What Hydraulic Fluid For A Log Splitter: A Complete Guide

- February 12, 2024

- 0 comment

When it comes to maintaining the efficiency and extending the lifespan of your log splitter, understanding the importance of hydraulic fluid is paramount. For those operating non-kinetic powered log splitters, recognizing the pivotal role of hydraulic systems in delivering unmatched wood splitting power is crucial. This comprehensive guide delves into the essentials of hydraulic fluid, offering insights into how these systems operate, the appropriate types of oil to use, and the significance of choosing the right product for your machinery.

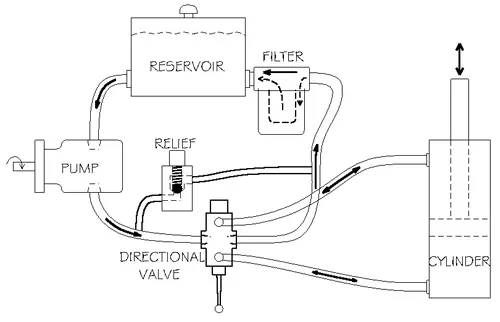

Log Splitter Hydraulic Systems Explained

Hydraulic systems are the powerhouse behind log splitters, using pressurized fluid to create the force necessary for splitting logs. This system includes several key components: a Reservoir for storing the fluid, a Pump to increase the fluid’s pressure, Valves to direct the flow, and Cylinder to transform hydraulic pressure into physical force. The effectiveness of this process heavily relies on the hydraulic fluid used, emphasizing the importance of selecting the right type and maintaining it correctly.

Choosing the Right Hydraulic Fluid

Choosing the correct hydraulic fluid is crucial for the smooth operation of your log splitter. The manufacturer will usually recommend specific types of hydraulic oil, such as AW22 or AW32, which are designed to perform well under the machine’s operating conditions.

In colder environments, where temperatures fall below 32 degrees Fahrenheit, switching to an automatic transmission fluid might be recommended to maintain optimal functionality. Always refer to your log splitter’s manual before selecting a hydraulic fluid to ensure compatibility and prevent potential damage to your equipment.

Hydraulic Oil vs. Hydraulic Oil Fluid: What’s the Difference?

While “hydraulic oil” and “hydraulic fluid” are terms that are sometimes used as if they’re identical, there are important differences between them. Hydraulic oil is a specific kind of hydraulic fluid designed for use in high-pressure conditions and is notable for its potential flammability. On the other hand, hydraulic fluid encompasses a broader category that includes various types of liquids, such as water-based solutions, which can cater to a range of operational requirements and safety considerations. Despite their differences, both hydraulic oil and fluid play vital roles in lubricating, cooling, and facilitating power transmission in hydraulic systems.

Choosing the Right Hydraulic Fluid for Your Log Splitter

Selecting the appropriate hydraulic fluid for your log splitter involves choosing between mineral-based oils and synthetic alternatives. Mineral-based oils are directly derived from crude oil and offer reliable performance for most applications.

However, synthetic hydraulic fluids, which are formulated in laboratories, are gaining popularity due to their superior lubrication properties and enhanced performance, particularly in older machinery. The decision between these two types should be based on your specific requirements and the recommendations for your particular log splitter model.

The Benefits of Additives in Hydraulic Oils

To enhance their performance under varying conditions, many hydraulic oils are infused with specialized additives. Understanding these additives and their benefits can help you choose the most suitable oil for your log splitter:

- Anti-wear: Increases the lifespan of your machinery by providing extra lubrication and protection against wear and tear.

- Cold Flow: Improves the oil’s performance in cold temperatures, ensuring your log splitter operates smoothly even on chilly days.

- Anti-foaming: Prevents the formation of foam and bubbles, which can disrupt the hydraulic system’s efficiency and safety.

- Anti-oxidant: Reduces the buildup of sludge within the system, extending the time between oil changes.

- Anti-rust: Offers a protective coating to metal parts, minimizing the risk of rust and corrosion.

- Environmentally Friendly: Some hydraulic oils are biodegradable and made from vegetable sources, offering an eco-friendly option without compromising on performance.

By considering these options and additives, you can make an informed decision that ensures your log splitter operates efficiently, remains protected under various conditions, and has a longer service life.

The Role of Viscosity in Hydraulic Systems

Viscosity plays a critical role in the performance of hydraulic systems, including those in log splitters. It’s a measure of a fluid’s thickness and its ability to flow. For hydraulic systems to operate efficiently, selecting a fluid with the appropriate viscosity is essential.

Lower viscosity fluids, which are thinner, are ideal for cold environments as they flow more easily at lower temperatures. Conversely, higher viscosity fluids are thicker and better suited for warmer climates where they won’t thin out too much. The viscosity of hydraulic oil is typically indicated by an ISO grade, which assists in choosing the correct oil to match the operating conditions.

Understanding Hydraulic Fluid Types

Hydraulic fluids are categorized into various types such as HL, HM, and HR, each denoting different characteristics and applications. These classifications provide insight into the fluid’s base composition and the additives it contains, which can enhance performance in specific situations:

- HL: Oils in this category are designed with properties to prevent oxidation and rust, suitable for general hydraulic systems.

- HM: These fluids include anti-wear additives, making them ideal for hydraulic systems where mechanical components are under high stress.

