changes in a log splitter cannot be overstated. It’s a crucial maintenance task that ensures the machine operates efficiently, reliably, and safely over its lifetime. While the process requires some effort and investment in quality fluids and filters, the payoff in terms of performance and durability is well worth it.

For those looking to maintain their log splitter, I highly recommend establishing a routine maintenance schedule and sticking to it. Use high-quality fluids that meet or exceed the manufacturer’s specifications, and don’t shy away from spending a bit extra on premium products; the benefits they provide in the long run are invaluable.

In conclusion, whether you’re a seasoned wood-splitter or a novice, taking the time to properly maintain your log splitter through regular oil and hydraulic fluid changes is a wise investment in the machine’s performance and longevity.

Frequently Asked Questions

- How often should I change the oil in my log splitter?

Typically, you should change the oil after the first 20 hours of use (for new machines) and then every 100 hours of use or at least once a year, whichever comes first. - What type of oil is best for my log splitter engine?

Most manufacturers recommend using a high-quality 10W-30 or SAE 30 engine oil for log splitters, but always check your owner’s manual for specific recommendations. - How do I know when to change the hydraulic fluid in my log splitter?

Hydraulic fluid should be changed every 100 hours of operation or annually. Signs like decreased performance or strange noises from the hydraulic system can also indicate it’s time for a change. - Can I use any hydraulic fluid in my log splitter?

It’s essential to use the type of hydraulic fluid recommended by your log splitter’s manufacturer, as using the wrong fluid can damage the system or reduce its efficiency. - What are the steps for changing the hydraulic fluid?

The basic steps include draining the old fluid, replacing the hydraulic filter (if applicable), and refilling with new hydraulic fluid to the correct level. - Do I need to change the hydraulic filter every time I change the fluid?

It’s recommended to change the hydraulic filter with every fluid change to ensure the system remains free of contaminants and operates efficiently. - How much oil does a log splitter engine take?

The amount of oil required varies by model. Refer to your log splitter’s manual for the specific oil capacity of your engine. - What should I do with the old oil and hydraulic fluid?

Dispose of old oil and hydraulic fluid properly at a local recycling center or hazardous waste disposal facility to comply with environmental regulations. - Can I change the oil and hydraulic fluid myself?

Yes, most people can perform these maintenance tasks themselves with basic tools and by following the manufacturer’s instructions. However, if you’re uncomfortable with the process, consider hiring a professional. - What are the signs that my log splitter needs an oil or hydraulic fluid change?

Signs include dark or dirty oil, decreased machine performance, strange noises during operation, or if the specified maintenance interval has been reached.

We’re eager to hear from you! Do you have personal stories or insights to share about changing the oil and hydraulic fluid in your log splitter? Drop your experiences and tips in the comments section below. Your valuable input could assist other enthusiasts in making knowledgeable maintenance decisions for their equipment. Let’s help each other keep our log splitters in peak condition!

Edward Smith

Forestry AuthorWoodworking is about more than crafting; it's a harmonious connection with nature, mastering tools, and preserving our environment. I'm here to share my knowledge and experiences with you, forging a future where we can embrace wood's beauty and utility while safeguarding our forests' health and diversity.

Leave your comment