- HR: Fluids classified as HR contain viscosity index improvers, offering a stable performance across a broader range of temperatures.

Understanding these classifications helps in selecting a hydraulic fluid that aligns with the specific needs of your log splitter, ensuring optimal performance and protection for your equipment across different environmental conditions.

Hydraulic Fluid Capacity and Maintenance

Every log splitter has its specific hydraulic fluid requirements, typically ranging from 3.5 to 7 gallons. It’s crucial to consult your operator’s manual to determine the exact quantity needed for your particular model. Using the right type of hydraulic fluid is equally important; options like Dexron III Automatic Transmission Fluid, 10W AW Hydraulic Oil, or Pro Mix AW-32 Hydraulic Fluid are widely recommended and available at most suppliers. Ensuring you use approved fluids will help maintain the efficiency and longevity of your machine.

How to Add Hydraulic Fluid to a Log Splitter

Priming and Maintenance Tips

Before putting your log splitter to work, priming the hydraulic system is a step that shouldn’t be skipped. This involves running several cycles with the splitting wedge to eliminate any trapped air, ensuring the system operates smoothly. Such preventive measures not only enhance the performance of your log splitter but also safeguard against potential damage that could invalidate your warranty.

Conclusion

Selecting the correct hydraulic fluid and maintaining your log splitter are critical practices that significantly impact the machine’s performance and durability. Adhering to the manufacturer’s guidelines, gaining a good understanding of hydraulic system intricacies, and performing routine maintenance are all actions that contribute to the optimal functioning of your log splitter over many seasons. By taking these steps seriously, you’ll ensure that your log splitter remains a reliable asset for your wood-splitting tasks.

FAQs

- Can changing the hydraulic fluid improve the efficiency of an older log splitter?

Yes, changing the hydraulic fluid in an older log splitter can significantly improve its efficiency. Over time, hydraulic fluid degrades and may become contaminated, which can reduce the system’s efficiency and the machine’s overall performance. Fresh fluid can restore the hydraulic system’s smooth operation and improve the splitter’s power and responsiveness. - Is it possible to use synthetic hydraulic fluid in my log splitter, and what are the benefits?

Synthetic hydraulic fluids can be used in most log splitters and offer several benefits over their mineral-based counterparts, including better temperature stability, reduced wear, and longer fluid life. However, it’s essential to check the manufacturer’s recommendations before switching to synthetic fluids, as they may require different handling or compatibility considerations. - How does altitude affect the choice of hydraulic fluid for my log splitter?

Altitude can affect the performance of hydraulic fluids due to changes in atmospheric pressure and temperature. At higher altitudes, fluids may thin out more than at sea level, potentially requiring a higher viscosity grade to maintain optimal performance. It’s a good idea to consult with the manufacturer or a hydraulic systems expert when operating hydraulic equipment in significantly different altitudes than usual. - Can hydraulic fluid additives extend the life of my log splitter’s hydraulic pump?

Yes, certain hydraulic fluid additives can help extend the life of your log splitter’s hydraulic pump. Additives such as anti-wear agents, corrosion inhibitors, and antioxidants can protect the pump and other system components from wear, corrosion, and oxidative degradation, thereby extending the equipment’s service life. - How does hydraulic fluid contamination occur, and what can I do to prevent it?

Hydraulic fluid contamination can occur through several means, including ingress of dirt and debris, water condensation, and internal component wear. To prevent contamination, ensure that the hydraulic fluid reservoir is sealed properly, use clean funnels and containers when servicing the fluid, and replace the hydraulic filters according to the manufacturer’s schedule. - What should I do if I accidentally use the wrong hydraulic fluid in my log splitter?

If you accidentally use the wrong hydraulic fluid, it’s important to drain the system as completely as possible and replace it with the correct fluid type recommended by the manufacturer. Running the machine with the wrong fluid may lead to reduced performance or damage. After replacing the fluid, monitor the log splitter closely for any signs of abnormal operation or decreased efficiency. - Are there any signs that indicate it’s time to change the hydraulic fluid, aside from the operating hours?

Yes, there are several signs that can indicate it’s time to change the hydraulic fluid, including changes in the fluid’s color (it becoming darker or more opaque), a burnt smell, increased noise from the hydraulic pump, or decreased performance in splitting logs. Any of these signs could indicate that the hydraulic fluid is degrading and should be replaced to maintain optimal performance.

We hope this deep dive into the world of hydraulic fluids for log splitters has illuminated the path to peak performance and longevity for your machine. But remember, the learning doesn’t stop here! We’re eager to hear from you—whether it’s a golden nugget of wisdom, a burning question, or simply your experience with maintaining your log splitter’s hydraulic system. Drop a comment below and let’s keep the conversation flowing. Your insights not only enrich our community but help us all grow together. Don’t forget to share this article with fellow log-splitting enthusiasts. Together, let’s split the challenges and share the solutions!

David Murray

Forestry AuthorI'm David Murry, a forestry equipment specialist with a focus on chainsaw operation. With over 13 years of experience, I've honed my skills in operating and maintaining a wide range of machinery, from chainsaws to log splitters. My passion for the outdoors and commitment to sustainable forestry drive my work, which emphasizes safety, efficiency, and staying updated with industry advancements. Additionally, I'm dedicated to sharing my expertise and promoting environmental awareness within the forestry community.

Leave your comment